Carrying out insulation of the foundation and blind area, you should never skimp and save on materials, and the process itself. This can lead to unpleasant consequences in the future. In particular, cracks may appear on the walls, which will grow significantly over time. In addition, there is a risk of deformation of the house and heat leakage.

Those buildings, the foundation of which has not been insulated, and there is no blind area, will require serious overhaul in a couple of decades. And this is at best, and at worst, some sections of the foundation will have to be replaced.

Therefore, further we will try to figure out how to properly insulate the foundation and make a blind area.

What is insulation required for?

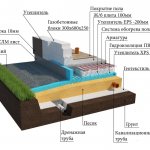

There are many types of foundations, but among them one universal one can be distinguished, which is suitable for many different buildings - this is the insulated Swedish plate foundation, which has been widely used not only among large developers, but also private builders.

The insulated slab foundation differs from the others in that the structure itself is covered on top with a special insulation. This prevents the negative influence of temperature differences on the base of the building.

A builder with vast experience will easily answer the question about the need for insulation. And it will highlight the following reasons:

- If the constructed building is located in an area with a very high level of humidity, one simply cannot do without insulation of the foundation. There is a logical explanation for this. The thing is that moisture droplets penetrate deeply into each crack, and after the air temperature drops below 0, the freezing process takes place. As a result, they expand and lead to the destruction of the concrete.

- Insulation of the foundation makes it independent of the climate and allows you to preserve the entire structure of the building.

- Thermal insulation reduces the effect of moisture on the foundation from the side of the ground.

To protect the walls from the harmful effects of the soil, in which heaving processes take place with the onset of frost, it is necessary to insulate that part of the soil that is in contact with the structure. It all depends on the soil.

For example, in dry sandy soils, there is no significant expansion during frost, while soil with a high clay content practically pushes the building to the surface of the earth.

To avoid such negative consequences, you need to make a blind area and, at the same time, lay a special thermal insulating layer with it. This layer is made on the basis of expanded clay, polyurethane foam, and expanded polystyrene. This makes it possible to keep the temperature above zero in the soil areas close to the foundation throughout the year. Thus, the risk of negative impact of soil heaving processes on the foundation is reduced.

Dimensions (edit)

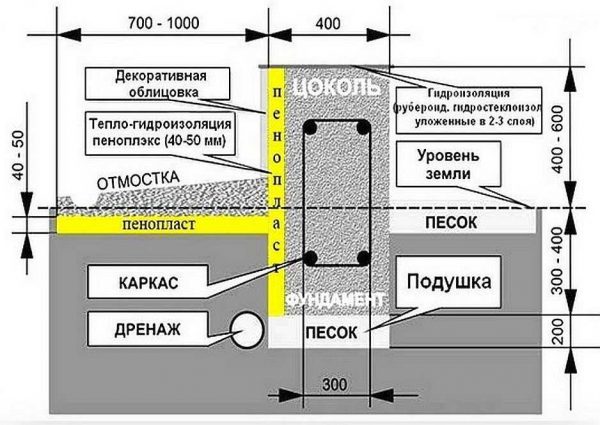

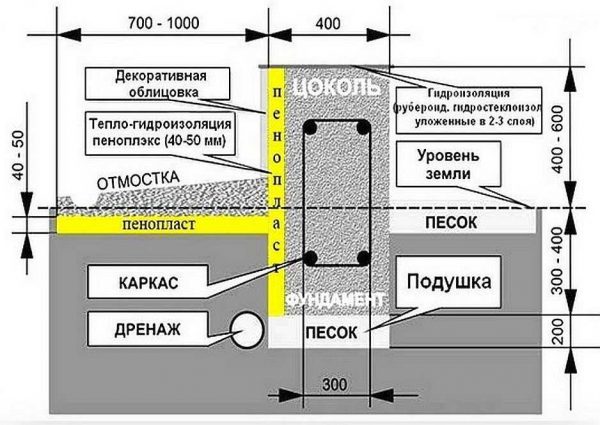

Since the main task of the blind area is to divert melt and rainwater, its width should be at least 20 cm larger than the overhang of the roof. But experts do not advise making it less than 60 cm - moisture can seep to the foundation.

The width of the protective belt also depends on the type of soil. If these are normal soils that drain water well, then 60 cm is enough. If the house is on loam, other heaving or unstable soils, the width should be up to 1 meter.

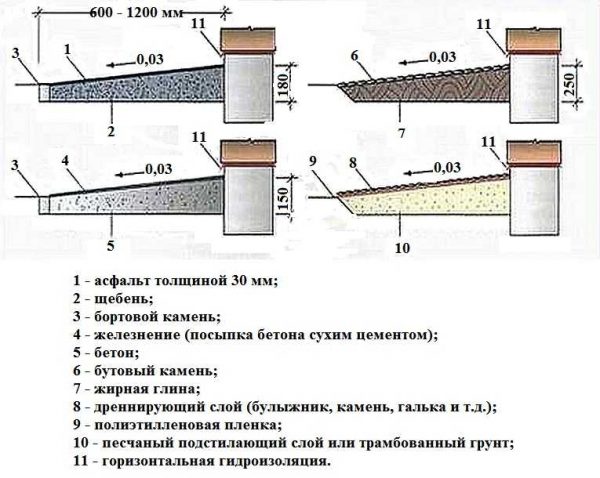

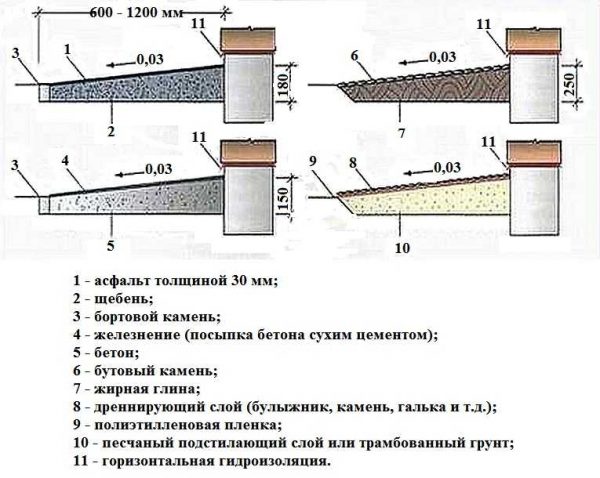

The main parameters of the blind area for the normal drainage of water from the foundation

But the blind area must also deepen.Its depth depends on the type of soil, on the functions that it will perform and on the thickness of the top finishing layer.

If the house is on normal non-powdery soils (not clay or clay-containing soils), and they will not walk on the surface, it is enough to make a bed of sand 10 cm thick. You can lay tiles, stone, etc. on top. This means that the depth of the trench will be about 10-20 cm - it already depends on the thickness of the finishing material. Only for the cover, which is composed of fragments, a border is needed. So you dig in edge stones around the perimeter, strengthen them, and only then pour sand on the bottom of the trench.

If the formwork is to be used as a walkway, a heavier weight-distributing underlay is needed. At the bottom of the ditch, first, crushed stone of a medium-sized fraction of about 15-20 cm is laid, and sand is already on it, and only then a finishing coating.

Options for arranging a blind area with crushed stone, rubble stone, asphalt

What else is required is compliance with the slopes: the decline comes from the house. This will allow moisture to drain into the drainage system or surrounding soil. The amount of slope depends on the type of protective coating used. For concrete and asphalt, the slope is 3-5% (for 1 meter, the height difference is 3-5 cm). When laying stone, tiles, porcelain stoneware, the slope is 5-10%.

How to insulate the foundation

There is a huge amount of materials intended for basement insulation. Among them, the most effective and common ones stand out.

It:

- glass wool;

- expanded clay raw materials;

- Styrofoam.

But the most common option, of course, is polystyrene or its analogue - expanded polystyrene. They are most often used to insulate the foundations of those buildings that are operated in a very unfavorable climate with frequent and sharp changes in temperature.

Expanded polystyrene has a low cost, but at the same time has a high quality of thermal insulation. Its structure is almost 90% small air bubbles. The application is relevant for buildings that are built on a clay type of soil.

This material, in turn, is divided into two types:

- With a foamed structure, and a sheet thickness of more than 2 cm.

- With an extruded structure and a thickness of about 5 cm.

It is best to insulate the foundation and blind area using the second option.

But there is one contraindication: it should not be used when the building has a basement and there is a very real risk of flooding it.

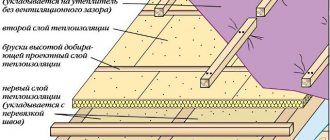

The slab can be 3-12 cm thick. The thickness is chosen depending on the type of premises, the way it is used, as well as on the climatic conditions that exist in the area where the building is built.

It is always recommended to use thicker slabs in the corner part of the house, since it is this part that freezes more than others.

What to choose: Styrofoam or Penoplex?

Penoplex can lie in the ground for a long time without losing its characteristics.

There are two most common methods - insulation of the basement with extruded polystyrene foam and ordinary foam. Each of the materials can be used for thermal insulation work, while there are still differences. Also read: “Thermal insulation of walls with foam from the inside: technology of work”.

As you know, both heaters belong to the same group of polymers, only a different method is used for their manufacture. As a result, these polymers have different characteristics. Insulation of the basement with penoplex has an advantage due to its high performance. Let's make a small comparative characteristic:

- thermal conductivity - for foam, the coefficient is 0.029-0.034 W / m * C versus 0.037-0.043 W / m * C for foam;

- vapor permeability - practically absent for each of the compared materials;

- fear of moisture - penoplex is not afraid of water and can lie in the ground almost forever, while foam is destroyed by moisture;

- density - penoplex has a maximum density of 45 kg / m. cube versus 35 kg / m. foam cube.

At the same time, the insulation of the basement with penoplex will cost much more. But, knowing how important it is to make a high-quality thermal insulation layer on the plinth, it is better not to think about savings, since it will most likely come out sideways. Extruded polystyrene foam is superior to ordinary polystyrene in everything, so experts unanimously say that it is necessary to use it.

Modern paint for heating pipes can be applied even to hot pipes, while the thickness of the layer must be controlled. It does not smell and dries very quickly.

In each individual case, the optimal pipe diameter for heating is slightly different. The calculation takes into account the type of heating system, the length of the circuit, the speed of movement of the coolant, etc. More details here.

The working process

- Work on the preparation of the foundation for insulation.

To proceed directly to the work itself on the insulation of the foundation, it is necessary to remove that part of the soil that is adjacent to the wall outside the building. To do this, you need to dig a trench, the depth of which will correspond to the depth of the foundation itself, while its width should be at least 50 cm.

The part of the wall that was in the ground is cleaned, if necessary, it can even be washed, but then it is necessary to allow time for it to dry completely.

- Foundation waterproofing.

Basically, roofing material or liquid-type rubber is used for waterproofing walls. These products are applied with a spatula to the wall surface. The foundation is covered with 2 layers of roofing material. Roofing material is attached by heating a blowtorch.

- Warming with expanded polystyrene.

Everything is simple here. The insulation used for the foundation is prepared and attached to the waterproofing using mastic or a special adhesive mixture.

- Warming with expanded clay.

Expanded clay is a less known insulation material in comparison with expanded polystyrene. However, it has very good thermal insulation properties. This is due to the fact that it has a porous structure and creates a good air cushion. But its use is meaningless in a humid climate, because under the influence of moisture, expanded clay immediately loses its insulating properties.

All work is carried out in the same way as when insulating with expanded polystyrene, that is, a similar trench is dug, only a waterproofer is laid on its bottom, on which a layer of expanded clay is poured on top. After each poured layer, tamping must be carried out. Then a blind area is made on top, but do not forget to put plastic wrap so that the water from the solution does not go into expanded clay.

- Insulation with polyurethane foam.

In terms of its characteristics, the material is not inferior to the popular foam, but its use is much easier, since it is not required to pre-prepare the wall surface and make waterproofing. It has a liquid state and is applied to the wall with a special device.

Is it worth it to insulate the base with penoplex

The best option to insulate the basement is to lay plates of extruded polystyrene foam on it. This material does not allow water to pass through and retains high thermal insulation properties even in a humid environment. Since the basement of the house is in contact with the ground and is constantly exposed to atmospheric precipitation, penoplex, like Technoplex, due to their technical characteristics, are excellent for insulating this structure.

You can also use Technoplex for insulating the basement - extruded polystyrene foam from TechnoNICOL.

With self-insulation of the basement of the house from the outside with foam, you can use two brands of this thermal insulation. Slabs "Penoplex Stena" are able to provide reliable heat and waterproofing not only for the basement, but also for the columnar foundation of the building. "Penoplex Comfort" is specially designed for use in outdoor work related to the repair and construction of private houses.

Comparison of building materials for thermal conductivity

Blind area works

The blind area is a special concrete strip that is located around the perimeter of the entire building. For the construction of the blind area, materials are used that prevent moisture penetration. The width of this element must be at least 1 meter.

In the process of insulating the blind area, you must clearly follow the existing recommendations regarding this process.

As a material for insulation, materials such as are used:

- expanded polystyrene (fits under the screed);

- polyurethane foam (sprayed with a special apparatus).

The process of insulation with polyurethane foam is simpler in the sense that it is not necessary to additionally process the joints of the plates, since they are simply absent here.

Advantages and disadvantages of thermal insulation of the basement with expanded polystyrene

Insulation of the basement with extruded polystyrene foam makes it possible to maintain its thermal insulation properties even in extremely humid environments. Compared to many other materials, this insulation is able to withstand impressive loads, preventing subsidence. Expanded polystyrene has other advantages in application:

- Frost resistance;

- High thermal insulation characteristics;

- Not affected by moisture;

- Well mounted, easy to cut;

- The material is relatively inexpensive;

- The service life is 40-50 years.

Among the shortcomings, it will be fair to highlight the following:

- The material is subject to combustion, therefore, the basement of the building must be treated with non-combustible materials before laying.

- It absorbs moisture well, therefore, before installation, it is necessary to treat the base with waterproofing materials.

- The heat insulator can be damaged by rodents, and therefore it is necessary to install a reinforcing mesh.

- It is exposed to mechanical damage - filling it with soil, you will need to install protection in the form of shields or reinforcing mesh.

- Not recommended for use in buildings subject to ground movement.

What not to do when insulating the foundation

If we deviate from the basic technologies, the insulation of the foundation and the blind area will not lead to the expected result. You need to watch out for the following points:

- it is necessary to store the insulation in clearly defined conditions, since improper storage leads to a loss of insulating properties;

- it is impossible to carry out insulation work in conditions of high air humidity;

- you need to select the parameters of materials as accurately as possible;

- it is necessary to process the seams correctly.

As is clear, the insulation of the foundation and the blind area is not only a prerequisite for reliable thermal insulation of the base, but also affects the duration of operation of the entire structure.