A warm house is the basis for a comfortable stay for a family. Today the market offers several types of insulation, but one of the most popular is insulation of housing with penoplex. This is a unique material that can be used to insulate any type of structure. It surpasses analogues in its properties and is actively in demand. Insulation with material is possible for various parts of the building. The approximate price for building insulation is approximately 2 thousand rubles for 1 square meter.

Thermal insulation of walls, floors and ceilings for the building with penoplex. What does the service include

Unlike most options for insulating buildings, this material can help insulate any structure, for its versatility it is firmly rooted in the list of the most demanded for this service. This material is obtained by secondary smelting, it was obtained by testing the predecessor. The material turned out to be pliable and easy to use.

The advantages of insulation with this material:

- Due to its high density, it is able to withstand heavy loads.

- Able to keep warm for a long time with minimal material consumption. To insulate the house, a layer of 5-6 cm.

- Has a good sound insulating effect.

Penoplex insulation is a universal service. Insulation is performed for walls inside and outside the house, for foundations, roofs and additional structures, floors and balconies, ceilings and prefabricated partitions.

The most popular service is insulation of building walls... This is a convenient option for insulating a building, because it is through the walls themselves that most of the heat escapes. The material is simply attached and the work itself is quite simple, it includes several stages:

- Cleansing the top layer of walls from dust or dirt.

- Installation of material with mortar.

- Additional fixing of sheets with a dowel.

- Application of the first layer of plaster using mesh.

- Applying the second word of plaster.

- Final finishing using facade decor.

Since the material is placed on a wet solution, this technology is called "wet". The technology is suitable for insulating a building outside and inside. It is also possible to apply the service for the floor and ceiling using a similar technology.

Briefly about expanded polystyrene

The main advantages of the material are:

- High vapor permeability

- Low heat transmittance is the main characteristic for any thermal insulation material

- Environmentally friendly and fireproof - does not emit harmful toxic substances, therefore it is suitable for insulation from the inside

- High moisture resistance - it does not absorb moisture

- Resistance to defamation loads

- Durability - up to 5-6 decades

Expanded polystyrene does not rot and the appearance of insects, mold or fungi inside. However, as with classic styrofoam, it must be handled with care. With a careless attitude during the installation process, it is easy to break it, as a result, render it unusable.

Types of services. Approximate prices and features

Insulation of the building facade is carried out in several stages. The price is indicated per square meter. Its primer costs 50 rubles... Warming from 400 rubles, applying the final stage - a decorative layer also from 400 rubles.

Insulation of the basement is worth from 400 rubles... Additional reinforcement with a special mesh also from 400 rubles... Preliminary soil from 50 rubles... If necessary, a decorative stone can be added on top of the panels, the cost of which depends on the quality of the stone, on average it goes from 1000.

The price is also formed from the final type of work. There are people who order exclusively the service of insulation, and there are those who are interested in the further decoration of the building from the outside and aesthetics.

The cost of work on the insulation of the facade with foam

The cost of any construction work traditionally consists of the cost of the material itself and the work of the construction team. Today, many companies offer turnkey facade works, ie. the indicated price includes materials, preparatory work, and topcoat.

Prices for insulation of facades with polystyrene foam fluctuate in the range of 1600-2000 rubles / sq.m. At the same time, the price increases slightly with an area of work less than 100 square meters and slightly decreases with an area of more than 350 meters. The numbers given are relevant for insulation of medium thickness, i.e. 10 cm, if a thicker insulation is used, the price will rise proportionally. The scope of work offered by construction firms is usually standard and includes the installation of scaffolding, cleaning the facade, installing corner and window profiles, fixing insulation, mesh reinforcement with a double adhesive layer and finishing with decorative plaster. Some companies add facade painting to this list.

Modern market realities force construction companies to separately allocate the cost of work only for facade insulation, without materials to attract customers. This allows the developer to order work with materials he has independently purchased and provides significant savings, since the cost of insulation in this case will be 700-1000 rubles / sq. M. In this case, only the prices of registered construction organizations are considered. If you use or semi-legal brigades, the price will be much lower, but the quality is also highly questionable. As for saving on buying materials on your own, you first need to figure out their composition. For insulation you will need:

- primer

- insulation glue

- Styrofoam

- dowels

- reinforcing mesh

- plaster

- decorative plaster

- topcoat.

Quite a long list, the price of each element of which "jumps" pretty decently, depending on the quality of the material or the promotion of the manufacturer. However, for insulation, the most significant characteristic is the thickness of the foam. The recommended insulation thickness for residential buildings is 10-25 cm, depending on the region. There are recommendations to insulate facades with 5 cm thick foam, but in fact, this does not greatly reduce the heat loss of the building. Prices for polystyrene foam for insulation fluctuate between 2000-2300 rubles / cubic meter. for the PSB-S-25F brand, 2500-3000 rubles / cubic meter. for PSB-S-35 and 3500-4000 rubles / cubic meter. for PSB-S-50). If we translate this into an area, then 1 sq.m. insulation costs from 150 to 400 rubles, depending on the thickness and density. If the thickness is 5-10 cm, then its price is from 50 to 100 rubles per sq.m. If you add up the cost of all the materials mentioned above per 1 sq. M., You get an amount of 250-500 rubles per sq. M. m.

This is significantly less than the 700-1000 rubles pledged by construction organizations for each square meter, even with the maximum thickness and cost of the foam.

What is house insulation for?

The 21st century was marked in Russia by the beginning of rapid private construction. A huge number of our compatriots are striving to become owners of their own homes. In this situation, new economical construction technologies play a special role. Due to the harsh climatic conditions of most of the territory of Russia, a significant share of the costs in the construction of buildings falls on heat conservation systems.

Various technologies provide significant cost savings house insulation... The buildings erected in this way are distinguished by a comfortable and environmentally friendly internal microclimate. They are cheap to operate due to their low heating costs in winter and are protected from excess heat on hot summer days.

Correctly insulating a house with lightweight heat-insulating panels reduces the load on supporting structures and meets the most stringent building codes. At the same time, the total volume of expensive building materials decreases. For example, the proportion of bricks in the load-bearing wall can be reduced by 70% of the amount required in SNiP in order to provide the necessary thermal insulation characteristics. The total cost savings for the construction of the building box, taking into account labor costs for installation and decoration of external walls, can be more than 50%! In addition, additional protection of external walls from adverse environmental influences is provided, which significantly extends the service life of buildings.

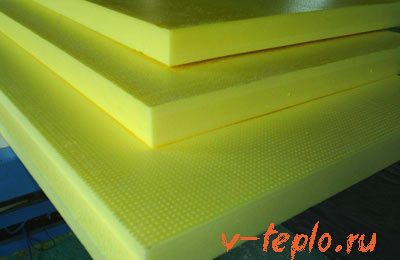

Penoplex is the best material for insulating walls from the outside

Due to the availability and wide variety of modern thermal insulation materials, thermal insulation of wooden structures, brick buildings and wall insulation outside a panel house are becoming especially relevant. Penoplex is a material for insulating walls from the outside, which every year is gaining an increasing number of fans, and here's why.

5 advantages of Penoplex: wall insulation from the outside according to all the rules!

- Low thermal conductivity. The thermal conductivity coefficient of 0.032 guarantees that the insulation of external walls with Penoplex will be really effective.

- Moisture resistance. Any technology of external wall insulation using Penoplex boards guarantees 0% moisture absorption!

- Resistance to temperature extremes. Insulation of brick walls, as well as insulation of buildings from other materials, can be carried out at any time of the year, because Penoplex insulation can withstand both -100 and + 75 ° C!

- Durability. The cost of wall insulation will be justified if you use high-quality materials. Penoplex slabs will serve you for at least 50 years!

- Ease of installation. The L-shaped edge of the slabs makes it easy and simple to carry out wall insulation with Penoplex. The cost of work will be minimal!

Still have questions? Do you want to order thermal insulation of the walls of a country house or apartment? Call us! Wall insulation with Penoplex plates is always economical and effective!

Appointment of estimate calculations for facade insulation

As for similar types of work, the basis of production is the estimate. This is an extremely important document that reflects the list of actions performed by the contractor, their scope and materials required for implementation. Before the contractor can start implementing his part of the agreements, the task between him and the customer is to agree on a budget for the performance of the required work. It is for this purpose that a document such as an estimate serves.

Among other things, its preparation can solve two more important problems. Namely:

- selection of the most optimal options for carrying out work and types of materials used to save the budget;

- drawing up a detailed plan of actions to be performed during the production process.

That is why a qualified and responsible approach to the preparation of estimate calculations is the key to success and obtaining a decent result when carrying out facade insulation.

External wall insulation with expanded polystyrene

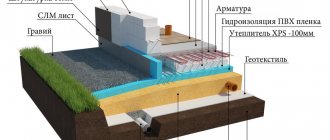

Starting work, it is necessary to calculate the total area of the surfaces to be insulated and purchase the required amount of material, prepare a working tool. The optimal thickness of the heat-insulating layer, which allows you to save up to 55% of heat, is within 8-10 cm. It is recommended to buy polystyrene foam of the appropriate width or lay 2 layers of 4-5 cm each, overlapping the upper joints of the lower one.

The work should be broken down into 3 main stages:

- Surface preparation

- Installation of expanded polystyrene

- Finishing work

Surface preparation

First, the surface must be prepared for the installation of thermal insulation boards. After walking around the perimeter of the house, you should carefully examine the walls for cracks, bumps and deep depressions. Having found defects, they are marked and then eliminated.

It is not recommended to insulate the walls with expanded polystyrene directly on the brickwork. The surfaces are pre-coated with a putty mixture or plaster. The smoother the surface, the less the thickness of the connecting layer of glue will be required.

Some craftsmen, relying on the waterproofness of the material, begin laying it directly over the plaster. However, one should not give in to haste, since under the constant influence of moisture, polystyrene foam will begin to collapse. It is recommended to cover the wall with one of the following waterproofing materials:

- Parchment

- Roofing material

- Bituminous mastic

Installation of expanded polystyrene

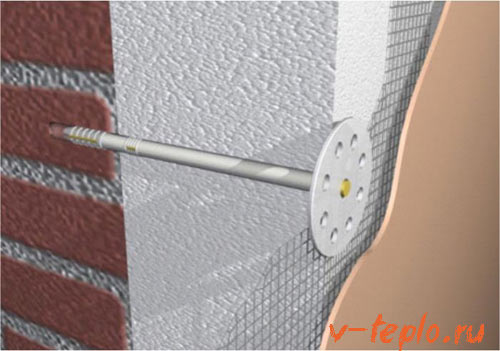

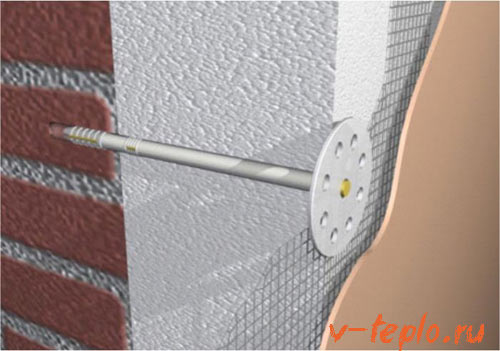

Laying the slabs must begin from the corner of the room, gradually moving first to the side, then upward. The vertical joints of the upper row should not coincide with the lower ones. A combined method is used as fasteners:

- Special glue

- Dish nails

First, a layer of glue is applied to the wall with a notched trowel in the form of stripes. It should not be very thick so that the insulation fits snugly to the surface. It is checked by the level that the slab lies exactly horizontally and vertically. There is no need to rush - the glue will set no earlier than after 7-10 minutes.

It is necessary to strive to press the plates against each other as tightly as possible. If gaps are formed, they are laid in small pieces of material and coated with glue.

Having laid all the sheets, you should take the dish nails and fasten each of them. First, 5 holes are drilled with a drill (4 in the corners and 1 in the center), then dowels are installed and carefully hammered in with a hammer so as not to damage the expanded polystyrene. In order to save money, you can place nails at the seams, thereby fixing two plates at once.

Did you know that air heaters are ideal for heating large retail spaces?

Finishing work

After completing the installation of the insulation, it is necessary to apply a vapor barrier film and be absent from work for two or three days. During this time, the glue will completely harden. Then a reinforcing mesh is applied to the surface. It can be attached in any convenient way, for example, with special glue.

After that, the wall is covered with plaster again. The applied layer must be at least 5 mm. The finishing option of cladding can be absolutely anything: siding, hinged metal or wood products, decorative plastering. Everyone should choose based on their preferences.

How to properly insulate a house.

Depending on the required goals, various technologies are used, which allow the correct insulate the house, differing in quality, construction speed, durability, price and other characteristics. The choice of this or that insulation option depends on the financial capabilities of the customer and the requirements of the design solution for the facade decoration. Consider the most common of them that satisfy the largest number of customers, optimal in cost and finishing options.

Ventilated wet facade system: a technology based on the creation of a multilayer thermal insulation system, consisting of a heat-insulating, protective-reinforcing and decorative layer. The decorative layer is made by wet application of special plaster or paint of the required colors and textures.

1 — base (outer wall of the building); 2 — polymer glue "Color-Plast K" for gluing boards to any base; 3 — decorative layer (bark beetle, fur coat, paint); 4 — corner protection profile for reinforcing corner joints; 5 — thermal insulation layer - mineral plate (left), polystyrene or expanded polystyrene (right); 6 — protective layer of polymer glue "Color-Plast K" 7 — plastic dowel for attaching insulation; 8 — fiberglass mesh; 9 — fire cut from mineral wool slab (for fire-hazardous heaters); 10 — starting basement profile; 11 — acrylic soil "Color-Plast G";

Ventilated curtain wall assumes the presence of an air gap between the insulation layer and the outer finishing layer. The ventilation gap is created constructively between the thermal insulation layer, fixed on the outer surface of the wall and the decorative and protective facing layer, fixed on the metal supporting substructure. The cladding of the outer decorative layer can be made with ceramic tiles, porcelain stoneware, natural and artificial stone, various types of siding, composite panels, aluminum and steel cassettes, etc. Wet coatings, plasters and paints are not used. Due to technological features, this type of facade insulation is the most expensive option for a ventilated facade.

Insulation of an old house.

Against the background of constantly increasing energy prices, the need to insulate buildings in use, built in violation of heat-saving requirements, has acquired particular importance. For example, up to 90% of the buildings of cheap mass construction of the Soviet era were erected with gross disregard for heat losses, which were compensated by low prices for heat carriers. Most of the heat losses on winter days were paid for by the state. Excessive overheating of premises on hot days was not taken into account at all. The comfort of such housing left much to be desired.

Nowadays, the situation has changed dramatically for the worse. On the one hand, a significant part of the housing maintenance costs fell on the shoulders of the tenants themselves. At the same time, utilities constantly strive to save money, simply by reducing the temperature of the batteries, and do not invest in the reconstruction of buildings. Living conditions are deteriorating, and utilities are becoming more expensive.

Nevertheless, there is a way out in this situation! Thermal insulation of external walls will significantly increase the thermal comfort of housing. Even with a low coolant temperature in the batteries, it will become significantly warmer in winter, and in summer the heat will no longer cause such discomfort as before.

Private home owners will also be able to save up to 70% of their annual costs!