The reasons that the gas boiler smokes

Basically, the reasons why a gas boiler smokes are as follows:

- Insufficient air flow.

- Excess air.

- Poor fuel quality.

- Insufficient gas pressure.

- Burner blockage.

- Insufficient coolant temperature.

Lack of air

Insufficient air flow is usually associated with poor ventilation, a blockage in the chimney, or a change in air flow. If the problem is related to the ventilation of the room where the gas unit is located, it must be cleaned and adjusted.

It happens that the flow of air does not allow ice on the head or a blockage in the pipe to penetrate. Then you have to get rid of these obstacles.

Sometimes, in strong winds, pressure drops appear in the pipe, which prevents the flow of air to the burner. In this case, it is worth correcting the design of the gas boiler or installing a deflector on the pipe head.

With a lack of oxygen, the fuel does not burn completely, which is why soot is formed.

Excess air masses

Excessive air flow usually occurs with strong draft, if there is no adjustment. Excessive thrust occurs due to changes in the weather: low temperatures, changes in air pressure, in strong winds.

With an excess of air masses, the flame is unstable, there is a lack of temperature, as a result of which the gas does not completely burn out and forms soot.

Note! Too little or too much air can be caused by an incorrectly adjusted burner on the unit.

Poor fuel quality

If the fuel contains moisture or impurities, then during combustion they form soot and reduce the performance of gas equipment. In this case, experts recommend installing a filter at the inlet of the gas line.

Insufficient gas pressure

Also, the reason why a gas boiler can smoke is the low gas pressure. Often this phenomenon occurs in severe frosts, when many consumers are actively starting to consume fuel. Signs of low pressure are:

- short flame with separation;

- decrease in boiler power.

Also, the reasons for insufficient fuel pressure can be:

- blockage of the pipeline;

- malfunctions in the gas meter.

Burner blockage

During operation, especially if the gas is of poor quality, sooner or later the burner becomes clogged with soot and dirt. When fuel is burned in a contaminated burner, not only the gas itself burns out, but also the dirt accumulated on the nozzles, which results in soot.

To prevent this from happening, it is necessary to regularly clean the nozzles or change them.

Insufficient coolant temperature

All boilers have such a characteristic as the maximum temperature of the heating medium. Usually it is 80-85ºC. If the temperature of the liquid is not high enough, the resulting flue gases become too cold, which leads to a weakening of draft and smoking.

Why does moisture appear in gas boilers?

In addition to condensation in the chimney of a gas boiler, moisture can also form in water pipes. The main reason lies in the temperature difference.

Also, the appearance of "dew" on pipelines is influenced by:

- improper ventilation (insufficiently powerful hood);

- high level of humidity in the room;

- incorrect operation of heating equipment.

The device of a gas boiler does not allow you to completely get rid of condensate.However, it is in your power to reduce the rate of moisture formation and its amount.

Fighting condensate in an atmospheric boiler

If an atmospheric wall-mounted or floor-standing gas boiler is installed in the house, then the combustion products are heated to 170-200 ° C. The gases formed during combustion also contain water. However, it does not condense, but turns into steam and is discharged through the flue duct along with other smoke and volatile soot particles.

When starting floor gas equipment after a long idle period, a small amount of condensation is allowed, which will evaporate after the boiler warms up. In the cold season, the boiler works non-stop, so the appearance of liquid is unlikely

If condensation forms in the chimney, then the problem is in the poor-quality thermal insulation of the chimney. Moreover, the formation of condensate drops on the smoke channel can occur both due to insufficient insulation, and from excessive insulation.

In pipes made of stainless steel, the problem of condensation formation can be solved by installing a condensate neutralizer and completing it with a drainage element for condensation moisture deposited on the surface of the pipe.

When assembling ordinary metal chimneys and sandwich chimneys, it is imperative to follow the assembly and connection procedure of elements, which provides for the spontaneous drainage of condensate outside the flue channel.

Dew prevention in a turbine boiler

Closed burner models are equipped with a coaxial flue. It has a slope of 3 ° towards the outside, i.e. from the boiler, it provides spontaneous drainage of condensate to the street.

The internal channel of the coaxial system is constantly cooled by the air flow from the outside, so that the temperature difference during normal operation is minimal.

The standard length of the coaxial smoke exhaust system is 1.2 meters. If extension is required, (always indoors) the distance should not exceed 6 meters. There must be at least 0.6 m between the outlet of the outer part of the coaxial chimney and the nearest obstacle (wall, large tree, etc.).

If the boiler is equipped with a coaxial chimney, problems with the formation of condensation occur during frosty periods. They are solved by insulating the part of the smoke channel located outside the house, strengthening ventilation or starting the boiler at full capacity.

When using a boiler with a coaxial chimney in northern regions, it is advisable to insulate the outer part of the exhaust pipe. This will prevent the formation of condensation on the flue gas flue. After all, the difference between the temperatures of the incoming air stream and the outgoing flue gases will be reduced.

The boiler can be temporarily supplied with air from the room. Most turbine models of floor-standing and wall-mounted gas boilers are designed for the possibility of installing separate supply and exhaust systems. You just need to find the plug of the hole to which the chimney should be connected, and slightly open it.

With a slightly opened cover for the exhaust duct, you can wait out the frost. Then it must be covered tightly. Even in these cases, increasing the boiler power during the frost period helps. In automated systems, a temporary reduction in the interval between the temperatures of activation and shutdown of the boiler set by the owners works well.

Feature of condensing boilers

The ideal solution would be a condensing boiler that is properly balanced with the heating system, correctly configured and operates in the appropriate mode. In this case, the appearance of condensation is absolutely not harmful, because its energy is rationally used by the system itself.

The amount of gas saved directly depends on the amount of condensate formed.The condensation heat generated during the operation of the equipment is collected and redirected to the heating circuit. The efficiency of such a boiler is 98%.

Fault classification

All problems with gas boilers can be divided into categories:

- Primary or secondary. Primary ones are evidence of problems of an indicator nature in the operation of one or even several nodes. If the fault has not been repaired, a secondary fault appears. It is the result of ignoring the problem. After a secondary malfunction occurs, the equipment stops working.

- Hidden or obvious. The first group includes leaks of heat exchangers or butt joints, breakdowns in the hot water supply or heating circuits, as well as other malfunctions that a person cannot identify without appropriate training.

- Gradual or sudden. Some damage develops imperceptibly due to a change in the parameters of the functioning of units or a change in conditions, while others are unpredictable and suddenly appear at the least suitable moment.

- Final damage. Sometimes the cause of an accident can be identified immediately. For example, after a fall, the unit immediately stops working. Then the cause is mechanical damage.

Burner damping

Burner damping is one of the most common faults. If this happened during the start-up of the device, the reason is:

- Excessive cravings

- violation of gas evacuation, lack of traction;

- incorrect operation of the sensor;

- shortage of thermocouple contact.

The first reaction to burner damping is to check the draft. It is very simple to do this - you need to light a match or a candle, and then bring the flame closer to the air duct. The presence of a stable draft will be indicated by the tip of the flame, which will go inside the boiler body. The fire must not go out. In the absence of traction, the tip will deviate slightly. Sometimes the cravings are excessive. Then the fire will immediately rush into the air duct, begin to swing strongly or go out altogether.

Another common cause of burner extinction is a thermocouple, or rather insufficient contact. In this case, when the boiler is started, the burner ignites, but the flame quickly goes out, having emitted a quiet pop before that. Such a malfunction can be corrected by yourself. To restore work, you just need to clean the contacts.

Traction normalization methods

If the burner goes out immediately after firing up, the reason may be hidden in the draft sensor. This problem cannot be solved by restarting the equipment, because the sensor is a supervisory component that blocks the operation of the unit.

To diagnose a breakdown of this spare part, you just need to close the terminals, bypassing the sensor, and then start the equipment. If the boiler turns on normally and continues to work as usual, the sensor is out of order. You can replace it on your own. If the unit does not start, then you should immediately turn off the gas and call a specialist. Only a master will be able to carry out the appropriate diagnostics of the boiler using specialized devices. He must inspect the main and auxiliary elements when diagnosing equipment.

Excessive draft can provoke blocking of the unit, the air mass breaks off the flame, due to which the gas supply is cut off. The thrust force can be determined without turning off the equipment, because with its abundance, the flame acquires a light yellow tint, instead of blue, or it becomes colorless. In addition, in the presence of strong thrust, the device operates with a constant hum.

The cause of problematic draft may be incorrect placement of the chimney or boiler. Strong gusts of wind can disrupt the free flow of air, an excess of pressure appears, and the chimney can be clogged. As a result, the flame is extinguished and the boiler is blocked.To prevent this from happening, it is worth entrusting the installation of heating equipment, as well as the arrangement of the chimney to specialists. They take into account in their work not only the current rules and standards, but also the direction of the winds, as well as many other features.

Why does soot appear?

During its operation, a gas boiler burns a large amount of natural gas, which is impossible without oxygen. To burn one cube of gas, you need 10 cubic meters of air, and if it is not enough, the gas simply will not completely burn, forming a huge amount of soot in the process. This can only be prevented by providing sufficient air supply.

Before adjusting the airflow, pay attention to the flame. In order not to look inside the boiler, risking your eyesight, you should use a mirror:

- The flame can periodically skip or fly off if there is too much air. In addition, the device will be very noisy.

- If the air is supplied in sufficient quantity, the boiler works evenly, the burner flame is also even and has a bluish tint.

- In case of a lack of air, the flame turns reddish or takes on a yellow tint, the unit functions unevenly, turns off and smokes.

When soot is released, dust particles are quickly drawn into the platform. There, it blocks the air channels, the chimney itself, and also forms places of strong accumulation of soot inside the structure. Dirt accumulates on the walls of the chimney, sticks to the burner, due to which the boiler stops working.

Why does the boiler smoke?

The boiler is smoking. Black smoke is coming out of the chimney. Soot settles in the boiler, in the chimney, flies out of the chimney. Why the cauldron can smoke? (10+)

Why does the boiler smoke?

The material is considered an explanation and addition to the publication:

Heat supply with coal. Functional experience. Coal heat supply experience. Warm, comfortable, but troublesome. Comfort and safety of coal heat supply.

The boiler is smoking. Black smoke is coming out of the chimney. Soot settles in the boiler, in the chimney, flies out of the chimney. Why the cauldron can smoke?

A selection of materials for you:

AT

Everything you need to know about heating and climate control Important factors in the selection and maintenance of boilers and burners. Fuel comparison (gas, diesel, oil, coal, firewood, electricity). Do-it-yourself ovens. Heat carrier, heating devices, pipes, underfloor heating, circulation pumps. Chimney cleaning. Conditioning

Smoke cauldron maybe for some reason. Insufficient air flow, excess air flow, poor fuel quality, insufficient fuel pressure, contamination of spraying devices, disturbed turbulation of the air flow in the burner, unsatisfactory boiler temperature.

Insufficient air flow may be due to the wind, if the ventilation hole for air flow into the space of the room with the boiler is made on the wrong side of the house from which the chimney is located. Then wind currents can create pressure drops that prevent air from entering the boiler furnace. With insufficient air flow, the fuel does not burn completely and soot is formed. A sign of a minus air is the dark crimson color of the flame. Provide a supply of clean air into the boiler room from the required side of the house. Insufficient air flow, and therefore soot, may appear due to a clogged chimney or the boiler itself.

Excessive air flow occurs when there is excessive draft, if the draft regulator is not supplied. Excessive cravings can appear at very low temperatures outside. With excessive draft, the flame is white. Due to the excess air flow, the temperature of the exhaust gases becomes insufficient for complete combustion of the fuel.

Insufficient or excess air inflows may appear due to incorrect adjustment of the boiler burner, primary, secondary and tertiary air flows in the boiler.

Poor quality of fuel, presence of moisture, foreign impurities, etc. Third-party impurities, burning, themselves create soot and disrupt the natural process of fuel combustion.

Insufficient fuel pressure. This primarily applies to gas. In severe frosts, gas consumption increases. There is a decrease in the pressure in the line. The low pressure in the line is immediately visible by the short flame, which sometimes breaks down, and by the drop in boiler power. Insufficient head of the diesel fuel can be caused by clogging of the filter or freezing (paraffinization) of the diesel fuel.

Contamination of spray devices. Boiler spraying devices are subject to constant cleaning and periodic replacement. If such a procedure was not done with the required frequency, then the boiler may smoke.

Violation of turbulation. In boilers, the flow of heated gases swirls precisely to ensure complete combustion of the fuel. If the swirl goes wrong, does not correspond to the calculated values, then the fuel does not completely burn out, and soot appears.

Unsatisfactory boiler temperature. Most boilers have restrictions on the temperature of the heat carrier in the boiler. Many boilers function well only at a heat carrier temperature of 80 degrees Celsius. In another case, gases enter the chimney too cold, which leads to a decrease in draft and smoking.

Flame separation and its causes

The flame begins to detach or skip as a result of a change in thrust. As soon as it becomes insufficient or excessive, the burner ceases to function normally, therefore, the performance of the entire boiler system may depend on the timely removal of combustion products, as well as the uniform supply of oxygen. Correct traction not only contributes to the normal operation of the equipment, it prevents it from overheating. The burner evenly heats up all circuits, and the flue gas monitoring sensors do not block the operation of the equipment. Constant monitoring of the air draft and exhaust gas discharge is a guarantee of the smooth functioning of the unit.

The burner operation depends not only on the draft, but also on the integrity of the nozzles. As a result of a violation of the order or integrity of their outgoing openings, a breakthrough or flame separation occurs. Hole placement can be disturbed as a result of:

- Preventive cleaning;

- an attempt at tuning by a non-professional;

- incorrect functioning of the burner.

If the injectors themselves are damaged, they should be replaced immediately. The strong pressure in the gas pipeline also causes a breakaway. Elimination of this problem is possible only by contacting the gas service, because independent intervention in the gas pipeline is prohibited.

How does the season affect the boiler operation?

Sometimes the reason for the burner to go out is a rise in the outside temperature. This happens during a warm period, most often in July-August, when the temperature reaches its peak. It is at this time that the air draft is greatly weakened.

The reason for the decrease in draft is the small temperature difference outside and inside the building. Therefore, in the summer, it is not recommended to use the boiler constantly or at full capacity. It is better to just periodically turn it on exclusively to heat the required amount of water, and then turn it off.

If the control sensor works normally in winter, it can block equipment in summer for no apparent reason. In this case, the fault lies with the manufacturer. This is possible only with unfair work and poor quality workmanship. You can solve the problem simply by replacing the element.

All heating devices need to be treated with respect. Reducing the likelihood of breakdown is possible only with the help of competent installation, correct adjustment and periodic maintenance.It is advisable to carry out diagnostics at least twice a year - before and after the end of the heating season. In addition, it is better to entrust installation, maintenance, and adjustment to specialists who guarantee the quality of their work.

Source: vse-pro-stroyku.sqicolombia.net

Then, after a while, after analyzing the possible nuances and risks, it was decided to equip the air boost. First, an experiment was carried out with a compressor from an aquarium (air flow rate 100 l / h). There was no effect at all. Then, for this purpose, a VKMts-100 fan with a power of 72 W and an air flow rate of 250 m3 / h was purchased at random.

The fan is designed for continuous operation.

Since at the time of the experiment, the boiler was already clogged, and again to disassemble it for cleaning ... I VERY didn't want to, without much hesitation, an adapter to the hose was quickly built from improvised means. The case went, in particular, a can of some kind of deodorant, an adapter from the sewer pipes, a hose and a certain amount of electrical tape. A curved steel tube (pictured) was attached to the other end of the hose. Hose - regular PVC (green) 3/4 ″ diameter. And the tube, by the way, is from the frame of a children's bicycle, this orange (these were produced back in Soviet times), with an inner diameter of 9 mm.

This tube was inserted into one of the holes in the lower part of the burner tube, through which air is drawn in during the operation of the boiler. Well, after all that, the fan was turned on.

The changes were especially striking in the dark. If the flame in the boiler was red without aspiration, then during the pressurization process it had a blue color, albeit with a slight admixture of red. The presence of red indicates that there is still insufficient air; therefore, it is necessary either to use a more powerful fan or to reduce the resistance to air movement from the fan to the gas burner. Since we did not have the opportunity to use a wide hose (ideally it should be equal to 10 cm, i.e. coincide with the diameter of the fan outlet), naturally, as a result of this, there is not enough air supply. However, as an option, you can position the fan close to the burner and, accordingly, shorten the length of the hose. This will also help to reduce aerodynamic drag.

In this case, of course, it will be necessary to take measures to exclude excessive heating of the fan from the gas boiler. For example, you can use sheet asbestos or fiberglass for these purposes.

However, since the boiler was already clogged, this event was not enough: after all, there was practically no draft. Then, with the help of a cloth, the annular gap between the boiler drum cover and the conical adapter was sealed. The temperature of the boiler body and chimney was periodically monitored, but it did not exceed 150 ° C. And ... soon the water temperature began to gradually rise (by about half a degree per hour) while the gas consumption remained unchanged. Finally, she reached the norm for our home. And the house is not small, there are carpets on the walls everywhere, and they interfere with the convection of warm air coming from the heating pipes, so the water temperature in severe frosts should be at least 92 ... 94оС. Whereas in front of the pressurization device the temperature was less than 70 ° C and was not going to rise more.

After that, the fabric was removed, the gap was depressurized. The fact is that excessive heating of the chimney is dangerous, at least in terms of fire. And the chimney will burn out faster. Finally, with a sharp gust of wind (when the thrust increases sharply, which can lead to a flame blowout), the existing gap plays the role of a spare section through which part of the air from the room will flow; therefore, less air will pass through the boiler and thus the risk of flame blowout will be reduced. But, in those days the weather was calm, the risk was minimal.

Thus, the problem with the boiler was solved: it stopped clogging with soot; the soot that was inside, apparently, burned out safely, because now the thrust is excellent. The fan has been running for probably a couple of months now. The flame in the cauldron is still blue with red flashes. No more clogging.

By the way. Periodically, the flame becomes completely blue (as it should be), then again with red flashes. The period of these changes is several hours. This clearly indicates that the composition of the gas is changing. Or something is mixed there (for example, gases from our chemical plant in Ufa; of course, this, apparently, is more economical than simply burning them in the atmosphere in the form of an eternally burning torch). Or the gas flow is uneven in its chemical composition. In addition to propane-butane, other components with a higher molecular weight may periodically appear, respectively, requiring more oxygen for combustion.

The only problem is now. The fact is that when the water temperature reaches the set one, the gas regulator (located outside the boiler on the side) automatically switches the boiler to the incomplete supply mode; at the same time, the flame burns much weaker, respectively, less gas is supplied. But the airflow does not change, therefore, there is an excess of oxygen, the gas-air mixture is depleted. This sometimes results in a flame appearing inside the pipe (bottom of the burner). Naturally, there is nothing wrong with that, the flame will not come out even theoretically. But ... somehow it is ugly roofing felts, either indecent, or it is not yet clear how. And we are not so accepted, such technical obscenities. We never act according to the principle "if only it works." The problem is that now, at the moment the gas supply to the burner decreases, it would be necessary to turn off the fan and turn it on only when the gas flow returns to the nominal one. Well ... there will be time, let's think about the reed relay. A small magnet for it can be attached to a switch plate that (partially) shuts off the gas supply. And place the reed switch itself outside the housing in which the plate is located. Fortunately, the case is aluminum, i.e. non-magnetic.

And the last one.

Something is written here above. However, I hope you know that unauthorized interference with gas equipment is FORBIDDEN in our country. Therefore, we do not recommend that you use any of what was discussed here. It was said so, for information, for informational purposes. Well, and for especially "advanced" (more precisely, moved ... well, or they have such a profession) in terms of formalities, citizens - for them personally we inform the following: everything that you have read here (about the gas boiler and its improvement), most likely , was not in sight. We ourselves do not remember how it was and what it was ... We wrote a fairy tale here, so, night fantasies. Not all A.S. Pushkin to read, let there be such a fairy tale.

Well, for those who have a hard time with physics - chemistry, we do not even recommend reading such articles, and even more so, to apply the knowledge gained in practice. We say this for sure, without any fairy tales. Take pity on yourself and others. Live Long! That's it for you, really, in such cases, you need to call the master, buy a new boiler, well, etc. Best regards to you all.

Source: www.dissertacii-diplom-ufa.ru

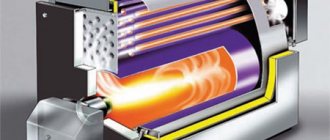

The principle of operation of a solid fuel boiler

Solid fuel boilers work on the principle of upper combustion: the fuel starts burning from the upper layers, gradually the flame goes down, keeping the heat supply at a sufficient level.

The operation of solid fuel equipment is simple. The combustion process begins with the smoldering of the first fuel fill in the combustion chamber and gradually intensifies. However, by limiting the access of oxygen, it is possible to achieve a maximum deceleration of combustion, which contributes to the economical consumption of combustible material.

The flue gas moves gradually into a separate combustion chamber where it is ignited. The advantage of boilers of this configuration is the maximum complete combustion of toxic compounds and soot, which ensures environmental friendliness and even usefulness. From the total mass of combustion products, only smoke remains, which does not contain toxins.

In solid fuel boilers, the principle of upper combustion is implemented, which consists in the fact that the fuel starts burning from the upper layers of the bookmark. The fire gradually descends, slowing down smoldering, but keeping the heat supply at a sufficient level. The time of complete combustion of one fuel load is determined by the volume of the boiler and its model.

Causes of boiler fuming

Some signs help determine what to look at in the first place when fumes and soot appear in the room. Conditionally, the causes of smoke can be divided into 4 groups:

- Clogged chimney is one of the most common problems. This can be either a foreign object that has entered from the outside, or the result of using low-quality fuel.

- The discrepancy between the chimney power of the boiler or the height of the building is less common and is detected almost immediately, at the very first heating. In a situation where at first everything was fine, and then began to smoke, this reason should not be considered.

- Damage to the chimney is the least likely case. But if the boiler gives off smoke at the beginning of a new heating season, then inspection of the pipe should be one of the first tasks.

- Weather conditions affect natural draft in only two cases: a low chimney height and an incorrect location of the fresh air inflow point.

ATTENTION! A problem that occurs immediately after the installation of the equipment indicates errors made during the installation process.

The smoker should be raised above the roof ridge. The diameter of the pipe is selected in strict accordance with the power of the boiler: a small cross-section simply cannot cope with the removal of smoke from a serious firebox. You should also avoid right angles in places where the pipe changes direction - this makes it difficult for air to circulate, which is not the best reflected in the draft. Visual inspection allows you to identify these shortcomings and eliminate them.

If the gas boiler smokes

In addition to errors associated with improper installation of equipment, fuel quality plays an important role in the operation of the unit. This issue is especially relevant when using liquefied gas from a cylinder.

After the combustion of clean fuel, a small amount of dry soot remains. Flakes of this substance accumulated in the pipe can be easily removed. It is enough to knock on the chimney from the outside and remove the crumbling soot through the technical window.

After combustion of gas with a large number of impurities on the walls of the chimney, gradually narrowing the lumen, greasy soot sticks. It is quite difficult to cleanse this substance. A regular pipe brush may be useless. In such a situation, it would be best to disassemble and clean the smoker separately.

Quite often, a gas boiler smokes due to improper adjustment of the flame intensity. If the user, in violation of all instructions, turned on the burner of a cold boiler at full power, then the appearance of smoke will be a natural result. The problem can be avoided by gradually increasing the combustion temperature after kindling.

Problems with the solid fuel boiler

Sometimes the heating device smokes due to the banal filling of the ash pan. Before looking for another possible source of problems, you should empty the blower and check the condition of the grate.

The second most frequent malfunction of a solid fuel boiler is a clogged chimney. The reason is poor quality fuel. When using raw wood or wood with a high resin content, not only soot is formed, which easily crumbles after tapping on the flue gas hood.Resinous soot with a high moisture content adheres firmly to the walls, after which it hardens and narrows the pipe diameter.

ATTENTION! If raw firewood is used and there is no proper thermal insulation of the smoker, then this leads to the formation of condensation. When combined with soot, it turns into a corrosive substance that can damage the chimney. When the pipe is corroded, the draft is disrupted.

The main reasons why gas boilers AOGV are smoked

There are usually two reasons why AOGV gas boilers are smoked:

- poor gas quality;

- chimney problems.

It is necessary to check the presence of draft in the chimney using a lighted match brought to the entrance to the channel: if the fire deflects, then the draft is present; if the flame burns evenly, then there is no thrust. If there is no draft, check the chimney - whether it is clogged, whether there are cracks in the pipe or ice crust on the head.

What to do if the boiler smokes

Regardless of why fumes began to appear, it is necessary to stop kindling and conduct a visual inspection of the equipment for damage.

IMPORTANT! Particular attention should be paid to the traction stabilizer if it is integrated into the exhaust system. Sometimes it is enough to adjust the confuser or check the condition of the interrupt valve to get rid of problems for a long time.

Smoke immediately after the installation of the equipment indicates errors made during installation. In this case, it is necessary to recheck all components and connections to ensure the integrity of the flue pipe and correct installation.

At the beginning of the heating season, smoke in the boiler room indicates a clogged or damaged exhaust system. Usually, after fixing the problems, the thrust is restored.

If the gas boiler gives off smoke when it starts up, and then everything gets better, then it makes sense to check the burner. Clogged, it not only "pleases" with soot, but also reduces the performance of the unit. In a solid fuel boiler, the reason for the "starting" smoke is often the low quality of firewood.

Device and principle of operation

All solid fuel boilers, regardless of modification, consist of several main parts. This layout is considered a classic, which is the basis for other design solutions.

- Housing. Manufactured from high strength steel. The thickness of the casing sheet is determined by the capacity of the heating installation. For small solid fuel heat generators, it is at least 4 mm.

- Furnace chamber. Equipped with a door and serves for filling a portion of "fuel" with its subsequent combustion. The technological process in modern boilers takes place in three stages: fuel drying, oxidation with the release of volatile substances (wood gas) and its afterburning. The intensity of combustion is regulated by dosing the air entering the compartment. For this, the solid fuel boiler has a damper.

- Heat exchanger. Manufacturing material - steel, cast iron. It prepares hot water for the heating system, heated by high temperature flue gases. In the classic design, the boiler has an interbody space called a water jacket. Circulation and heating of the coolant takes place here.

- Grate. Steel structures made mainly of cast iron. Serves for stacking firewood, briquettes, coal and materials used as "fuel".

- Ash pan. The lower compartment of the solid fuel boiler. Burnt fuel particles are poured into it through the grate. Has a door through which ash is removed.

- Elements of automation. The simplest solid fuel plants are equipped only with a draft regulator. The rest needs to be bought. For the convenience of ignition, you will need to purchase a gas burner, to prevent overheating of the coolant - a thermal valve.

- Revision holes.Necessary for maintenance of the heating system (cleaning from soot).

The principle of operation of boilers of this group is not much different from the functioning of a conventional furnace. After filling a portion (coal, wood) into the combustion chamber and igniting it, the temperature of the water in the "jacket" begins to rise. The intensity of heating depends on the setting of the boiler and the type of fuel. By changing the position of the valve, the user restricts the oxygen supply by adjusting the flame level. This affects the change in the temperature of the water in the "jacket". As the bookmark burns out, the fuel reserves are replenished, at the same time the ash pan is cleared.