Home / Tips

Back to

Published: 17.11.2019

Reading time: 5 min

0

1614

Do not forget to carry out timely maintenance of gas boilers.

The operation of heating equipment leads to wear of parts, so it can break. Maintenance of wall-hung boilers helps to identify the source of the problem in a timely manner and eliminate it.

- 1 Types of procedure

- 2 Service objectives

- 3 What is included in the list of services

- 4 Performing the process 4.1 Inspection of important components

- 4.2 Cleaning from contamination

- 4.3 Functionality check

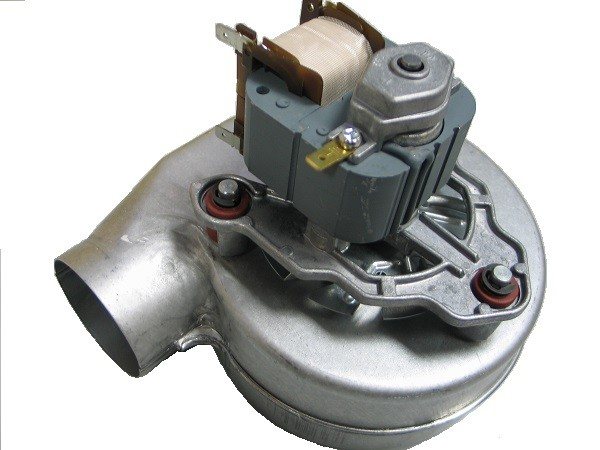

Turbine service

Gas boiler turbine

The smoke exhauster ensures proper removal of carbon dioxide, soot and smoke after the combustion of the gas mixture. After dismantling the fan, it is worth checking the chimney outlet leading to the street for clogging. The fan must be cleaned of dust and lubricated by the shafts. The condensate collector leading to the turbine must be sealed.

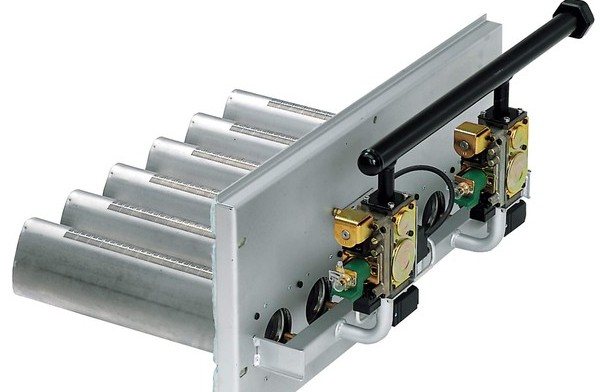

Cleaning the gas burner chamber and heat exchanger

gas boiler burner

After removing the cover, we clean the outer fins of the heat exchanger from combustion products with a coarse brush. A well-cleaned heat exchanger ensures uniform heating of water or other heat carrier and prevents local overheating.

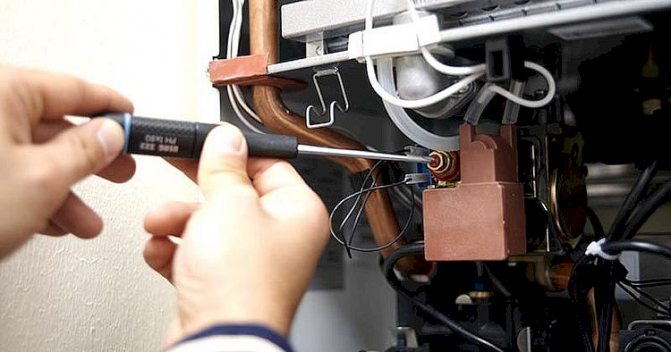

Using a soft copper brush, remove soot residues from the ignition electrodes and the ionization sensor, which are in the chamber, and wipe them with isopropyl alcohol. Finally, you need to check the gap from the electrode to the burner, which should be about 4 mm.

Heating system inspection intervals

Now, when the need for regular maintenance of equipment is beyond doubt, it is necessary to clarify the question of what this concept means. The answer to this question is a little more complicated than it seems at first glance. The necessary procedures and the frequency of their implementation largely depend on the purpose of the boiler unit and what systems and devices are included in its composition. Typically, a list of required "procedures" is provided by the manufacturer of the particular installation model.

As a rule, regardless of the model, boiler unit maintenance is divided into three types of work: cleaning, checking and adjusting. Cleaning the gas boiler includes the following procedures:

- Cleaning of burners and all components that determine the quality and direction of the flame.

- Cleaning the fuel combustion chamber, which becomes covered with soot during operation.

- Cleaning the gas ducts inside the boiler and fuel filters.

Works that are included in the mandatory and related to verification:

- The integrity of the device design.

- The health of the electronics.

- Ignition electrodes.

- Serviceability of machines that shut down the installation in the event of emergency situations.

- Gas valve pressure.

- The integrity of the gas pipeline and tightness at the junction of the gas supply routes.

When servicing a gas boiler, all its nodes are regulated. This is done to set the parameters recommended by the manufacturer.

The timing of the service is clearly spelled out in the contract with the service company. As a rule, maintenance of gas equipment, with the performance of all the above works, is carried out once a year. Most often, it is done before the start of the heating season. It is recommended to descale the heat exchanger after five years from the start of operation of the boiler equipment.In some service organizations, it is customary to carry out preventive flushing of heat exchangers, with a frequency of 1 time in 2 years.

Chemical descaling

gas boiler heat exchanger

There are operating conditions (they are indicated at the end of the article), under which it is necessary to service the gas boiler in the form of cleaning the heat exchanger from scale. In this case, the supply pipes are unscrewed and the entire heat exchanger is dismantled. For chemical cleaning, it must be filled with a solution of hydrochloric acid, which dissolves blockages. After 10-15 minutes, drain and rinse with running water. If during flushing there are still difficulties with the passage of water, the cleaning process should be repeated.

List: what is included in the maintenance of gas equipment

In the operating manual, you can find the requirements for the maintenance of a gas boiler.

At the same time, the description of the work is quite detailed. To understand the need for such work, you should study the instructions in detail.

Maintenance operations:

- Visual inspection of the boiler. Check the condition of the burner.

- Certain parts of the system should be cleaned. These include ignition electrodes, fire detectors, and a retaining washer.

- Air sensors should be purged.

- Filters are cleaned and, if necessary, replaced.

- Boiler parts that come into contact with fire must also be cleaned. It is important to clean the gas burner itself. In addition, the system needs adjustment.

- Carbon deposits must be removed from the chimney. But this operation is not included in the service, it should be ordered and paid separately.

- The electrical component of the boiler is checked and repaired if necessary.

- Adjustment of the gas burner and other elements. Its adjustment takes place after determining the composition of the combustion products.

- Regulation of the boiler operation, if it is connected to the system.

Read more about boilers with a built-in boiler in our article.

- Checking the security system. This is a must. The security group does not work all the time, so there is no case to make sure that it is working properly. But her correct work directly affects the safety of the whole family. The inspector creates a simulated accident and checks the quality of the equipment.

- Checking the tightness of the solenoid valve that blocks the gas supply.

- Checking the quality of all gas supply connections. The elements should be assessed for corrosion and tightness.

When performing a major overhaul, you will need to flush the heat exchanger. All operations should be done regularly. The life of the whole family depends on the quality of the equipment. Every detail must be intact.

Expansion vessel pressure adjustment

During the production of a gas boiler, nitrogen is pumped into the expansion tank, but during operation, manufacturers are allowed to pump with ordinary air. An expansion tank is necessary to compensate for excess pressure that occurs as a result of heating and cooling of the coolant. In addition, it has the function of protection against water hammer in the heat supply system.

For complete prevention of a gas boiler, using a pressure gauge, you need to measure the pressure in the expansion tank. For most wall-hung boilers, the pressure required for operation is 1 bar. The exact numbers must be clarified in the documentation for the boiler. In the event that the pressure is insufficient, it is required to pump nitrogen or atmospheric air there with the help of a compressor. In case of excessive pressure, it is necessary to bleed the excess through the valve.

Device, types and principle of operation

When choosing a heating system for their home, many owners prefer to install a gas boiler that is almost silent and can heat a large area of the house. Its components are as follows:

- burner;

- heat exchanger;

- thermostat;

- control device;

- one or two circular pumps;

- expansion tank;

- pressure gauge;

- thermometer.

Read more: types and principle of operation of a gas boiler.

The principle of operation of gas boilers:

The thermostat is designed to measure the temperature in a room. As soon as the need arises, the heating mode is switched on with the help of the valve, after which the circular pump starts working, under the influence of which the water flows along the heating circuit. Then the valve opens and the burner ignites.

In the heat exchanger, energy is generated from the combustion of gas, which begins to heat the water. As soon as the air temperature in the room becomes optimal, the pump is automatically turned off. After a while, the process is repeated.

When installing a gas boiler, contact the expert for help.

Depending on the current capabilities, two types of boilers can be distinguished: double and single-circuit. The latter are used only for heating, so their design is much simpler than that of double-circuit ones: there are no heating elements for the production of hot water.

A double-circuit gas boiler is used to heat the home and supply hot water. This is ideal if there is no room for a boiler. Its device provides for two circuits. The first is a closed system with heated water passing through it, which heats the room. When the faucet is opened in the kitchen or bathroom, the hot water supply to the heating circuit is stopped, after which it enters the water supply system.

Comparison of wall-mounted and floor-standing gas boilers: Boilers in this category are divided into condensing and convection. In condensing units, the steam generated from the combustion of gas is discharged outside through the ventilation. In the second version, the heated steam also passes through the heat exchanger, additionally heating the water. Convection boilers last a long time and do not corrode, as there is no condensation inside the case. But condensing ones are characterized by high efficiency, which is achieved by using energy not only from the combustion of gas, but also from the liquid released during combustion.

Maintenance of gas boilers:

Cleaning the filters

Inbound filtering is required. If water is used as a heat carrier, then often the stream contains fine sand, silt, scale, rust or metal shavings. Dirt entering the system can disrupt the inlet flow sensor, clog the heat exchanger, etc.

The filter and flow sensor are cleaned with ordinary running water and a hard-bristled brush. Further, before reassembling, to soften the O-rings that prevent leakage, they must be treated with silicone grease to achieve a tight connection.

Gas pressure adjustment

Measuring and adjusting the minimum and maximum gas pressure will allow not only to achieve the correct operation of the boiler, but also to save. The exact pressure range is indicated in the instructions. For wall-mounted boilers, it is at least 2 mbar. The maximum pressure is 13 minibars.

If there are no errors, start the gas boiler and open the gas valve. Using a differential pressure gauge, we measure the minimum gas pressure in the system. To measure the maximum possible pressure, turn on the boiler in the "chimney sweep" mode and check the pressure in this mode. If necessary, we adjust the pressure to the rated values.

Overhaul

After the expiration of the operational period specified in the passport for the product, the gas boiler is subject to technical diagnostics. The main task of engineering and technical measures is to determine the possibility of further safe operation of the equipment.

Overhaul is carried out in order to restore the technical characteristics of gas heating equipment.Worn parts and functional units are replaced as necessary.

In addition to diagnostics within the framework of capital services, they perform:

- Flushing the heat exchanger.

- Comprehensive inspection and cleaning of all closed boiler units.

A competently carried out set of measures is a guarantee of the serviceability of the gas equipment during the subsequent period of operation.

Scale build-up in the heat exchanger coil due to improper maintenance leads to a gradual deterioration in the efficiency of the equipment

Cleaning the heat exchanger from scale is carried out after the first five years from the date of commissioning of the boiler unit. Although most service organizations recommend performing preventive flushing every two years.

A simple flushing procedure for the boiler heat exchanger eliminates the problem during the scale formation phase.

For a major cleaning, remove the casing of the device and disassemble all removable parts of the unit. Separately, the heat exchanger is dismantled and, with the help of a pumping station, it is thoroughly washed with chemical reagents.

This flushing allows you to remove all scale that has formed in the pipelines and fins of the heat exchanger over several years. After that, the boiler is assembled and the system is filled with a coolant.

In addition to servicing the gas boiler itself and the gas pipeline leading to it, it is important to regularly check the condition of the chimneys.

Cleaning the smoke channels designed to remove combustion products from gas appliances and create traction is not included in the list of measures necessary for the master to perform.

He can do this work for an additional fee. If desired, the chimney can be cleaned on your own. It is advisable to flush it at least once a year.

The Importance of Correct Gas Pressure Setting

When the pressure drops below the permissible values, the boiler automation is not able to accurately regulate the heating temperature and works at maximum values. The electronics opens the maximum pressure and heats the boiler to the required temperature, but due to insufficient pressure, it is impossible to maintain the required temperature. The automation shuts off the gas and after reaching the minimum allowed temperature, again heats the boiler to the maximum in the maximum possible mode.

If the gas pressure exceeds the rated values, the flame height is too high. This can lead to premature burnout of a heat exchanger that is not designed to operate in this mode.

Compare this with normal operation, in which the temperature is gradually brought to the required values, after which it is maintained at a minimum gas flow. In this case, there is a decrease in gas consumption due to the smooth dynamics of heating and cooling.

Types of service for gas boilers during operation

In total, there are 3 types of service: routine, current and overhaul. The first type is carried out at regular intervals. A schedule is made that should be followed.

Scheduled maintenance tasks:

- Maintain quality equipment by regular cleaning and lubrication.

- Finding breakdowns and eliminating them. Serious emergencies can be foreseen when replacing obsolete parts.

- Replacing items that are not designed to last. These include gaskets.

Maintenance is performed when the system crashed unexpectedly. Then they call the master, who fixes the breakdown. Overhaul is carried out periodically at a certain time, which is indicated in the schedule.

As a rule, major repairs are carried out every few years.

During the procedure, the most important elements of the boiler are changed or restored.A deep check is performed to detect problems. In this case, tests are carried out to check the functionality of the parts.

Is it necessary to chemically clean the inside of the heat exchanger?

Under normal operating conditions, no. The service life of the heat exchanger is about 6-7 years and it is easier after this time to make a preventive replacement. Disassembling and reinstalling annually will only increase the risks associated with possible breakage of connections and the risk of subsequent fluid leakage.

However, there are reasons why it is worth performing an annual chemical cleaning. It is very hard water and contains too many mineral impurities. Scale builds up in the heat exchanger too quickly. Because of this, difficulties arise associated with insufficient water heating. With prolonged operation under such conditions, the heat exchanger generally ceases to pass enough liquid, overheats, burns out and the boiler fails.

How often should the boiler be serviced? Regularity of prevention

The gas boiler must be audited at least once a year, before the start of the heating season. Why is regular maintenance of gas boilers necessary? The answer is simple, it is necessary for a reliable and uninterrupted supply of hot water. Let's try to figure out what can happen if you do not conduct an annual audit of the gas boiler.

- Over time, the joints become more and more fragile, insulating materials use up their resource and cannot provide a sufficient degree of sealing. This applies to both the coolant and the gas.

- Excess dust and burning on the turbine impeller leads to its wear and tear and premature failure.

- Insufficient or excessive pressure in the expansion tank leads to sudden pressure surges, which leads to the destruction of joints, oil seals and hydraulic systems.

- If the filter is dirty, the water supply can be cut off. Also, poor filtration leads to clogging of thin tubes in the heat exchanger. If dirt gets into the water flow sensor, the boiler will not turn on when the hot water tap is opened.

- Incorrect gas adjustment leads to burnout of the heat exchanger, failure of the venturi nozzle or excessive gas consumption. Over time, the pressure in the gas pipe changes and only the annual pressure setting can ensure that the pressure meets the rating.

Pay attention to the gas boiler, do its maintenance and prevention, and then it will serve you for a long time

Causes of malfunctions

The reasons as a result of which a gas boiler can fail are very different. This can be a factory defect, improper equipment, non-observance of operating rules and a negligent attitude towards gas equipment. It is possible to ensure the smooth operation of the gas boiler if you contact the appropriate services in a timely manner in order to perform maintenance and troubleshooting. In this way, serious problems can be avoided. Gas boilers can come out of the standing position as a result of:

- power surges, the occurrence of which is due to the shutdown of the light; use of water of increased hardness, which contains impurities; untimely equipment maintenance.