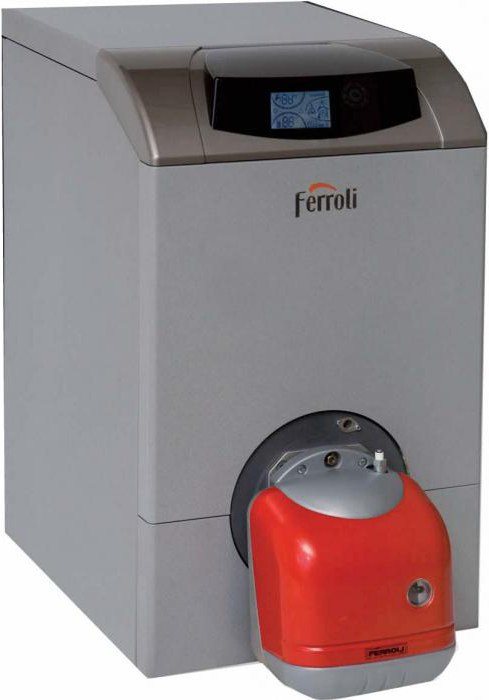

The heating equipment segment is currently in a transitional period. This is due to the emergence of new concepts and technologies for the development of units, as well as the introduction of electronic control systems. Boiler devices have always been considered the basis of this group of equipment. With the help of such installations, it is possible to provide heat and a small private house, and public buildings, and industrial premises. The buyer is offered a fairly wide range of options to choose from, including the Ferroli gas boiler in different designs. The Italian company has been known in Europe for more than 50 years, and for the last 20 years, Russians have also been getting acquainted with its proposals. The manufacturer strives not only to maintain the most successful technological achievements introduced during its activity, but also to actively improve the products with modern developments.

Features and benefits of Ferroli boilers

Of course, this is far from the only manufacturer using new technologies. Therefore, in a competitive environment, engineers strive to offer effective solutions in a variety of ways. First of all, the Ferroli gas wall-mounted boiler provides the required level of performance, consuming a minimum amount of fuel. Together with automated control and the ability to control temperature conditions, this allows the owner to optimize heating costs. By the way, about automation: the manufacturer also provides for the possibility of self-diagnosis of boilers, which is very important for users without technical training.

It is for Russian clients that it is valuable that the company adapts the models to harsh operating conditions. Poor water quality and voltage drops sometimes become the main problem of heating equipment. In turn, the Ferroli gas boiler is completely ready for use in such conditions: according to the manufacturer, the service life of the equipment is more than 40 years.

Ferroli gas boiler: types, instructions

In the field of heating equipment, new concepts and technologies are being developed. The range of options for buyers is extensive. Among others, Ferroli gas boilers stand out, which can be of various designs. The Italian company is engaged in modern developments and has been offering its products on the Russian market for about 20 years.

Features and benefits of Ferroli boilers

This company is one of the few that implements the latest technologies in production. Developers offer effective solutions in a variety of areas:

- The Ferroli wall-mounted boiler consumes the minimum amount of fuel at the required performance.

- Automated control.

- Temperature control capability.

- Self-diagnosis of boilers.

- Adaptation of models to harsh operating conditions (low water quality, voltage drops).

It is worth noting that despite such significant advantages and optimal characteristics, the service life of these boilers is more than 40 years.

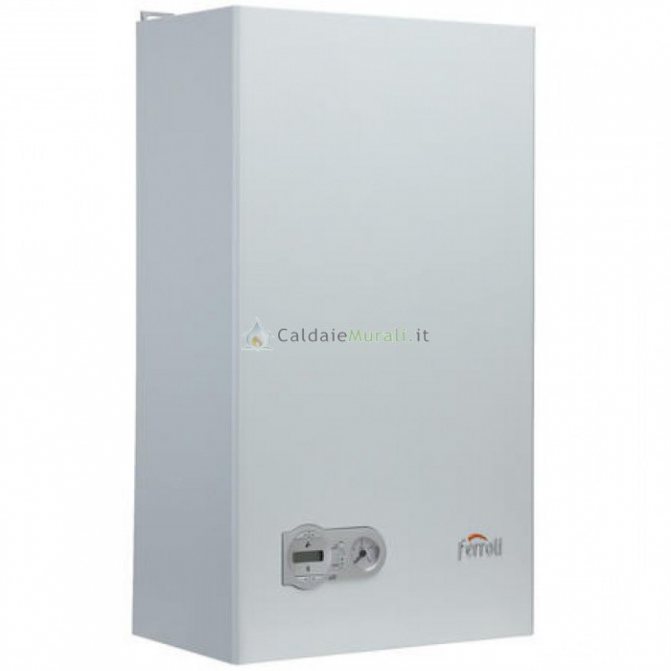

Wall models

These are the most common, popular and relevant types of boiler equipment, represented by the Diva, Divatop Domina, etc. models. The Arena model stands out among them, which can be purchased at an affordable price. It features a simple design with two heat exchangers. Its modification may be different from this and depends on the type of combustion chamber (open or closed). The design provides high heat transfer, which is an indisputable advantage. You can also note the proprietary details in the design, the resistance to voltage drops of the control board.All this ensures reliability and safety in operation.

Ferroli equipment for floor installations

And here we pay attention to the Pegasus and Atlas series in different modifications. These devices are most often made of cast iron and equipped with mounted or atmospheric burners. For example, the first version of the series in this group of boilers has all the advantages:

- Cast iron heat exchanger.

- Honeywell valve.

- Single stage burner.

- Signal contact.

- Connectors for pump circulation and room thermostat connection.

- Electric ignition.

- Possibility of connecting a boiler.

- Smoke exhaust control.

- Ionization probe for flame.

- Indicator to help track overheating.

Gas heating boilers in this category can boast of an additional option:

- Cascade control unit.

- External thermostat connection means.

- Turbo nozzles.

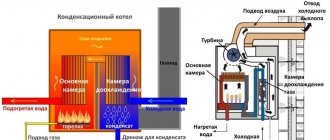

Condensing models

Such options are available to the consumer in the Econcept, Energy and Bluehelix series. These units are single-circuit, and some have increased power. For example, the first Econcept model on the list can deliver up to 300 kW. What distinguishes this group of boilers:

- Availability of weather-dependent automation.

- LCD design.

- Aluminum heat exchanger.

- Ceramic burner.

Such materials are less demanding on safety requirements, but wide functionality and improved ergonomics are a definite bonus for the client. The user can view all the main operating parameters. It is possible to change the operating mode of the boiler depending on the season, and to control the boiler using a remote control.

Components

The manufacturer also made sure that the user does not worry about additional accessories and offers a good line of products in this direction for each category.

Wall-mounted models can be supplemented with:

- A kit for a smoke exhaust system.

- Devices for cascade control.

Floor standing gas boilers:

- Boilers.

- DHW priority systems.

- Turbo nozzles.

- Cascade control devices.

Condensing units:

- Outdoor temperature sensors.

- Control boards for multi-circuit systems.

- Hydro shooters.

- Mounting manifold frame.

- Special sets of fittings for connecting boilers.

How to operate Ferroli models

We can say with confidence that the manufacturer has also taken care of convenient and comfortable operation by the user thanks to equipping most of the models with automated controls. They can be included initially in the basic configuration or supplemented as special options. The user just needs to set a certain mode on the panel.

In order to start up the boiler, it is necessary to open the burner and fire it up. Do not forget to plug the unit into the mains. And after all, you just have to press the START button.

There are also situations when the boiler does not start immediately. Don't worry. If it does not work within 15 seconds, then you just need to restart the system.

When turning off you need:

- Drain the water or add antifreeze to it (if the external environment is at sub-zero temperatures).

- Disconnect the unit from the mains.

- Close the valve.

- Turn off the button.

Maintenance instructions

Of course, high-quality and professional boiler maintenance is required once a year. Between these checks, it is worth periodically washing the equipment casing with a cloth and soapy water. Analyze combustion regularly to monitor performance. Observe the fault indicator and ensure the correct operation of the unit. Most of the problems are associated with a lack of gas or power surges, so do not rush to immediately call the service center. Perhaps you can deal with the problem on your own.If, after eliminating these problems, the boiler does not work correctly, then the boiler check should be entrusted to specialists.

What consumers say about Ferroli boilers

When studying reviews in various sources, it is safe to say that no sharply negative or negative comments were found. Many users note good characteristics for noiselessness during operation of the equipment, which is especially important if you are installing a boiler in a residential building. Also, one cannot fail to note the excellent characteristics in terms of high performance and low fuel consumption. Even customers who are not always aware of this issue note a well-thought-out design.

It is not uncommon in reviews that you can find such an item as a leak in heat exchangers. But right away it is worth making a reservation that this problem in no way speaks of the low quality of the equipment. This problem is associated with incorrect and not entirely correct operation. It is worth remembering and taking into account that, for example, bimetallic heat exchangers cannot work with both gas and water. Therefore, the choice must be made competently, taking into account your needs. If there is only hard water in the pipes in the house, then it is necessary to initially focus on certain models in the company's lineup.

Finally

Heating equipment from a well-known Italian company can be safely called products with a European quality level. Of course, this is not the only manufacturer who treats their products so carefully and responsibly, nevertheless, its advantages are invaluable. All devices of the company are functional and relatively affordable compared to other manufacturers. The products fully meet all the requirements and justify the declared characteristics. Even if at first you purchased a unit with a basic configuration, and eventually realized that this power or functionality is not enough for you, then upgrading your own purchase can be easy and simple! Ferroli engineers have thought of everything to the smallest detail, taking care of their client with all their hearts. Such an acquisition will be indispensable in the household for many years!

If gas communications are connected to your house, then you can solve the problem of heating water and heating. The main condition in this case is to choose the right equipment, which occupies a central place in the heating system. All modern models of gas boilers are safe, reliable and easy to use, but there are still a number of details that must be considered when buying. After visiting the store, you will have to decide which boiler to choose, it can be single-circuit or double-circuit, floor-standing or wall-mounted. Modern models are non-volatile or powered by electricity. You can choose a model with or without a chimney. These parameters are easy to determine on your own, taking into account your needs and characteristics of the house.

Wall models

This is one of the most common types of boiler equipment, which in the line of the Italian brand is represented by the Diva, Divatop Domina, etc. models. Due to the affordable price and simple design, the Arena model is in the greatest demand. This is a double-circuit wall-mounted gas boiler Ferroli, in which there are two heat exchangers. The combustion chamber of such models can be open or closed, depending on the modification. The design itself allows for high heat transfer, but there are other advantages of boilers of this type precisely in the idea of Italian designers.

In particular, the developers use a primary heat exchanger made of copper, and its secondary counterpart is made of stainless steel. Branded parts are also used as accessories.For example, the valve is from Siemens, and the three-speed circulation pump is from WILO. To ensure stable operation, the Ferroli double-circuit gas boiler is equipped with a control board that is resistant to changes in the network. Together, the listed components provide high reliability of equipment and safety during operation.

Ferroli boilers technical characteristics

Heating appliances of the Italian brand are designed for private houses, apartments or industrial premises. It differs in installation method and technical parameters.

According to the method of installation, the units are of two types:

- Wall-mounted - a universal option for a house, apartment or summer cottage. The products are presented in many modifications. The Ferroli wall-mounted boiler is equipped with a steel combustion chamber with an anti-corrosion coating.

- Floor standing - powerful dimensional boilers, recommended for private houses and low-rise buildings. They are reliable, durable and affordable.

Floor standing boilers

Wall equipment

Number of circuits:

- Single-circuit equipment is designed to heat the coolant in the heating system.

- A double-circuit wall-mounted gas boiler Ferroli performs two functions: heating and water heating. Among the suspended modifications, there is only one model with a single-circuit design. The units have a built-in boiler with a volume of 50-150 liters.

Combustion chamber type:

- Open type - models are marked with the letter "C". The system takes air from the room and requires the installation of a chimney.

- Closed type - the chamber is operated by a fan blowing air from the street. It is designated by the letter "F".

Fuel for solid fuel boilers Ferroli

Plate type heat exchangers are traditionally installed in boilers. Less common is a knot of three tubes with coils. The material for the floor structures is heavy and durable cast iron. Heat exchangers for wall models are made of steel or copper.

A variety of equipment modifications allows you to choose an option that operates on available fuel: natural or compressed gas, electricity, coal or wood, diesel.

All equipment received a reliable emergency protection system:

- preventing pump blockage;

- smoke removal sensor;

- anti-freeze system;

- self-diagnosis function;

- bypass from water pressure drops;

- overheat protection.

The average power of household boilers is 10-45 kW. Industrial equipment is capable of providing about 150 kW. The plant efficiency is 92-109%.

Units for floor installation

This variety is represented by the Pegasus and Atlas series in various modifications. As a rule, these are cast iron units supplied with atmospheric or hinged burners. The advantages of such models are well illustrated by the Ferroli floor-standing gas boiler in the initial version - Pegasus. The model is equipped with a cast iron heat exchanger, a Honeywell valve, a single-stage burner, a signal contact, as well as connectors for a circulation pump and a room thermostat. To facilitate operation, the developers have provided electric ignition and the ability to connect a boiler.

Security features are also worth noting. The boiler has a smoke exhaust control, an ionization sensor for the flame, and also offers the ability to monitor overheating using a Ferroli bimetallic indicator. Gas heating boilers of this category also have an additional option. Suffice it to note the cascade control unit, means for connecting an external thermostat and a turbo nozzle.

Variety of heating technology Ferroli

The brand's catalog contains equipment operating on various types of fuel.

Gas

Wall hung gas boiler with a capacity of 60 kW

Ferroli wall and floor gas boilers comply with European quality and safety standards.The main units of the units are made of corrosion-resistant materials. Burner and pump control is automated. You can adjust the processes on the panel screen or from the remote control. Most models have two circuits, which allows you to prepare hot water for domestic needs. The units are presented in a wide power range. They are designed for small apartments and spacious buildings.

The most economical option for heating equipment is a condensing boiler. Its efficiency is 107-109%. The technique helps to save energy resources and pollutes the environment less. Despite the many advantages of the technique, it cannot be used in all regions of Russia. This is due to the rules for the operation of boilers. The difference between indoor and outdoor temperature must not exceed 20 ° C. Also, the disadvantages of the models include the high cost.

Solid fuel

Non-volatile equipment is manufactured for domestic and industrial use. It is equipped with mechanical adjustments. Most of the models are produced with a cast iron combustion chamber. The fuel is coal, firewood, and when installing a special burner - pellets. The most popular is the SFL series. When using it, installation of a direct insulated chimney is required.

Universal

Boiler with replaceable burner for gas and oil

A multi-fuel boiler supplied by Ferolli is called a multi-fuel boiler. Equipment with an inflatable burner operates on gas / diesel. These are products of the ATLAS series. When using it, modifications with weather-dependent control are recommended. Solid fuel / fuel oil boilers of the GF N series have a body protected from heat loss by a layer of insulation. The coolant temperature in the circuit is at least 60 ° C.

Electrical

Ferroli electric boilers heat water using a heating element. Equipment power from 6 to 24 kW. The boilers are compact in design. The control is carried out using the display. It is possible to program a weekly cycle. Models of the LED series can be combined with underfloor heating, an external hot water boiler. The units are connected to a 220 V network.

Condensing models

Ferroli condensing equipment is available in the Econcept, Energy and Bluehelix series. These are already single-circuit units, among which there are options for increased power. For example, the Econcept model is capable of delivering power up to 300 kW. The features of condensing devices include the presence of weather-dependent automation and a large liquid crystal display. In addition, the Ferroli gas wall-mounted boiler in the Econcept series has an aluminum heat exchanger and a ceramic burner. The use of these materials is due to lower safety requirements. Actually, the purchase of a condensing unit is beneficial from the point of view of wide functionality and increased ergonomics. The user will be able to view all the main operating parameters, use the boiler modes depending on the season, and control the connected boiler using a remote control.

Components

For each category of boilers, the manufacturer also provides additional accessories. In particular, wall-mounted models of the double-circuit type can be supplemented with a kit for smoke exhaust systems and devices that allow the equipment to operate on liquefied gas. In turn, the Ferroli floor-standing gas boiler can be equipped with boilers, DHW priority systems, turbo nozzles and cascade control devices. Condensing units have the largest range of additional options. They can be provided with outdoor temperature sensors, control boards for multi-circuit systems, hydraulic switches, a mounting manifold frame, as well as special sets of fittings for connecting boilers.

User's manual

Most Ferroli models are fitted as standard or optionally with automated controls for ease of use. The user sets the modes and makes settings through a special panel. To start the equipment, it is necessary to open the burner and perform ignition. But before that, you should turn on the unit to the network, and then press the special start button, which is equipped with the Ferroli gas boiler. The instruction also provides for a situation in which starting the equipment will not work. If the boiler does not start up within 15 seconds, the system should be restarted. The boiler should be turned off not only by closing the valve and turning off the button. It is recommended to disconnect the unit from the mains, but it is important to take into account that in this state the boiler will not be protected from freezing. To avoid this, you should either drain the water or add antifreeze to it.

Advantages and disadvantages of equipment

The products of the European manufacturer have become popular due to their adaptation to the climatic conditions of Russia.

Advantages:

- Efficient work, high level of efficiency - 92-99.5%.

- Equipment management is simple and straightforward.

- A wide range of Ferroli products allows you to choose a boiler that meets the individual requirements of the heating system.

- The safety of equipment operation is ensured by numerous protection systems and sensors.

- The use of special materials makes the operation of the boilers quiet.

- Affordable cost of heating equipment.

All products of the Italian brand have received a stylish modern design. It fits harmoniously into the interior of the room.

Disadvantages:

- The electronic board of the equipment is sensitive to voltage fluctuations; it breaks down during sudden surges.

- The heat exchanger becomes clogged with deposits during operation and requires cleaning.

- Volatility - electricity is needed to ignite the burner.

To avoid problems in operation, it is better to entrust the connection, maintenance and repair of boilers to the specialists of the service center.

Maintenance instructions

To maintain the boiler in good condition, the user must regularly clean the equipment casing with rags and soapy water. A complete technical inspection must be carried out at least once a year. Combustion analysis is also recommended. It is important to monitor the operating parameters at which the Ferroli gas boiler operates. The instruction instructs the owners of the equipment to carefully monitor the indication of faults. Most of the cases of incorrect operation of equipment are associated either with voltage surges or with a lack of gas. It is recommended to contact the service center only after the elimination of such problems and the next check of the boiler.

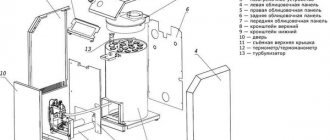

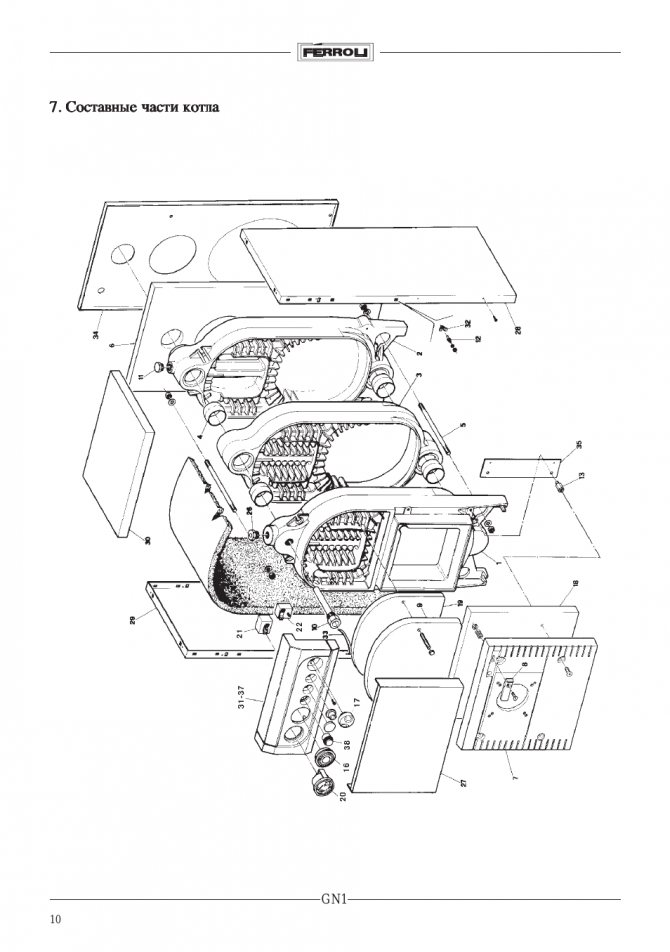

... Boiler components ...

Page 10

- Picture

- Text

RENNOi

7. Components of the boiler

-OK1-

10

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

From the instructions for using the gas mask: - Pull on until the goggle is in front of the eye!

Manualza! Manualza.ru

Still not with us?

Ferroli boilers reviews

There are practically no frankly negative reviews about Ferroli products. On the other hand, there is a high performance, well-thought-out design and low fuel consumption. Separately, the owners point to the low noise level of the equipment, which is very important when installed in residential buildings. And yet there are nuances of operation that should be remembered when buying Ferroli gas boilers. Reviews quite often note leaks in heat exchangers. This is a common problem, but it has nothing to do with the quality of the hardware. Similar phenomena occur due to improper operation when working with hard water is allowed. Therefore, you should initially focus on models that can work with both gas and water.For example, bimetallic heat exchangers are not suitable for such needs.