How to start a gas boiler: preparation

There is a simple instruction explaining how to start the gas boiler shown in the photo. The starting start is performed when the installation and piping of all elements of the heating equipment is completed, and the correctness of the work has been checked by the relevant authorities.

The location of the heating unit must be selected in accordance with safety standards and rules that prevent the occurrence of fires. The boiler must be located at a certain distance from the wall, which depends on the manufacturer's recommendations. By the way, for some models of gas appliances, this requirement is not relevant. Also, make sure that there are no flammable materials or objects nearby.

In addition, it is forbidden to place boilers near windows, since their work is disrupted. Equal positioning of the device case is of no small importance - even slight distortions are unacceptable.

After the installation is completed, they begin to connect the equipment to the cold water source: the plugs are removed from the nozzles, and a filter with a ball valve is placed at the inlet. Such a device protects the heating structure from all kinds of contaminants that cause breakdown. Ball valves must be installed on all branch pipes used for piping.

When solving the problem of how to start a gas boiler, special attention should be paid to the piping from the gas main. They do not carry out these installation work on their own, but invite specialists from the relevant services who are engaged in connecting, sealing and, if necessary, installing a gas meter.

Until the moment you turn on the gas boiler, a separate power line should be laid specifically for the heating unit. The equipment must be supplied with an electric cable with a plug, and an outlet must be installed next to the device, separating it from the others.

After that, the boiler is connected to the chimney, in which the draft and its performance are checked. She must go outside. The installation work for the installation of the chimney depends on the type of heating device.

Completing the preparation for start-up, the boiler is disconnected from the power supply to fill it and the heating system with cold water. Then they check for leaks, turn on the thermostat to the maximum value so that the operating mode switch lights up in automatic mode.

Where do we start?

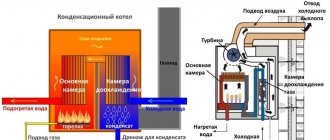

A household gas boiler is a powerful and efficient device designed to heat the coolant and run the heated liquid through the heating system of the house. Modern boilers heat not only batteries, but also water in the tap in large volumes, have electronic control and various safety mechanisms. When buying a boiler, you should pay attention to the heating area, so that it is slightly larger than your living space.

Naturally, you have already installed the unit itself and completed all the necessary connections and piping of the heating system. We checked the chimney and draft, as well as the device itself for proper operation and the absence of leaks. This stage of work, as a rule, takes place in the presence of employees of the gas industry, who carefully record all the results and "give the go-ahead" to use this device.

Some models of household gas boilers are very demanding to install. It is necessary to strictly comply with the instructions in the instructions - observe the distance from the wall, do not install the device near windows or at an angle. You can now start heating.

Before starting the boiler itself, it is necessary to fill the heating system - pipes and batteries, with a coolant, that is, with water. For this, unscrew the valve at the bottom of the boiler. For different models of boilers, the "appearance" of this supply valve may be different, but it cannot be confused with anything. As a last resort, check the instructions for your device.

Having opened the valve, we will begin to supply water to pipes and radiators. Be sure to control the pressure level, we are waiting for a mark of 2 - 2.5 atm. This indicator can be measured using a pressure gauge built into the boiler.

If the first start-up of a gas boiler takes place during the cold season, it is better to preheat the premises with the help of alternative heaters and supply "summer" water - about 18-20 °.

When the required pressure inside the system is reached, it is necessary to bleed air that may remain inside the batteries and pipes. Air congestion significantly worsens the heat transfer of your battery, is this a result you achieve?

To quickly and efficiently bleed air, it is necessary to unscrew the Mayevsky taps on each battery. At first, you will hear a hiss or hiss - this is normal. If water starts to run out of the radiator, it means that there is no airlock here.

Bleed air from the battery, which is the highest in level.

When you have checked all the heating devices, look at what the boiler pressure gauge now shows. The pressure will probably drop slightly and you will need to recharge the heating system with water.

But in addition to plugs in the pipes, the normal operation of the boiler can be hindered by the air inside the circulation pump. It's easy to fix. Some models are equipped with an automatic air venting system, but, as a rule, it is not effective enough, so it is better to get rid of the airing manually the first time.

To do this, remove the front cover from the boiler body, then look for the pump itself - a cylindrical part with a plug for a flat screwdriver. Sometimes, the pump is located behind the dashboard, which can be easily pushed back or removed from the valves. To release air from the pump, plug the boiler into a power outlet and start heating the water. The boiler starts to start up. The pump will also begin to be included in the working process - this will be confirmed by incomprehensible gurgling sounds inside the unit - do not be alarmed, this is air. We take a flat screwdriver and slowly unscrew the cap. When water flows, we twist the plug back. This procedure should be carried out several times. When you stop hearing the gurgling of water inside the device, and your gas boiler starts to work, it means that you managed to get rid of the air inside the pump completely. At this stage, you should again check the readings of the manometer with the instructions for the device. In principle, you can stop at this - now your boiler will heat the water inside the radiators, and if it is a double-circuit unit, then in the water supply.

After starting the boiler, the distant batteries are turned on to the maximum, and the near ones are screwed on. For this, special regulator valves are used, which are installed on the inlet pipe of the radiator. After debugging the heating system, you can set the comfortable temperature of the batteries.

But it will not be superfluous to carry out pressure testing and flushing of the heating system. After these procedures, you will be 100% sure that the inside of the radiators is clean and your heating system has no leaks.

Rules for filling the system with water before turning on the gas boiler

Before igniting the gas boiler and turning on the heating system, first it is filled with cold coolant, which, after heating, will circulate through pipes and radiators.During the first launch, everything is carefully checked so that the work in the future is uninterrupted, and the equipment does not require repair.

There is a special valve in the body of the unit, located near the branch pipe, for supplying the coolant to the system. During the filling process, the pressure in the system is monitored, thanks to the presence of sensors and pressure gauges. They are already installed in modern boilers, and you do not need to purchase them additionally. When the appliance is filled with water, a mark rises on the sensor. When it reaches the 1.5-2 atmosphere mark, the water supply is shut off and thus the filling is completed.

These pressure parameters can be changed, since they depend on the manufacturer's requirements for the operating pressure in the heating system. But the filling with cold water does not finally end there, since recharge will be required after the structure has been freed from air jams.

Switching on the boiler

- The gas boiler is plugged into an outlet.

- The switch should be set to zero.

- The gas supply turns on (the valve on the gas pipe opens).

Further steps may differ for different models of gas boilers.

For example, the switch for Aton or Danko boilers must be set to the "asterisk" icon, press the entire switch and hold it for 5-10 seconds.

Then, without releasing the switch, press the button located next to it.

The unit will respond with a characteristic click and hum. Then the regulator is released and the required power is set.

To turn on the Baksi boiler, you also need to turn on the gas, plug in the plug and press the "Start" button. Operation sound will appear. The device needs to be given a little time, and it will automatically ignite the flame.

After that, you need to press the power button again and thus connect the heating circuit (the corresponding icon will appear on the display). In conclusion, using the buttons, the desired temperature is set.

Buderus heaters are characterized by high reliability. - a brief overview of popular models and their cost.

We will consider the types of generators for gas boilers.

To organize a full-fledged heating system in a private house, it is necessary to install a boiler. The article discusses the main criteria for choosing heating equipment.

Removing air pockets before igniting the gas boiler

Before igniting the gas boiler, you need to fill the heating structure with cold liquid heat carrier. But filling with water alone is not enough. It will either not work, or the degree of heating of the room will be insufficient. A full-fledged first start is impossible without bleeding the air accumulated in the system. Often, modern gas boilers have a special system that automatically releases air when filled. But often its effectiveness is insufficient: you will still need to manually reset air jams. Only then can the launch be carried out.

It is necessary to remove air plugs before turning on the gas boiler not only from the heating unit, circulation pump, but also from all heating radiators. The process should start with batteries - for this, as mentioned above, they are equipped with Mayevsky cranes. They are opened by substituting a container from below. There will be a slight whistle at first, indicating that air is gradually escaping from the system. After removing the plugs, water begins to flow. Then the taps are closed. A similar procedure should be done with each of the radiators.

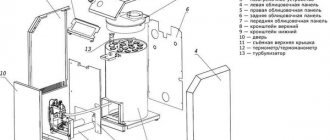

New generation of AGV devices

Russian factories produce AOGV - 23.2 - 1. This is a household heating gas cylinder. It is intended for heating houses with an area of 140-200 sq. meters. There is a device with a slightly lower power for heating an area of 100 - 140 square meters. m. Otherwise, these two types of heaters practically do not differ from each other.

Recently, a more modern model AKGV - 23.2 - 1 with a water circuit has appeared. It can also be used for home heating and hot water supply. And instead of a pipe running inside the boiler, three steel sections are installed, which are made by a special stamping method and are hollow inside. The sections are mounted vertically and are connected into one chimney, through which the products of gas combustion are fed into a separate chimney.

How to choose gas heating boilers?

New generation of AGV devices

The water is heated with the help of a special coil, which encircles absolutely the entire circuit inside the boiler and the water that is used for everyday life flows through it. And the boiler also heats up the water for heating. That is, it turns out that this device is two in one.

The set of the new model includes an injection burner, which ensures efficient combustion of gas without residue. This kind of burner works great even when the gas pressure in the pipeline is dropped.

Useful Tips

To start the boiler, it is necessary to supply power and set the heating regulator to the required operating position. The presence of a faint hum indicates that the circulation pump is working. Using a screwdriver, slightly unscrew the cover in the detected part. But this must be done before the water starts flowing. If liquid begins to seep out, screw the cap back into place. Such actions are performed several times and after that the air locks will be completely removed from the system. The bubbling sounds will also disappear and the pump will run quietly.