In any heating system, an emergency situation can occur associated with increased heating of the coolant, in which it expands and disables the boiler. To prevent an accident leading to significant financial losses, a safety valve is used in the heating system, installed in the immediate vicinity of the boiler.

The relief valve is used in all communal and individual heating systems of private houses, where it is the main element for protecting boiler equipment and increasing the safety of its maintenance. For its correct installation, you should accurately select the device according to the technical characteristics of the system and know the technologically competent installation site.

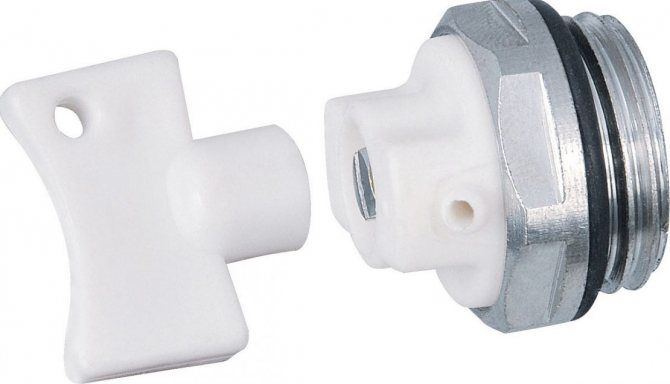

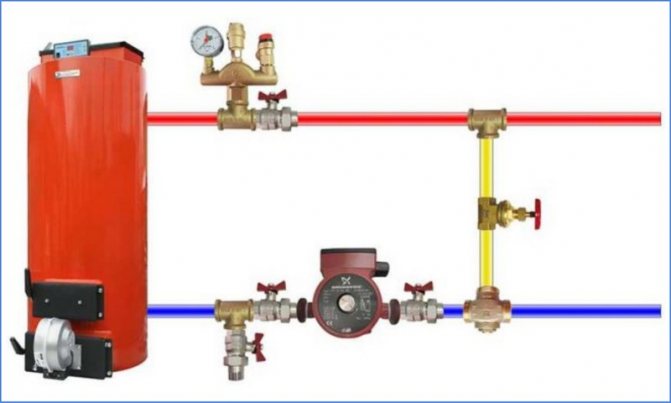

Drain valve in the boiler piping

Safety valve purpose

Unlike heating systems with an open expansion tank, where pressure drops lead to an increase in the volume of the coolant in the tank or, in emergency situations, the evaporation of water into the environment, in a closed loop all processes take place inside the boiler and the pipeline. To remove the surplus of the expanded working fluid from the closed system, automatic valves are used, tuned to its physical parameters, more precisely, pressure.

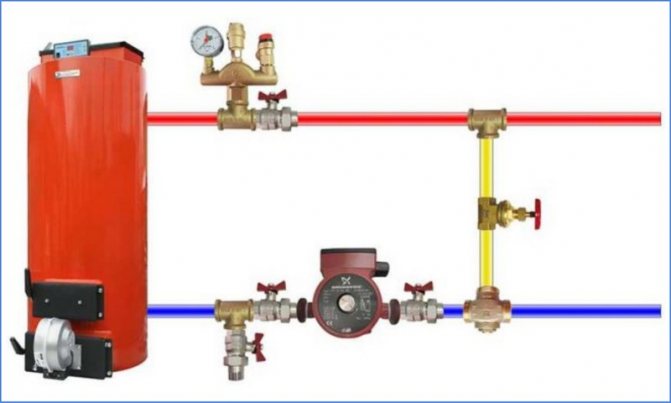

During operation, the coolant has the highest pressure and temperature at the boiler outlet, in addition, heating equipment is the most expensive in the system - because of these factors, a safety valve of the heating relief system is installed next to the boiler and is designed to protect it.

How the relief valve works

Appointment

The relief safety valve protects the heating system from the consequences associated with overheating of the coolant. This device is a necessary attribute of a solid fuel boiler piping, and is also part of a heating system with a heat exchanger installed in the furnace.

Unlike liquid fuel, gas and electric boilers, solid fuel units are characterized by high inertness and the inability to quickly adjust the intensity of heating the liquid in a water jacket or heat exchanger. When overheated, the coolant boils, and as a result of vaporization, the pressure in the closed volume rises sharply.

It can turn around

:

- leaks at the joints of the pipeline elements;

- damage to fittings and pipes made of polymer material;

- explosion of the boiler water jacket, which is dangerous for people and can cause a short circuit of the electrical equipment in the boiler room.

The overpressure relief valve can be installed separately, but usually this device is part of the safety group, complete with a pressure gauge and air vent.

Principle of operation

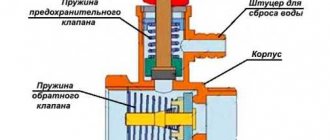

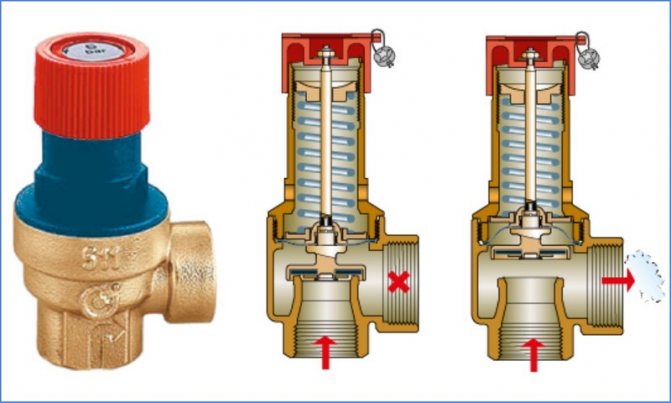

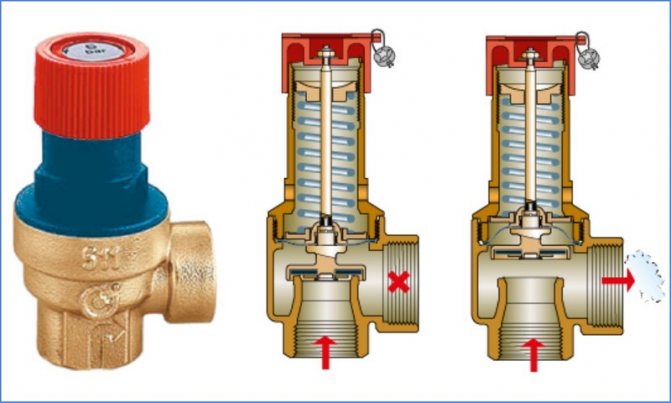

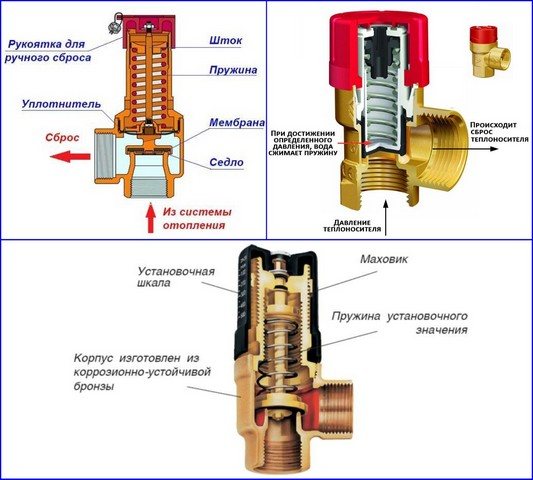

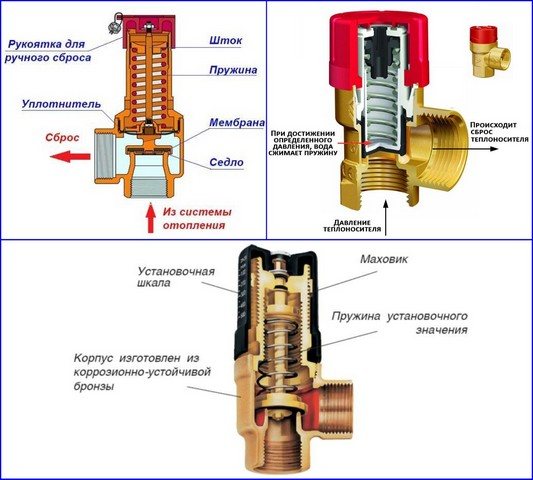

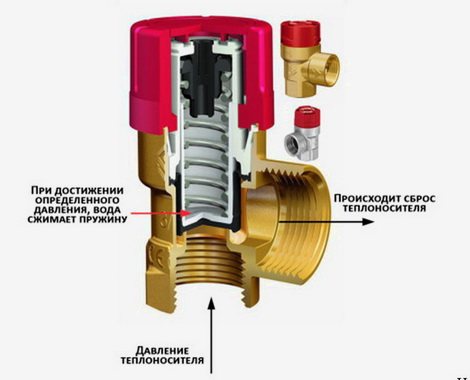

The valve protecting the boiler has a simple device and works according to a principle that is understandable even for a schoolchild. The instrument consists of a straight fitting with a 90 degree elbow and a spring-loaded hermetic seal that closes off the side passage. When the pressure in the system increases from overheating, exceeding the clamping force of the spring holding the valve in a stationary position, it rises up and opens the side hole.

Excess liquid begins to pour out from the side and is sent to a container, drainage or sewer system. After venting part of the coolant, the pressure in the system and on the valve weakens, the spring puts it in place, blocking the side pipe.

Spring type constructive device

Varieties of valves

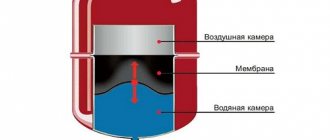

The membrane, under the action of the pressure of the superheated heat carrier, rises and is discharged into the drain

The following types of mechanisms are suitable for installation in a heating system:

Reset

According to the principle of the simplest safety device, a relief valve for heating functions: the gases or heat carrier formed, after reaching the overpressure limit, press on the membrane and leave the system.

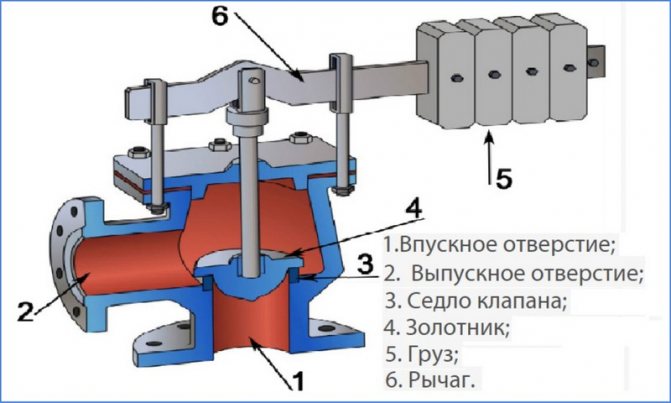

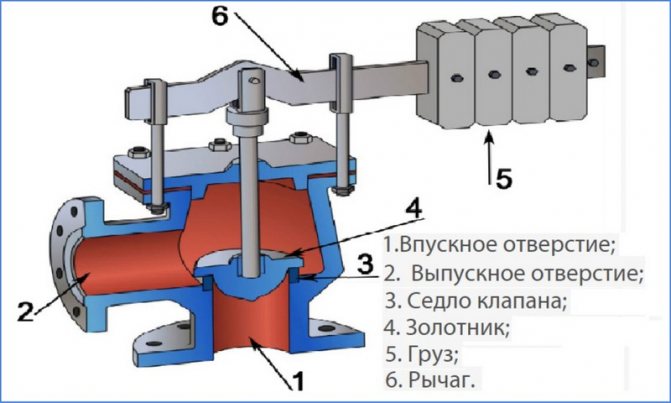

Lever-cargo

Suitable for pipes with a diameter of 0.2 m and larger. In heating systems in which the heat source is a boiler, lever-cargo valves are not installed. These mechanisms use a weight to increase the effect on the membrane. In order to determine the pressure force, upon reaching which the valve is put into operation, adjustment is carried out by changing the weight of the load.

Back

An emergency device of this type is mounted to relieve excessive pressure. Additionally, it allows the coolant to move through the pipes only in one flow, determined by the project.

Spring loaded

In a ball valve design, overpressure depends on the weight and size of the ball.

The most demanded device used for an autonomous heating system. The device is durable, simple design: the stem is pressed by a spring. Adjust the parameters of the device triggering with a possibly present control mechanism. The force of impact is determined by the degree of compression.

Ball

It has a very simple design: the hole is closed with an ordinary steel ball (by weight force). The opening pressure of the valve is calculated in advance, it directly depends on the diameter of the hole and the weight of the ball.

Air

The purpose of such a valve is to free the system from the gases that form, which create traffic jams and prevent the heating from working properly.

Design

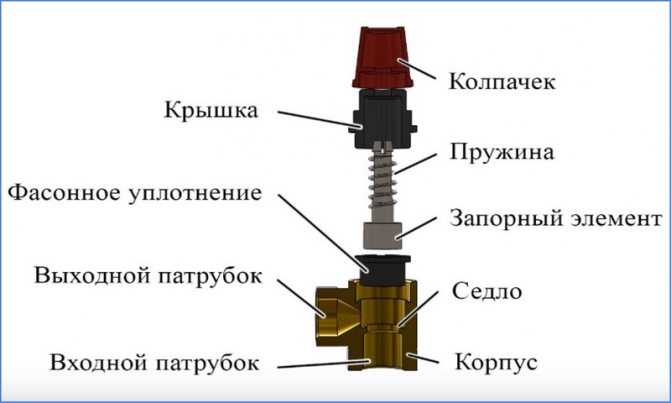

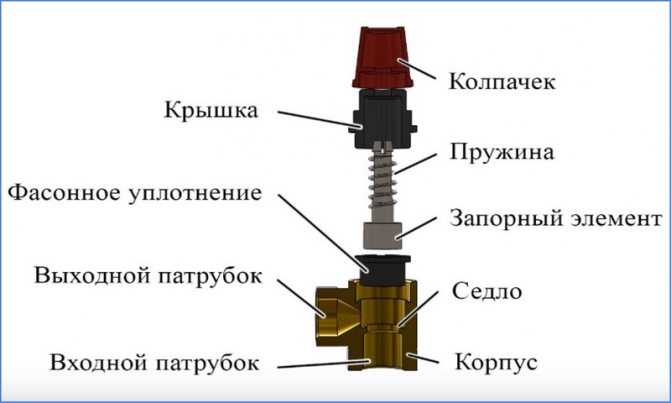

A typical boiler safety valve has a collapsible design and consists of the following main elements:

Housing... It is usually made of brass and looks like a tee. On its sides there are a lower inlet threaded hole, a lateral outlet pipe and an upper seat, on which the shaped seal is seated.

Locking group... It is a spring-loaded pulley with a cylindrical (disk) end locking element, on which an elastic rubber seal in the form of a cup (disk) is put on.

Cap... A black heat-resistant polymer cap is screwed into the upper threaded branch pipe of the brass body, which holds the spring-loaded stem in the working position. On the upper edges of the lid there are projections along which the top cap shaped in the lower part, connected to the shut-off rod, slides. When turning through a certain angle, the cap rises together with the stem and opens the side branch pipe - this allows the safety valve to be used for heating always open in manual mode.

Cap. The polymer part is usually red in color with a ribbed side surface, screwed to a hollow stem with a screw. The shallow protrusions in the lower part of the cap, when it rotates, fall on the teeth of the cap - the handle rises together with the spring-loaded shutter and opens the side channel, allowing manual pressure relief.

Adjusting washer... The inner wall of the cover has a thread, in which the adjustment nut rotates, when it is lowered down, it compresses the spring - thus increasing the valve response threshold. By unscrewing the nut upwards, the spring is weakened and the response pressure decreases. For turning, the nut is equipped with a transverse slot in the upper part for a flat screwdriver.

Valve for water heating boilers - design and appearance

Recommendations when choosing

Brass valves have a low coefficient of thermal expansion, rarely break, do not deform

Before purchasing specific safety equipment, it is required to study in detail the technical parameters of the boiler plant. It is strongly recommended that you carefully read the manufacturer's instructions for the boundary parameters of the equipment.

The following criteria play a major role in the selection of the required valve:

- heating unit performance;

- allowable pressure in the system for the heat output of the heating equipment;

- valve diameter.

In addition to the above, it is necessary to check that the pressure regulator of the protective mechanism has a range suitable for the parameters of the heating unit. The response pressure should exceed the operating value of the normal functioning of the system by 25-30%.

The valve diameter must match the size of the inlet. Otherwise, under the influence of hydraulic resistance, the valve will not be able to fully perform its functions.

It's not bad if the device is made of brass. It has a small coefficient of thermal expansion. This characteristic excludes the destruction of the body under excessive pressure. The control unit is made of high temperature resistant materials that maintain the required rigidity even in the event of contact with boiling water.

Varieties

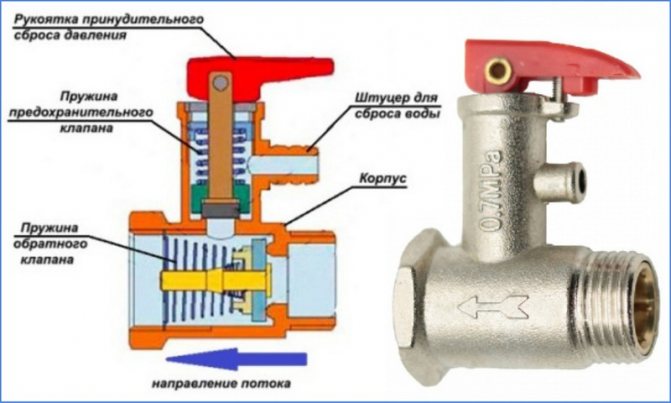

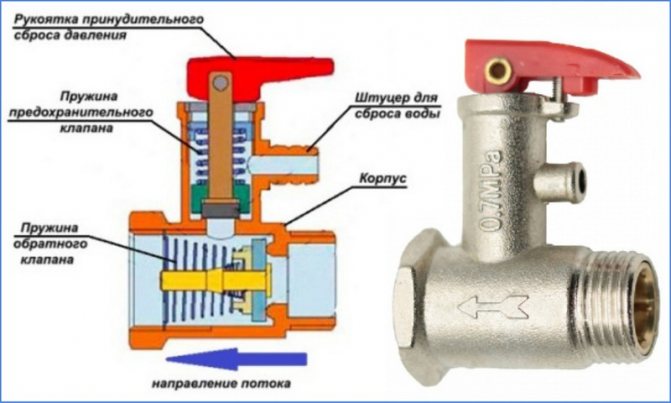

The existing types of valves are able to work with boiler equipment from leading foreign (Vaillant, Baxi, Ariston, Navien, Viessmann) and domestic (Nevalux) manufacturers on gas, liquid and solid fuels in situations where automatic control over the operation of the system is difficult due to the type of fuel. or broken when the automation fails. Depending on the design and the principle of operation, safety valves are divided into the following groups:

- By the purpose of the equipment in which they are installed:

- For heating boilers, they have the above design, they are often supplied on fittings in the form of a tee, in which a pressure gauge for checking the pressure and a vent valve are additionally installed.

- For hot water boilers, there is a flag in the design for draining water.

- Containers and pressure vessels.

- Pressure pipelines.

- According to the principle of actuation of the pressure mechanism:

- From a spring, the clamping force of which is regulated by an external or internal nut (its work is discussed above).

- Lever-cargo, used in industrial heating systems designed to discharge large volumes of water, their response threshold can be adjusted with suspended weights. They are suspended from a handle connected to the shut-off valve by the principle of a lever.

Lever-load modification device

- Locking mechanism response speeds:

- Proportional (low-lift spring) - the sealed lock rises in proportion to the pressure and is linearly related to its increase, while the drain hole gradually opens and closes in the same way with a decrease in the volume of the coolant. The advantage of the design is the absence of water hammer at various modes of movement of the shut-off valve.

- Two-position (full-lift lever-cargo) - operate in open-closed positions. When the pressure exceeds the response threshold, the outlet opens completely and the excess volume of the coolant is vented. After the pressure in the system is normalized, the outlet is completely closed, the main design flaw is the presence of water hammer.

- By adjustment:

- Non-adjustable (with caps of different colors).

- Adjustable with screw parts.

- According to the design of the adjusting elements for compression of the spring with:

- An internal washer, the principle of operation of which was discussed above.

- Outside screw, nut, models are used in household and communal heating systems with large volumes of coolant.

- With a handle, a similar control system is used in flanged industrial valves, when the handle is fully raised, a one-time drain of water can be performed.

Designs of various models of drain valves

Installation features

The device for relieving excess water pressure is set taking into account the presence of an expansion tank in the heating system - the valve is triggered after the volume of the diaphragm tank is exhausted.

Boiler safety group

The safety device is mounted on the pipeline connected to the outlet of the boiler, at a distance of 20-30 cm from it.

In this case, the following conditions are met

:

- if the valve is installed separately, and not as part of a safety group, a pressure gauge is mounted in front of it to control the pressure;

- it is forbidden to install shut-off valves (taps, gate valves) between the boiler and the safety valve, as well as a circulation pump (it is not designed to pump a mixture of water and steam);

- a drain pipe is attached to the valve outlet pipe, which diverts the excess coolant to the return pipe or to the sewer;

- in a system with natural circulation of the coolant, the emergency valve is installed at the highest possible point.

The emergency device installed on the heating boiler must be replaced after 7-8 operations, since the valve loses its tightness due to wear of the disc and spring.

How to choose a valve for a heating boiler

When choosing a safety valve for heating, they are guided by the following considerations:

- The decisive factor for the selection of a safety valve is its set pressure. The usual standard for household appliances used in a heating system is calculated to be 3 bar. This indicator is due to the fact that in most individual closed circuits with radiators using circulation pumps, a heat carrier is transported with a standard pressure of 1.5 bar. Its fluctuations when heated to the highest temperatures can reach 2.5 bar, and a limit value of more than 3 bar indicates overheating of the coolant and can become critical for polymer pipelines (the boiler can withstand significantly higher hydraulic loads).

- Among the models on the market, there are a lot of products from China of little-known brands. The Russian-Italian product Valtex possesses a good ratio of price and quality, valves from the Italian manufacturer of boilers Baksi. Many well-known suppliers of electric boilers with the brands Vailant, Ariston, Baksi additionally produce related equipment, which also includes safety valves.

- In terms of cost, ease of installation and functionality, it is best to purchase a security group. The unit additionally includes a pressure gauge (allows you to control the adjustment process and the pressure in the system) and an automatic valve for bleeding air in the circuit.

Note: Some manufacturers (Valtex) make the handle of the non-adjustable safety valves red, yellow and black to indicate the maximum allowable pressure (e.g. black handle 1.5 bar, red handle 3 bar, and yellow handle 6 bar) ...

Safety valve installation diagram

Air vents in the heating system

There may be a hump in the supply line in the system. The bubble will easily enter this hump, but it will be extremely difficult for it to exit. Sometimes it's impossible at all. Here we have the most difficult case. Depending on the steepness of the hump, we can never take this air out of the system at all. Only if you cut the pipe at the very top and cut in the valve to bleed the air.

There are complex devices in the heating system, from which air cannot escape in principle. This is, for example, a radiator.If the radiator has an inlet and outlet on one side (for example, on the left), and the second side (right) has plugs at the top and bottom, then this radiator will collect air on the right and it will never leave there. And we will not be able to expel this bubble from there by any manipulations. Another popular case is when water enters the radiator from the bottom and exits from the bottom. Then a bubble can form at the top of the radiator and you cannot expel it through the bottom of the radiator either.

Bubbles in the heating system

It is clear that air can occupy the entire pipe along some length of it. This is an airlock. It is irresistible for natural circulation and for small (conventional) circulation pumps. But there may be small bubbles that rush through the system along with the water. Such bubbles can simply circulate, or they can combine when they meet. If there is a place in the system for collecting these bubbles, then during the operation of the heating system, an air lock will collect in this place. After that, the circulation will stop. Bubbles can also collect in traps (radiators). In this case, the part of the radiator in which the air has collected becomes cold.

If the circulation in our system is quite fast, and there are no obvious humps and traps, then the bubbles circulate through the system and create gurgling sounds. As if water is poured in a thin stream from one container to another. I regularly hear this kind of sound in one of my bathrooms, in which there is a beautiful, but not very successful in configuration, heated towel rail. Bubbles run through it so actively that some parts of the heated towel rail are sometimes cold, sometimes hot.

How to install

When installing the safety drain fittings, observe the following rules:

- Typically, a pressure relief valve in the heating system is installed in a household circuit in a single copy. Its main points of placement are directly above an electric, solid fuel, gas boiler at its outlet or next to a horizontally located pipeline. If this is not possible for technical reasons, the main condition for correct installation is installation in the supply line up to the first shut-off valve.

- The outlet side pipe is usually connected to a sewer or drainage system, if it is technically difficult or the volume of the coolant in the circuit is not high, you can use a flexible hose, which is lowered into a container of a suitable volume.

- The liquid must be removed with a rupture of the jet through a funnel or a hydraulic seal to ensure the system is operational when the sewer is clogged.

- For installation in a pipeline, use a BOTTOM tee of a suitable diameter, the standard being 1/2, 3/4, 1 and 2 inches. The diameter of the pipeline inlet to the valve must not be less than that of the system.

Valve safety groups - varieties and price

When the valve is triggered

Situations when an emergency release of pressure occurs:

- There is little coolant in the pipeline.

- Auto-fill failed.

- The absence of the expansion tank or its overlap. It also affects blood pressure a lot.

- Equipment breakdown, lack of air in its upper segment worsens the situation.

Valve functionality

When the boiler is operated at a very high power, a lot of steam is produced, which is impossible to handle even with the most reliable expander.

Why the valve can leak

The pressure relief valve in the heating system can leak for various reasons. In some situations, this is an acceptable natural process, in other cases, a leak indicates a malfunction of the device.

Leakage of the protection valve can be caused by the following reasons:

- Damage to the sealed rubber cup, disc as a result of repeated use.If, during repair, the replacement part cannot be found on sale or it is not included in the package, you will have to change the device completely.

- In spring types, the opening of the side drain pipe occurs gradually, with boundary pressure values or short-term surges, the valve may partially work and drip, which does not indicate a malfunction.

- Leakage can be caused by incorrect settings or malfunctions of the expansion tank - damage to its diaphragm, air escape through a depressurized housing or a damaged nipple. In this case, sudden pressure surges are possible as a result of water hammer, causing a periodic short-term flow of the coolant through the safety valve.

- Some adjustable valves are leaking because fluid seeps down the stem from the top during actuation.

- If a back pressure is created at the branch pipe above the instrument response threshold, a leak also occurs.

Appearance, cost of some brands of drain valves

The safety valve of steam boilers is designed to protect them from overpressure in the system caused by various factors, and is an indispensable element in the operation of this type of equipment. A wide range of safety devices from Chinese, domestic and European manufacturers are available for sale at a relatively low cost. When buying, it is rational to choose a protective group from several devices, which additionally include a pressure gauge and an air bleed valve.

Safety valve in heating, installation, operation, structures

The safety valve in the heating system opens when the pressure rises above the set value, after which part of the coolant is discharged through it. Then the pressure decreases and the valve closes. The simple principle of operation also implies an uncomplicated design. Nevertheless, there are several important rules for the installation and operation of the emergency valve, which it is better not to violate so as not to lead to the destruction of the boiler, for example ...

When is a safety valve needed?

In a closed hydraulic system where the fluid is heated, a safety valve and an expansion tank must be installed. When heated, materials and substances increase in volume, especially gases and liquids "grow" significantly.

If there is no free space, then the pressure inside the system will begin to rise. The hull will deform, stretch, and eventually collapse, releasing the liquid outward. A safety valve is required in all closed, heated, liquid-filled systems.

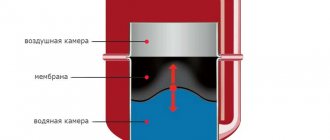

Joint work of the valve and the expansion tank

The expansion tank in the heating system is designed to stabilize the pressure. But it is a mistake to think that a safety valve is not needed with such a tank. The tank may not work properly, just be out of air.

Another mistake is the opposite opinion that the valve can take over the functions of the expansion tank - release the pressure as soon as it has slightly increased. This device is structurally not designed for multiple operations and after several discharges, a constant leak appears through it ...

The safety valve is designed only to operate in the event of an emergency increase in pressure, above the norm, after which the personnel must take measures to eliminate the causes of this situation.

When does the valve usually work?

There are four typical situations when a valve is triggered in heating.

- Liquid is pumped into the system by a manual pump without pressure control, or the automatic filling turned out to be defective and gives increased pressure.

- The heating system is faulty - the expansion tank was not installed or was blocked by a valve.

- The expansion tank is not working properly - there is no air in it.

- Boiler boiling with massive steam release.

In which systems is pressure protection installed

- The heating system of a private house is equipped with a safety valve. Even if automatic boilers have quick shutdown protection when the temperature rises, it is recommended to equip the system with an independent pressure relief valve.

- It is also installed in the hot water supply (DHW) system, except for the case when the water is heated in a flowing way ....

- Emergency pressure relief is installed in separate closed circuits of the system, heated by a heat exchanger or other source of energy.

- In various hydraulic (air) systems operating under pressure, or with a compressor….

Safety valve design, how it works

The main structural element of the pressure valve is the spring acting on the closing poppet. In the normal position, the disc is pressed against the seat and does not release liquid from the pipe. In the event of an emergency increase in pressure, it rises and the liquid begins to seep into the side outlet.

How and where is the safety valve installed

The emergency valve in the heating system is always installed on the main flow line leaving the boiler.

Do not install any shut-off valves between the valve and the main line. In fact, the safety valve should be installed in the supply as close as possible to the boiler heat exchanger, and there should be no taps between them, and the diameter of the pipes should not decrease.

With solid fuel boilers, the emergency valve is installed as part of a remote safety group.

On automated boilers, the valve can be found under the boiler in the supply.

It is recommended to equip the valve outlet with a transparent hose directed to the drain.

What is the response pressure, which valve to choose

The standard set pressure of the safety valve for a home heating system is 3 atm. The usual preliminary air pressure in the expansion tank is 1.5 atm. The operating pressure in the system after warming up to maximum temperatures is 2.0 - 2.5 atm.

Accordingly, with an increase in this value, the situation becomes "emergency". Upon reaching 3.0 atm, or slightly lower, the valve should start to operate. Recall that the lowest tensile strength of individual heating equipment, low-quality expansion tanks, for example, is only about 4.0 atm, and it is often exceeded with manual pumping of a coolant ...

It is only necessary to choose a safety valve for a heating system from a well-known manufacturer. This device is simple, but it must be made precisely, and not all residents will like the explosion of the boiler ...

What the regulations require

From the standards, you can find out that on the way to the valve from the heat exchanger, there should not be not only shut-off devices, but also regulating devices, as well as a pipeline with a smaller diameter than the valve itself. The pressure setting should be 15 to 25% higher than the fluid working pressure. The response threshold should be checked at least once a year during the scheduled maintenance of the system….

How the device works

An air valve (or several) is installed in the heating system, in places most likely for the accumulation of air bubbles. This prevents the formation of a large congestion, the heating works smoothly.

We recommend that you familiarize yourself with: Repair and replacement of damaged sections of polypropylene pipes

Mayevsky crane

Such devices were named after the name of their developer. The Mayevsky crane has a thread and dimensions for a pipe with a diameter of 15 mm or 20 mm. It is arranged simply:

- In the body of the valve body, 2 through holes are made, which, in the open position of the Mayevsky crane, are connected to the heating system.

- These holes are sealed with a taper threaded screw.

- Air is discharged through a small (2 mm) opening directed upwards.

In order to bleed air from the system, unscrew the screw 1.5-2 turns. Air blows out with a whistle as communications are under pressure. The end of the airlock outlet is characterized by a drop in pressure and the appearance of water.

Note! The Mayevsky crane is a simple and reliable device for bleeding air accumulations. It does not clog or break because it has no moving parts. Its design is simple and reliable.

On the market, you can find several varieties of the Mayevsky crane, which are the same in design, but differ in the way of adjusting the locking screw. There are:

- with a comfortable handle for unscrewing by hand;

- with a regular head for a flat screwdriver;

- with a square head for a special key.

For an adult, the principle of unscrewing the locking screw does not matter. However, in a home with children, it is safer to use devices that must be unscrewed with a special device. Having unscrewed the usual tap with a comfortable handle, the child can scald with boiling water.

Automatic faucet

The automatic air relief valve is based on the principle of a float chamber, the design includes:

- vertical case with a diameter of 15 mm;

- float inside the body;

- a spring-loaded valve with a cover, which is connected and regulated by a float.

The automatic air valve for the heating system works without human intervention. Normally, when there is no air in the system, the float is pressed against the valve cover by the pressure of the liquid filler. At the same time, the lid is tightly closed.

We recommend that you familiarize yourself with: How to make a warm floor from polypropylene pipes with your own hands

As air accumulates in the valve body, the float goes down. As soon as it drops to the critical level, the spring valve opens and bleeds out the air. Under the pressure of the carrier in the system, the space is again filled with liquid. The float rises to close the spring valve cover.

When there is no coolant in the communications, the float lies at the bottom of the valve. As the system fills, air leaves the tap in a continuous flow until the coolant reaches the float.

Note! A small amount of air is constantly present under the cover of the automatic valve. This is normal and does not affect work in any way.

A distinction is made between the following configurations of automatic air valves for heating:

- with vertical air discharge;

- with lateral air discharge (through a special jet);

- with bottom connection;

- with corner connection.

For the layman, the design features of an automatic crane do not matter. However, for a professional, there is a difference in choosing between devices.

It is considered that:

- a device with a nozzle and a side hole is more reliable in operation than an automatic valve with a vertical air discharge;

- The bottom-connected valve is more effective at trapping air bubbles than the side-mounted valve.

If the design of the Mayevsky crane has not undergone changes for many years, then the device of automatic valves is constantly being improved and supplemented.

Manufacturers offer automatic valves with additional devices:

- with a membrane to protect against water hammer;

- with a shut-off valve, for the convenience of dismantling the device during the heating season;

- mini valves.

Note! The disadvantage of an automatic valve is that it gets dirty quickly.Limescale, debris clog the internal, moving parts of the device. This leads to a weakening of the efficiency of its work or complete failure.

Automatic air valves for heating need frequent inspection and cleaning. The undoubted advantages of these devices include the ability to install them in hard-to-reach places.