Here you will find out:

- What is a gas burner

- Classification of gas burners

- Other differences

- Gas burners for universal boilers

- Homemade units

The heart of any gas boiler is a burner with a heat exchanger installed above it. The burner burns the gaseous fuel by generating heat. In turn, the heat is absorbed by the heat exchanger and sent to the heating system. It is the burners that the current review will be devoted to.

We will tell you what a gas burner for a solid fuel boiler is, and also give information about the types of burners for gas boilers.

What is a gas burner

The gas burner is one of the most important components of any boiler. She is responsible for creating a stable flame. It is here that the combustion of the supplied fuel takes place. The resulting heat rises up to the heat exchanger, where it almost completely passes into the coolant. Combustion products together with heat residues are discharged into the atmosphere in one way or another.

The device of a gas burner for a boiler is extremely simple - it includes several main components:

Low emission of nitrogen oxides and carbon monoxide gases during combustion makes the boiler almost flawless in environmental terms.

- Nozzle - gas is emitted from here;

- Ignition system - provides gas ignition;

- Automation system - controls the temperature;

- Flame detector - monitors the presence of fire.

To put it simply, this is how it looks. And how different types of gas burners differ from each other in different models of boilers, you will learn a little later.

A modern gas burner for a heating boiler is a device that has certain requirements. First of all, the noiselessness of work is important. I immediately recall some models of Soviet instantaneous water heaters, where the flame rustled with the force of a hurricane. Modern samples burn relatively quietly (attention is also paid to quiet ignition, without pops and explosions). The design of the combustion chambers has an additional effect on the noise level.

Long service life - if you recall the old gas units, they served for quite a long time (in those days, everything was done for centuries). Today, there are no such technologies anymore, so burners in boilers often break down. There is only one way out - to buy units from trusted brands, where components of normal quality are used. As for any Chinese junk from unknown manufacturers, everything is obvious here - you shouldn't take it.

The same applies to cheap Russian-made boilers - short-lived burners are often installed in them.

Complete combustion of the gas is another important requirement. A burner for a gas boiler must burn the fuel completely, with minimal emission of carbon monoxide and other related components. However, everything here depends not only on it - the other components also influence the quality of combustion. We must not forget about the proper discharge of gas, for which you need to have a clean chimney with good draft at your disposal. As for the principle of operation of a gas burner, it is simple:

In the burner, the combustion gas is combined with air. At high temperatures, a chemical reaction takes place with the formation of carbon dioxide and water.

- The boiler detects a discrepancy between the temperature in the heating circuit and the parameters set by the users;

- The gas valve opens, gas begins to flow into the burner;

- At the same time, the ignition system is triggered;

- The gas is ignited and a flame is formed.

At the same time, the control of the presence of a flame begins to work - if the fire suddenly goes out, the automation will cut off the supply of blue fuel. As soon as the temperature in the heating system reaches the set limit, the gas supply will be shut off.

Flame control is implemented differently in gas burners. Somewhere there is a simple thermoelement, and advanced boilers with electronics-based automation are endowed with ionization control systems.

How to choose a gas burner

Application of gas burners

The principle of operation and design of a gas burner

Classification

How to choose a gas burner for a boiler

How to match the gas train to the burner

How to install a gas burner

Application of gas burners

These devices are designed to economically and efficiently burn gaseous fuels to generate heat. Gas burners are used in boilers, grain dryers, drying drums, industrial ovens, heat generators and other heating units. Gas burners are widely used in heating and technological processes.

The principle of operation and design of a gas burner

What is a gas burner? It is a device that mixes gas and oxygen in the ambient air. The resulting mixture is fed to the outlets, where it is ignited by a spark from a piezoelectric element or electricity. The result is a constant torch flame.

Types of gas burners

Classification of gas burners by the type of power regulation:

- Single stage gas burners - operate at one preset power from the range possible for the given burner. Single-stage gas burners are used in boilers, furnaces and low-power units. The principle of operation is turning on and off the burner of a boiler or heat generator to maintain a given temperature level in the system.

- Two stage gas burners - have 2 modes of operation - 100% and 50% of the total capacity. The transition from one operating mode to another is carried out by an automatic system. The indicated power levels can also be adjusted from the possible range for a given burner.

- Sliding two-stage gas burners - also have 2 modes of operation, but the transition from one mode to another is smooth. Most of these burners can be converted into modulating ones by installing a special automation unit.

- Three stage gas burners - can operate in three power modes.

- Modulating gas burners - allow you to smoothly change the power according to temperature or pressure in a heating boiler or steam boiler, heat generator, oven, drying drum, depending on the sensor used.

You can order two-stage and modulating Ecoflam BLU burners from us, one-stage, two-stage and modulating Lamborghini gas burners, buy Unigas and FBR gas burners of any type.

Depending on the length of the flame head gas burners are available with short, medium, long and universal flame head. The length of the flame head is selected depending on the thickness of the firebox door.

How to choose a gas burner?

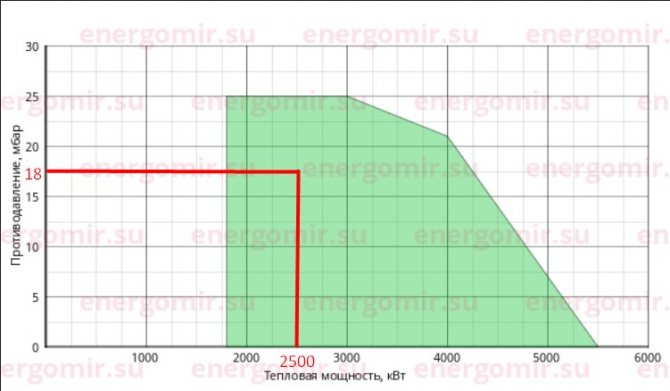

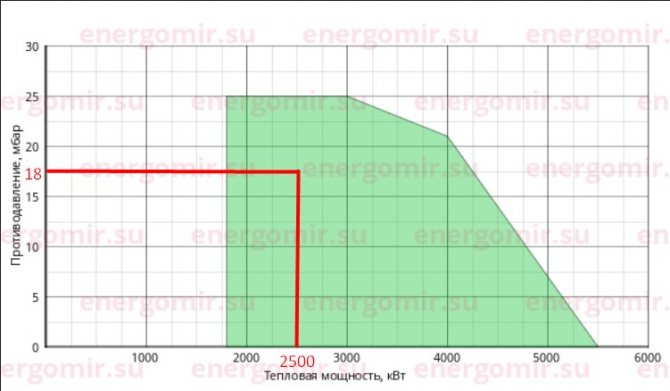

The main parameters when selecting a gas burner are its power and the number of stages. They are determined by the parameters of the unit and the technological process (mode) in which the burner should operate. The burner power must not be less than the unit's combustion power (or its full power), taking into account the resistance of the furnace to exhaust gases (back pressure). To take these parameters into account, the burner capacity diagram is used.

On the vertical axis, we see the backlash of the furnace, which is measured in millibars (mbar). 1 mbar = 0.1 kPa. On the horizontal - power in kilowatts (kW).Take the point where these 2 parameters intersect. If it is inside the torch work area, this torch is right for you. If the point is to the right and higher, you need a burner with a higher power. If to the left, then you need a lower power burner.

If the device is located in the mountains or the seaside, then it is necessary to correct the calculations taking into account the atmospheric pressure. If necessary, experts will help you make calculations.

After determining the power and operating mode (number of stages), it is necessary to take into account the thickness of the front wall, or door, boiler, heat generator, furnace, in order to select the required length of the burner nozzle, as well as the dimensions of the combustion chamber.

The length of the head of a gas-fired burner must be selected so that it is greater than the wall thickness of the unit, but not more than 100 mm. If the wall thickness is too thin to find a suitable burner, special spacers made to order are used.

The dimensions of the combustion chamber determine the possible range of flame sizes for the gas burner. An unsuitable torch can lead, at best, to suboptimal operating parameters of the unit, and at worst to melting of its walls or the burner itself.

Another important parameter is the diameter of the hole for the gas burner. It will not be possible to install the selected model if its nozzle diameter is larger than the hole diameter. Most often, the burner is installed on a special plate that can be replaced, but this is not always available.

Our experts can do all the calculations and help you take into account the nuances. Just call or write to the online store of burners and boilers "Energomir".

How to choose the right rail for a gas burner?

The most important parameters for the selection of a gas multiblock are the available pressure of natural or liquefied gas, as well as the composition of the automation. The gas train is selected in such a way that the resistance of its gas path is no more than the available pressure in the gas pipe, otherwise the gas will simply not reach the burner. The gas train must include a stabilizer filter and a minimum gas pressure switch, which will turn off the burner if the pressure in the pipe is lost. This is necessary to prevent gas escape after an abnormal burner shutdown. The maximum pressure switch protects against a sudden increase in burner power in the event of a pressure surge in the gas system, and the valve tightness block protects against gas penetration into the room where the burner is installed.

How to install a gas burner?

Installation of a gas burner is a complex technological process that requires special preparation in view of the great danger of any gas objects, therefore we do not recommend installing gas burners on your own. The company employs specialists certified by manufacturers who are able to carry out the installation of equipment quickly and efficiently.

Classification of gas burners

For a long time, the market was dominated by the simplest boilers, devoid of complex electronics and advanced automation. They needed full-fledged chimneys and had to be installed in rooms with good ventilation. Today, there are units on sale that can be operated in almost any conditions. Traditional models are sold along with them. They all differ in the design of gas burners.

Atmospheric gas burners

The use of atmospheric gas burners greatly simplifies the design of heating equipment. They work due to the natural flow of oxygen, and full-fledged chimneys are used to remove combustion products. Since oxygen is taken from the room, there must be good ventilation in it. Let's take a look at the main advantages of atmospheric boilers:

- Simplicity of design - has a direct impact on the cost of equipment;

- Low noise level - there are no additional fans, only the flame is buzzing;

- Higher reliability - a completely understandable pattern is triggered here that equipment with a minimum of parts breaks down much less and less often;

- Energy independence - thanks to this, the equipment can work in buildings in which there is no electrification.

There are also some disadvantages:

- Not the highest efficiency - you have to put up with this drawback. More advanced gas boilers with closed burners are more economical and efficient;

- The need for a full-fledged chimney leading to the roof is an additional cost in houses under construction;

- The installation of a boiler with an atmospheric gas burner should be carried out in a specially designated room, where there is ventilation and a window - sometimes it is problematic to follow these requirements.

It is also necessary to note the possibility of incomplete combustion of gas fuel.

"Turbocharged" burners

We have come close to the most modern heating equipment equipped with closed-type gas burners. Such boilers are often called "turbocharged". They are equipped with compact chimneys, often extending directly behind the opposite wall. This is very convenient, especially when the building is under construction - no need to worry about arranging the chimney and ventilation ducts.

A heating boiler with a closed combustion chamber is a heating unit in which a gas burner is enclosed in a special chamber. Oxygen is supplied here from the outside, through a special coaxial chimney. Through it, combustion products are removed. A powerful fan with automatically controlled speed controls all flows. If desired, the "turbocharged" boiler can be mounted in an absolutely sealed room, devoid of ventilation and windows.

A coaxial chimney is a kind of "pipe in pipe" design. It serves for intake of outside air and for removal of combustion products. Such a chimney is displayed at an arbitrary point of the nearest wall, but not closer than half a meter to the nearest windows (more stringent requirements may be imposed).

Advantages of gas boilers with closed burners:

- Can be installed in any room - in kitchens, basements, bathrooms (even in the bedroom);

- Increased safety - gas burns in an isolated chamber. Even if it goes out, and the automation does not react to it, the gas-air mixture will be removed outside the apartment / house;

- Increased efficiency - gas boilers with closed burners are indeed more efficient, but this does not apply to all models;

- More efficient temperature control - for this, a fan speed control system is used here;

- High environmental friendliness - the fuel burns almost completely.

Unfortunately, there were some drawbacks:

Increased safety and efficiency come at the price of higher noise levels and higher maintenance bills.

- Increased complexity - gas burners for heating boilers have a more complex design, which makes it difficult to carry out repair work;

- Slightly reduced reliability - the more parts, the lower the reliability of the system (the cheapest samples and Chinese models often fail);

- High price - in order to buy a "turbocharged" boiler, you will have to pay a round sum (they cost 10-15% more than their atmospheric counterparts);

- Increased noise level - the fan installed in the system emits a hum (the noise level depends on the specific model);

- Lack of non-volatility - when the light is turned off, the equipment will stop working. The problem is solved by installing an uninterruptible power supply.

Despite this, the use of these boilers for heating houses and apartments is becoming a certain trend.

Closed-type burners are equipped with so-called condensing boilers, which are characterized by increased efficiency due to the extraction of heat from combustion products.

Types of household gas burners used indoors

Gas burners are several types and are used with different types of boilers.

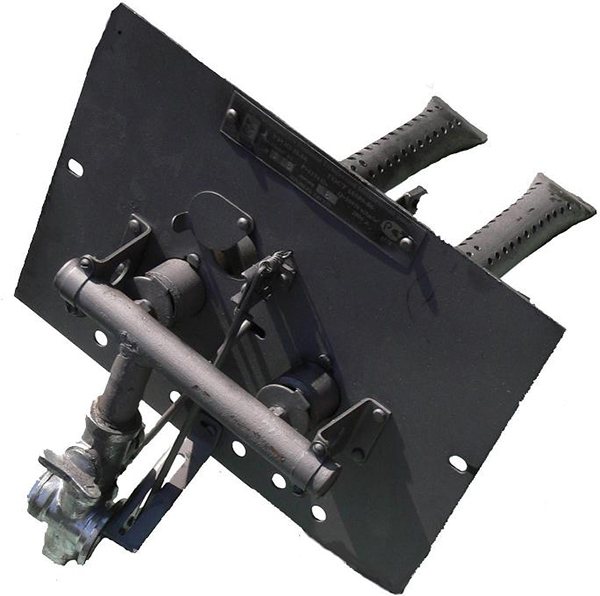

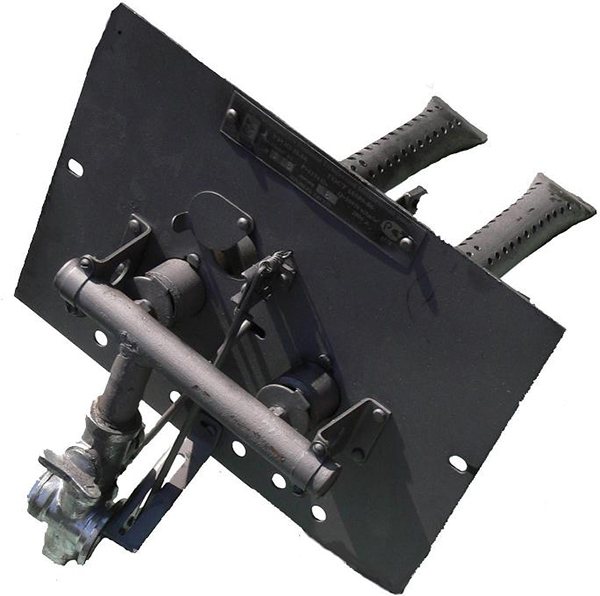

Atmospheric

Nozzles of this type are used in floor-standing and wall-mounted boilers with open combustion chambers. They work in the same way as the burner on the stove: gas is mixed with ambient air without artificial injection. Visually represent a set of hollow horizontal tubes with holes on top.

Gas is supplied through the injector, air is drawn into the flow due to the pressure difference, a fuel mixture is formed, which is ignited by a spark. Combustion takes place through the upper holes. Torches are distributed over the allotted area, due to which uniform combustion is ensured.

Photo 1. Atmospheric gas burner with hollow horizontal tubes and holes, suitable for wall and floor boilers.

Advantages:

- energy independence;

- simplicity of design;

- maintainability;

- low noise level;

- affordable cost.

Using an atmospheric burner, you can convert a solid fuel boiler to gaseous fuel. For this, the nozzle is mounted into the ash pan chamber.

Main disadvantage atmospheric devices - low power... It is impossible to mix a large volume of air into the gas flow due to natural draft, therefore powerful devices are only blown.

Reference! Maximum power of atmospheric burners - up to 9 kW. This is enough to heat a room with an area 90 m2.

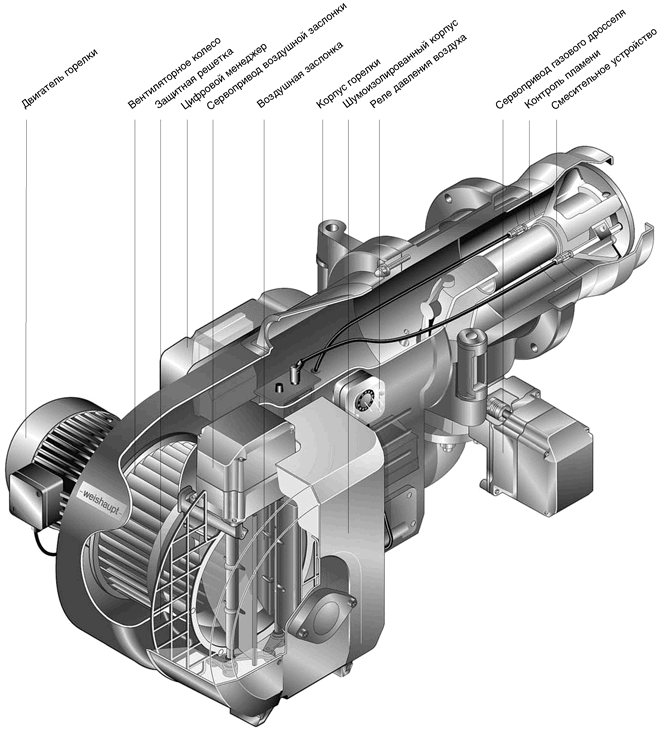

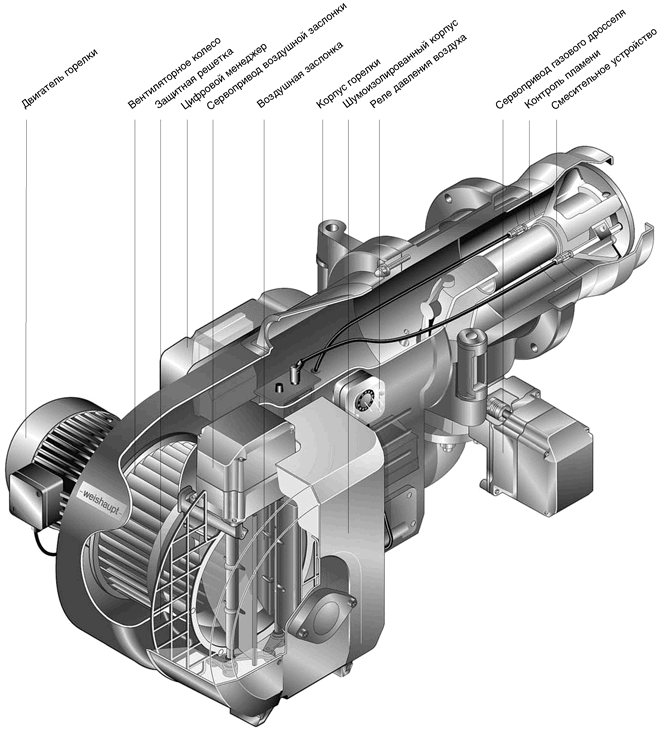

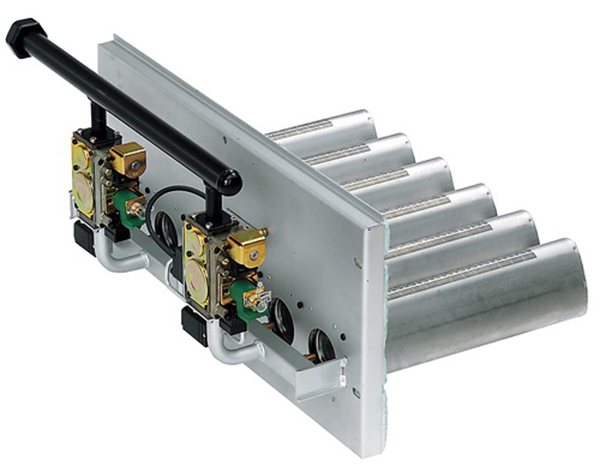

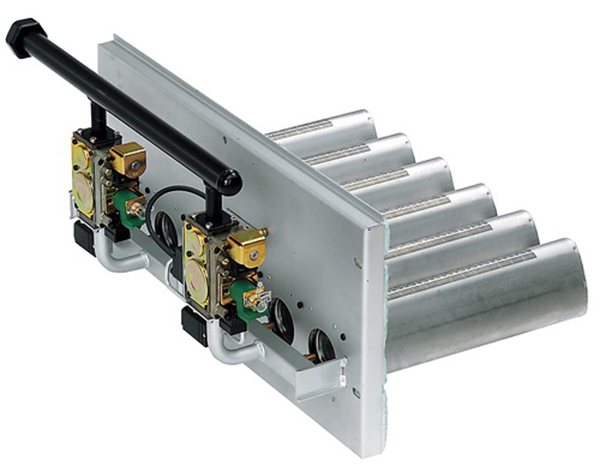

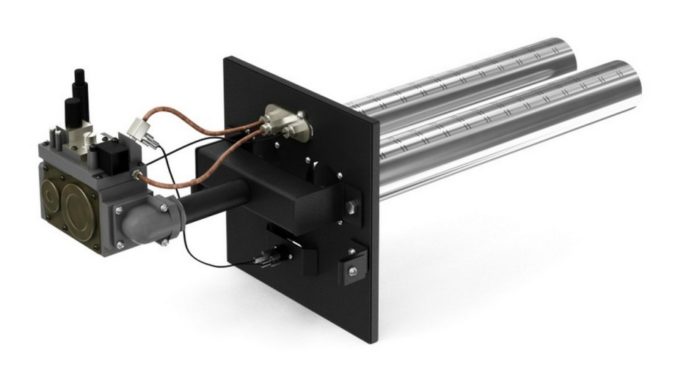

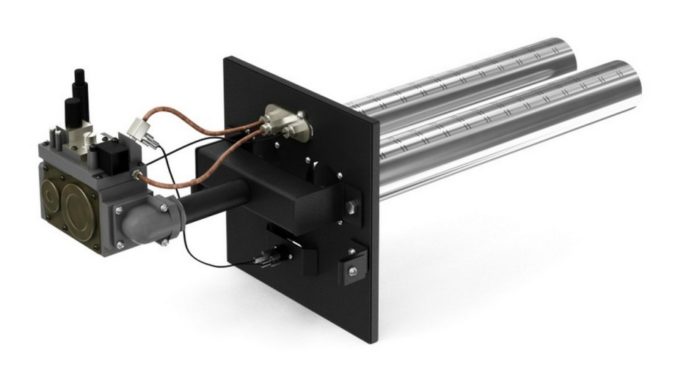

Turbocharged blast

The devices are used in boilers with a closed combustion chamber, the design provides special fan for forced air supply in the right amount. The main technological difference from atmospheric injectors is that the air-fuel mixture is formed not at the inlet, but at the outlet to the combustion area. And also there is a fine adjustment of the air supply.

The burners are manufactured in modular design, put on single- double-circuit boilersequipped with automatic control systems.

Photo 2. Giersch blowing gas burner for boilers with automatic control and a closed combustion chamber.

Auxiliary devices are included in the package of turbocharged units:

- gas and air filters for additional cleaning;

- relay that regulates the fan speed;

- gas flow regulators (flow rate, starting pressure);

- reducers stabilizing gas pressure;

- automatic devices that turn on / off the fan and gas flow in case of interruptions.

Thanks to the forced air injection, turbocharged burners benefit from the following positions:

combustion with high efficiency (not less than 90%);- no power limitations;

- ecological cleanliness of combustion;

- constant coolant temperature due to flame modulation;

- gas savings - programming the boiler to decrease or increase the temperature at specified time intervals;

- management and security - Automation minimizes user involvement.

Many models of turbocharged burners are divided into sections, which ensures complete combustion of the gas, quick and uniform heating of the heat exchangers, and soot does not form.

disadvantages: high price, noise and dependence on electricity, which is why they are equipped with uninterruptible power supplies.

For ovens

The constructive difference between nozzles for furnaces is the use of a larger number of distribution pipes and flame diffusers for uniform heating of the heating device body. When choosing, it is important to consider features of the furnace equipment:

- In brick ovens, atmospheric burners, since inflatable ones need a sealed firebox.

- When installing atmospheric nozzles in a bath or house ensure sufficient air flow, check the condition of the chimney.

- If the stove runs not only on gas, but also on other types of fuel, a turbocharged one will do. nozzle.

- Atmospheric heating pads can be installed in any type of oven, regardless of material.

In case of interruptions and pressure surges in the gas line, the safest option for heating would be a turbocharged nozzle with an automatic control function.

Photo 3. Atmospheric gas nozzle, equipped with torch diffusers, suitable for all types of furnaces.

For garage

It is forbidden to install gas boilers or stoves in a room where a car is parked and fuels and lubricants are stored. For such equipment you need separate boiler room and permission from the relevant authorities.

Since there is no need to constantly heat the garage, portable heaters, convectors and heat gunsoperating on bottled fuel. The principle of their operation is simple: the gas burns in the nozzle, and the fan distributes heat. For the garage, both atmospheric and low-power ventilated devices are used.

Factory burners are equipped with reliable automation that turns off the heat generator at overheating, flame extinction, fuel depletion, excess of CO2 level... Despite the fact that such devices provide smokeless, almost complete combustion of fuel, for safety, high-quality ventilation is carried out in the garage.

Other differences

Consider the division of gas burners by type of ignition. The easiest option is with a burning igniter (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to heat the coolant. There are two drawbacks here - increased gas consumption and low safety (the igniter may go out). Primary ignition is carried out with matches or with the help of a piezoelectric element that gives a spark.

Natural gas from the mainline gives an even combustion, without forming excessive soot on the walls of the chimney.

Electronic ignition of the burner provides for the presence of a high-voltage converter in the gas boiler. Energy is taken from batteries or the electrical network. The first option is used in non-volatile boilers that do not have electronic automation. The second option is relevant for complex units with electronics on board. Together with such ignition, modules for ionization control of the presence of a flame are often installed.

There is also a split according to the type of fuel used. Natural gas supplied from the pipeline is cleaner, it is supplied with optimal pressure (we do not consider cases of pressure surges in both directions). The flame in the boiler is clean, without soot. The equipment is connected to the network without alterations. There are burners that can work on propane - this requires setting up the system and installing a jet. The flame from the combustion of propane gives off a yellow color, there is an increased deposition of soot on the chimney.

Jets allow you to normalize the propane pressure to an acceptable value - they are supplied as a set or purchased separately.

Boiler selection by parameters [X]

Home »Catalog» Burners

Burner manufacturers

- Bentone

- De Dietrich

- Buderus

- Elco

The burner is an integral part of the boiler, which is designed to provide combustion processes for gaseous or liquid fuel. This device provides evaporation, if the fuel is liquid, mixing with an oxidizer (air), flame distribution and flame formation. Depending on the type of fuel, they are gas, oil (diesel burners) and combined, according to the type of regulation they are single-stage, two-stage and modulating (with smooth power control).

This section presents forced draft burners that are used in conjunction with universal (gas / diesel) steel or cast iron floor boilers (for example, De Dietrich GT). Atmospheric boilers already have a built-in gas burner.

When using a universal boiler, it is possible to install a gas or diesel burner. This is especially true when the main gas has not yet been supplied. You can install a diesel burner and the boiler will run on diesel fuel. When the main gas is supplied, we change the diesel burner to a gas one and the boiler continues to operate on gas.

On the page of our website, you can not only get acquainted with the modifications of diesel and gas burners, but also buy them without leaving your home. So, let's consider each of the types of burners separately.

Gas burners for universal boilers

A gas burner for a solid fuel heating boiler is a rather complex unit. It was created to transfer heating equipment from one type of fuel to another. That is, you can purchase a solid-fuel (universal) unit for working on wood, and when a gas main appears, transfer it to work with natural gas.

It is best to entrust the maintenance of even the simplest gas burner to a master - the services of a specialist will come out cheaper than buying a new unit.

The automatic gas burner for a solid fuel boiler is built according to a fan circuit. Gas is supplied here, mixed with air, after which the finished fuel-air mixture is sent to the nozzle. Here it is ignited, forming a high-temperature flame torch. The burner is equipped with a powerful fan, an automation system, a reducer and a gas filter. The unit requires electricity to operate. The product itself has a modular design (removable).

A typical example is a gas burner for a Cooper boiler. The boiler itself is a pellet boiler, but you can connect a replaceable burner to it and convert it to natural or liquefied gas.

How is air supplied?

Atmospheric models operate on natural draft that occurs during combustion. Air from the room enters the burner, where it is mixed with natural gas, and then fed into the combustion chamber.

In turn, fan burners use forced air, which is sucked by a fan directly into the combustion chamber. It can be supplied both indoors and outdoors through a connected air duct. The design of such devices is much more complicated, however, thanks to this, it is possible to achieve a higher efficiency, as well as to provide accurate regulation of the heating temperature.

Homemade units

Some craftsmen make gas burners for boilers with their own hands (for solid fuel boilers). It should be warned that this is unsafe. Yes, and no one will connect such a structure to the gas main. Most often, such "crafts" are made on the basis of any expired gas units. Remember that a homemade gas burner for heating your home is far from the best option. It is best to purchase the simplest gas-fired non-volatile boiler and convert it to bottled gas.

Atmospheric GG

Atmospheric flame burner

Typically, such gas burners for boilers are used in floor-standing versions of boilers. The power of these units is low: the heating potential allows you to heat a building with an area of up to 100 sq. M. Another type of atmospheric burners (also called turbo burners) is adapted for gas boilers, which are set to use natural gas by default. In cases of fuel change, another version of the GG is installed. This work should be entrusted to a specialist.

In atmospheric versions, air is naturally guided to the gas connection area. Methods of ignition of such a gas mixture: piezo ignition or electrical impulse.

The design of this burner is a hollow tube with many holes or a network of tubes in which gas moves under a certain pressure.

Turbocharged burner in gas boilers, its advantages:

- reliable work;

- simplicity of design;

- security;

- lack of noise;

- compact parameters;

- low weight.

Requirements

In order for a heating unit to work efficiently, the burners used in it must meet certain requirements. Therefore, you should not try to make a burner with your own hands, although you can often find advice on how to make this boiler element yourself. Primary requirements:

- the main purpose of this part of the boiler is to produce a gas-air mixture of a certain concentration to reduce the volume of incombustible residue. Modern burners must provide efficient combustion, bringing the fuel combustion rate closer to one hundred percent;

- this part should be easy to install and dismantle, while the fasteners should be as reliable as possible;

Advice! The ease of dismantling and installing the burner is an important characteristic, since many owners service this boiler element with their own hands.

- the service life of a good burner should be comparable to the service life of the boiler itself, while the operational characteristics of the element should not change for the worse over time;

- during operation, the element should not make significant noise;

- low emission toxicity is an important quality indicator. This is achieved by increasing the efficiency of the cell, thereby reducing the concentration of carbon monoxide in the emissions.

Advice! Today it is possible to purchase burners that can operate on different types of fuel. The most popular options are elements that can operate on natural and liquefied gas, as well as on gas and diesel fuel. Moreover, the transition from one type of fuel to another occurs as quickly and easily as possible.