Thermal insulation of a house from a rounded log

Insulation of a house from a log is performed when heat loss is detected at the junctions of structural elements. Thermal insulation can be in-wall, external or internal.

Important! Sealing and warming are not the same thing. If the insulation allows the house to "breathe", then the sealant does not.

Log buildings retain heat well, provided that all gaps between the logs are thoroughly buried. If the thickness of the walls allows you to withstand frost, then you can limit yourself to caulking, preserving the structure of natural wood both outside and inside.

How to insulate a log house outside? Before the start of the insulation work, the new log house must stand for at least a year so that it has time to dry out and settle.

If the house is old, any external insulation begins with the preparation of the facade - they dismantle the hinged elements, carry out the necessary repairs, clean and level the surfaces.

Important! Before starting work, treatment with an antiseptic and fire retardant is required.

External insulation

The position of the dew point in the insulation outside can be predicted only if the thickness of the insulation corresponds to the heat engineering calculation. A smaller layer can do more harm than heat. The dew point can be located in the middle of the wall and move to the inner surfaces during sudden cold snaps. The inside of the wall will get wet. But it is worth repeating - there are no identical situations, the choice of insulation, insulation methods must be done taking into account all the features of the project, layout, structures, climate, operating mode.

There are additional construction nuances when insulating, these are ventilation gaps, additional vapor barrier, wind protection, do not forget about them when starting to insulate a house. Having opted for the natural cellulose insulation Ekovat, you can get any free consultations from the Teploservice specialists by phone 8 (812) 9999812. We will carry out insulation of any complexity at any stage of construction, repair and operation. Teploservice works with certified cellulose-based insulation.

Elimination of gaps between logs in a log house

This requirement is met by fibrous materials, the most common of which is mineral wool.

Mineral wool is made from fiberglass, slag and rocks. The fibers are held together with organic binders and impregnated with water-repellent compounds.

- Glass wool is inconvenient to install because it has spiky fibers

- Slag wool is acidic and releases aggressive substances when the humidity rises.

- Stone wool has no disadvantages, except for the common to all fibrous materials

Mineral wool has the following characteristics:

- Thermal conductivity coefficient - 0.038 - 0.053 W / mhK

- Sound absorption coefficient - 0.95

- Density - 75 - 200 kg / cu. m

- Compressive strength - 0.04 - 0.06 MPa

- Water vapor permeability - 0.49-0.60 Mg / (m × h × Pa)

- Maximum operating temperature - over 800 degrees

The following brands of mineral wool are used in construction (the number in the designation corresponds to the density of the material):

- P-75 - for thermal insulation of horizontal surfaces without load on the insulation (interfloor floors between the logs)

- P-125 - for thermal insulation of inclined and vertical surfaces without load on the insulation (roof and walls)

- ПЖ-175 and ППЖ-200 - for thermal insulation of any surfaces with a load on the insulation (floors with cement screed and flat roofs)

Stone wool P-125 is optimal for insulating houses.

Insulation of log houses

To perform high-quality thermal insulation at home, you need to insulate all surfaces in contact with the spring environment.

These include:

- Window and door openings

- Roof

- Floors

- Walls

Work should begin with caulking the seams between the crowns of the log house. The walls are caulked from the street and from the inside. For this, jute and synthetic tape insulation or moss are used. Next, the openings, floors and roof are insulated. This is often enough. If not, proceed to the thermal insulation of the walls.

How to insulate a log house outside?

Insulation from the outside of the facade is performed as follows:

- The sheathing beams are nailed to the walls horizontally with a step, a couple of centimeters smaller than the width of the mineral wool slabs. Their width should be slightly more than the thickness of the insulation layer

- Plates are inserted between the bars. Laying is carried out in at least two layers with bandaging of joints

- Insulation for a wooden house is closed from the outside with a windproof membrane. This film material protects mineral wool from moisture, but allows vapors to pass from the insulation layer to the outside. For the membrane to work correctly, it must be hung with the rough side out.

- A vertical crate is nailed to the bars for attaching finishing materials. Thus, a ventilation gap is created between the thermal insulation layer and the outer cladding for ventilation of the walls and insulation.

- Finishing materials are attached to the crate. It can be lining, imitation timber or block house

Internal insulation of a log house

Since wood is a good heat insulator, when insulating from the inside, the dew point (the point with the freezing point of water in which condensation forms) rarely moves outside the walls.

We suggest that you familiarize yourself with Making chacha from grapes at home

Nevertheless, measures to remove moisture from the log house will not be superfluous. To do this, experts recommend leaving a ventilation gap between the walls and the insulation of at least 2 cm.If air circulation is provided in the ventilation gap, then the insulation of the log house from the inside is possible using vapor-proof materials - polystyrene and others.

Warming is performed as follows:

- To provide a gap, a vertical wooden lathing is nailed to the walls.

- A membrane is attached on top of it

- With a step slightly smaller than the width of the insulation, mount the counter-crate

- Between its beams, slabs of mineral wool or foam are inserted in several layers

- Hang up a vapor barrier film

- Walls are sheathed with finishing materials - clapboard, drywall, chipboard, etc.

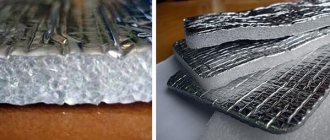

This roll material is made of polyester foam, covered with foil on one side. Penofol is absolutely not afraid of moisture, which means it does not require steam - waterproofing. Penofol strips are attached to the slats providing a ventilation gap with foil towards the room. The material is laid with an overlap of 10 cm. The joints are sealed with construction tape. There should be a gap of 2 cm between the insulation and the finishing materials.

The modern building materials market allows you to choose insulation for the outer walls of a wooden house for every taste. In addition to the materials described, OSB, sprayed thermal insulation, etc. are used for internal insulation.

Caulking is an important stage in the construction of a wooden blockhouse, which helps to seal gaps, seams and openings.

If in the past seams and openings had to be caulked with dry moss for logs, linen and hemp tow, bast fiber or felt, then over the years new technologies have appeared in the production of natural materials. Now on the construction market there are heaters made of jute fiber, flax, flax, mineral wool.

Caulk from bottom to top.

Caulking should be carried out from the bottom groove along the entire perimeter of the log house.If only one wall is caulked, then this can lead to a distortion of the entire frame. As it dries, the timber shrinks, which is why cracks form in the walls, so wooden structures will have to be caulked even after construction is completed.

The choice of material for insulation

Primary requirements

To insulate a log house from the outside, the materials used must meet the following requirements:

- High level of thermal insulation.

- Environmental friendliness.

- Hygiene.

- Air permeability.

- Moisture resistance.

- Fire safety.

Important! For a wooden house, it is better to use only natural materials.

For caulking, such natural materials as moss, tow, hemp, felt, jute and tape insulation based on flax or jute have proven themselves excellent.

The properties of these materials are shown below:

- Moss is resistant to decay and has antibacterial properties.

- Felt requires special processing, otherwise moth larvae will start in it.

- Jute and linen are strong, dense, decay-resistant materials with low hygroscopicity.

Insulation outside

For external insulation, mineral wool or ecowool is suitable, especially if a ventilated facade is planned.

Plates made of expanded polystyrene (polystyrene) or basalt are used when installing a "wet facade".

Important! Penoplex is not suitable for insulating a log house from the outside, as it has a very low vapor permeability.

Nuances and proper insulation: avoiding mistakes

We decided on the scope of work and the choice of materials. A lot of money and labor have been spent, it will be a shame if, due to mistakes, you do not get the desired effect. To keep the house warm:

First, insulate the inside: floor, ceiling, roof, windows, doors. Caulk the gaps and seams between the logs. If the effect is not enough, insulate the house from the outside.

Insulate the facade after precipitation, after a year and a half. The new house has a shrinkage of 3 - 10%. If it is old, the period is not important, but treat the wood with an insecticidal solution, get rid of the living creatures. Birds love to pull caulk from crevices, looking for insects.

Treat the wood with an antiseptic to prolong the life and prevent mold. Let the house dry. When applying impregnations, follow the instructions given by the manufacturer.

If the logs are the same, fill the crate under the insulation horizontally (there will be no gaps), although the vertical position makes it easier to align with the plumb line (level).

The advantage of the horizontal arrangement of the lathing is the uniform weathering of moisture from the insulation. With vertical - it accumulates at the bottom, the material dries longer.

If there is a gap between the logs, add pieces of insulation. The fewer voids, the higher the quality of the work.

Secure the ends of the film with tape or twist like a seam in jeans, and press down with a stapler so that they do not unfold. The vapor permeability of the membrane must be at least 1400 g / m2.

Take seriously the choice of windproofing. It protects the insulation from external influences: moisture and wind. To the outside, it works with the opposite effect. To dry the insulation, there is a ventilated gap, which should be at least 5 cm.

The correct insulation technology ("sandwich") looks like this: log house wall + tight-fitting insulation (preferably 2 layers with overlapping joints) + membrane, that is, windproofing film + air space (ventilation) and lathing for siding or other decorative material for the facade, on which the last layer is fixed - the cladding.

To insulate a log house only from the outside is a transfer of funds. You can save heat and save on fuel by carrying out comprehensive thermal insulation.

When external insulation is impossible, this does not mean that inside it is necessary to make a "thermos". Wood is an excellent insulation material, do not “cut off” it with foil.

Internal wall insulation with air ventilation is ineffective. Lay the insulation tightly to the logs, increasing the heat capacity of the wood by thickening.

Note: Calculate the dew point. According to the rules, with external insulation, it is in insulation, with internal - in wood, closer to the street.

How to caulk the walls correctly?

Insulation from the outside does not mean that caulking is not necessary or that it is enough to process the wall from the inside. This is mistake. With or without insulation, it is necessary to caulk. The process looks like this:

- start at the bottom;

- walk along the contour of the house;

- you process one crown from the outside, then from the inside;

- second row - repeat, and so on to the very top.

The main rule of caulking is the uniformity of work in the office on both sides of the walls. Stepping back from it, you will disrupt the laying of logs and create distortions in the structure. This will lead to the appearance of "cold bridges" in the area of windows and doors.

The process is laborious, so the caulk is replaced with a sealant. It is synthetic but provides 100% sealing. Positive reviews about the quality - you choose.

How to properly insulate a log facade, do it yourself steps

Before carrying out work, the grooves must be cleaned and treated with an antiseptic.

Important! Caulking of log walls can only be done manually.

Feature of work:

- They are performed first outside, then inside the house.

- You should start from the bottom row of logs, gradually going up.

- The lower crown is poured completely, along the entire perimeter, only after that they move to the next row.

Important! You can't completely bury one wall and then tackle another. This is fraught with distortion of the house.

Ventilated facade

If the insulation inside the wall is not enough, then external or internal insulation of the log house can be performed. A crate is placed on the prepared walls, which is treated with an antiseptic, and insulation is laid under it. For thermal insulation, mineral wool is most often used.

Ecowool has high heat and sound insulation properties, but only a qualified specialist should work with it.

After installing the insulation, a waterproofing vapor-permeable membrane is mounted. It allows moisture and air to escape, but does not allow moisture and wind to pass through.

We suggest that you familiarize yourself with Chia grains how to use

After waterproofing, a crate is placed on which siding is attached: vinyl, wooden or block house.

Important! Always leave a gap between the waterproofing and the finish as this is required for ventilation.

Wet facade

The technology of making a "wet facade" requires a flat wall made of any material (wood, brick, foam blocks, etc.). The key word is flat (wall), so the method is unacceptable for cylindering, but it is suitable for a house made of timber.

It is called wet because in the production of work water is used, which is part of the building mixtures. The order of work is as follows:

- Preparation - includes thorough cleaning and leveling of the walls. It is imperative to install all the elements for attaching antennas, gutters, lighting, etc. and cover them with an anti-corrosion compound.

- After the repair or plaster layer has dried, the walls are covered with a primer.

- A plinth profile is installed. This must be done strictly horizontally and always below floor level.

- An adhesive composition is applied, in small portions, as necessary during the installation of insulation boards.

- The first row of slabs is laid on a plinth and glued tightly to the wall.

- The next row of insulation is laid, displacing the vertical seam to the right or left, at least 200 mm to ensure dressing.

During the installation of the plates, additional mechanical fasteners are required - dowels.

The installed insulation is protected with a reinforced plaster layer using an adhesive mixture and a mesh. First, the corners and slopes are processed, then the remaining surface.

Important! The mesh should be immersed in the adhesive, but not in contact with the insulation.

Thermal panels are a building material that serves both for insulation and decoration of the building facade. The lower part consists of insulation (expanded polystyrene or polyurethane foam). The upper one plays the role of finishing and is made of clinker tiles, thin facing bricks, stone, porcelain stoneware.

Installation of thermal panels is carried out at any time of the year:

- To insulate a house from a log from the outside with the help of thermal panels, a wooden frame is assembled.

- Next, the basement profile is fixed. Necessarily strictly horizontally and below floor level. In some cases, you can do without it.

- It is recommended to start the installation from the left corner of the house, moving from left to right.

- Use glue foam, then fix the panels with self-tapping screws.

- The gap between the profile and the wall is filled with mounting foam and the joints are sealed.

Finish the installation of thermal panels with grouting.

The main requirements to rely on when choosing a mezhventsovy heater:

- the optimal level of density and elasticity, which provides reliable protection of the home from drafts;

- low thermal conductivity, which contributes to long-term preservation of heat;

- fast absorption and release of moisture, taking into account changes in air humidity from the inside and outside of the room;

- resistance to the development of microorganisms;

- durability, including the preservation of the microstructure of the material and resistance to the effects of natural factors;

- absence of substances posing a danger to human health.

The peculiarities of insulating houses made of rounded logs are due to the properties of wood.

- Wooden log cabins shrink by 6 - 8% during the first half of the year, therefore, insulation work should not be started earlier than a year after the completion of construction. Since new timber houses keep warm well, there is no need to rush

- Wooden walls breathe. Depending on the season and weather conditions, the moisture content of the wood changes, so the logs must be ventilated. If the surface of the walls is covered with a vapor-proof material, excess moisture will have nowhere to go and the logs will begin to rot

- Log buildings have an attractive appearance, which is why many homeowners do not want to degrade it by insulating facades. Internal insulation is less effective, but if certain rules are followed, it brings success

Naturalness is a guarantee of quality

The best option for insulating a log house are seals made from natural materials. They are usually made in the form of ropes or ribbons. Ropes are a classic form, but it is easier to work with a tape seal, since it is distributed between the crowns of a log house quickly and evenly.

Tape mezhventsovy insulation can be made of flax, flax-jute and pure jute. You can buy it from us directly on the website or by placing an order by phone.

The width of the belt is selected taking into account the size and profile of the bar or log. The main natural products include:

- jute;

- linen;

- hemp (hemp fiber);

- moss. Batting and felt made of cotton or woolen yarn are not recommended to be used as a seal between the crowns. Such materials are indeed capable of retaining heat, but at the same time they tend to retain accumulated moisture, which is absolutely unacceptable for a mezhventsovy heater. In addition, pests develop well in them.

We suggest that you familiarize yourself with How to insulate the floor on the second floor

All about jute

Jute belongs to the linden family. Its natural shade matches well with the wood color. Jute fiber is a recognized leader among mezhventsovy heaters.

Jute tape is mezhventsovaya. You can buy it from us directly on the website or by placing an order by phone.

When the walls shrink, the jute tape is evenly compacted between the crowns. It practically does not rot.

Jute is the same natural material as wood, therefore it absorbs and releases moisture depending on the ambient temperature. Jute linen is not damaged by moths, birds do not take it away. Mezhventsovy insulation can also be used as a complex product, for example, in the form of jute and flax-jute felt.

Flax is not only in demand, but also a more affordable building material, which has long been used for caulking a wooden frame. Flax fiber and linseed tow are made from the stem of flax.

Caulking with flax (linen) is a good solution for insulating a wooden log cabin.

The quality properties of flax fiber have a long service life and remain elastic for many years.

A significant disadvantage of flax is its susceptibility to rotting. In addition, linen insulation is attractive for birds, which take it apart for their nests, and rodents, who equip holes and passages in it.

Hemp fibers

Hemp is a natural material made from hemp. Such insulation has a high rate of thermal insulation, is resistant to mold and mildew. However, it is rarely used as insulation between crowns, due to its high cost and limited production in the field of application.

Moss application

Sphagnum moss has been considered the best choice for insulation material for many years. Moss for a log house is characterized by hygroscopicity, bactericidal properties, resistance to moisture.

And this is a moss with an exotic name "cuckoo flax". You can buy it from our company.

The disadvantages of moss include its low fire resistance, installation complexity and attractiveness for birds, which pull fibers between the crowns to arrange the nest.

The attractiveness of the frame in the seams between the joints can be given by a jute rope.

Tips and tricks for protecting a log building

This procedure includes the following steps:

- Antiseptic treatment (from decay, insects and rodents).

- Fire retardant layer device (for fire safety purposes).

- Finishing (primer and coating).

The correct process will preserve the beauty and safety of a wooden house.

Insulation of a log house from the outside necessarily includes caulking, thermal insulation of walls, ceilings, window and doorways. Further work depends on the design, purpose and age of the building. All processes can be done by hand, but to ensure guaranteed isolation from the cold, the owner of a residential building should contact a specialist.

Savings during work or savings during further operation: we consider the benefits

Waste of energy resources of the Soviet times has gone into oblivion, now we pay for them at European prices. This drains the budget of the middle class citizens. There is only one way out - to save. How to do this if the house needs to be insulated, and this is an expensive pleasure? Calculate what you get after insulation: 1. Sum up the annual heating costs. 2. Divide this figure by three (or two) - this is (X) the minimum savings on energy resources, with proper insulation of the house. 3. Calculate the funds invested in the project. It's –Y. 4. Divide Y by X. The result is the payback period. If the figure is less than 40 (so much insulation serves), you save.

If you received a disappointing result, do not be discouraged, look for an opportunity to save money on something else. There are no unequivocal advice, everything is individual. Having made the calculations, make sure that you are on the right track.

Tips on how to save money: 1. Do not rush to insulate the facade until the internal sources of cold are eliminated. 2. Choose quality materials - this is a guarantee of durability. 3. Use gas and water meters. The norms for consumption SNiPs are overestimated. 4. Select “A ++” class electrical equipment.This will save energy consumption 3-4 times. 5. Adjust ventilation, save heat whenever possible. 6. Optimize the operation of your heaters. 7. Use automatic heaters. 8. Purchase a heating boiler at the rate of 1.2 kW per 10 m2. 9. Walk around the house with a lit candle, the flame will indicate problem areas - isolate the “cold bridges”.

Financial clarity will give you a clear picture of what to do first, allowing you to consciously move on to the next step. The basics of insulating a log house are given in the article. If you do not make mistakes, this is a budget option, in which the operation of housing will require less energy, and the money and labor spent will be a profitable investment.

Thermal insulation of a house with mineral wool

A number of log house projects are presented on our website, for example: Or you can see all prices for log cabins. You can calculate the house or sauna you need with maximum accuracy using our log house cost calculator. To order and buy a log house, call:

- Vologda

- Moscow,

Comments (1)

No comments yet.