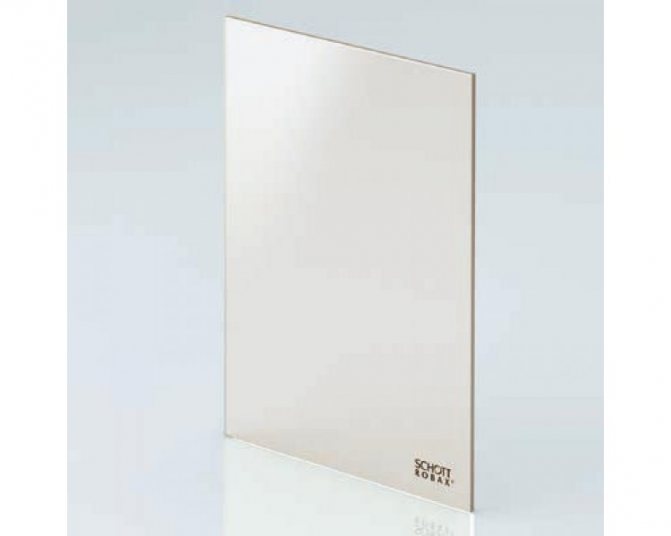

Schott Robax® Heat Resistant Fireproof Glass

By purchasing heat-resistant, fire-resistant glass for a fireplace from us, you will receive high quality products at the most favorable prices, both retail and wholesale. brings to your attention glass for fireplace | fireproof screens | heat-resistant glass Schott Robax®

It is best to use special heat-resistant glass for protective screens and viewing panels of fireplaces. They are also actively used for glazing braziers, ovens, ovens and barbecues.

German-made glass-ceramics Schott Robax® has not only a beautiful and aesthetic appearance, but also the highest technical and consumer characteristics:

- the ability to withstand large thermal loads;

- optimal sheet thickness;

- high level of strength;

- the temperature coefficient of expansion is close to zero.

The main quality criterion when choosing glass for fireplaces is fire resistance. After all, its main function is to prevent sparks from entering the room, withstanding high temperatures. Protective glass for the fireplace from is a German quality and the lowest prices to date

... Delivery across Russia, Moscow and the Moscow region.

Choice of doors

When choosing doors for the oven, you must remember about all the factors that will take part in the impact on it. First of all, this is heating, which will entail expansion. This point must be taken into account when installing the furnace.

To do this, you need to follow some rules:

- The distance between the brick wall and the door should be small enough. Subsequently, it is filled with non-combustible material. Usually kaolin fiber or basalt wool is used. In the absence of these materials, ordinary asbestos is used.

In addition, you can advise several recommendations that will help with the choice of this equipment:

- To contemplate the flame, it is necessary to purchase cast iron doors with glass inserts, or all-glass structures. But you need to be prepared for the fact that you have to pay for aesthetics!

- For stoves that use mixed fuels, coke or coal, cast iron structures must be selected. For wood-burning heating option, choose steel or glass.

- To be sure of the safety of children and pets, metal structures with a heat shield are used. Its maximum heating temperature is 40 degrees.

- To avoid cracks in heat-resistant glass, the thickness of which is 4 mm, at the time of installation, a small space is left with a seal. This will help avoid cracking during overheating.

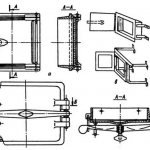

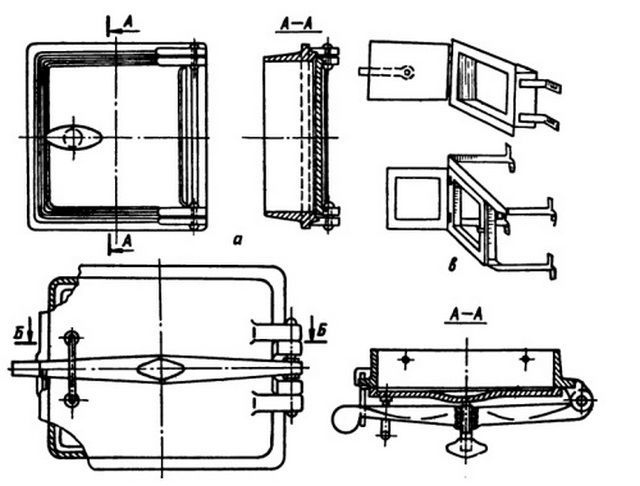

Furnace door installation diagram

In addition, it is recommended to use double-leaf structures. Usually, a slot is cut out in the outer ones, through which the regulation of the air flow passes. The internal ones will hold back sparks and coals, preventing them from entering the room.

By using mixed fuel, different slot widths can regulate the air flow, without which the combustion process is impossible.

Sometimes special sensors are installed in the doors that show the degree of heating and the opening / closing of the doors. They can be adjusted both manually and using the control panel.

Iron casting made on the stove door

Rates

| Name | The cost |

| Fireproof glass for fireplace 4mm | wholesale price 10,500 rubles / sq.m |

| Fireproof glass for fireplace 5mm | wholesale price 11,500 rubles / sq.m |

| Refractory glass ceramics 4 mm | wholesale price 10,000 rubles / sq.m sale of glass sheets |

| Round fireproof glasses of any diameter. Thickness 4 mm Refractory glass of various diameters | Rub 450 / pc |

Tempered glass preheating sheet

| 5,000 rubles / sq.m |

Fireplace shield

| RUB 6,500 for 1 pc. |

Basic properties of fireproof fireplace glasses

So, we found out that heat resistant glasses are made specifically to resist heat energy. Consequently, they have a low thermal expansion rate. Perhaps the best type of fireplace glass is quartz glass - it is known to withstand temperatures of about 1000 degrees! This also includes borosilicate glass, as well as several other types.

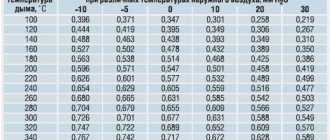

Note! The thermal stability of this material depends on a number of factors, including the chemical composition, dimensions, material quality and the degree of heat transfer.

Heat resistance is increased by hardening, polishing and chemical treatment, at the same time all defects on the surface are removed. The material made in this way is widely used in the construction of fireplaces. And thanks to the use of innovative technologies, fireplace glass is not only heat-resistant, but also safe. It has a low noise performance, and if desired, it can be laminated or tinted.

If we compare heat-resistant glass with simple glass, then in half an hour it heats up to about 50-200 degrees - much depends on the type and production technique (for comparison: ordinary glass heats up to as much as 500 in the same half hour).

Note! Today, not only fire-resistant glass is produced, but even glass-ceramics, albeit transparent, with a low thermal expansion index.

The material not only protects the combustion chamber from fire - it also allows you to watch the playing flames with pleasure. If the fireplace is equipped with this glass, then the room will be reliably protected from fire and accidental sparks. At the same time, it also provides excellent air supply, which is important for normal fuel combustion.

Video - Heat-resistant glass production

Specifications

| Manufacturer | Schott |

| Producing country | Germany |

| Glass type | Tinted, heat-resistant glass ceramics |

| Glass thickness | 4.0 or 5.0 mm |

| Glass width | 1100.0 mm |

| Glass length | 1954.0 mm |

About glass for the fireplace, protective screens for the fireplace

The combustion chamber of the fireplace poses a certain threat to the room due to the large number of sparks, coals emitted by cracking wood and hot ash. Closing the opening with a steel or cast-iron flap is inconvenient, in addition, all the beauty of the flame disappears and heat transfer decreases.

Therefore, in modern fireboxes, glass is used for the fireplace, which is strong enough not to scatter when closed, and heat-resistant to withstand the thermal head of the flame.

GLASS FIREPLACE DOOR DEVICE

The idea of using glass as a material for fencing a fireplace insert has been around for a couple of hundred years. In those days, quartz glass was used for fireplaces in the form of separate mosaic fragments on a bronze or copper fireplace screen. The glasses had to be changed periodically, as the screen moved too close to the fireplace got hot and the mosaic cracked.

Today there is no alternative to the use of a glass valve:

- Fireplace doors made of heat-resistant glass do not expand or deform from the heat, like cast iron or steel, thanks to this, it is possible to obtain minimal gaps and high quality sealing between the frame and the edge of the door;

- Fireproof glass for a fireplace does not burn and does not oxidize, retains its original appearance throughout the entire period of operation;

- The main thing is that a fireplace door with glass allows you not only to enjoy the play of fire, it is the only possible way to control the combustion process so that the flame does not turn into decay with the formation of carbon monoxide.

Today, rarely any fireplace insert is made with a black metal shutter, most often these are high-temperature fireplaces designed to use universal fuels, including those with a high content of tar and tar. But even in such structures, the manufacturer tries to use fire-resistant glass for the fireplace, since it is easier to see with your own eyes what is happening in the firebox than to guess from the sound or the thermometer readings. True, the owners have to regularly look for a means and a way than to clean the glass of the fireplace from soot.

For a small country house and summer cottage, a cast-iron fireplace with glass is most often chosen. In addition to a beautiful appearance, this choice has a purely practical advantage - heat-resistant glass for the fireplace provides faster and more uniform heating of the room. The champion in terms of heating efficiency is considered to be a round fireplace with glass, which is able to heat and illuminate the room at the same time.

Types of fireplace inserts

Fireplace with closed hearth

The heart of any fireplace is the firebox - a compartment inside the portal in which fuel is burned.

Standard firewood, coal and peat combustion device:

- Cast iron grate (grates). Firewood is stacked on them, air is supplied, ash and ash wake up.

- Ash box. For collecting and removing waste material.

- Lining. Protects the back of the device from overheating, reflects the generated heat into the room.

- Deflector. Delays combustion products from being directly drawn into the chimney, contributes to an increase in the efficiency of the hearth.

- Exhaust pipe. Removes smoke and soot from the oven.

- Air supply regulator. Increases or decreases the volume of oxygen supplied to the grates.

- Afterburning system. Converts unprocessed fuel particles and gases emitted by them into thermal energy.

- Glass cleaning mechanism. Provides air to the door, preventing soot from settling on it.

By design, the fireboxes are open and closed.

In open structures, firewood is only fenced with a decorative grill. It is beautiful, exotic, allows you to admire an open flame. The downside is that there is a possibility of sparks hitting the floor, the efficiency of an open fireplace is extremely low, since almost all the heat in the literal sense of the word goes into the chimney.

Closed designs are more economical. The firebox is hermetically closed by a door, smoke collectors and fuel afterburning systems are installed inside.

Where glass is used

The use of fireproof glass in the design of the fireplace gives them great importance. Thanks to the transparency of the hearth, the effect of a live picture is created, only absolutely safe, excluding the occurrence of a fire. Usually, a glass fireplace is not equipped with a chimney, so it can be concluded about the type of fuel on which it works.

Fireplace in the bedroom

Built-in model

Portable biofireplace

Original apparatus

Glass pyramid

Evening fire

Modern interior

The number of glass elements can be completely different. There are hearths made of metal, but with panoramic doors, which must be glass. These fireplaces use both gas and wood as fuel.

It should be noted that, due to the strength of tempered glass, the limit of its applicability covers all types of fireplaces. Fire resistance and toughness have led to yet another application. Such glass is often used to frame the floor surface in the immediate vicinity of the fireplace.It is not afraid of small objects falling and remains safe for a long time.

Fully transparent firebox

Varieties of fireplace doors with glass

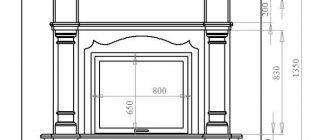

Fireplace doors with glass are constructed from a metal frame with hinges and doors with a selected glass unit.

Fireplace glass doors usually have a cast iron or steel frame, and they are also equipped with a handle. It is important that the handle is made of a material that does not heat up. Doors are differentiated by size, material from which the frame is made, design, colors. Many models have various interesting patterns and ornaments.

There are models on the market that open according to the guillotine principle. Thanks to them, the fireplace can function both closed and open. Since doors with heat-resistant glass weigh a lot, it is recommended to pay attention to products with an automatic opening mechanism, upon contact with which the risk of burns is reduced to zero.

Features of caring for glass furnace doors

Even self-cleaning glasses require regular maintenance, but cleaning the glass surface is allowed only after the door has cooled down. Working on a hot surface can cause irreparable damage to the heat-resistant material.

For cleaning, it is better to use special compounds, they not only instantly clean the doors from soot, but also create an additional protective layer that facilitates subsequent cleaning. Despite the strength of the fire-resistant material, it is strongly not recommended to use abrasives - they can damage the polish and the top protective layer.

U-shaped fireplace door

It is almost impossible to make heat-resistant glass for a fireplace with your own hands. The experiment can result in injury and fire. It is, of course, possible to independently install the doors in an existing or under construction hearth, but in the absence of the appropriate skills, it is better to entrust this responsible work to specialists.