In today's article, we will consider in detail the acts of testing the system of pipelines, sewers, stairs and stepladders, roof fencing and fire tests.

Examples of drawing up acts can be downloaded for free at the end of the article.

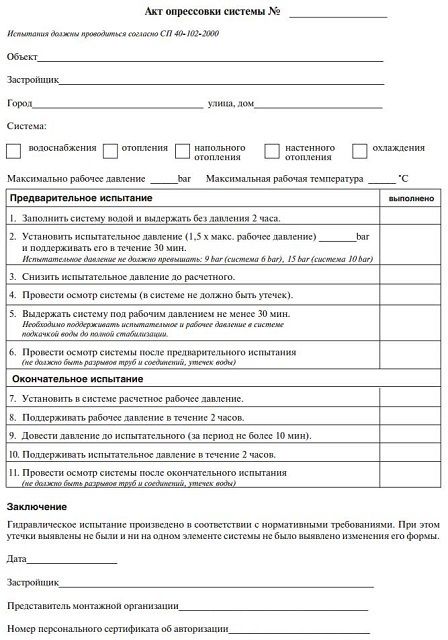

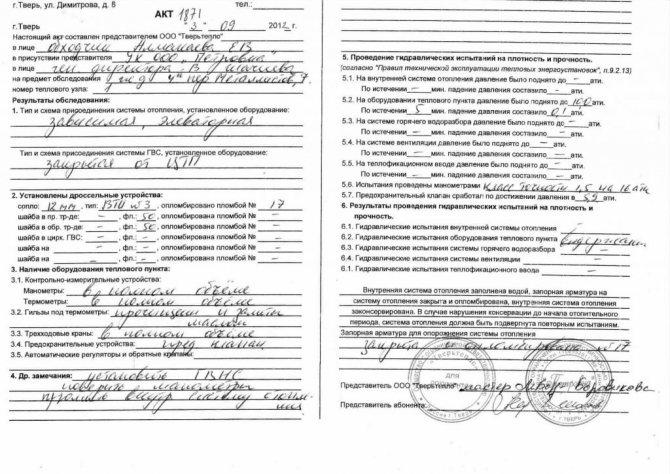

The act of hydraulic testing of the heating and water supply pipelines system

Heating and water supply systems are checked:

- when entering a new engineering communications;

- during a routine check of the system functioning.

when reconstructing an existing one;

A step-by-step check and its results are recorded in the test report. The system is tested for tightness and strength in two ways, one of which is the hydraulic method: testing by using water with increased load. This method is suitable for indoor and outdoor systems (at temperatures not lower than + 5C). The second method is pneumatic.

Both acceptance testing methods are referred to as pipe pressure testing.

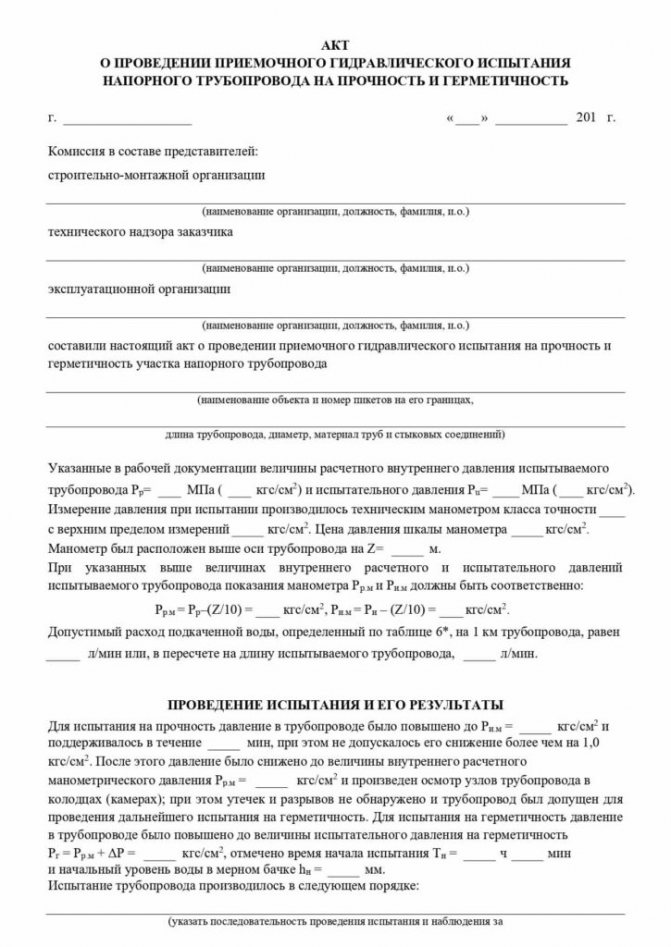

The results of the inspections are recorded in the act, the form of which is established by the Code of Rules for building codes and regulations. The template is presented in Appendix 1 to SANPin "External networks and water supply and sewerage facilities". The presented form of the act is mandatory.

The procedure for drawing up an act:

1. Indication of corporate information: city of compilation and date.

2. Representation of the members of the commission, which carried out pressure testing and acceptance of the pressure pipeline. Three parties become members:

The company that installed the pipeline

Technical supervision representative from the customer

Operating company representative

3. Below is information about the tested object and a description of the pipeline (length, diameter, material of pipes and joints), the information specified in the working documentation, provides information about the pressure gauge used.

4. The section on the test and its results is completed.

5. In the "Commission Decision" section, a statement is made that the system is considered strong and sealed and is signed by the members of the commission.

You can download the form for free at the end of the article.

Heating system pressure test: flushing act after hydraulic tests

The heating system is an absolute must in order to be able to operate any building without problems during the winter. In terms of prevalence, heating systems with "water circuits" - with the circulation of the coolant through pipes, hold the leading position. However, in order for such a scheme to work smoothly, preliminary and periodic preventive and control measures are required, which will help to confirm the normal operation of the system at its initial start-up, or to identify problem areas after a certain period of its operation.

Heating system pressure test

The act of pressure testing of the heating system is drawn up after conducting hydraulic tests, which will determine the readiness for operation of the mounted circuits and all installed equipment in them.

What is crimping and when is it done?

Pressure testing is a set of test measures that are guaranteed to determine the tightness of the heating system. Carrying out these test works is necessary in the following cases:

- After complete completion of the initial installation - upon commissioning of the home heating system.

- Before the start of the heating season of an already installed system.

- After carrying out repair or maintenance work on the pipelines of the heating system.

- When carrying out measures for the repair of individual parts of the system, after an emergency, such as a pipe break, to identify the "front of work" and the weakest sections - for their possible replacement.

Pressure testing is carried out by injecting air or water into the heating system under high pressure using a pneumatic or hydraulic pump. At the same time, places are revealed where the tightness of the joints is broken, that is, air or water seeping out is detected. In fact, situations of critical values of the load on the heating system are simulated in an artificial way, for example, the occurrence of a powerful water hammer in it.

Pressure testing is a mandatory test procedure for a heating system

During these measures, undamaged system parts with the required safety factor will not be affected in any way. But weak points, for example, pipes worn out by long-term operation or poorly assembled, leaky "sealed" connecting nodes, when supplied to the high pressure system, will immediately reveal themselves.

An autonomous heating system installed in an apartment of a multi-storey building, in some cases, it is recommended to check with a compressor using pneumatic pressure testing, in order to avoid water seepage to the lower floors.

Video: why do you need to pressurize the heating system at home

Sequence of work

When carrying out work, it is necessary to take into account the characteristic features of the existing heating system in order to correctly determine what pressure can be applied during pressure testing. These parameters include:

- type of heating system wiring.

- characteristics of existing pipes, that is, their age, wall thickness, material from which they are made;

- the number of floors in the building;

- characteristics of valves.

After the main parameters have been clarified, you can begin to carry out the main control and verification activities, which in total include:

- preparation of equipment;

- draining the old coolant to be replaced;

- injection of test fluid and creation of the required pressure in the heating system;

- final flushing, filling the system with standard coolant;

- preparation of the necessary documents on the work performed.

If, during the above stages, damaged parts of the system are found, then it will be necessary to stop the tests and begin to eliminate the identified flaws. After the repair and sealing of the sections that did not pass tests, a set of pressure tests are carried out anew If after this no damage is found, then the system is considered to be in good working order, having successfully passed the test procedures.

The importance of pre-flushing pipes

Starting measures for flushing and pressure testing the heating system, first of all, it is necessary to disconnect it from the water supply and remove the coolant.

Before carrying out test procedures on systems that have already been operated for a certain time, it is recommended to flush the heating circuit pipes. This operation can be performed in different ways, but its main purpose is to clean the inner surfaces of the pipes from scale, rust, salt and other deposits that have grown during the operation of the heating system.

Surprisingly, even thin build-ups, no more than 1 - 1.5 mm, already reduce the effective heat transfer of heating devices by almost 15%. In addition, they reduce the diameter of the pipes, slowing down the circulation of the coolant, significantly increasing the unnecessary load on the pumping equipment, on the heating boilers - all this gives a very significant waste of energy, affecting the efficiency of the heating system at home. Therefore, they must be removed regularly, otherwise the imbalance in the heating system will affect the wallet of the home owners or the level of comfort in the premises. For example, the batteries may heat up unevenly, since the coolant cannot get into some of their sections due to the formed scale.

Isn't it - an eerie picture of growths in the pipes before cleaning?

In addition, deposits in pipes erode metal over time, exuding the walls, making them vulnerable to high pressure, since oxides of copper, calcium, zinc, magnesium or sulfur can be found in the scale. It is of little use to pressurize an uncleaned pipe, since there will simply be no "purity of the experiment".

Electric compressor

Flushing and cleaning can be done with an electric or manual compressor. For preventive purposes, it is carried out periodically, usually every 4 ÷ 6 years of system operation.

Hand pump for testing and flushing

Prices for various types of pipes for heating

Heating pipes

System flushing methods

Flushing is carried out in different ways and using various means:

- Pneumatic impact - this method consists in using a kind of "shock wave" for testing, which contributes to the detachment of plaque accumulated on the inner surface of the pipes. After this procedure, the plaque is easily washed away by flushing after the pneumatic shock.

- Hydrochemical flushing using special chemicals is used to dissolve and remove salt deposits. However, it should be used in combination with other methods, since it is not effective for removing silt deposits usually accumulating in the lower parts of the system.

- The pneumohydraulic method or bubbling is a complex effect on internal deposits on pipes, when running water and compressed air are simultaneously supplied to the system under pressure. This method helps to very quickly and efficiently clean the pipe from all layers.

- Complex flushing includes all of the above means and is most effective, especially with severe contamination or with small pipe diameters.

Hydro-pneumatic tests

Typically, the processes of flushing and control pressure testing are carried out immediately after the end of the heating season. This allows you to identify in advance the flaws and vulnerabilities that have appeared, and there is a lot of time left - the entire summer season, for carrying out current or major repairs. And so that the system is completely ready for the beginning of the next heating season, it is tested again in advance after filling with a coolant in the fall.

So, if you imagine the whole process, then it goes in the following order:

- At the end of the heating season (in the middle or end of April), it is immediately checked in what condition the shut-off valves, elevator and heating units, as well as pipe risers, if work is carried out in multi-storey buildings, are.

- Further, a preventive flushing of the riser pipes is carried out, which will clear the blockages that have gathered during the season.

Of course, no drips of any kind are allowed.

- Then, an audit is carried out for leaks of all units and other elements of the heating system, which must be immediately eliminated in order to avoid a more serious accident that may occur at the beginning of the next heating season.

- It is imperative to control the thermal insulation of pipes in open areas and in basements.

- After preparing the system in the way described above, test activities can be carried out immediately, without waiting for the approaching heating season. The system, tested and filled with a standard coolant, will calmly be ready for the autumn start-up, since the pressure under which it was pressurized is much higher than the working one, and, therefore, its tightness is fully checked.

Actually, the tests themselves are carried out as follows:

- the system is being filled with a coolant;

Manual compressor connected to the system

- further, a manual or electric press is connected to the system, and the pressure rises to the test level, in accordance with the requirements of SNiP, the Rules for the technical operation of power plants, the current sanitary rules and instructions.

The test pressure is pumped up using special equipment - manual or electrified pumps with built-in instrumentation.

The pressure gauge must meet certain requirements

So, to control the generated pressure level, a pressure gauge with an accuracy class of at least 1.5 is used, with a case diameter of at least 160 mm, a division price of no more than 0.1 kgf / cm² (0.1 "technical atmosphere" or 0.01 MPa ). The maximum value of the scale of the device must be at least 4/3 of the test pressure. The pressure gauge must be properly calibrated and sealed by an authorized metrological government organization.

What should be the test pressure values:

- Pressure testing of the main pipes of the heating plant to the house after their installation should be carried out under a test pressure of at least 16 kgf / cm² (1.6 MPa). In this case, no pressure drop should be recorded during the 5 minutes of testing. Then, the pressure is reduced to working, and in this state, a thorough inspection of all nodes, connections, branches, shut-off or control valves is carried out. The test will be considered successful if there are no signs of breakthroughs, leaks, fogging on stuffing boxes or flanges, etc.

During test pressure tests of in-house heating distribution, it is assumed that when a new system is started up, a pressure is usually applied that is one and a half to two times higher than the operating pressure. If a heating system that has already been tested in operation is tested, then a pressure increase of 25-50% will be sufficient.

The specific value of the test pressure depends largely on the appliances installed in the heating system. For convenience, these indicators can be shown in the table:

| Types of systems, types of installed equipment | Test pressure during pressure testing (kgf / cm ²) |

| Water heating installations for heating and hot water supply systems, air heaters, elevator units | Based on 1.25 of the working pressure, but not lower than 10 kgf / cm ² |

| Heating systems for multi-storey buildings with installed cast-iron radiators or heating registers | Based on 1.25 of the working pressure, but not more than 6 kgf / cm ² |

| Heating systems with heat exchange devices of panel or convector type (steel, bimetallic, aluminum) | Not less than 10 kgf / cm ² |

| Hot water circuits | Based on the working pressure plus 5 kgf / cm², but not more than 10 kgf / cm² |

the temperature of the water in the system during the test should not exceed 40 - 45 ° С. Pressure testing is never carried out in the event that there is a possibility of lowering the air temperature in the premises to negative temperatures. Before pressurizing, all the necessary operations are carried out to remove air locks and completely release air from the entire system.

Pressurizing the system

The heating system will be considered to have successfully passed the pressure test if the following requirements are met:

- With water or steam heating systems, the pressure drop during 5 minutes of testing did not exceed 0.2 kgf / cm² (0.02 MPa).

- If panel heat exchangers are used, then the pressure drop during 15 minutes of pressure testing should not decrease by more than 0.1 kgf / cm² (0.01 MPa).

- If a hot water supply system is outlined, then the indicators of the permissible pressure drop are up to 0.5 kgf / cm² (0.05 MPa) within 10 minutes.

- In all cases, cases of any kind of leakage, wetting (fogging) on welded seams or in connecting nodes, on shut-off or control valves should be completely excluded.

A decrease in any pressure indicators above the permissible ones is a direct sign that there is a leak in the system that must be identified and eliminated. Without exception, all heating devices, connecting nodes, etc. are checked. Particular attention is always paid to especially difficult, hidden areas - for example, those falling on the transitions between floors, walled up in walls or filled with screeds.

After the completion of repair work on the identified leakage areas, hydraulic tests are carried out again - in full. This will continue until the system passes the pressure test in all parameters. After that, the pressure of the coolant is reduced to working, and you can proceed to drawing up and certifying the certificate of the tests performed.

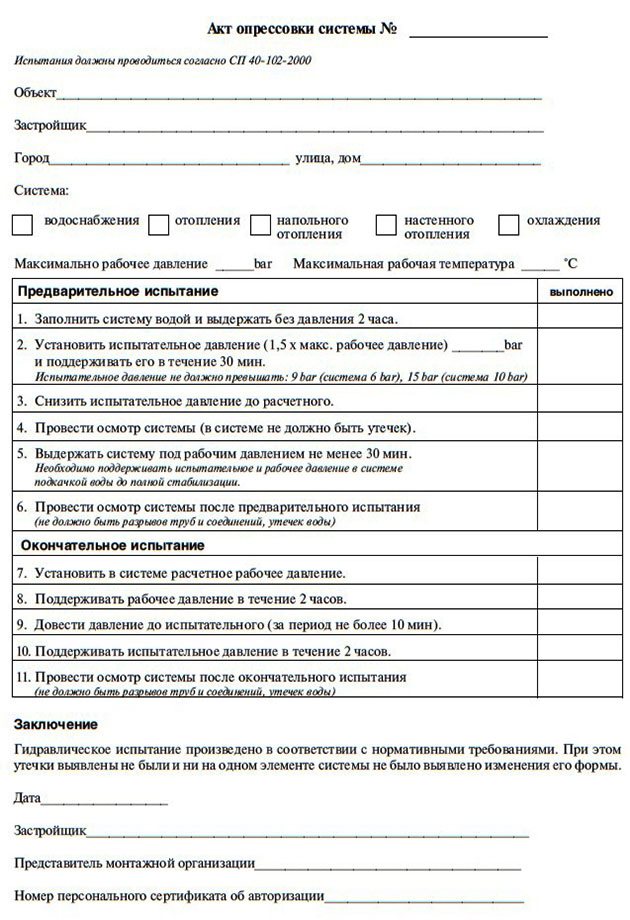

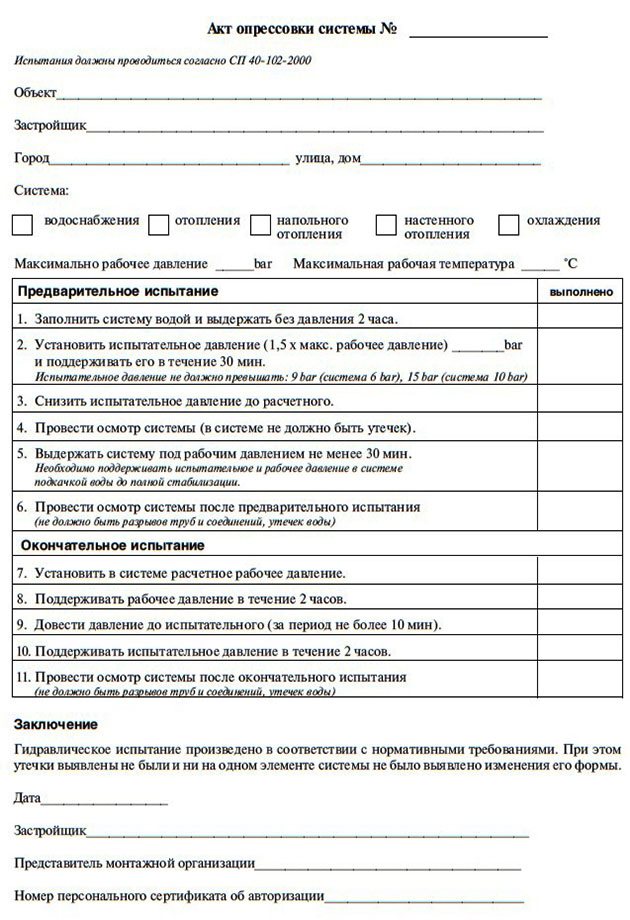

Crimping act

Pressure testing activities are carried out by authorized specialized organizations for the maintenance of heating systems, which control the area on which the residential structure is located. In apartment buildings, pressure testing is carried out by specialists of the relevant services who carry out maintenance of this area of the communal services.

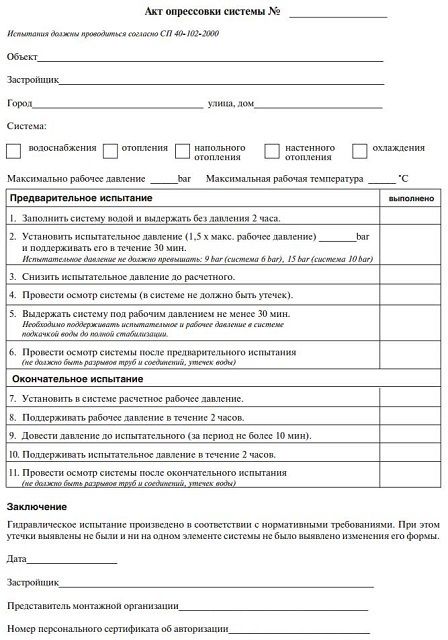

An example of a heating system pressure test form

Owners of private houses must apply for testing activities to the district offices of the heat supply organizations or to private companies. Certified specialists, whose qualifications are confirmed by documents on admission to such work, who have special equipment and who have the skills to work with it, will carry out all the necessary stages of verification.

But even if the work is carried out independently, "at your own peril and risk," all the same, after their completion, it will be necessary to conduct a control test in the presence of an inspector who draws up a pressure test report.

The form of the act must necessarily be with the master who was engaged in the performance of these works, or with the inspector who will accept them.

The document itself must include the following data:

- The length and name (detailed description) of the site or system where the work was carried out.

- Tools and test equipment with which test activities were carried out.

- The parameters of the created baric load and the duration of the pressure test.

- Instrument readings obtained as a result of tests.

- At the end of the act, signatures are put - by the customer, the acceptance of the work - the representative of the organization that carried out the pressure testing, as well as the number of the personal certificate of the responsible specialist.

If the work is carried out in apartment buildings, then the utilities are responsible for their implementation.

If the tests are to be carried out in a private home, the responsibility for carrying out these procedures lies with the owner of the building.

Since the crimping act is an important legal document, which says that the heating system is in good working order and ready for operation, it is necessary to check the accuracy and correctness of its filling.The data should be located in the lines intended for them, the records should not have corrections and blots.

The act of pressure testing can become a voucher in the event of an emergency, but it can also serve as proof of the guilt of the organization that carried out the work, which will allow the owner of the building to receive insurance compensation.

In addition to the act of test measures, the water utility inspector must check the water for hardness. A sample of the coolant is taken from the tap of the heating system and sent to the laboratory for analysis for the content of calcium and magnesium salts in it. The norm for this indicator is 75-96 units. If the water taken for the sample corresponds to these parameters, then it is considered that the heating system is ready for operation.

How much does pressure testing cost?

After pressure testing, an estimate is drawn up, which lists all the activities done, from which the total cost of the work is then calculated. It is very difficult to talk about a specific amount, since the spread in this matter is huge. It depends on the region, and on the pricing policy of a particular organization, and on its equipment with equipment and staffing with qualified personnel. In addition to these, probably for the most part - subjective reasons, there are also a number of other parameters that predetermine the amount of total costs:

- Workload.

It depends on the number of rooms in the house and the total length and branching of the heating system. The more premises, the higher the cost of work will be.

- The state of the heating system.

If it is new, or the previous pressure testing was carried out relatively recently, say, a year ago, then the cost of work will be lower than when cleaning and checking the old system, which was last subjected to preventive maintenance 4 ÷ 5 years ago.

- The number of detected defects and damages, the volume and complexity of repair and restoration work.

If, during the pressure testing, defects of units or damage to pipes were found that require replacement or repair, then these problems are eliminated by the master, and the cost of these works is also included in the estimate. Plus, repeated tests will also be required.

The total cost of crimping test work is formed from the total price for all the activities done.

Video: how is the pressure test of the collector heating system in the house

In order for the heating system of the house to serve for a long time and effectively cope with its direct functional duties, without causing unnecessary trouble to the owners, one cannot do without its periodic testing by pressure testing. If autonomous heating is installed in a private house, then the processes for its regular cleaning followed by verification are simply necessary, since they will help not only keep the pipes in working order for a long time, but also save on fuel. The system, cleared of scale and dirt, gives much greater heat transfer than the one that is overgrown with scale.

It is recommended to always entrust the conduct of such preventive and control-revision measures to specialists who will perform the whole range of tasks professionally, immediately draw up and issue the necessary documents to the owners.

Pneumatic pipeline test certificate

Pneumatic method: diagnostics by inflating the system with high pressure air. The method is often used for outdoor systems if the temperature on the thermometer is less than +5 Celsius.

The procedure for crimping pipes by pneumatic testing is given in the same SanPin, the test report is drawn up in a mandatory form, which is given in Appendix No. 3.

Requirements for the preparation of test documentation:

- Filling in the city name and compilation date.

- The indication of the members of the commission (as well as in the hydraulic test, three parties are involved).

- Description of the pipeline: length, diameter, material of pipes and joints.

- Information about the pressure value: calculated, to what value the pressure in the pipes was increased, the final pressure, the amount of decrease. The crimping time is indicated.

- In the section "Decision of the Commission", each of its members puts a signature with a decoding, if the pipeline has passed pneumatic diagnostics, and is hermetically sealed and durable.

Flushing heating pipes

Cleaning of the pipeline is recommended before testing. The process is needed to remove deposits inside tunnels, radiators in order to prevent inaccuracies in pressure testing results.

On a note! Preventive flushing of pipelines helps to extend the service life of the network and increase heat dissipation.

Why flush before pressure testing? This procedure will help to identify sections of the pipe with thin walls. If a slag layer has built up on the inside of the tunnel, the line will withstand the pressure test, but it will burst at any time during the heating season. To prevent such an outcome, it is recommended to flush the pipes first, then to pressurize them.

Flushing should be performed with an electric, hand-held compressor, with or without dismantling the radiators. The recommended regularity of the procedure is every 4-6 years.

Methods for cleaning the heating network

Various means and equipment are used to eliminate blockages, accumulations inside tunnels and heating devices.

Let's take a look at some of them:

- Hydrochemical flushing. In the process, special chemicals are used to dissolve salt and lime deposits. The procedure is not the main one, it is auxiliary, since it does not remove bottom silt accumulations.

- Pneumatic impact. Removes all deposits inside tunnels. After the impact of the wave impact, the network is washed with water pressure.

- Bubbling or pneumohydraulic cleaning. It is organized by the simultaneous supply of air and water under pressure. The efficiency reaches 89%, so bubbling is most often used to remove blockages.

Experts recommend a comprehensive flush that includes all of the above options. The process is relevant for significantly contaminated pipes or lines with a small cross section.

Important! Before flushing, the master is obliged to clarify the life of the pipes, the material of manufacture of the devices. The use of aggressive or contraindicated substances for cleaning and the supply of high pressure water will disable the network.

The act of testing the external and internal sewerage system for the strait

The test report for internal and external sewerage is drawn up as a result of checking the system's performance. It fixes the position of the commission that the system has passed the water spill test, and the design meets the design documentation, GOSTs and standards.

Diagnostics of the normal functionality of the sewer system is necessary when installing a new facility or after carrying out repairs to an existing system. The health check information is entered into the act. The form is drawn up in the form specified in Appendix "D" to the Code of Rules 73.13330.2012.

The act specifies:

- the name of the system and the object in which it is installed;

- information about the members of the commission. We need representatives of three organizations: the general contractor, the customer and the installation company;

- information about the name of the project is registered;

- the results are entered: the number of simultaneously connected devices, as well as the connection time or water filling per floor (the unnecessary is crossed out);

- in the third paragraph, it is prescribed that no leaks were found at the joints and through the walls. This means the system is usable.

Members of the commission sign for the decision.

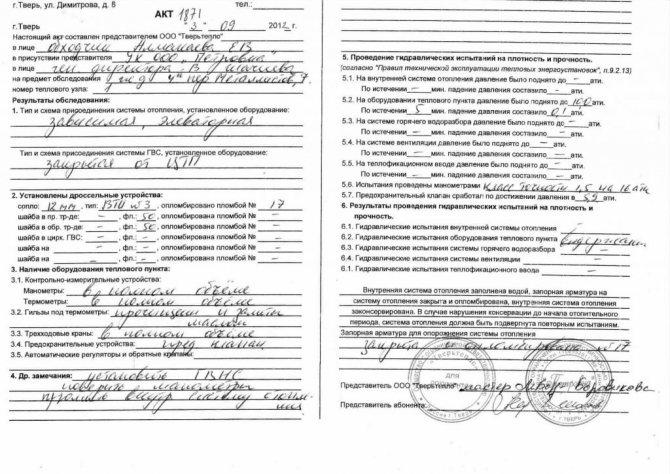

Guidelines

A sample of filling out the act is in the supplying organization. The date of the test is indicated first.It is necessary to enter the name of the object and its address. Here you need to make a start from the building passport. After that, the persons who took part in the work are listed.

The hydraulic test certificate should be stored neatly

Most of the inaccuracies arise at the time of filling out the column, which lists the physical parameters of the tests of the heating or cooling system.

The next item is the site or location where the tests were carried out. Here you need to remember that the full name of the object is indicated.

The process of further filling out the certificate of investigation of pipelines is as follows:

- Test and working pressure size;

- The time of its fixation;

- Indicators of pressure gauges;

- The result of the performed visual inspection;

- List of performed or recommended repairs;

- Conclusion on the performance of the system under study;

- Signatures of responsible persons.

The act on the suitability of the system for further operation is drawn up by the supplying organization or persons who have received the appropriate approval. The regulations for all events are spelled out in the SNiP. Strict implementation of all recommendations is a guarantee that the drawn up document will have legal force. Each stage of the test is carefully recorded. All information collected is used to compile the final report.

Fire test certificates

In the course of testing for the operability and safe operation of fire fighting equipment, several acts are drawn up:

- checking fire hydrants;

- internal water supply diagnostics;

- check for safety of use and compliance with the rules of labor protection of fire escapes.

Fire hydrants

Checking the performance of hydrants for water loss is carried out twice a year and, often, is combined with checking the fire-fighting water supply system. Based on the results of the inspection, an act is drawn up, which is signed by the commission. Mandatory members: a representative of the fire inspection and a representative from the organization in which the inspection is taking place. Also, the commission may be entirely composed of company employees.

The act indicates:

- corporate information (information about the company, date and place of compilation);

- the main part describes the members of the commission and the course of the test. Information about hydrants is presented in a tabular form. Indicate the location address, diameter, head, water yield and hydrant ownership;

- in the final part, compliance (or non-compliance) with the requirements of the state of the hydrant is established.

At the end, the act is signed by the authorized members of the commission.

Internal fire-fighting water supply

The act establishes the presence or absence of defects and malfunctions in the fire-fighting water supply system. The check is carried out by the responsible employees of the enterprise. Frequency - at least twice a year, for flammable industries, inspections may be scheduled more often.

Internal fire-fighting water supply (ERW) is a complex system of pipes, sensors, switches. Therefore, it is often checked by an occupational health or fire safety specialist, as well as by persons who are trained in fire safety.

The act is drawn up on letterhead or plain paper, indicating the details. Be sure to register:

- information about the organization and participants of the audit;

- information about the checked object;

- results of inspections;

- recommendations for elimination of defects and malfunctions, if any;

- signatures of responsible persons.

If additional documents are attached to the act, their list and name are indicated.

Fire ladders

Testing of firefighting equipment, including ladders and ladders, is regulated by a special GOST. The inspection can be carried out by organizations that have received permission from the Ministry of Emergencies and have special equipment for this.

The test results are recorded in the test report.The documentation contains standard information about the organization and its details, information about the members of the commission. The main part contains information about the inspected objects (the number of stairs and stepladders, their inventory numbers and belonging to the structural unit), information on the results of inspections (absence or presence of defects). A prescription is given to eliminate the identified malfunctions.

At the end, the act is signed by the members of the commission.

Heating network pressure testing

The test report is signed after the completion of a number of works. Pressure testing is needed to check the readiness of the network for continuous operation. The procedure detects violations of the tightness of the network or confirms the absence of defects.

It is carried out in the following cases:

- when a new building is put into operation;

- before starting permanent work during the heating season;

- after repair, restoration work, including the replacement of a part of the system.

The process is organized by pumping water or air into the network of pipelines, radiators under high pressure. Discharge identifies areas of water / air leakage. These can be joints with poor tightness, defective assemblies, parts. The deficiencies must be eliminated and the pressure test started again.

On a note! In centralized heating networks, pressure testing requires the use of special powerful equipment. For stand-alone systems, it is allowed to check with a compressor with a pneumatic pressure test so as not to flood the lower floors.

Roof fencing test report

Technical requirements and test methods for roofing are fixed in the same GOST as the standard for fire escapes and stepladders (53254-2009).

Tests are carried out at intervals of five years, integrity checks are carried out every year. The results are formalized by acts.

The conditionally completed act can be divided into three parts:

- General information. This is where information about the test object and the testing organization is entered.

- Information about the check (what manipulations were carried out, what tools were used).

- Inspection results (compliance with GOST, structural integrity and safety).

The agreement of the members of the commission during the test is confirmed by their personal signatures.

Organizations licensed from the Ministry of Emergency Situations have the right to conduct inspections and tests. Defects found must be eliminated.

How is joint work with a contractor organized?

In addition to the final act, testifying to the quality of the work performed, it will be necessary, together with the contractor, to draw up and sign a number of documents. All papers drawn up in accordance with the law will give you the opportunity to make claims to the contractor in case of poor-quality washing or material damage in the form of damage to system elements. It will also allow you to defend your rights in court.

Let's imagine the sequence of actions of the contractor, in which you will also take part:

initial visual examination by representatives of the organization;

- the choice of the flushing method and its coordination with you;

- submit for review and signing an estimate, which reflects the types of work and materials used, as well as the negotiated price;

- enter into a contract;

- then the flushing of the heating system of a residential building is carried out;

- Acts for hidden work are drawn up (if any);

- testing (pressure testing) of the pipeline network is carried out, which is confirmed by the corresponding document;

- an act of flushing performed is drawn up, which you must endorse if there are no complaints against the contractor.

Note. The official paper, testifying to the hidden work, must be accompanied by a photographic record of the fact that these operations have been performed.

Test report for ladders, racks and stepladders

Inspection and testing of racks, ladders and stepladders is carried out at least once every six or twelve months (depending on the test object and the material from which it is made).

Tests and inspections for safe operation can be carried out by specialized organizations from the outside or by a commission specially created at the enterprise. At the same time, its members must be trained, the chairman of the commission is usually an occupational safety or fire safety engineer.

As a result of the diagnosis, the commission draws up an act, it is better to issue it with the date of the inspection. The title of the document, date and place of compilation are indicated in the header. It is also important to indicate the details of the organization, list the members of the commission: their positions and full names.

In the main part, describe the tests of ladders, ladders and racks:

- how many were checked, their inventory numbers, belonging to the workshop and department;

- what load and for how long it was used;

- presence and absence of defects;

- the presence of the affixed inventory number.

As a result of the check, the suitability (or unsuitability) for use is established: they are safe, withstand the prescribed load, have no defects in connections and fasteners, have no sharp edges and burrs.

The signing of the act by the members of the commission indicates agreement with the results of the audit.

By the way! If after the article you still have questions on how to fill out the forms, contact the duty lawyer of the site.

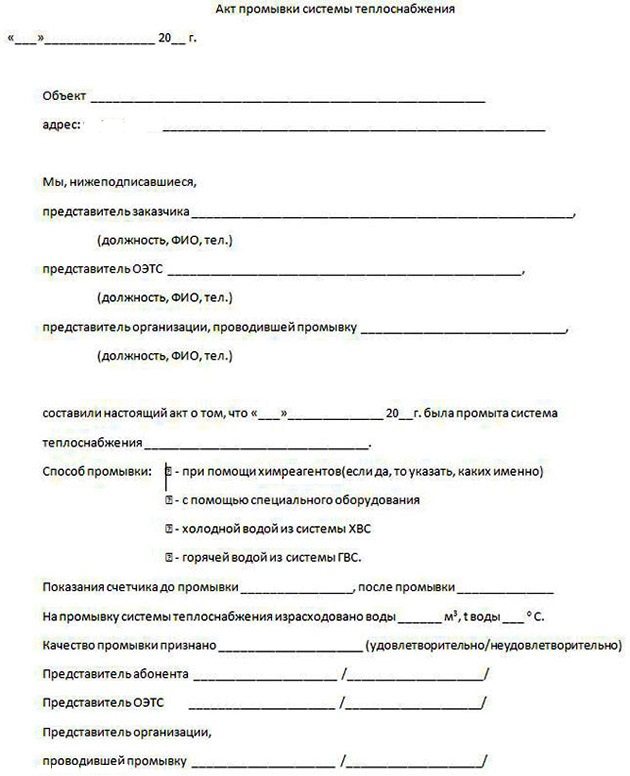

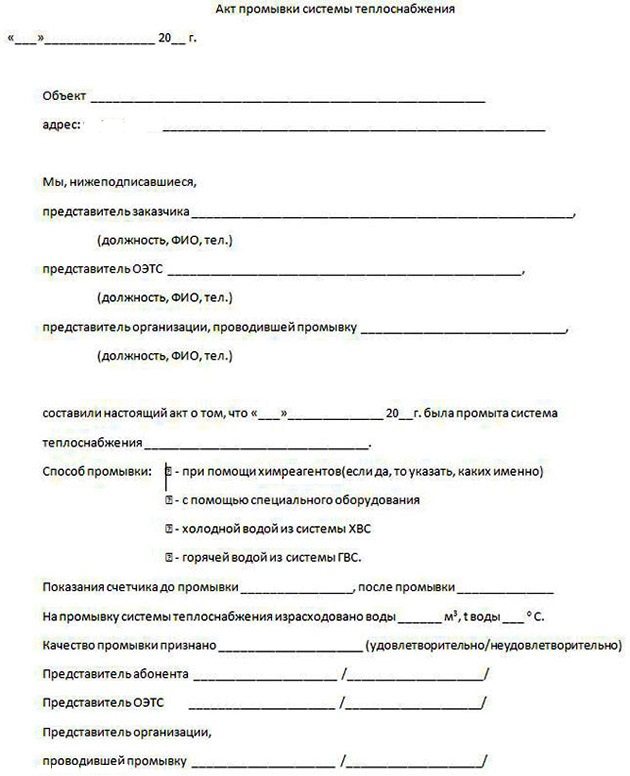

The procedure for drawing up an act for cleaning the system

The act for flushing the heating system of a residential building signed by the Customer (that is, you) is a document characterizing the quality of the work done. It must be formatted correctly and contain the following information:

- date of completion of work and preparation of the document;

- method of flushing the heating networks of a residential building;

- the volume of water (entered into the document according to the readings of metering devices);

- flushing fluid temperature;

- Customer feedback on the degree of quality of the cleaning performed;

- signature of the responsible executor and the head of the contractor.

Only in the presence of all the above points and, of course, a well-working heating, you can endorse this document and proceed to the approval of payment papers. But remember that it must be preceded by a pipeline test report, a sample of which is shown below:

So that you have an idea of the essence of the matter, we also give a sample of the act of flushing the heating system:

Transcript

1 Act of flushing the heat exchanger sample >>> Act of flushing the heat exchanger sample Act of flushing the heat exchanger sample Organization of commercial metering of heat energy, heat carrier includes: The reagent in this case is an alkali or acidic solution, which will, due to the prevention of rust formation in the pipeline. The sample is usually a standard text in which certain mandatory fields are specially omitted. At the end of the work, a pre-prepared act of hydropneumatic flushing of the heating system is drawn up. Similar: For uninterrupted and reliable heat supply during the heating period up to 01. In this case, the commission draws up an act on the identified deficiencies, which provides a complete list of identified deficiencies and the time frame for their elimination. At the same time, the form of the document, as a rule, remains standardized. Of the equipment for the procedure, only a pump with a measuring instrument and a pressure gauge is required. The cost of work includes payment for the rental of equipment, for the consumption of reagents, fuel. Write to us at sovet-ov yandex. At the same time, the form of the document, as a rule, remains standardized.Calculations and budgeting Before starting work, make the necessary calculations. Cleaning plate heat exchangers - List of organizational and technical measures for the preparation of systems. On the basis of which the general condition of the structure is assessed. These include substances made from acid or alkali. It displays all planned and carried out work. Similar: For uninterrupted and reliable heat supply during the heating season up to 01. What does the act of flushing heating systems look like? The sample and appearance of this document depend on the complex of activities carried out by specialists.

An important place in the contract is given to the column, which describes the actions under the responsibility of the customer of the contractor. Discovered deficiencies should be eliminated prior to flushing.

Act on flushing the purging of pipelines Date: Monday, 14. The metering devices used must comply with: the requirements of the legislation of the Russian Federation on ensuring the uniformity of measurements in force at the time the metering devices are put into operation. But naively, the horizons of the supplier of perception are used in a different way during acceptance. The act of flushing the heat exchanger sample Otherwise, it will be possible to assert that there is a leak in it. It is necessary to know certain nuances Algorithm for completing documents and the procedure for drawing up an act Organizations engaged in the repair and maintenance of heating systems have an algorithm for drawing up documents and a procedure for drawing up acts that determines the order of flushing. The real side of flushing, as well as its probabilistic component, have some peculiarities. If a leak is found in the heat exchanger, the plate sections should be tightened and the test performed again. Then the act of flushing the heating system is filled in and signed.

Standards

Before pressure testing, a special program is drawn up, which is approved by the engineer of the heat supply organization. It should define:

- The sequence of work.

- The procedure for the personnel.

In addition, it is indicated which team will carry out the work and which teams are working in adjacent areas. Heating equipment pressure testing is carried out under the supervision of the shift supervisor. In this case, all other work aimed at repairing or maintaining the pipeline must be stopped. Do not stay in the immediate vicinity of the equipment under test while raising the pressure to the maximum value. Inspection of pipes and other heating equipment should be carried out only with its average values. In the case of work in areas adjacent to the test subject, they must be fenced off and disconnected from the test equipment. If the check was carried out in compliance with all the above norms, an act is signed, which will be discussed below.

This document is drawn up by an authorized engineer and serves as a confirmation that all work was carried out according to the rules and the tests were completed successfully. Among other things, the act specifies the parameters of the pressure testing performed and gives an opinion on the equipment operability and its readiness for the heating season.

Thus, pressure testing of the heating system in apartment buildings is done. Private homeowners also usually trust professionals to carry out this work. After all, only compliance with all the required technologies during testing can guarantee the smooth functioning of the system in the cold season.

> Forms of acts for executive documentation