Document year: 2019

Document group: Acts

Type of document: Act

Download formats: DOC, PDF

Test reports are drawn up in the form of forms of documents, in which the result of testing the operability of mechanisms and equipment is entered.

In today's article, we will consider in detail the acts of testing the system of pipelines, sewerage, stairs and stepladders, roof fencing and fire tests.

Examples of drawing up acts can be downloaded for free at the end of the article.

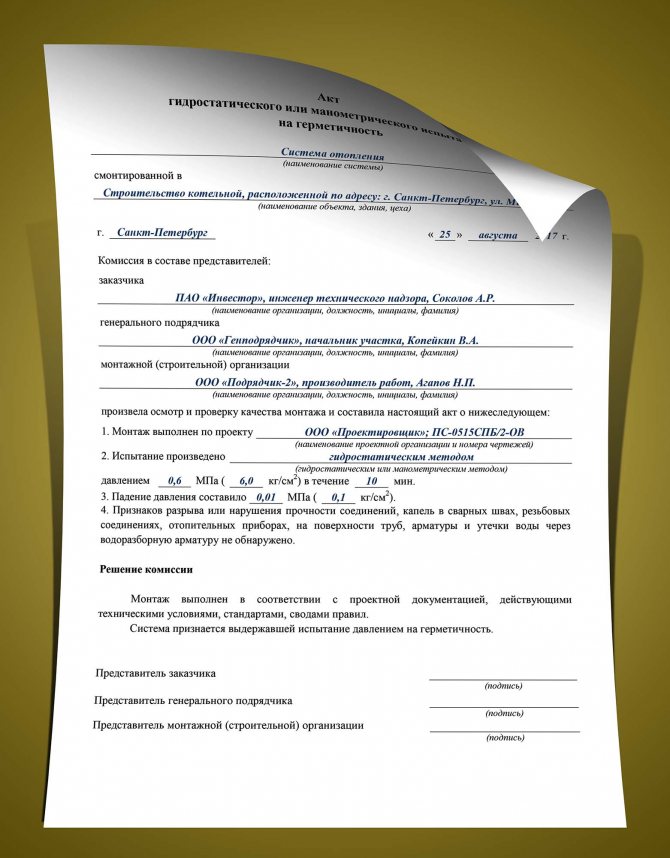

The act of hydraulic testing of the heating and water supply pipelines system

Heating and water supply systems are checked:

- when entering a new engineering communications;

- when reconstructing an existing one;

- during a routine check of the system functioning.

A step-by-step check and its results are recorded in the test report. The system is tested for tightness and strength in two ways, one of which is the hydraulic method: testing by using water with increased load. This method is suitable for indoor and outdoor systems (at temperatures not lower than + 5C). The second method is pneumatic.

Both acceptance testing methods are called pipe pressure testing.

The results of the inspections are recorded in an act, the form of which is established by the Code of Rules for building codes and regulations. The template is presented in Appendix 1 to SANPin "External networks and water supply and sewerage facilities". The presented form of the act is mandatory.

The procedure for drawing up an act:

1. Indication of corporate information: city of compilation and date.

2. Representation of the members of the commission, which carried out pressure testing and acceptance of the pressure pipeline. Three parties become members:

| The company that installed the pipeline |

| Technical supervision representative from the customer |

| Operating company representative |

3. Below is information about the inspected object and a description of the pipeline (length, diameter, material of pipes and joints), the information specified in the working documentation is given, information about the pressure gauge used is given.

4. Completed section on the test and its results.

5. In the "Commission Decision" section, a statement is made that the system is considered strong and sealed and is signed by the members of the commission.

You can download the form for free at the end of the article.

The essence and types of crimping

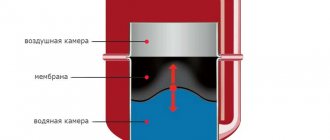

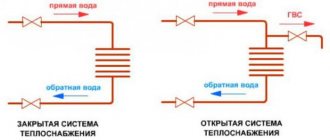

Nowadays, heating is most often carried out by the "water circuit" system. In this case, the heated water circulates through the labors, imparting its thermal energy to the premises. Leaks are unacceptable, the pipeline must be completely sealed for normal operation. Pressing, on the other hand, deliberately creates a volume in the pipe that is greater than normal.

When this is done with air, it is called pneumatic pressing.

When using water, then hydro-pressing. The latter method is considered safer and therefore more popular. For this reason, an example of hydraulic pressing is given as a blank.

When testing, it is recommended not to exceed the pressure inside the pipe by more than 15 MPa. When it comes to raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the normal operating pressure by more than 30%.

In multi-storey buildings, they resort to pneumatic pressing if the pipes are very old and there is a possibility of flooding. But then a level of risk arises and all residents must be notified of the tests being carried out.

The work process is simple, but multi-stage.The algorithm looks like this:

- The necessary materials and equipment are being prepared.

- Draining the liquid that was in the heating system earlier.

- Uploading a new one.

- Create the highest possible test pressure.

- Taking control measurements after 10 minutes.

- Flushing, adjusting the heating system to normal pressure values inside.

- Documentary registration of the work performed, the formation of reports and acts.

But this is how the list of procedures looks only if there are no "thin spots" in the heating system and, accordingly, the tightness in it is not violated. If the pressure drops quickly, does not hold, then the system needs repair work. In such a situation, the specialist performs the necessary actions (pipe replacement, sealing of connections, cleaning, etc.), and then starts pressure testing from the very beginning. Only a heating system that has passed the test is approved for the heating season.

An important nuance! Pressure testing should be carried out after cleaning and flushing the pipes. Otherwise, salt and other deposits inside them can mask possible external damage and breakouts.

If there are deposits of the order of 1 cm on the inner surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the total indicators. For documentary confirmation of cleaning, a special act is also drawn up.

Pneumatic pipeline test certificate

Pneumatic method: diagnostics by inflating the system with high pressure air. The method is often used for outdoor systems if the temperature on the thermometer is less than +5 Celsius.

The procedure for crimping pipes by pneumatic testing is given in the same SanPin, the test report is drawn up in a mandatory form, which is given in Appendix No. 3.

Requirements for the preparation of test documentation:

- Filling in the name of the city and the date of compilation.

- The indication of the members of the commission (as well as in the hydraulic test, three parties are involved).

- Description of the pipeline: length, diameter, material of pipes and joints.

- Information about the pressure value: calculated, to what value the pressure in the pipes was increased, the final pressure, the amount of decrease. The crimping time is indicated.

- In the section "Decision of the Commission", each of its members puts a signature with a decoding, if the pipeline has passed pneumatic diagnostics, and is hermetically sealed and durable.

Important nuances of tests

Actually, the act of conducting hydraulic tests becomes evidence of the tests carried out.

In this case, the checks themselves can be carried out in one of two ways:

- manometric;

- hydrostatic.

The first method of testing involves the use of pressure gauges that record and demonstrate the pressure in the system.

Please note: with the help of manometers, the value of the excess pressure is determined, which allows us to conclude that the test is reliable. The second method checks the real readiness of the system for operation by checking the operability at a pressure 50% higher than the standard

Any test lasts at least 10 minutes, the permissible pressure drop during pressure testing is not more than 0.02 MPa

The second method checks the real readiness of the system for work by checking the operability at a pressure 50% higher than the standard. Any test lasts at least 10 minutes, the permissible pressure drop during pressure testing is not more than 0.02 MPa.

Good to know:

the main document confirming the conduct of tests is the corresponding act.

The act of testing the external and internal sewerage system for the strait

The test report for internal and external sewerage is drawn up as a result of checking the system's performance. It fixes the position of the commission that the system has passed the water spill test, and the design complies with the design documentation, GOSTs and standards.

Diagnostics of the normal functionality of the sewer system is necessary when installing a new facility or after carrying out repairs to an existing system. The health check information is entered into the act. The form is drawn up in the form specified in Appendix "D" to the Code of Rules 73.13330.2012.

The act specifies:

- the name of the system and the object in which it is installed;

- information about the members of the commission. We need representatives of three organizations: the general contractor, the customer and the installation company;

- information about the name of the project is registered;

- the results are entered: the number of simultaneously connected devices, as well as the connection time or water filling per floor (the unnecessary is crossed out);

- in the third paragraph, it is prescribed that no leaks were found at the joints and through the walls. This means the system is usable.

Members of the commission sign for the decision.

Preparation of contract

After the document is drawn up and approved in accordance with all the rules, they begin to draw up a contract for flushing heating batteries. It displays all planned and carried out work. The contract specifies the cost of the full scope of work, the obligations of both parties are described in detail. Here are exact end dates all the work carried out on flushing heating systems. The contract necessarily includes penalties. They will come into force if the deadlines for the completion of the work are not met or if the measures taken to flush the equipment are performed poorly.

An important place in the contract is given to the column, which describes the actions under the responsibility of the customer and the contractor. This point is useful if a conflict has arisen and the parties cannot come to an agreement. The contract describes the sequence of making changes, it says on what conditions it can be terminated.

So your the contract is drawn up and signed by both parties. From this moment it comes into force. The customer can safely start flushing the heating batteries.

Fire test certificates

In the course of testing for the operability and safe operation of fire fighting equipment, several acts are drawn up:

- checking fire hydrants;

- internal water supply diagnostics;

- check for safety of use and compliance with the rules of labor protection of fire escapes.

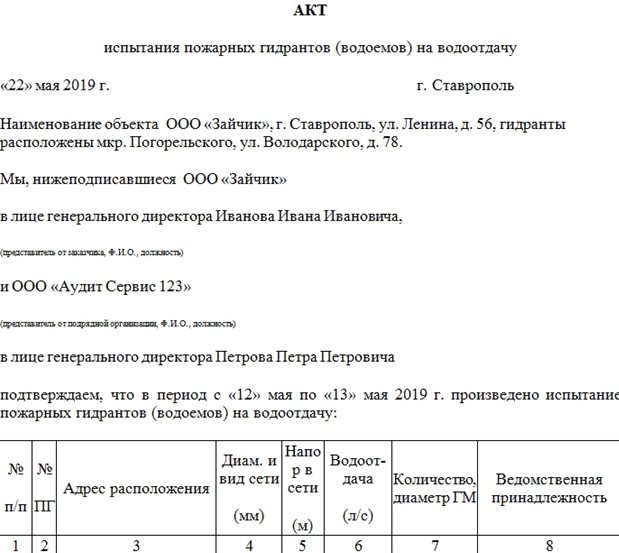

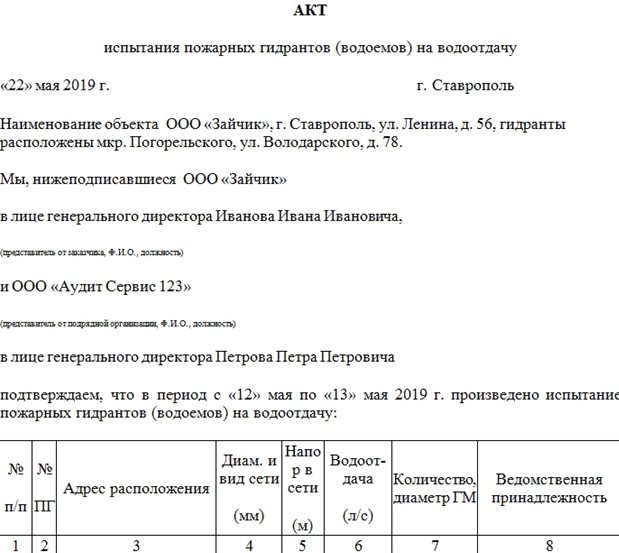

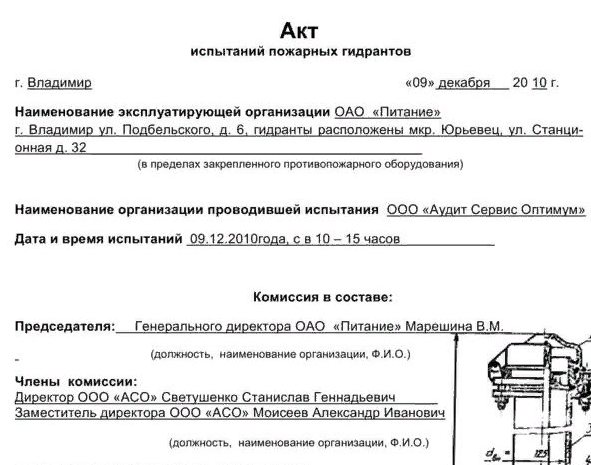

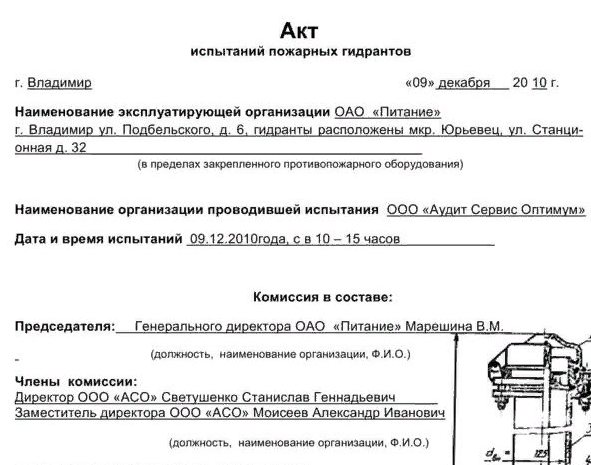

Fire hydrants

Checking the performance of hydrants for water loss is carried out twice a year and, often, is combined with checking the fire-fighting water supply system. Based on the results of the inspection, an act is drawn up, which is signed by the commission. Mandatory members: a representative of the fire inspection and a representative from the organization in which the inspection is taking place. Also, the commission may be entirely composed of company employees.

The act indicates:

- corporate information (information about the company, date and place of compilation);

- the main part describes the members of the commission and the course of the test. Information about hydrants is presented in a tabular form. Indicate the location address, diameter, head, water yield and hydrant ownership;

- in the final part, compliance (or non-compliance) with the requirements of the state of the hydrant is established.

At the end, the act is signed by the authorized members of the commission.

Internal fire-fighting water supply

The act establishes the presence or absence of defects and malfunctions in the fire-fighting water supply system. The check is carried out by the responsible employees of the enterprise. Frequency - at least twice a year, for flammable industries, inspections may be scheduled more often.

Internal fire-fighting water supply (ERW) is a complex system of pipes, sensors, switches. Therefore, it is often checked by an occupational health or fire safety specialist, as well as by persons who are trained in fire safety.

The act is drawn up on letterhead or plain paper, indicating the details. Be sure to register:

- information about the organization and participants of the audit;

- information about the checked object;

- results of inspections;

- recommendations for elimination of defects and malfunctions, if any;

- signatures of responsible persons.

If additional documents are attached to the act, their list and name are indicated.

Fire ladders

Testing of firefighting equipment, including ladders and ladders, is regulated by a special GOST. The inspection can be carried out by organizations that have received permission from the Ministry of Emergencies and have special equipment for this.

The test results are recorded in the test report. The documentation contains standard information about the organization and its details, information about the members of the commission. The main part contains information about the inspected objects (the number of stairs and stepladders, their inventory numbers and belonging to the structural unit), information on the results of inspections (absence or presence of defects). A prescription is given to eliminate the identified malfunctions.

At the end, the act is signed by the members of the commission.

Important nuances of tests

Actually, the act of conducting hydraulic tests becomes evidence of the tests carried out.

In this case, the checks themselves can be carried out in one of two ways:

- manometric;

- hydrostatic.

The first method of testing involves the use of pressure gauges that record and demonstrate the pressure in the system.

Please note: with the help of manometers, the value of the excess pressure is determined, which allows us to conclude that the test is reliable. The second method checks the real readiness of the system for operation by checking the operability at a pressure 50% higher than the standard

Any test lasts at least 10 minutes, the permissible pressure drop during pressure testing is not more than 0.02 MPa

The second method checks the real readiness of the system for work by checking the operability at a pressure 50% higher than the standard. Any test lasts at least 10 minutes, the permissible pressure drop during pressure testing is not more than 0.02 MPa.

Good to know:

the main document confirming the conduct of tests is the corresponding act.

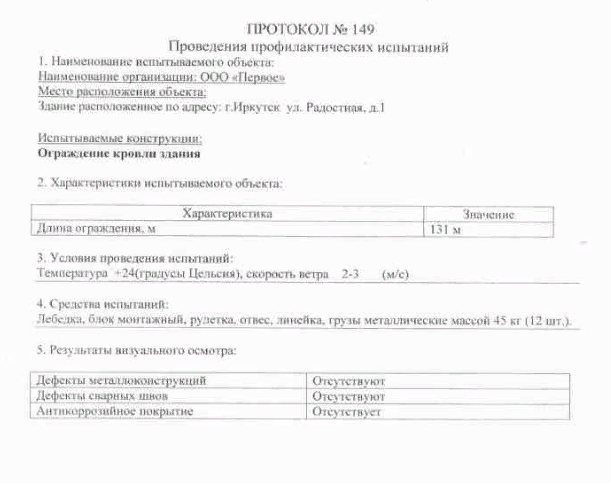

Roof fencing test report

Technical requirements and test methods for roofing are fixed in the same GOST as the standard for fire escapes and stepladders (53254-2009).

Tests are carried out at intervals of five years, integrity checks are carried out every year. The results are formalized by acts.

The conditionally completed act can be divided into three parts:

- General information. This is where information about the test object and the testing organization is entered.

- Information about the check (what manipulations were carried out, what tools were used).

- Inspection results (compliance with GOST, structural integrity and safety).

The agreement of the members of the commission during the test is confirmed by their personal signatures.

Organizations licensed from the Ministry of Emergency Situations have the right to conduct inspections and tests. Defects found must be eliminated.

When work is done

All measures that relate to checking the heating for leaks are performed in such cases:

- During preparation for the heating season;

- When replacing sections of the circuit;

- After the repair of heating devices;

- When the real estate object is put into operation.

The test procedure itself is a confirmation of the tightness of the circuit

.

This procedure includes the following components:

- Supply of air or water at a given pressure to heating pipelines using special equipment;

- Finding deformations in the heating scheme;

- Elimination of violations.

It is worth noting that modern heating schemes allow such events to be carried out with a minimum number of personnel.

Test report for ladders, racks and stepladders

Inspection and testing of racks, ladders and stepladders is carried out at least once every six or twelve months (depending on the test object and the material from which it is made).

Tests and inspections for safe operation can be carried out by specialized organizations from the outside or by a commission specially created at the enterprise. At the same time, its members must be trained, the chairman of the commission is usually an occupational safety or fire safety engineer.

As a result of the diagnosis, the commission draws up an act, it is better to issue it with the date of the inspection. The title of the document, date and place of compilation are indicated in the header. It is also important to indicate the details of the organization, list the members of the commission: their positions and full names.

In the main part, describe the tests of ladders, ladders and racks:

- how many were checked, their inventory numbers, belonging to the workshop and department;

- what load and for how long it was used;

- presence and absence of defects;

- the presence of the affixed inventory number.

As a result of the check, the suitability (or unsuitability) for use is established: they are safe, withstand the intended load, have no defects in connections and fasteners, have no sharp edges and burrs.

The signing of the act by the members of the commission indicates agreement with the results of the audit.

By the way! If after the article you still have questions on how to fill out the forms, contact the duty lawyer of the site.

What is a crimping act, why is it needed

Crimping act - legally binding document

... It is the official proof that:

In the form of the act there are several points

that should be filled out as accurately and completely as possible. Namely:

- the name of the object (house, site) where the check was carried out;

- time and date of crimping;

- test area (e.g. heating main or node)

- devices with which the system was tested;

- results of visual inspection of seams, joints, taps;

- the value of the working pressure and load on the heating system, the duration of the load;

- the values shown by the pressure gauge at the end of the test;

- pressure drop indicators;

- data on the elimination of defects and leaks;

- conclusion on the readiness of the system for operation;

- the signatures of the responsible parties.

The forms of the hydraulic test report may slightly differ from the forms of pneumatic pressure testing. When choosing it, you can be guided by SNiP 3.05.04-85

.

The act must be signed on the same day when the heating system was tested. The act is endorsed by the responsible persons from the organization that conducted the tests, from the organization carrying out technical supervision, and from the managing organization.

A heat supply system is an engineering structure that allows you to observe and maintain the temperature parameters of a building in the winter months. A big misconception is that the heating system can work smoothly without various planned preventive measures. Of the latter, hydraulic tests of the heating system are of great importance.

These activities are carried out to find weak points in the system that can let users down at the most inopportune time. You can see the crimping process in the photo below or in the video in our article.

Important nuances and technical points

What does flushing the heating system imply and what important nuances and technical points should be taken into account in the process of work? The fluid contains chemicals that make it easier to flake off limescale and other metallic deposits formed during use.In this case, the reagent is an alkali or an acidic solution, which will, due to the fact, prevent the formation of rust in the pipeline. The reagent, circulating for a long time in the pipeline and heating radiators, washes away sediments that reduce the performance of heating.

Chemical cleaning

The customer should be aware that the chemicals used in flushing heating systems are very toxic and corrosive. Disposal of such waste into the ordinary sewer is impossible. Therefore, in order to dispose of them, a special container is required. The contractor is obliged to deal with the disposal. Pre-neutralization of alkali with acid or vice versa, depending on what was used in the process.

Unfortunately, the reagents are not able to cope with the sludge deposited on the walls of the pipeline and batteries. Therefore, there is a second way to flush the heating system of a house or apartment.