The principle of operation of the furnace and its scheme

At its core, Buleryan is one of the most practical combinations of a wood-burning stove and a potbelly stove. The principle of operation is based on the physical phenomenon "forced convention".

An opening is provided at the bottom of the structure, into which cold air flow from the room enters. Moving along the pipes that interact directly with the firebox, it quickly heats up and goes outside.

Firewood combustion products are not immediately removed outside, entering another chamber, where they are re-combusted at very high temperatures. Afterburning the air-gas mixture allows you to increase the efficiency up to an immodest 80%.

The high temperature of the convection air at the outlet makes it possible to heat almost any room in terms of volume or a one-story spacious house. Thanks to surface pipes, access to the hot surface of the furnace is limited, which makes its use as safe as possible. Buleryan can be combined with a heating circuit on a liquid heat carrier.

Learn more about the technical characteristics of wood-burning stoves

Furnace advantages

Below are the main functions and advantages of the Buleryan oven:

- minimum time for heating the room;

- work does not depend on communications;

- the heating process occurs evenly;

- any type of solid fuel is suitable;

- saving;

- high efficiency;

- the stove is capable of working up to twelve hours on one armful of firewood (or other combustible materials).

Interesting fact: Canada is considered the birthplace of the Buleryan stove, where it was created by famous power engineers.

Which pipe is suitable for the chimney

Before direct installation work, you should decide from which pipe the chimney will be made

It should be remembered that Buleryan is a long-burning stove, therefore it is important for it to select the highest quality elements. Otherwise, in the process of using the structure, you can expect that there will be constant smoke in the house.

If the work is done by hand, then usually the choice is made independently.

The most popular chimney elements are:

Ceramic products that are ideal for this particular type of oven. In appearance, the chimney looks like a sandwich pipe. Ceramics are characterized by excellent resistance to high temperatures or temperature drops. Also, it is this material that reduces the likelihood of condensation on the walls of the structure.

It will be quite simple to install such a pipe with your own hands, but it is important not to damage it during this work. The chimney made of stainless steel is also well suited for buleryan. However, such a design, in any case, needs additional insulation.

During operation, very often the metal is deformed from high temperatures or under the influence of other factors. The installation of such a pipe is considered simple, since it is already initially sold complete with various fittings, tees and other necessary parts. The asbestos pipe is not considered suitable for the selected stove. It initially needs high-quality and full-fledged insulation, however, even such work cannot guarantee that condensation will not form on the inner walls. Its constant presence will negatively affect the service life of the entire stove as a whole. In addition, asbestos is distinguished by an unpleasant and pungent odor, which will be present in the room as well. Brick is considered a good choice for a chimney. It is time-tested and also considered a traditional material for the formation of stoves and fireplaces.However, it is important to remember that the structure from it will not be mobile, so it will not be possible to transfer it from one place to another in the room.

When choosing a material, it is important to take into account that the work will be done by hand, and you should also take into account the location of the furnace itself, the frequency of its use and other important points.

Oven advantages and disadvantages

The advantageous characteristics of the oven are as follows:

- It quickly and evenly heats the room.

- It is easy to install, operate and maintain.

- High efficiency - 85%.

- Minimum consumption of heating material.

- The longest period of work on one fuel tab.

- Universal purpose. The stove can be used for any premises and greenhouses.

No matter how good the advantages of the Buleryan heating stove are, it also has disadvantages:

- This type of stove can only operate on one type of fuel - wood.

- The model needs to reduce the fire hazard, for which it is necessary to insulate the chimney pipe.

- Burning dust on the oven body causes a very unpleasant odor.

- When the furnace is fired, caustic condensate collects in the chimney, which must be removed regularly.

Condensation can be reduced by using only dry wood.

As already mentioned, the Burelyan boiler works only on wood fuel, but this type can also include peat and wood briquettes, as well as pellets. It is preferable to use coarse fuel, even massive lumps. If the smoke damper is correctly adjusted, the fuel will burn slowly, giving off heat and not requiring additional refills.

The Buleryan long-burning stove is considered the most profitable option for space heating. The design of the stove is very simple, and if you show the desire, then it can be made in a handicraft way.

Buleryan furnace device

The device of the furnace determines the principle of operation of the Buleryan heater, which is assembled from the following elements:

Buleryan furnace device

- Arc-bent pipes that make up the body. Moreover, inside the body, at the very branch pipe for the removal of combustion products, there is a U-shaped sump that separates the primary combustion chamber from the secondary.

- Double-layer wall that works as an additional convector. In addition, a branch pipe of the chimney is also built into the wall.

- The front wall, into which the door is cut for loading fuel into the combustion chamber, the blower pipe with a throttle valve and the ash pan (container for collecting ash).

Moreover, it does not matter at all whether the Buleryan stove is assembled by hand or made at the factory - the effect of using such a heating device will surpass all expectations. That is why the most economical homeowners strive to make such a stove exclusively with their own hands.

And further in the text we will acquaint you with the process of assembling the stove, and with the stage of installing the heater in the room.

That is why the most economical homeowners strive to make such a stove exclusively with their own hands. And further in the text, we will acquaint you with the process of assembling the stove, and with the stage of installing the heater in the room.

https://youtube.com/watch?v=-HFG5zFEgqM

Installation work

If everything is prepared, the drawings have been studied, then you can start working. A step-by-step process for making a furnace device as follows:

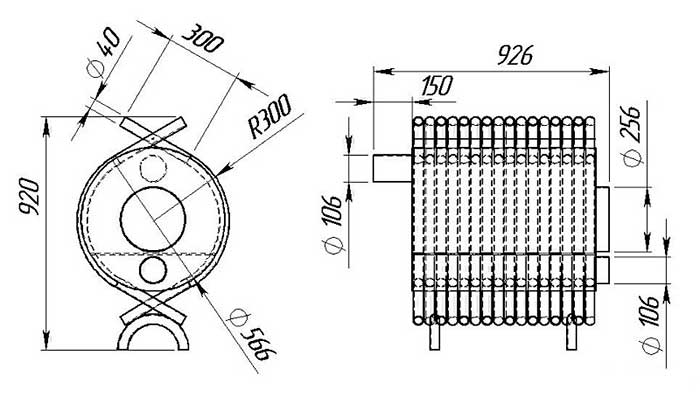

- At the very beginning, you need to assemble the frame of the future stove. It will be made of intertwined curved pipes that form a kind of air heater, and the firebox will also be located there. To do this, use a pipe bender to bend the pipes so that they have a radius of curvature of about 225 mm and a length of 120 mm.

- Then you need to weld the elements to each other with metal strips to get a fairly stable and reliable base.The structure must be solid, without any holes and holes, so that smoke does not penetrate into the room where the device is installed.

- At the next stage, they begin to manufacture the afterburner. The easiest way to assemble it is from sheet metal. It is necessary to cut out the partitions and mount small recesses in them for the air heat exchanger.

- Now it is required to weld 2 baffles ¼ of the length to the pipe using a manual welding machine.

- Then the injectors must be installed in the first 2 pipes. The waste products of pyrolysis will be delivered to this place. It is necessary to check all welds for leaks and, if necessary, trowel them.

- 2 elements are cut from sheet iron, which will play the role of the back and front walls. In one of the parts, a small hole is made for the chimney.

- A hole is also cut on the second element, where the door is attached. It can be made from a pipe with a diameter of at least 350 mm. The design must be made two-layer, in which case one part will be located inside the loading chamber, and the second will cover the firebox from the outside.

- After the door is prepared, a throttle hole is made in it. The choke itself can be mounted from a piece of pipe with a rotating damper, while its dimensions must completely overlap the lumen. Also, a reliable lock is installed on the structure.

Structure

Diagram of Buleryan's device for heating a house

As can be seen from the figure, Buleryan is a structure of several bent pipes (usually more than six) (1), welded in such a way that a combustion chamber (2) and (6) is formed inside. To divide the combustion chamber into two zones, a special partition is welded into the structure. Firewood is first burned in the primary chamber (6), and then burned out in the secondary chamber (2), while ensuring maximum efficiency. Air constantly circulates through the pipes from bottom to top, ensuring optimal heat exchange in the room. Firewood and briquettes are mainly used as fuel for the stove. For laying firewood and extracting ash, there is a door (11) on the front wall of the stove, which, thanks to the seals and the special design of the lock (10), is able to close hermetically. A blower (8) is welded to the door to regulate the air supply to the primary chamber. To supply air to the secondary chamber, there are injectors on the pipes (14). Ash is collected in an ash pan (7). To regulate the combustion process, there are draft regulators (9) on the door and on the exhaust pipe located on the rear wall.

For normal operation of buleryan and less accumulation of soot in the chimney, it must be insulated.

Buleryan do it yourself

Since the main tool in the work will be the welding machine, check its operability. It will take a lot of time, and if you are an inexperienced welder and have never held welding in your hands before, you should not take on the job, in this case there is a high probability of wasting time. Practice before starting on the training seams, if all is well, you can start.

Tools for work:

- Welding machine.

- Scissors for metal.

- Bulgarian.

- Small hammer.

- Tube bending tool.

Materials (edit) for work:

- Thick-walled pipes.

- Metal sheet - thickness not less than 5 mm.

- Corner 25 × 25 mm.

We define space for the oven by dimensions

It is important to observe safety precautions, it is on the basis of it that we will determine the place for the future device. The distance from walls and ceilings should not be less than 80 centimeters. Dimensions are calculated based on the square of the room, the smaller the room, the smaller the stove will be. Otherwise, there are no contraindications to the place, the main thing is that there are no flammable materials in the vicinity.

For the organization of heating a country house, you can also make a Butakov stove. Details here:

Recommendations for use

- The chimney pipe for your stove should be assembled in the opposite direction to the movement of the exhaust gases, which practically eliminates the likelihood of leakage through it during the operation of wood tar. In this case, the latter will return to the chimney and burn out in it.

- Observe the fire safety requirements when arranging the installation site of the stove and the surrounding space.

- Be sure to provide for the possibility of simplified installation / dismantling of the chimney for regular cleaning from tar and soot deposited on the walls.

- The "Buleryan" stove must be configured according to your preferences.

- Remember to periodically inspect the top of the chimney to remove any resin build-up that appears.

- Empirically, the optimal furnace mode is selected, which is characterized by the maximum burning time and the minimum degree of flue gas pipe clogging. To operate the unit in the specified mode, the channel should be cleaned at least twice a season.

- Before placing the wood in the firebox, it is advisable to pre-dry it over the stove.

- In addition to logs, in order to save money, it is recommended to add briquettes made of sawdust and wood chips to the firebox.

Design features and principle of operation

Buller-breneran differs from the usual "potbelly stove" as follows:

- The furnace is surrounded by curved vertical pipes in which the air is heated. Thanks to this solution, the stove heats the room very efficiently, while its body remains relatively cold.

- The blower is made in the form of a pipe cut into the furnace door and is equipped with a damper (choke), through which the power of the furnace can be controlled.

- The upper quarter of the firebox is separated by a plate with holes. This space plays the role of a combustion chamber for wood (pyrolysis) gas, which is formed during the high-temperature decomposition of organic molecules.

Axonometric section and specification

Note that Buleryan and similar furnaces are not gas-generating (pyrolysis) in the full sense of the word. In a real pyrolysis heat generator, higher temperatures are created, and air is forced on. The creators of the buller sought to simplify its design, as a result of which the pyrolysis in it proceeds sluggishly and not in full. This mode is commonly referred to as partial gas generation.

The above-mentioned partition does not reach the front wall of the furnace for 20–25% of the length of the furnace. Due to this, the main flow of flue gases on the way to the afterburner is deflected towards the front of the furnace. Thus, Buleryan belongs to the front-burning furnaces, which are superior to the classic ones in ease of control.

The flue duct begins with a horizontal section having a length of 0.8–1 m. This element, as it were, holds the draft, allowing most of the flue gases to burn out in the firebox.

The gate damper, installed at the beginning of the vertical section of the chimney, has a cut-out measuring 25% of the entire area, due to which it can under no circumstances be closed tightly. Thus, the risk of carbon monoxide poisoning of people is completely eliminated.

The operating mode of the unit is regulated by means of a slide gate:

- when firing up (flame mode), it opens completely;

- when switching to the mode of long burning (smoldering) - it closes.

The heat in the firebox calms down a little, while the gases in the chimney cool down and its work resumes. The draft is restored, the heat in the firebox increases again, the formation of flue gases becomes more intense, they flash again in the economizer and the firebox dies out again. In the long burning mode, this cycle repeats constantly.

The main positive design parameters

https://youtube.com/watch?v=zKA7kgImfnY

This wood-burning stove has many advantages:

- the installation of equipment is considered simple and quick, so you can even implement all stages with your own hands, which significantly reduces the cost of this process;

- the heat transfer rate is very high, therefore Buleryan is an effective and reliable equipment;

- during the operation of the structure, oxygen is not burned in the premises;

- the chimney is created from sections of the pipe that must be suitable for this issue, and the connections between them must be tight and strong;

- this stove can be used not only in a country house or in a bathhouse, but even in a private house, replacing full-fledged heating with various systems connected to central communication highways.

The disadvantages include the need for the constant presence of a person who must maintain combustion with fuel

Also, although the furnace is created quite simply, it is important to know what elements it consists of, while it is important to choose them correctly and correctly so that they perfectly cope with the tasks set, and also serve for a very long time, in accordance with the tasks set. Especially a lot of attention must be paid to the chimney, since if it is selected and installed incorrectly, it can be expected that gases from combustion will penetrate into the living quarters.

What you need to work

Before you start making, you need to prepare everything you need.

Tools:

- welding installation;

- Bulgarian;

- electric drill;

- set of drills;

- clamps.

Welding machine

Materials:

- heat-resistant steel sheet (100x200 centimeters);

- steel sheet (40x70 centimeters);

- 4-meter pipe (diameter - 11 centimeters);

- profiled pipe (about ten meters);

- loops;

- pens;

- slight constipation;

- pieces of frame and pipes (30-35 centimeters) in reserve.

Heat-resistant boiler steel is an important element. The fact is that this material is able to withstand very high temperatures for a long time. This ensures reliable and long-term operation of the unit.

Heat Resistant Boiler Steel

If you do not have the specified material at home, then be sure to purchase it at a hardware store.

Interesting article: finishing the stove with artificial stone

Getting Started

So, the theoretical part is over, so you can already start manufacturing the heating device.

Take 8 equal pieces of metal pipe and bend them in the middle with a pipe bender, making an angle of about 80 degrees. To create a medium-sized furnace, pipes with a length of 1-1.5 m will be enough.

The prepared pipes are welded together into a single structure.

This structure will also serve as a frame. Therefore, metal sheets are welded to the pipes, which will become the furnace body. The metal plate will become a tray for the firebox and firewood will burn on it. To make it easier to care for the stove, you can weld a pallet of two plates at an angle.

Buleryan furnace tubes

The next stage is the preparation of the front and rear walls of the buleryan. First you need to make a pattern from thick cardboard, based on the resulting parameters of the stove. According to this template, walls are cut from a metal sheet. In the front part, you need to make a hole for the door. Its diameter is usually equal to the diameter of the furnace divided by two. It is better to shift the center of the window slightly below the buleryan axis. Around the perimeter of the window from the outside, a ring should be welded from a narrow metal strip.

Pipes in the buleryan oven

The back wall is done in the same way, only the hole in it will correspond to the diameter of the branch pipe and be located in the upper part.

We turn to the manufacture of doors for the oven. It is made from the same metal cut to fit the diameter of the front hole. To improve the tightness, it is advisable to weld a narrow metal strip onto this workpiece along the entire perimeter.Also, it is imperative to make a hole in the door and weld a blower with a valve to it.

The stage of creating a Buleryan oven with your own hands

To ensure safety of use, a semicircle made of metal sheet should be welded to the inner surface of the door, which serves as a heat-reflecting screen.

The hinges are welded to the outer wall and the door can already be fixed.

A chimney from a T-shaped pipe with a diameter of 110 mm is mounted to the hole on the rear wall. A cutout must be made in the pipe for connecting a branch with a valve.

Buleryan stoves serial versions

You can also DIY this valve. A metal circle must be cut out along the inner diameter of the bend, and a hole must be drilled in the bend itself so that the valve axis is inserted horizontally. All these parts are assembled and welded. A piece of rod is fixed outside, which will serve as a handle. You can put a wooden block on it for convenience.

Now we make legs from pieces of pipes and the oven can be tested.

Ready-made Buleryan oven made by yourself

In making buleryan with your own hands, as well as in another responsible business, you just need to adhere to the technology and the created product will certainly delight you with excellent work.

Buleryan oven review

The principle of Buleryan's work

In fact, Buleryan is an ordinary stove, but the walls of this stove are so cunning that even full-size Russian stoves cannot compete with it. After all, the body of the Buleryan furnace plays the role of a forced convector through which all the air in the room is pumped. Moreover, convection is carried out in a natural way - due to the different densities of heated and cold air.

Other advantages of such a heating device include, firstly, the widespread drawings of the Buleryan stove - any master who knows how to search for information on the Internet can make this stove with his own hands. Secondly, the available structural material - the furnace is assembled from pipes and sheet metal. And, thirdly, a relatively simple assembly technology - the parts cut according to the drawings are connected by conventional welding.

Well, the very principle of operation of the furnace is implemented as follows:

Sectional view of the Buleryan furnace

- Any solid fuel is oxidized in the combustion chamber of the heater: from wood to peat.

- The energy released in the process of fuel oxidation is used to warm up the body.

- The heated tube housing draws in cold air drawn from the floor.

- Then the air passes through the tubular wall of the furnace, warming up to a sufficiently high temperature, and exits through the outlet branches, spreading throughout the heated room.

- The cooled air descends to the floor level, and the whole cycle repeats from the very beginning.

Moreover, both the home-made Buleryan and the "factory" oven operate on the principle of natural convection. There are no fans or other artificial generators of supply and exhaust forces in the oven. Convection is carried out by heating the air in the tubular wall of the furnace.

Accordingly, the exhaust force is created by the movement of air masses upward (from the pipe), and the supply force is created by the vacuum created by the warm air "shooting" from the pipe. And by regulating the process of fuel combustion in the furnace, you can increase or decrease the volume of circulation of the coolant (air) in the room.

Moreover, a typical Buleryan operates in two modes - the warm-up phase, when the case warms up, and the heat transfer phase, when the surrounding space warms up. And the choice of a specific mode is determined by the position of the plug on the chimney (chimney).

Useful tips for use

"Incorrect" installation of chimneys is due to the need to protect the structure from the resin that is formed as a result of wood combustion. If this moment is not foreseen, then the resin will flow out of the stove, and with this installation it will remain in the chimney and gradually burn out.

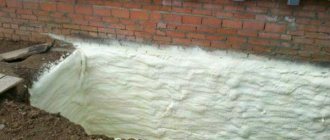

At the end of the assembly, the Buleryan stove is installed on a flat and fire-resistant base and connected to the chimney. In this case, it is necessary to comply with fire safety rules.

Clogging with resin for the Buleryan oven is almost inevitable. Over time, resinous layers build up and clog the device. This is reflected in a noticeable reduction in the efficiency of its work, a decrease in thrust, problems with the free movement of the gate. So it's time to start cleaning the oven.

A lighter version of such cleaning consists in heating the device with aspen wood. Unfortunately, the practical benefits of such a measure are small and short-lived.

The best way to eliminate resin contamination is by burning. To do this, the furnace is strongly melted with an open ash pan, in fact, igniting all the channels. As a result, the resinous deposits are burned.

Some craftsmen use oxygen to burn the furnace, bringing the nozzle of the cylinder to the opening of the ash pan. This is an extremely dangerous operation that violates fire safety rules. Careless manipulation of the oxygen cylinder near open flames may result in an explosion.

As fuel for the Buleryan stove, you can use not only firewood, but also wood waste (shavings) or special briquettes. An important condition is the low moisture content of the fuel. The less moisture, the less resin is formed inside the stove, and the less often it will need to be cleaned.

During the operation of the furnace, it is necessary to select such a mode of operation in order to obtain maximum heat with minimum formation of resin. If the best option is found, cleaning will need to be performed only a couple of times during the heating season.

Making such a device on your own is not an easy task. But the result is a highly efficient and convenient heater. Experts note that with proper installation and observance of the operating conditions, the service life of the Buleryan furnace is practically unlimited.