In a private house, the heating system is different from that installed in multi-apartment buildings. It may sound ridiculous, but the systems in private homes are much more complex in design. After all, they can include a warm floor, and radiators with a large number of connections. The heating system is pressurized with air only after final installation. In order to do this work, you need to use special equipment - automatic or manual. If there is one, then there will be no difficulties. But when pumping air or liquid into the system, it is necessary to take into account the fact that the time intervals are specified in the standards.

Crimping - what is it?

Pressure testing of the heating system with air in a private house is needed in order to check the tightness of all connections. Once you have done all the installation work, you need to carry out a test and commissioning. But if leaks are found, use of the system is prohibited. Pressure testing is a test of a heating system by injecting air or liquid into it under pressure, which will exceed the working one by about two times.

In private households, you need to carefully check all the contours of radiators, underfloor heating, as well as connections. Be sure to pay due attention to boilers, electric pumps, water heating boilers, if any, in the design of the system. The requirements for crimping will be discussed later in our article.

With the help of pressure testing, you can determine the ability of all elements and materials to withstand high pressure for a long time. In the event that the tests have ended successfully, you can start operating the equipment. If not, then the defects are eliminated and re-diagnosed.

Pressure testing of pipelines with air SNIP - Security portal

Pressure testing of a pipeline is a technological operation performed in a relatively small isolated section of a pipeline. This section is specially tested by applying increased pressure, close in value to the maximum permissible. Pressure testing of pipelines allows you to verify the integrity of the line, the quality of installation work and the installation of fittings.

Pressure testing is a necessary and important operation to identify weak points in the assembled pipeline

Air pressure testing of the heating system according to SNiP

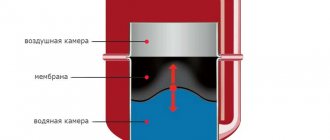

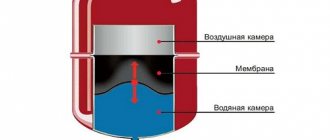

There are hundreds of connections in any heating system. It is a connection of pipes and radiators, ball valves, circulation pumps and expansion tanks. In sectional batteries, the weak point is the connection of the sections to each other through a gasket; in the presence of warm floors, additional threaded connections appear between the boiler and the collector and between the collector and the underfloor heating system.

All these connections are checked after installation, that is, the heating system is pressurized with air SNiP clearly and unambiguously stipulates the norms for pressing heating systems. Technically, pressure testing is carried out by creating a high pressure of air or water in the system to detect defects and leaks of the coolant.

Pressurizing the system and removing air from the circuit

After completing the installation work to create the heating system, it is disconnected from the boiler, the hermetic expansion tanks are turned off, and in open systems the expansion tanks are sealed. This is the preparation for checking the heating circuit for its operability. The operation of testing a heating system with high pressure is called pressure testing.It can be carried out both with air and with the help of hydraulic pumps with water.

According to the norms of SNiP, pressure testing is mandatory:

- when putting a new system into operation;

- after replacing system elements (risers, batteries, pipes);

- in preparation for the heating season.

In accordance with the rules of SNiP, a crimping act is drawn up. In newly installed circuits, air pressure testing of the house heating system is most often performed. It is believed that after pressure testing, if no defects have been identified that require elimination, then the system is completely ready for operation. After completing the system tests, filling the system with water usually begins. It is very likely that another problem will arise - it will be necessary to ensure the release of air from the heating system, which will inevitably disrupt the operation of the entire circuit.

Source: https://sivcomsks.com/opressovka-truboprovodov-vozduhom-snip/

When is the crimping done?

All work is carried out strictly in accordance with SNIP-41-01-2003, which clearly indicates when, in what ways, the heating system is pressurized. In the same document you will find everything about the requirements for ventilation and air conditioning. There are three cases where a test is required:

- Primary pressure testing - performed immediately after the completion of installation work. Diagnostics is performed before the pipes are embedded in the grooves. The underfloor heating system must also be accessible - it must not be poured before crimping. It should be noted that it is allowed to re-diagnose all contours after making the screed and sealing. In this case, you can get rid of the trouble.

- Periodic hydrotesting should be carried out every year before the start of the heating season and immediately after it. The purpose of the test is to pre-prepare the heating system for operation.

- An extraordinary test should be performed after each repair or long equipment downtime. Diagnostics is especially important in cases where water is drained from the system.

In all these cases, pressure testing will be a means that will allow you to diagnose the system and identify all problem areas in the equipment in advance. Indeed, in the event that a leak appears, heating will not be very effective in the cold season.

Pressing the heating system at home: why is it needed and how to carry it out yourself

- Construction and repair

- Heating

1 star 2 stars 3 stars 4 stars 5 stars We will tell you when crimping is needed, what tools are needed and give step-by-step instructions on how to carry it out.

ShutterStock

Pressure testing of a home heating system is a method of testing a pipeline with an excess pressure exceeding the operating pressure. This method is suitable for complex multi-component systems. In a country house, the owners have to think about it on their own. Here's how to do it.

Features of crimping

What is crimping

Necessary equipment

Stages of work

What is crimping

Pressing a home heating system is a test of the pipeline for strength and tightness with liquid or air. If the pipes can withstand this, then they are serviceable for a year. Therefore, the check is carried out every year, before the heating season and after emergency, repair or service work. But at the same time, it should not be carried out too often unnecessarily.

SNiP for testing recommends using a pressure 1.5 times higher than the working one. For example, for a heating system of a country house in which the value usually does not exceed 2-3 atmospheres, the test can be carried out by increasing it to 3-4.5 atmospheres.

When and why you need to check

In general, the procedure is carried out only in a few cases:

- immediately after the installation of the heating system;

- if some elements of the system were subjected to serious mechanical stress;

- before the start of the heating season, when the system has been shut down for a long time.

Necessary equipment

In professional conditions, when pressure testing of the heating system in an apartment building is carried out, special electric pressure pumps are always used.

For a private home, you can buy a small compressor. There is only one requirement for the compressor: the pressure it builds up must be sufficient for testing. Almost all models are suitable for cottage systems, since even domestic compressors usually provide an operating value of 6-8 atmospheres. In this regard, manual crimpers are good because they allow you to accurately set the desired value. Too high a load is dangerous as it can damage the pipeline. If no leak occurs during the test, then such equipment is considered to be serviceable and ready for operation.

In this case, the pipeline must be equipped with a membrane expansion tank, which serves as a compensator for pressure surges and water shocks.

In addition to a pump to pressurize the heating system, a manual pressure gauge will be required to monitor the increase in values and prevent them from excessive growth. You can use the readings of the safety group pressure gauge (a set of several devices responsible for the safe operation of the pipeline). The main thing is that the pressure gauge is in good working order.

Work rules

Now let's talk about what the requirements are for the procedure for pressing the heating system with air. All diagnostic work must be carried out in the warm season. It is possible to test heating at subzero temperatures, but only in emergency cases. At the same time, it is necessary to maintain the temperature inside the room above +5 degrees.

The tests can be considered successful if:

- During the diagnostics, you did not find any fogging of the seams, leaks in radiators, pipes, boilers, fittings, and other devices.

- Decrease in pressure for 5 minutes of diagnostics is no more than 0.2 bar.

- In the case of panel heating, the pressure on the pressure gauge did not drop by more than 0.1 bar in 15 minutes.

- A drop of no more than 0.5 bar in 10 minutes is allowed in hot water systems using metal pipes.

- As for plastic pipes, a fall is allowed within half an hour, but not more than 0.6 bar. During the next two hours, the drop should not exceed 0.2 bar.

- If tests are carried out with compressed air of panel and steam heating, the pressure drop in the first 5 minutes by more than 0.1 bar is not allowed.

What is needed for crimping

First, you need to create a commission for the verification of all devices. It is necessary to verify the equipment used during the pressure testing and all household meters and systems. Before the check, a package of completed documentation is drawn up. In the course of the operation, all its details are recorded in acts.

It is necessary to check the insulation of the water supply and heating mains. If the insulation is outdated and has lost its properties, it must be replaced. Also, do not forget about the insulation of external communications.

The crimping operation requires the presence of members of the energy saving organization. All personnel involved in the work must be instructed about the safety rules and sign the appropriate log.

The pressure in the system does not need to be raised above 45 kg / cm2. The pressure build-up is carried out by means of a compressor. Before that, it is necessary to check all the shut-off valves and carry out dismantling with flushing, the most clogged places of the system.

Diagnostic methods

In total, according to SNIP-41-01-2003, two methods can be distinguished by which it is allowed to carry out tests of the heating system:

- The water test is the main method by which all circuits are tested.In this case, water must be pumped into the lower part of the pipes through the tap. It is allowed to pump liquid both with an automatic and a manual pump-pressure operator. The advantage of this method is that it is very easy to carry out all the work, and the efficiency of detecting leaks at altitude. The fact is that traces of liquid will immediately appear on the pipes.

- Testing with air is not a very effective method as it is difficult to detect leaks. But it is allowed to use this technique at negative temperatures - the air will not freeze. A compressor is used to force air into the system. It is connected with an adapter to the pipeline. In order to find a leak, you need to listen. Once you find an approximate location for the leak, use a soap solution.

Rules for crimping SNiP

The norms for crimping the heating system are described in documents such as SNiP 41-01-2003, and also 05.03.01-85.

Air conditioning, ventilation and heating - SNiP 41-01-2003

It is possible to carry out hydraulic checks of water heating systems only at positive temperatures in the premises of the house. In addition, they must withstand a water pressure of at least 0.6 MPa without damage to the tightness and destruction.

During the test, the pressure value should not be higher than the limit for the heating devices, pipelines and fittings installed in the system.

Internal sanitary systems - 3.05.01–85

According to this SNiP rule, it is necessary to check the water heat supply and heating systems with the expansion vessels and boilers by hydrostatic pressureequal to 1.5 working, but not less than 0.2 MPa in the lower part of the system.

The heating network is considered to have passed the test if it holds for 5 minutes under test pressure and does not fall by more than 0.02 MPa. In addition, there should be no leaks in heating equipment, welds, fittings, threaded connections and pipes.

Test pressure

According to SNIP 3-05-01-85, which was replaced in 2003, pressure testing must be carried out in accordance with the rules. When carrying out work in apartment buildings, it is necessary that:

- The pressure was more than 1 MPa (this is 10 bar) - for hot water supply systems and heating circuits with heaters.

- At least 10 bar for panel and convector heating systems.

- At least 6 bar for circuits with pressed steel or cast iron radiators.

- The pressure for hot water supply must be higher than the working one and from above another 5 bar (but cannot exceed 10 bar).

If panel heating and heat exchangers are used, the head should not have a pressure greater than the maximum allowable for the devices. In the event that you are conducting an air test in a steam or panel heating, you need to check the pipes that fit the ventilation equipment. The air must have a pressure of 1 bar.

Technical requirements

In order to fully comply with the technical requirements, only a certified employee should carry out the pressure testing of the heating system. The employee must have special equipment. SNiP regulates the normalized pressure level. The recommended parameters should be 1.5 times higher than the working ones, but at the same time not lower than 0.6 MPa. The technical rules of operating heating networks assume that the supply pressure should be 1.25 higher than the working pressure and not lower than 0.2 MPa.

The normal operating pressure of heaters in a private house up to three floors is no more than 2 atm. In houses with five floors, the operating pressure is 3–6 atm. In buildings from 8 floors and above, the operating pressure is from 7 to 10 atm. The pressure to be tested must be brought to the maximum level. This parameter is often associated with the characteristics of the constituent parts of the heating system. Pipes, radiators, fittings in multi-storey buildings are in a worse condition than the same parts in a private house.

If the work is carried out by professionals, specialists are guided by a number of regulatory documents, namely:

- SNiP 41-01-2003 "Heaters, ventilation systems, air conditioning systems";

- SNiP 3.05.01-85 "Sanitary technical equipment inside buildings".

And also there are technical rules governing the operation of thermal power plants, which are approved by the Order of the Ministry of Energy of the Russian Federation.

According to these rules, work can be carried out once every 5-7 years with existing communications. If these works are not performed, the efficiency of the heating system will decrease.

Plates and deposits often appear on the pipes, which almost halve the permeability. The circulation quality of the media also decreases. If the requirements specified in the documents are not met, then the usual preparation for the heating season can turn into an emergency situation, which will entail a lot of problems. If a situation arises in cold conditions, then the heating system should be defrost, which will entail a complete or partial replacement of pipes.

Test procedure

According to the rules for the technical operation of thermal devices, tests should be carried out in the following sequence:

- The circuit is filled with water using a pressure tester. The temperature of the liquid should be around 45 degrees. The air must be vented through special vents.

- Further, water is pumped with a pressure for at least 10 minutes. During this time, you need to visually inspect all the seams, pipe joints, the connection of all equipment, fittings.

- After that, the pressure can be brought to maximum pressure and held for 10 minutes. If the pipes are made of polymeric materials, then the tests should be carried out for at least half an hour.

- In the event that the pressure does not change during the tests, then it can be judged that there are no defects at all.

You can complete the tests and start directly operating the equipment.

What test tool is needed?

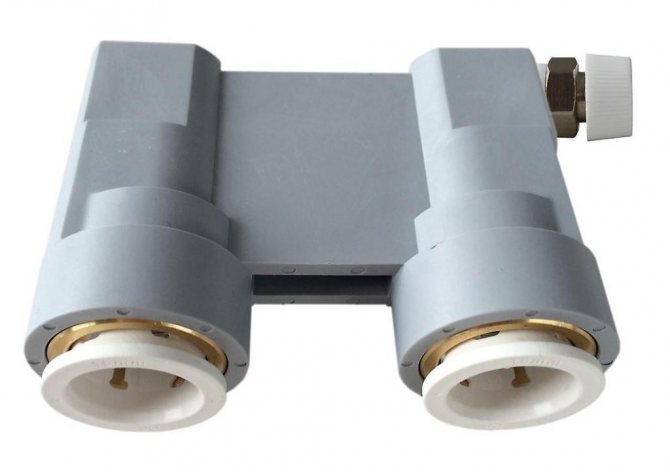

Now let's talk about what kind of crimping equipment is used during the work. To perform hydraulic tests, you need to use a special design of pumps (they are called pressure operators). You can find two modifications - electric and manual.

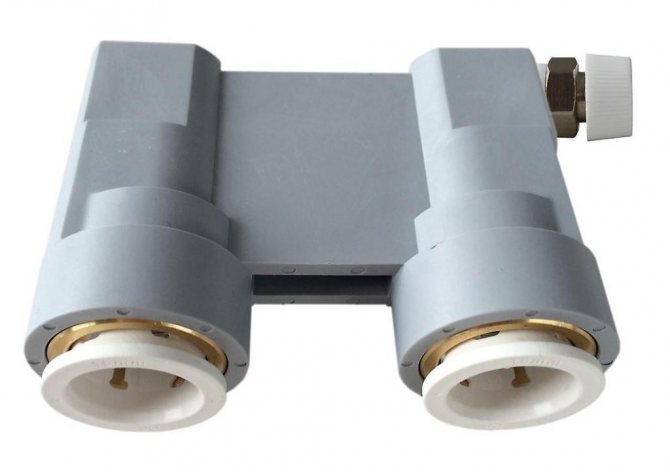

Hand pumps are a rectangular cuvette, water is poured into it, which is then pumped into the heating system. A plunger-type pump is placed on its side, with a handle on top of it. It is with its help that the pump plunger is set in motion. There are pressure gauges on the body, with their help the pressure of the liquid pumped into the system is monitored. One shut-off valve allows water to be cut off after pumping into the pipes is complete. The second valve allows the liquid to be drained from the tank.

Plunger pumps work in exactly the same way as simple piston pumps that are used to inflate bicycle or car tubes. But there is also a difference - in the design of the plunger pump there is a cylindrical steel piston, which moves in the housing with a minimum clearance. It is with the help of this that it turns out to pump liquid into the heating system with a pressure of up to 60 bar.

The main disadvantage of manual mechanisms is that it takes a long time to carry out crimping work. Moreover, the test time depends on the length of the heating circuits. Sometimes it takes several hours to fill it completely. Imagine how much energy you will spend to pull the handle.

It is with the aim of reducing costs and automating the process that electric pumps are used by specialists. They work according to the same principle as manual ones, only muscle strength is replaced by an electric drive. The great thing about automatic systems is that you can set the required level of injection pressure. As soon as it is reached, all equipment is turned off.

Automatic devices can pump liquid at a pressure of 40-100 bar.But there are also industrial designs that are capable of creating pressures up to 1000 bar.

Please note that the Ministry of Energy establishes requirements according to which it is necessary to use pressure gauges for control only of the spring type, their accuracy class must be 1.5. The circumference of the body must be more than 160 mm. The scale must be designed to measure the pressure, the value of which is not less than 4/3 of the minimum, the scale is less than 0.1 bar.

Varieties of testing and pressure testing of the system

As we were able to find out, when the tightness of the heating system is violated, heat transfer is significantly reduced. And the most important thing is that the working fluid is lost and it has to be constantly added. The norms that we talked about above must be taken into account when servicing heating systems by utilities and government organizations. As for private houses, it is not at all necessary to adhere to, for example, SNIP 3-05-01-85.

Pressure testing should be carried out after the work is handed over to the customer. The tests must be carried out prior to commissioning. Further tests are recommended to be repeated every 5 years. When pressure testing the heating system with air, what pressure should be maintained? As with the liquid method, the working pressure must be doubled.

To carry out diagnostics, you do not need to have special knowledge and skills, so anyone can do it. It makes no sense to purchase an electric or manual unit, since the most primitive will cost you at least $ 100. If you wish, you can rent a device; in big cities, this opportunity is often provided by individuals or companies.

In the event that you do not want to take risks and conduct tests on your own, you can hire specialists. Upon completion of the procedure, they will give you an act of crimping the heating system, which will indicate how and under what conditions the work was carried out. But the cost of the services of such specialists is quite high - you will have to pay about 2,000 rubles for each hour.

Crimping procedure

To check the heating system in this way, hydraulic tests of the following elements are carried out:

- Pipes.

- Heat exchangers.

- Boilers.

If leaks are detected during test activities, then a conclusion is made about the depressurization of the network.

Immediately before testing, the water supply and heat supply systems are isolated. They also visually determine the strength of the existing connections, check the valves for operability and assess their general condition.

At the next stage, the expansion tank and the heating boiler are turned off in order to flush heating devices and pipes from deposits of various nature, remove debris and dust.

If the hydraulic test involves filling the heating system with water, then a compressor is connected to the drain valve for testing with air. Gradually, the pressure in the system rises, its indicators are monitored on special pressure gauges. In the absence of changes, a conclusion is given about the good tightness of the system and the possibility of putting it into operation. In a similar way, the crimping of the warm floor with air is carried out, including some nuances.

If there is an allowable pressure drop during pressure testing of the heating system, then there are areas with defects in the system. During hydraulic tests, such places leak. If the check was carried out with air under pressure, then the joints and joints are treated with soapy water.

The air pressure test takes about 20 hours, while the pressure test takes only 1 hour.

If defects are found, repair work is carried out and pressure testing is carried out again. The steps are repeated until a good tightness of the system is achieved.Based on the results of the work carried out, an act of pressure testing of the heating system is drawn up. It is worth noting that the act of crimping the heating system is a necessary document.

It should be remembered that in most cases the check is carried out hydraulically. Air tests are carried out when it is impossible to fill the circuit with water or at low air temperatures, when the liquid simply solidifies.

Tests in apartment buildings

In apartment buildings, air pressure testing of the heating system can also be carried out. We will now consider the necessary conditions for carrying out the work. In the event that you find water leaks, they need to be repaired. But often, without high pressure in the system, it is quite difficult to find thin cracks in the seams. In apartment buildings, it is necessary to carry out pressure testing of both individual apartments and all highways.

You need to complete the preparation:

- Inspect all locking fittings. If the valves are made of cast iron, then be sure to replace the glands on them. Replace gaskets on flange connections. All bolts that have lost their original appearance must also be replaced. Be sure to install new pressure gauges, it is recommended to send the old ones for verification in order to decide whether they can be further used for measurements.

- Visually inspect all pipes and fittings to identify even minor defects and damage. If you find problem areas, you need to quickly repair them.

- Check the condition of the thermal insulation material on the highways laid in the basement and between floors.

After preparation, you can proceed to directly pressure testing:

- Fill the entire circuit with water of low hardness (to prevent limescale build-up). It is better to pump it into the system, of course, with an electric pump. Pressure - 6-10 bar. In a container with liquid, you need to lower the hoses - drain and supply. Next, connect the pump to the heating network and turn on the pressure operator. It is necessary to set the pressure in advance.

- Timed half an hour - during this period, the pressure should remain almost at the same level. In the event that the pressure does not drop, the test can be considered completed. You can fill the system with working fluid and start active operation.

- If the pressure drops, then there are defects in the heating system. The procedure for pressure testing the heating system with air is about the same, but you will have to use a soap solution - without it, it is difficult to find a leak. As soon as you find defects, you can proceed with the evacuation of the system and repair. After that, you carry out repeated diagnostics of all heating.

The inlet assembly is carried out in a similar way - the pressure in this case should be about 10 bar.

Scheme of pressure testing of the heating system with air

Air pressure testing of the heating system

The crimping procedure is carried out either with water or air. The latter option is preferred in the cold season in order to exclude the possibility of water freezing in the system in the event of a defect in it.

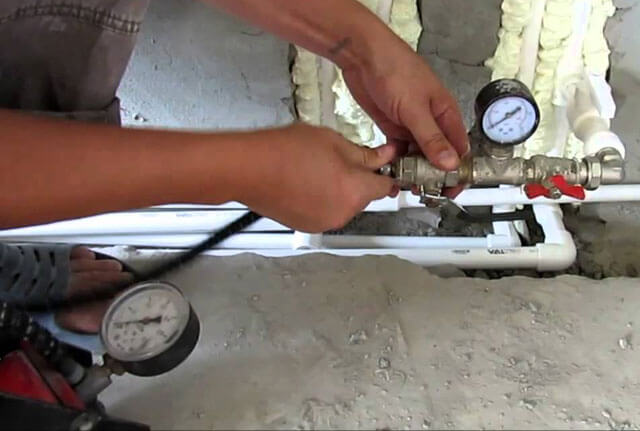

The technology for performing air pressure testing is quite simple. In any place convenient for you in the heating system (CO), a compressor is connected, which pumps air into the heating batteries and the mains of the system. Its pressure rises to a predetermined value. After that, the change in pressure is monitored by a pressure gauge.

In cases where the work is done efficiently, the pressure in the system does not drop over time.

Pressure testing of the heating system with air is performed in a specific sequence.

First, you must completely drain the water from the system.

Further, it is necessary to cover and seal the selected area of CO, which is subject to subsequent control. That is, the branch to be pressurized is completely cut off from the central water conduit.

This procedure is performed using the existing shut-off valves (valves or taps) located at the end and at the beginning of the section.

Before starting this stage of work, certain preparatory measures should be completed. Namely:

- Carry out a careful inspection of all valves;

- If necessary, add stuffing box seals to ensure complete tightness;

- Renovate piping insulation where necessary.

It is necessary to connect a compressor to the controlled area, the power of which is selected taking into account the internal volumes of the tested area.

Then it is required to create an overpressure in this section, the value of which should be at least two to three times higher than the working pressure set for CO. (That is, at an operating pressure of up to 2 atmospheres, the pressure in the system when pressing it with air must be brought to at least 5 atmospheres).

As a rule, the compressor is connected either to the CO drain valve or to one of the radiators, having previously unscrewed the Mayevsky valve (the air vent of the heating system) from it and replaced it with an adapter that allows you to dock the compressor hose.

Compressor connection

Next, all the joints in the system are checked for leaks (lack of tightness of the assembly). In this case, it is necessary to view exactly ALL connections, not only detachable, but also soldered (if CO is assembled from propylene pipes).

In cases where pressure testing is carried out with air, all connections should be pre-coated with soapy water. If this procedure is performed with water, then leaks will become noticeable without it.

Summarizing the above, we can say. That the crimping control process goes like this:

- We pump air. In heating batteries and CO lines, it must reach a given pressure., The value of which is controlled by a pressure gauge;

- When the required pressure is reached, turn off the compressor;

- We fix the initial pressure and leave the line for a day (the minimum control time is 8 hours);

- After the expiration of the time, we make a comparison of the value of the primary and actual pressure. In the absence of a difference, the work is done with high quality, and the system is sealed. Otherwise, it is required to search for the leak and perform modifications.

After performing the pressure test, the lines should be left under excess pressure for a day (24 hours). During this time, all possible leaks will appear. It should also be borne in mind that due to daily temperature drops, the pressure in CO will partially drop, since the air, cooling down, is compressed.

The pressure level in the system is controlled by a pressure gauge, which must be connected to the system through a check valve. Otherwise, no results can be seen.

After completing the quality control of the crimping, we move on to the next section. And so on until a complete check of the entire system.

After completing the pressure test, bleed the air. It should not remain in the heating system. It is filled with a coolant and a CO trial run is carried out.

If noises appear in the lines when the boiler heats up, it means that there are air locks in the system. It is necessary to deflate again.

Materials and equipment for work

The main tool for crimping pipes is:

- Pressing machines (manual and automatic);

- Air pressure gauge;

- Swedish key number 2;

- Gas wrench No. 2;

- Bayonet screwdriver No. 2;

- Consumables (sealing and gasket).

Testing in private homes

It should be noted that in autonomous heating systems, which are used in private houses, the pressure is usually no more than 2 bar. Therefore, in order to carry out the tests, it is necessary to pump liquid into the system at a pressure of 3.5-4 bar. It is allowed to use both the air method of pressure testing and the hydraulic one.

The sequence of the test work:

- First, drain the coolant and pump pressurized water into the heating circuit. It is imperative to add additives that are used when flushing the system. The circuit is filled with water through the branch pipe located in the lower part.

- The filters must be thoroughly cleaned before flushing. It is recommended to flush at least once a year.

- Next, drain the flushing fluid and fill the system with clean fluid. You can skip this step if you allow the flushing fluid to cool to 45 degrees. After that, it is necessary to pump in more water with the help of a pressure testing device in order to bring its pressure to 4 bar.

- If you are using a manual pressure tester, fill the tank with liquid, then connect it to the drain pipe of the heating system. Next, you need to open the taps and pump in water. This is done simply - you need to raise and lower the handle of the device. As soon as the required pressure is reached, close all valves.

- Leave the entire system filled for about half an hour and monitor the pressure carefully. In the event that a drop of less than 0.2 bar occurs over a period of 30 minutes, it can be said that there are no leaks. If the pressure drop is too large, then it is necessary to find and eliminate defects.

Remember that it is imperative to observe the permissible pressure standards when performing pressure testing. It should also be noted that there is a high probability of leaks inside the walls. In this case, you will need a heat radiation meter. Only he is able to detect the presence of hot liquid leaks in the walls or under the floor.

Some may ask the question: "What pressure should be maintained when pressing the heating system with air?" Air is not a liquid, therefore, it is allowed to inject about 2 bar into a system whose length is no more than 10 meters. But it all depends on the specific heating system, its length and volume. If it is relatively small, then the test pressure can be reduced.

Pressure testing and flushing of the heating system

Before pressing the system, it is necessary to remove rust and scale from the circuit. The pipelines are filled with water with special reagents and washed. The mixture can be supplied with a compressor. This device should generate a pressure of 1.3 times the working pressure. During these operations, the employee checks the tightness of the system, makes marks at the leaks.

During pressure testing of heating, the requirements of SNIPs are taken into account. When performing such work, it is necessary to take into account:

- type of contour routing;

- the material used (polypropylene, copper or metal-plastic pipes);

- technical characteristics of valves;

- number of storeys of the building.

According to the rules for performing work, flushing should remove all blockages and deposits in the circuit. If you do not perform this work, then the efficiency of the heating system in the third year of operation will decrease by 15%, which will increase the cost of heating the premises. Deposits in the Rehau pipes impair the circulation of the coolant, therefore, flushing must be carried out until clean water appears from the drain valve.

After cleaning the circuit from contamination, the crimping procedure is started. When carrying out such operations, it is necessary to turn off the circulation pump. The pressure device must pressurize the system 30% more than the operating parameters. In case of deformation or damage to the threaded connections, as well as malfunction of the shut-off valves, the destruction of the weak point may occur, after which the streams of water can flood the room.

When checking the boiler equipment and the circuit, water is supplied to the system under pressure of 2 atmospheres for a private house and 5 atmospheres for a multi-storey residential building. After that, a special device, a press, is connected to the circuit and compressed air is supplied.

Important! The maximum allowable pressure during pressure testing should not exceed 1.5 operating parameters.

After connecting the high pressure hose crimping machine, the load parameters are increased every 10 minutes until the pressure reaches the desired value. If the position of the pressure gauge needle on the device does not change, then the system is tight. If the pressure starts to fall, there are leaks in the water floor heating circuit or in the radiator heating system. Look for weak points in threaded connections, welds, or areas with gaskets installed. The tool for crimping metal-plastic pipes is exactly the same as for utilities from other materials.