A wide variety of heating means makes it possible to choose the most optimal samples from them. So not all boiler devices have the same performance, and, therefore, fuel consumption. Therefore, before buying this or that model, it is worth making the necessary calculations.

If you have correctly calculated the fuel consumption, the diesel boiler will work efficiently and will be able to maintain the required temperature in the room. Otherwise, various nuances in the operation of the device and the system as a whole are possible.

Liquid fuel equipment and its features

Devices fueled by kerosene, diesel fuel or diesel fuel can be used to heat industrial and residential premises.

Fuel for such boilers is contained in a special tank, which can be located in any place convenient for the consumer:

- In the boiler room

- On the street

- Underground

This feature is one of the main advantages of liquid fuel devices.

The most effective is the use of this heating equipment in non-gasified settlements, since the fuel consumption of a diesel boiler is not very high. The principle of its operation has insignificant differences from devices operating on other types of energy carriers.

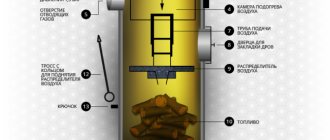

It has a combustion chamber in which a burner is located, which is necessary for burning diesel fuel. In the course of its operation, the coolant is heated, which is then supplied to the heating system. Combustion products are removed from the apparatus through the chimney. At the same time, they pass through the heat exchanger, partially giving off heat to it, which contributes to an increase in the efficiency of the device.

Diesel fuel boilers most often have a steel body, which is practically not subject to corrosion.

Under it are located control and automation units that control the operation of the equipment. Heat exchangers in diesel boilers are made of steel or cast iron so that they can withstand prolonged exposure to high temperatures.

To reduce heat losses during operation, as well as to make the diesel heating boiler consume less fuel, a heat-insulating gasket is placed under the outer casing of the device, which also protects users from burns.

Engines

Minivans of almost any generation are distinguished by a large selection of engines that have good potentials and low fuel consumption. Gasoline models are considered less reliable than diesel ones. Although there is a lot of controversy with diesel engines, some say that they are not the best ones, other experts say that the engines are perfect.

It is the Volkswagen Transporter with diesel fuel that remains the most demanded in the secondary market. They are not whimsical, the fuel consumption is low, they are designed simply, due to which they rarely fail. In addition, they are maintainable.

What does fuel consumption depend on?

The heating system is affected by a large number of different factors and loads.

It:

- Thermal insulation of the room

- House area

Naturally, the larger your home, the higher the consumption of a diesel heating boiler will be. The efficiency of devices, such devices, ranges from 90 to 95%. But such a result can be obtained only at the maximum speed of the device. Therefore, when purchasing heating equipment, you should not choose it with a margin. This will help to avoid unnecessary costs, since in this case, oil-fired heating boilers will consume less fuel.

General characteristics of diesel heating boilers

Possibilities of heating devices:

- The installation of a diesel unit does not require any agreements or special permits.

- The device works autonomously for 100%.

- Works without the release of carbon deposits or dirt.

- Needs a small room with a ventilation system and a container in which fuel should be stored. The container can be made of plastic or steel, with the ability to accommodate from 4 tons to 10 tons.

It is important to take into account that the dishes for storing the combustible mixture implies a specially equipped bunker, it can also be an isolated room. A container with diesel fuel, in safety measures, it is advisable to dig a little into the ground.

Before making a purchase of equipment, you need to carefully calculate everything and study its capabilities to the smallest detail. Only in this case, the spent finances will bring reliability, efficiency and comfort during the heating season.

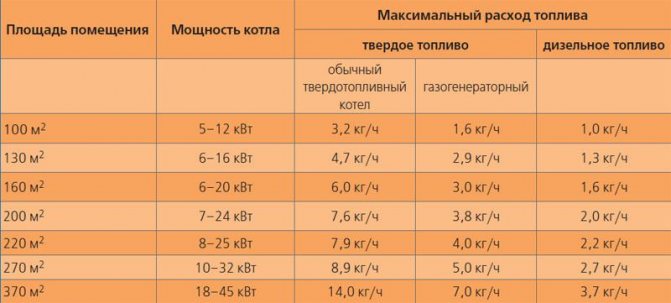

First of all, you need to calculate the consumption of a diesel fuel boiler for heating:

- The area of the room that needs heating at home.

- The power of the unit itself.

- How many days the boiler will operate at maximum capacity per year.

- With what load the device will work in recent months.

All of the above are the most important indicators for choosing diesel boilers.

What formula should be used to calculate

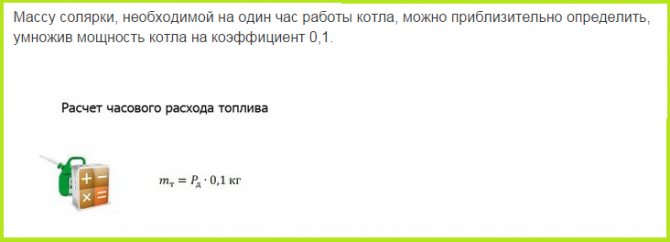

To calculate the fuel consumption of a diesel boiler for a particular room, you can use approximate calculations. For example, in the average statistical case, to obtain a power of 10 kW, you will need to consume 1 kg of diesel fuel per hour.

There is another option, it is based on the burner power readings, which must be multiplied by a factor of 0.1. The result is the amount of fuel for 1 hour of equipment operation.

Knowing these indicators, you can calculate the approximate figures that a diesel boiler consumes to heat a room with a certain area. For example, to heat your house of 150 m², you need a 15 kW boiler. Then multiplying this value by 0.1, we get 1.5 kg / h.

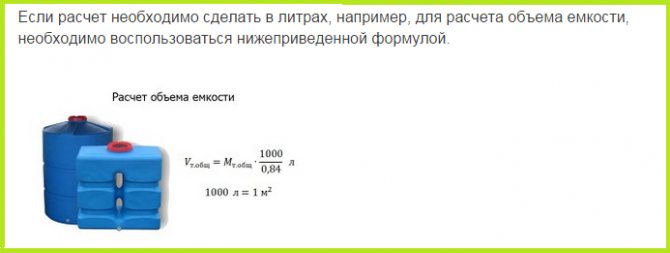

This means that when operating at full speed, your device will burn 36 kg (1.5x24) per day. And if we take 100 days at full load as the average operating time and the same amount at half load, then it turns out: 100x36 + 100x18 = 5200 kg. As you can see, more than 5 tons of diesel fuel will be spent to heat your premises in the autumn-winter period.

MTZ 82 - what affects fuel consumption per 100 km

To increase the "average" indicator of fuel consumption can:

- Attachments, including those not designed for the power plant of the unit;

- Motor malfunctions;

- Malfunctions and malfunctions in the fuel system;

- Vehicle speed;

- Types of work performed - plowing, transportation of heavy loads, and so on;

- Engine type - on MTZ 82 and MTZ 82.1 models. power units D-240, D-243 and their modifications can be installed;

- Connecting / disconnecting all-wheel drive;

- Working in higher or lower gears, general tractor driving style;

- “Difficult” soils;

- The depth of cultivation, soil moisture;

- Low quality of fuels and lubricants;

- Weather.

It is possible to reduce the loss of diesel fuel during the operation of Belarus MTZ 82 tractors by correctly adjusting the fuel system nozzles, avoiding the “aggressive” driving style, and maintaining the tractor and attached / towed equipment in good technical condition.

The influence of many factors leads to the fact that the figure "jumps", but such "jumps" significantly complicate the planning and control of fuel consumption.

As a guideline, you can use the average fuel consumption values of the MTZ 82, 82.1 tractors, established in 2012 for the products of the Minsk Tractor Plant by the Ministry of Transport and Communications of the Republic of Belarus. These norms can be transferred to the Russian reality.

Fuel consumption rate for the MTZ 82 tractor - average values

The regulatory document considers the main options for using the Belarus MTZ 82 and MTZ 82.1 tractors, provided they work on “medium” soils in acceptable weather conditions.

For cars with D-243 engines:

MTZ-82 with a PSE-F-12.5 trailer;

- transport mode - 7.7 l / machine-hour;

- transport mode (with the front driving axle off) - 7 l / mash.-hour.

MTZ-82 with a PL-7 trolley and a Nokka hydraulic manipulator - 7.3 l / machine-hour. MTZ-82;

- transport mode with a 2PTS-4 trailer - 6.8 l / machine-hour;

- transport mode with a trailer 2PTS-4.5 - 7.0 l / machine-hour;

- transport mode with a 2PTS-5 trailer - 7.5 l / machine-hour;

- transport mode with the Brodway Wasa 3000 sweeper - 11.0 l / machine-hour;

- transport mode - 5.5 l / machine-hour;

- sweeping with a brush - 4.3 l / machine-hour;

- snow removal with a dump - 6.6 l / machine-hour;

- snow removal with a blade and a brush - 6.9 l / machine-hour.

MTZ-82.1 with MP-5A watering machine;

- transport mode - 6 l / machine-hour;

- pump operation 32-3A - 5 l / mash.-hour;

- work of the NPO-60M2 pump - 4.6 l / mash.-hour.

MTZ-82.1;

- transport mode - 5.5 l / machine-hour;

- transport mode with a 2PTS-4 trailer - 6.8 l / machine-hour;

- transport mode with a 2PTS-4.5 trailer - 7.0 l / machine-hour;

- transport mode with a 2PTS-5 trailer - 7.5 l / machine-hour;

- transport mode with a PSE-F-12.5V trailer - 6.5 l / machine-hour;

- transport mode with a PST-9 trailer - 8.0 l / machine-hour;

- transport mode with a PST-11 trailer - 10.4 l / machine-hour;

- transport mode with the PTK-10-2 platform - 9.4 l / machine-hour;

- sweeping with a brush - 4.3 l / machine-hour;

- snow removal with a brush - 6.3 l / machine-hour;

- snow removal with a dump - 6.6 l / machine-hour;

- snow removal with a blade and a brush 6.9 l / machine-hour;

- transport mode with wood waste grinder IDO-25 "Iveta" - 5.5 l / mash.-hour;

- work of the wood waste grinder IDO-25 "Iveta" - 4.8 l / machine-hour;

- production of wood chips on the DDO plant - 3.6 l / machine-hour;

- work with a milling cutter - 4.2 l / machine-hour;

- work with a windrower - 7.5 l / machine-hour;

- work with a flat cutter - 8.0 l / machine-hour;

- mowing grass with the KDN-210 mower - 5.7 l / mash.-hour;

- removal of the asphalt concrete bed with the FD-400S milling cutter - 5.8 l / machine-hour.

For cars with D-240 engines:

MTZ-82;

- transport mode - 5.3 l / machine-hour;

- transport mode with a PSE-F-12.5B trailer - 6.2 l / machine-hour.

MTZ-82.1;

- transport mode - 5.3 l / machine-hour;

- transport mode with a 2PTS-4 trailer - 6.0 l / machine-hour.

* Consumption is indicated in diesel fuel. Please note that the consumption for the operation of the equipment is not summed up with the operation of the engine, the total consumption is obtained when the consumption for the operation of the attachments is added to the transport mode. For work on trailers, the total value is indicated.

Do you still have questions about the fuel consumption standards for the MTZ 82 and 82.1 tractors produced by the Minsk Tractor Plant? Ask our specialists by calling the toll-free number, or use the service “Request a call back”.

How to save fuel? And which device to choose?

Liquid fuel devices can be either one or two-circuit. Naturally, the latter will require a higher diesel consumption for work, which will lead to increased costs. Therefore, for such models, the best solution is to reduce the amount of hot water, which will save on fuel.

One more advice from experts. They recommend setting a lower temperature for the coolant, which also affects the diesel consumption.

And the last way is to install a thermostat in the warmest room.

Using these tips, you can reduce the amount of fuel needed to operate your heater and save money.

Very often a question is asked on forums. Which boiler equipment is more profitable - electric or diesel? Diesel heating boiler, what fuel consumption does it have?

The answer to it depends on various factors, such as the thermal insulation of the premises, the area of the house, the number of residents, the climatic zone and, of course, fuel prices. Knowing them, you can always calculate the approximate consumption of diesel and electricity, and compare the costs of them.

Specific indicators of fuel consumption in diesel generators and their physical meaning

When buying a DG, a technical passport of the engine must be attached - its main working unit. But it should be understood that these characteristics are given for operation at maximum speed and cannot give an exact answer to the question of the efficiency of the unit and how long it works without refueling.

A comparative approach to assessing data will be incorrect, since it initially contains a significant error.The choice of DGs on the modern Russian market is huge. Contrasting one delusion with another only on the basis of passport data may not lead to the desired result without taking into account a whole range of operational factors.

The specific fuel consumption indicator shows a generalized estimate for internal combustion engines based on the consumption per unit of power. The generally accepted assessment system in Europe, the Russian Federation and in many Asian countries is the amount of fuel consumed in kg for each kW of power per hour.

With this characteristic, it is easy to try on the parameters of DG operation for your needs and choose the most optimal model.