An autonomous home heating system is becoming one of the most common ways to heat a home.

Among the many options, gas boilers are preferred as the most efficient and economical installations.

The recognized leaders in the production of gas units are European companies, but their products are not always able to work effectively in Russian conditions.

Domestic manufacturers, having analyzed the experience of foreign colleagues, decided to use a completely different approach to the design and functionality of boilers.

Consider one of the models of the Russian gas boiler - Zhukovsky AOGV 23.

What functions does the Zhukovsky gas boiler AOGV 23 have?

The abbreviation AOGV 23 stands for Gas Heating Apparatus with a Household Power of 23 kW. This is a single-circuit floor-standing unit capable of effectively heating a room up to 200 m2.

Such opportunities are optimal for use in a private house, cottage or other premises. The boiler is designed to perform only one function, which allowed the manufacturer to eliminate all unnecessary parts and unused structural elements.

This increased reliability, reduced the number of failures and breakdowns. In addition, a feature of AOGV 23 boilers is energy independence.

In case of a sudden power outage, the boiler operation will continue as usual, which is important in the conditions of the Russian winter.... This feature significantly increases the reliability of the home heating system.

At the same time, the lack of power supply requires a specific location of the radiator system, since the circulation of the coolant will occur in a natural way.

Combustion chamber of an atmospheric boiler, with air intake directly from the room and natural smoke exhaust using a furnace-type draft.

Household antifreeze is used as a coolant, which increases the reliability of the heating system in severe frosts.

Recommendations for the operation of gas boilers

___________________________________________________________________________

Review of the gas boiler Ariston BS ii 24 ff Operation of the gas boiler Ariston BS ii 24 ff Review of the gas wall-mounted boiler Ariston Egis Plus 24 ff Recommendations for connecting the boiler Ariston Egis Plus 24 ff Adjustments of the wall-mounted gas boiler Ariston Uno Service and starting the gas boiler Ariston Uno

Ariston abs storage water heater installation

Gas boilers AGV-120 Malfunctions of gas boilers AGV-120 Review of automatic gas boiler AGV-80 Recommendations for installation and installation of boilers AGV-80 Gas boiler Alpine AKGV-11.6 Installation of boiler AKGV-11.6 Operation of gas boiler AKGV-17.4 Construction of Borin gas boilers AKGV-23 Review of gas boiler AKGV-23.2 ZhMZ Gas boiler AOGV-11.6-3 Economy Installation and service of boiler AOGV-11.6-3 Operation of boiler AOGV-11.6-3 Economy Review of gas boilers Borinsky AOGV-17,4 Installation and installation of the AOGV-17,4 boiler Design and maintenance of the AOGV-23 steel gas boiler Operation of the AOGV-23 ZhMZ gas boiler Malfunctions of the AOGV-23 ZhMZ boiler Parameters and construction of the AOGV and AKGV gas boilers Wall-mounted parapet gas boiler Aton Operation of the parapet gas boiler Aton Installation and installation of the parapet gas boiler Aton Installation and installation of the wall-mounted boiler Baksi EcoFor Review of the wall-mounted gas boiler Baxi Eco Four Devices and devices of the boilers Baksi Ecofor Review of the gas boiler Baksi Luna 3 Auto boiler matics Baxi Luna-3 Comfort Wall-mounted double-circuit boiler Baxi Luna 3 with Combi boilers Installation of a wall-mounted boiler Baxi Luna 3 Comfort Overview of a wall-mounted double-circuit boiler Baxi main four Installation of a wall-mounted double-circuit boiler Baxi Mine Fore Maintenance and adjustment of the Baxi boiler main four Characteristics of a floor-standing gas boiler BaxiSlim Components of the gas boiler Baksi Slim Adjustments and maintenance of the Baxi Slim boiler Installation and installation of the Baksi Slim boiler Wall-hung gas boiler Beretta Ciao CSI Installation of the gas wall-mounted boiler Beretta Ciao CSI Adjustments and maintenance of the Beretta Chao boiler Wall-mounted gas boiler Beretta City Installation and operation of the Beretta City boilers and connection of a gas boiler Bosch Gaz 4000 W Maintenance and service of wall-mounted boilers Bosch Gaz 4000 W 24 Overview of automation and malfunctions of boilers Bosch Gaz 6000 W Installation and operation of a wall-mounted gas boiler Bosch 6000 Wall-mounted gas boiler Bosch Gaz 6000 W Characteristics of a gas boiler Bosch 4000 W ZSA 24 Double-circuit boilers Bosch Gaz 4000 W ZWA 24 Combined gas boiler Buderus Logamax U042 / U044 Operation of boilers Buderus Logamax U042 / U044 Boiler device Buderus Logamax U052 / 054 Elements of the boiler's hydraulic system Buderus Logomax U052 / 054 boiler Buderus Logamax omax U072 Review of Buderus Logano G124 floor standing boiler Installation of Buderus Logano G234 floor standing gas boiler Adjustments and service of Buderus Logano G234 boiler Information about Buderus and Vaillant gas boilers Overview of STS boilers Design and installation of Danko floor standing gas boilers 10 Operation and maintenance of Danko floor standing boilers 10 Automation Overview of wall-mounted gas boilers Electrolux Basic Installation and installation of a gas boiler Electrolux Basic Construction of a floor-standing gas boiler Electrolux FSB Operation of a floor-standing gas boiler Electrolux FSB Installation and service of a floor-standing gas boiler Electrolux FSB Installation of a wall-mounted gas boiler Electrolux Hi-Tech Installation and operation of a gas boiler Electrolux Hi-Tech Overview wall-mounted boiler Electrolux Quantum Operation of boilers Electrolux Quantum Installation of a gas boiler Electrolux Quantum Maintenance and service of boilers Electrolux Quantum Double-circuit gas wall-mounted boiler Ferroli Diva Installation and installation of a double-circuit gas boiler Ferroli Diva Overview of gas wall-mounted boilers Ferroli Domina Installation and installation of gas boilers Ferroli Domina Wall-mounted gas boiler Ferroli Domiproject Operating modes of a gas boiler Ferroli Domiproject Malfunctions of Ferroli boilers Review of a floor-standing gas boiler Ferroli Pegasus Maintenance of a gas boiler Ferroli Pegasus gas boiler Hephaestus Imported boilers for heating systems Operation of a gas boiler KChM-5 Gas boiler KChM-5 Cast iron gas sectional boilers KChM

Gas boiler Kiturami World 5000 - Installation and adjustment Connecting equipment to the boiler Kiturami World 5000

Construction of a gas boiler KSG Hearth Installation and service of a boiler KSG Hearth Construction and operation of gas boilers KSV Installation and maintenance of gas boilers KSV Overview of an automated hot water boiler KV-G Construction and installation of a hot water boiler KV-GM Hot water heating boilers KVA Water tube gas boilers KVG

Cast iron gas boiler Lemax Leader Installation and maintenance of a gas boiler Lemax Leader Heating gas boiler Lemax Premium Comparison of gas boilers Lemax Premium-20 and Danko-20s Selection of boilers with simulating burners Gas wall-mounted boiler Navien Ace Components of two-circuit boilers Navien Ace Device faults and errors and service of the gas boiler Navien Deluxe Installation and installation of wall-mounted gas boilers Navien Electronic functions of boilers Neva Lux 7224 Gas boiler controls Neva Lux 7224 Wall-mounted double-circuit boiler Neva Lux 8224 Installation and installation of wall-mounted boilers Neva Lux 8224 Checks and diagnostics of a double-circuit boiler Neva Lux 8224 Repair of basic elements boiler Neva Lux 8224 Maintenance and service of the gas boiler Neva Lux 8224 Recommendations for the operation of boilers Neva Lux 8618 The device of the gas boiler Neva Lux 8618 Errors and malfunctions of boilers Neva Lux

Hinged gas boiler Proterm Lynx with instantaneous heating of DHW Installation and installation of a wall-mounted boiler Proterm Lynx Floor-standing gas boiler Proterm Volk KSO Installation and adjustment of a boiler Proterm Volk Operation and service of a solid fuel boiler Bober Review of a solid fuel boiler Proterm Bober Installation and installation of a boiler Protherm Bober Operationgas boiler Protherm Gepard Gas boiler adjustments Protherm Gepard Floor-standing cast-iron gas boiler Protherm Grizzly Gas wall-mounted boiler Protherm Leopard Cast-iron gas boiler Protherm Bear KLOM Installation and installation of the Protherm Bear boiler Characteristics and equipment of gas boilers Protherm Medved Installation and connection of the wall-mounted boiler and service Protherm Bear boiler Proterm Panther Wall-mounted gas boiler Proterm Panther Double-circuit wall-mounted gas boiler Proterm Jaguar Installation and installation of the boiler Proterm Jaguar Gas boiler Prometheus

Installation and installation of the Ross AOGV-12 gas boiler Installation of the Ross AOGV-16 gas boiler Recommendations for the operation of the Ross AOGV-20 boiler Review of the Ross AOGV-20 floor-standing gas boiler Review of the Ross AOGV parapet gas boiler Characteristics of the floor-standing gas boiler Siberia 11 Non-volatile floor-standing gas boiler Siberia 17 Gas heating boiler Siberia 23 Heating gas cast iron boiler Siberia KCHGO-16 Gas cast iron floor standing boiler Siberia KCHGO-50

Heating boiler piping schemes

Checks and adjustments of the Vaillant atmotec boiler Maintenance of the Vaillant atmotec boiler Construction and installation of the Vaillant turbotec 242 boiler Vaillant Turbotec / Atmotec gas-fired boilers Functions of the Vaillant Turbotec / Atmotec gas boilers Vaillant Turbotec / Atmotec boiler controls and automation Vaillant Turbotec / Atmotec Boiler control and operation Diagrams and control of the Vaillant Turbotec / Atmotec boilers water heating boilers Viesman Review of the gas boiler Viessmann Vitodens 100-W Review of the gas boiler Viessmann Vitogas 100-F Operation of the gas boiler Viessmann Vitogas 100-F Review of the floor-standing gas boiler Viessmann Vitomax 200 Maintenance of the boilers Viessmann Vitopend Review of the single-circuit boiler 100 Viessmann Vitogas WH1 errors of gas boilers Viessmann Vitopend 100-W Review of the combined boiler Viessmann Vitoplex 100 Gas boiler Zhitomir-3 Atem Installation and installation of boilers Zhitomir-3 Atem

Overview of the Nova Florida Vela Compact boiler Installation and connections of the Nova Florida boiler Checks and adjustments of the Nova Florida Vela Compact boiler Operating functions of the Nova Florida Vela Compact boiler Nobel gas boiler

___________________________________________________________________________

___________________________________________________________________________

- Malfunctions of the AOGV-23 ZhMZ boiler

- Parameters and device of gas boilers AOGV and AKGV

- Boiler automation Baxi Luna-3 Comfort

- Installation and assembly of the Baksi Slim boiler

- Adjustments and maintenance of the boiler Beretta Chao

- Determination of error codes and malfunctions of Rinnai boilers

- Errors and malfunctions of the gas boiler Termet

- The meaning of the error code and malfunctions of Vilant boilers

- Determination of faults and errors of Wisman boilers

- Questions about the maintenance of boilers Navien

- Questions on malfunctions of Kiturami diesel boilers

- Junkers boilers - Masters answer user questions

- Experts answer questions about Electrolux boilers

- Expert answers for the repair of Nova boilers

- Questions about the service of Hermann boilers

- Answers from Daewoo boiler maintenance masters

- Questions about the maintenance of boilers Ferroli

- User questions on the repair of electric boilers Evan

- Because of what the gas boiler AKGV lights up and immediately goes out

- What is the malfunction of the Alpha Color boiler, if it shows the error code E01

- Because of what the AOGV boiler ignites and goes out quickly

- How to eliminate error E01 on the Baltgaz boiler

- What is the breakdown if Dani's boiler ignites, but immediately goes out

- Why does the Danko boiler light up, but quickly goes out?

- The Demrad boiler stopped holding pressure, what is the problem

- Because of what the Gazlux boiler began to warm up and make noise

- What is the reason if the Keber gas boiler lights up, but quickly goes out

- How to fix error code 01 on the Kiturami boiler

- Because of what the Conord boiler ignites, but immediately goes out

- What is the reason if the Lemax boiler ignites and goes out quickly

- Why does the Mimax boiler ignite, but it goes out sharply?

- Why the boiler The hearth ignites, but immediately goes out

- Why the Ross gas boiler lights up, but goes out quickly

- What is the malfunction if the Siberia boiler lights up and goes out sharply

- Why does the boiler Signal light up and go out sharply?

- Because of what the Termet boiler can make noise and heat

- Why does the gas boiler Thermotechnician ignite, but suddenly goes out?

- How can I fix the E01 error on the Thermon boiler

- For this reason, the Electrolux double-circuit boiler began to hum and heat up

- For what reasons the Ferroli gas boiler gives an error with the A01 code

- For some reason, the Immergaz boiler does not function on hot water supply

- Why does the Navien gas boiler constantly turn off and turn on immediately when heated

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Heating boilers piping

- STS boilers

- Solid fuel boilers KBT

- Pellet boiler Peresvet

- Steel floor boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the gas boiler Termet

- Repair of Thermon boilers

- Repair of boilers Nova

- Boiler service Hermann

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Maintenance of Daewoo boilers

- Boiler malfunctions Demrad

- Mora boiler malfunctions

- Boiler repair Westen

- Immergaz boilers malfunctions

- Types of solid fuel boilers

- Combined boiler models and designs

- Oil and double-circuit boilers

- Cast iron boilers for coal

- Boilers with simulating burners

- Imported boilers for heating systems

Specifications

Consider the technical characteristics of the boiler Zhukovsky AOGV 23:

| Options | The values | ||

| AOGV 23-2 Economy | AOGV 23-2 Wagon | AOGV 23-2 Comfort | |

| Boiler type | Gas heating | ||

| Fuel type | Natural gas with the possibility of converting to liquefied gas | ||

| Functions | Heating (supply of coolant to the radiator system) | ||

| Efficiency | 89 % | ||

| Boiler power (max) | 23 kWt | ||

| Gas consumption | 2.55 m3 / h | ||

| Heated area | Up to 200 m2 | ||

| Heat carrier temperature | 50°-90° | ||

| Power supply | Absent | ||

| Boiler weight | 52 kg | ||

teplomex.ru

Floor standing gas boilers AOGV-6.9; -9.3; -12.5 They have been heating houses all over Russia for many years. Affordable price and simplicity of design made this brand quite popular with many buyers with low incomes.

Today we will take a closer look at the model range and technical characteristics of Russian-made boilers based on the operating instructions (passport) of this gas floor heating equipment. We will analyze the device and automatics of the device according to photo diagrams, prices, settings, as well as all malfunctions during the operation of the AOGV gas boiler, methods for their elimination and repair.

The lineup

Gas boilers "Termolux" are produced in the city of Taganrog, Rostov region. On the market we can find several modifications of AOGV boilers. The devices are produced both single-circuit and double-circuit - for heating running water, capable of operating not only on natural, but also on bottled gas. What models of boilers does the company produce? And there are several of them.

Gas floor boilers "Termolux"

Single-circuit floor-standing gas boilers AOGV for heating:

- AOGV 6.9; - AOGV 9.3; - AOGV 11.6; - AOGV 12.5; - AOGV 15; - AOGV 20.

The numbers in the name of a specific model of the device indicate the rated power of the boiler, it can be from 6.9 kW to 20 kW. Boilers "Termolux" can heat a private house or industrial premises with a total area of up to 200 m2. The most popular, judging by customer reviews, were the AOGV-6.9 and AOGV-9.3 models, designed for a small house with an area of 50-80 m2.

Double-circuit gas boilers AKGV for heating and hot water supply:

- AKGV 12.5; - AKGV 15; - AKGV 20.

These models have a built-in steel heat exchanger for domestic hot water production. True, given the small capacity of the boilers, the flow rate of running water will be quite small: 4-7 liters per minute. But this is usually enough for kitchen needs, for example, washing hands or dishes.

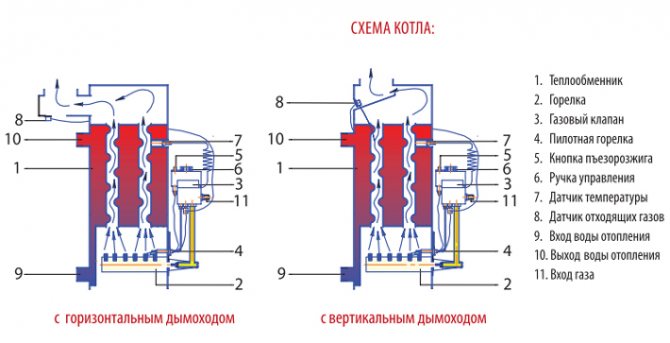

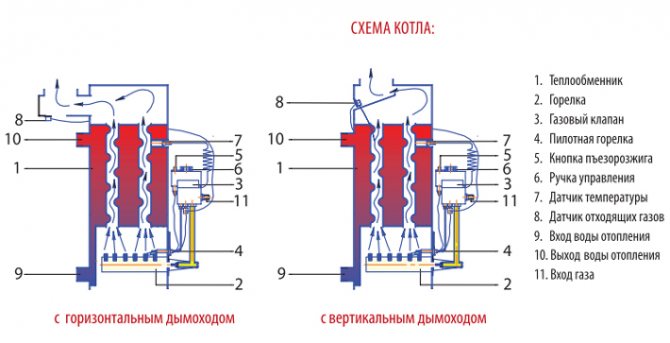

The device of the gas boiler AOGV 6.9 and 9.3: automation

Like most floor-standing gas appliances, AOGV "Thermolux" boilers consist of a heat exchanger in which the coolant is heated, the main and ignition gas burners, automation and a smoke exhaust device. Let's take a closer look at the diagram of the internal features of the Taganrog apparatus:

1 - heat exchanger for heating water; 2 - gas cock; 3 - thermostat for automatic maintenance of the required coolant temperature; 4 - thermometer; 5 - door; 6 - frontal shield.7 - thermal sensor with a fixing screw; 8 - lever attachment unit; 9 - damper; 10 - ignition burner; 11 - lever; 12 - valve with a button; 13 - air damper; 14 - air supply regulator; 15 - traction stabilizer; 16 - gas distributor.

Automation of the gas boiler AOGV "Termolux"

Setting up a gas boiler AOGV: instructions for the user

1. Adjust the chimney draft with the air damper. 2. Open the damper, press the valve button and light the igniter by bringing a lighted match to it. 3. Hold the button until the lever moves back one third of its diameter. 4. Open the gas valve to transfer the flame to the main burner. 5. Adjust the air supply to the boiler with the air damper and air regulator.

By observing these rules, the flame on the main burner should be blue-blue, steady and continuous. There should be no pops, hissing and soot formation during the boiler operation. It is recommended to periodically monitor the process of gas combustion and draft in the chimney.

The thermostat automatically maintains the preset temperature of the coolant in the heating circuit of the boiler, smoothly changing the volume of gas supply to the main burner. To change the temperature, it is necessary to turn the adjusting screw in one direction or the other, but no more than half of its turn. The temperature can be periodically checked against the readings of the thermometer located in the boiler.

When the set temperature is reached, the thermostat valve closes smoothly, transferring the operation of the gas burner to the “low flame” mode of reduced power. In the event of a temperature change, the thermostat will automatically adjust the gas supply to the burner, ensuring a constant temperature of water heating in the heating circuit.

If the area of the heated room is very small, the thermostat can completely cut off the gas supply to the main burner, while the igniter will always be on.

Technical characteristics of gas boilers AOGV "Termolux"

AOGV "Thermolux" boiler: technical characteristics

Advantages of the gas boiler AOGV "Termolux":

- simplicity of design; - low price for a boiler (from 12,000 rubles) and for spare parts; - the minimum diameter of the chimney on the AOGV-6.9 and AOGV-9.3 models is only 100 mm; - compactness.

Disadvantages of gas boilers AOGV "Termolux":

- outdated automation; - quality of materials and components; - lack of high-power devices in the range of boilers.

Malfunctions of gas boilers AOGV-6.9; -9.3; -12.5 and methods for their elimination

1. The main gas burner goes out or turns off.

There is insufficient vacuum in the chimney or it is clogged, which will require cleaning. Also check the thermostat setting, it may need to be repaired or replaced.

2. Smell of gas.

Check the threaded connections by washing them with soap, it may also be necessary to replace the gaskets.

3. The lever does not come off the valve button.

Adjust the position of this lever with the screw of its attachment. Check the thermal sensor for deformation.

Gas boilers AOGV-6.9; -9.3; -12.5

4. The boiler does not heat water well, the temperature of the heat carrier is insufficient.

Adjust the thermostat correctly by turning the adjusting screw.

5. Long orange flame on main burner.

Adjust the primary and secondary air supply to the main burner with the dampers. It is also necessary to check the draft in the chimney.

6. Poor circulation of the coolant: the water in the boiler is hot, and the batteries are cold.

Add coolant to the system, perhaps its amount is insufficient.

7. Main burner hiss.

Excessive chimney draft or excess air supply. Adjust the air dampers.

8. The water in the boiler is boiling.

With a small area of the room, the boiler power is not fully consumed.Open the choke and rods fully.

9. The boiler shuts down spontaneously.

There is no gas supply to the burner. Re-ignite the burner. Watching the video. Gas boilers AOGV-6.9; -9.3; -12.5 "Termolux" customer reviews are different. These devices are more focused on the unpretentious consumer who wants to buy a heating device with a minimum set of functions for little money. We examined the main technical characteristics and the internal structure of AOGV boilers according to the operating instructions, the model range, as well as their malfunctions and ways to eliminate these problems.

Advantages and disadvantages of the model

The advantages of Zhukovsky AOGV 23 boilers are:

- Reliability, simplicity of design.

- Independence from the power supply system.

- Simple and intuitive controls.

- Designed for use in Russian conditions.

- Designed to work in harsh climatic conditions.

- The service life is 14 years (or more).

- The cost of boilers is much lower than that of European counterparts.

The disadvantages of the units should be considered:

- The heat exchanger of the units is made of steel, inferior in thermal conductivity to cast iron.

- The appearance of the boilers is inferior to European models.

- The mechanical automation of the boiler is rather weak.

- The unit's dimensions and weight require installation in a separate room.

NOTE!

Most of the shortcomings to one degree or another are inherent in all atmospheric models, so they can be attributed to a specific design feature.

Equipment advantages and disadvantages

One of the advantages is the expanded range of models

Regardless of the configuration, the ZhMZ boiler has the following advantages:

- Extended range of models. This allows you to choose the best option for heating any object, taking into account the area of the building, layout, number of rooms, quality of thermal insulation, climatic conditions and other factors. The line of devices includes both budget devices designed for seasonal use and heating of small one-story summer cottages, as well as high-performance units for brick cottages with 2-3 floors.

- Relatively simple control: the manual for ZhMZ boilers contains detailed information on preparing equipment for connection, setting up, operating and safety rules.

- Most of the models are equipped with an imported automation unit with piezo ignition, so there are no problems with starting the unit.

- Single-circuit devices allow the use of antifreeze liquid, which facilitates the operation of the boiler house in the winter season, especially in regions with severe winters.

- The design provides for the possibility of installing two types of nozzles, due to which the equipment is compatible with both natural and liquefied gas.

- Increased maintainability, most of the parts are available in stores.

- Long service life: it exceeds 14 years.

The disadvantages of the equipment include an outdated design, a reduced level of efficiency and a considerable cost. Some users have doubts about the Russian assembly of equipment, but reviews indicate that its quality meets expectations. The manufacturer offers three modifications of boiler units - "economy", "wagon" and "comfort". The first two are easy to distinguish externally: the devices are equipped with a rectangular case, and the “comfort” varieties are round.

Which is better - Borinsky or Zhukovsky

The equipment of the Borinsky plant appeared on the market in 2009, but the same organization was engaged in gasification of Russian regions back in 1992. Today this manufacturer offers more than 30 models of different capacities, including those with two circuits. The characteristics of the devices of the two brands differ little, as well as the level of quality, therefore, if it is not possible to purchase a Zhukovsky boiler, you can order a Borinsky boiler with a similar power.

Varieties

There are three modifications of boilers Zhukovsky AOGV 23:

- Economy... Floor-standing unit with Russian automatics, tubular heat exchanger. There is a temperature sensor.

- Station wagon. Installed Italian automatic equipment SIT, modulated burner, coolant overheating sensor.

- Comfort. In addition to all the options of the Universal models, the boilers have the possibility of remote control, room thermostat, protection against excess temperature of the coolant.

Boilers of the Comfort modification can be distinguished from other varieties externally - they have a rectangular cross-sectional shape of the body, while the Economy and Universal are round.

Operating principle

All columns have a ventilated cavity between the body and the boiler

ZhMZ produces two main types of equipment for space heating - AOGV (Gas Water Heating Apparatus) and AKGV (Combined).

Their differences lie in functionality.

Both types are floor structures.

Both devices include a gas chamber with a viewing window, a heating boiler, and automation. The gas is fed into the combustion chamber, by burning it releases its energy and transfers it to the heating liquid - household antifreeze or water.

The liquid, heating up, expands and upon reaching a certain pressure "shoots" out of the boiler, begins to circulate through the pipes, quickly warming up all the rooms.

At the moment of the "shot", the pressure in the structure reaches critical values, so all heating devices (pipes, batteries) must be welded together.

The difference in the functioning of combined gas boilers is that they are double-circuit. The design has an outlet and an inlet for cold water, which, flowing through a specially modeled network, heats up, and then is used for its intended purpose.

Device

The principle of operation of the AOGV 23 boiler is based on heating the coolant using an atmospheric burner... Entering the tubular heat exchanger, the liquid reaches its maximum temperature, after which it is discharged into the heating system.

The movement of the coolant occurs under the influence of the thermal movement of the heated layers upwards, therefore, the placement of all pipelines must be planned with a certain slope. To adjust the temperature to a preset value, a three-way valve is installed, which mixes a certain amount of a colder return flow into the heated coolant.

Natural circulation is unstable and inefficient, which is why many owners install an external circulation pump to stabilize the system.

Installation features

A separate room is required to install the boiler

For the installation of ZhMZ equipment, a separate room is required, the dimensions of which depend on the equipment power and performance. If you want to install a two-circuit model, the work scheme is as follows:

- Radiators equipped with ventilation outlets are connected to the boiler.

- A pumping unit is installed in front of the boiler equipment, it is advisable to connect it to the return line.

- In the direction of movement of the working fluid, a sump is mounted in front of the pump, the use of this device is mandatory.

- A storage tank is placed in front of the pump.

In the case of connecting a single-circuit model, the system is closed only on the boiler, usually it requires less space. During installation, it is important to equip the boiler room, create fireproof conditions. After installation, the specialists conduct a test run, commissioning work. If you have problems with self-connection, it is better to contact a company specializing in the installation of gas equipment.

What kind of premises is best suited for?

AOGV 23 boilers are optimal for use in private houses, public or commercial premises. They require a separate room with the possibility of ventilation, therefore the installation of units in apartments is not recommended.

Also, production halls with a large number of openings and technological hatches that disrupt the air exchange mode and create drafts are not suitable for operation. They often blow off the flame, which stops the heating system and creates a danger of gas leaks.

The best option is a separate room in the basement (basement) floor with a window opening with an area of at least 8 m2.

The heart of the heating system

The main component of the heating system is the boiler.

It is on its power, reliability and quality that the heating rate, protection from the cold and a comfortable stay in the premises depend.

According to these indicators, ZhMZ products in a favorable light differ from the designs of other manufacturers. Moreover, it has a number of other advantages:

All equipment is non-volatile - the circulation of the coolant occurs by the force of pressure:

- progressive control system - pressure sensors for gas, liquid medium in pipes, fuel leaks automatically stop working in hazardous situations;

- a modern control panel will automate or remotely control the heating process;

- the ability to install additional attachments - thermostats, temperature indicators;

- the chimney has a wind protection structure, so that the flame does not extinguish even with strong gusts;

- simple device, high efficiency and maintainability - this will extend the service life and simplify maintenance.

The scope of application of gas boilers is extensive - from heating small private houses to heating large industrial enterprises. Products differ from each other not only in terms of power, but also in design, principle of operation and additional functionality.

Start-up and operating instructions

The boiler is started up after installation on a flat horizontal surface and connecting all communications:

- Gas supply.

- Direct and return lines of the heating system.

After installation, the system must be filled with coolant. The fill level is monitored using a signal pipe... The boiler is fired up using a piezo ignition unit or a lighted match (Economy series).

IMPORTANT!

To start the boiler, first ventilate the room for 15 minutes. After that, open the gas cock, turn on the handle to the "igniter on" position and drown it all the way. Wait in this position for 10-15 seconds, then press the piezo ignition button.

When a flame appears on the igniter, wait another 20-30 seconds, then release the handle... The igniter should continue to burn. After that, you can set the required coolant temperature.

During operation, no specific actions are required from the user, except for periodic cleaning from dust and soot.

Once a year, a foreman should be invited to perform maintenance. For all problems, contact the warranty or service workshop.

How to prepare the boiler for operation

To answer most of the questions that arise during the operation of equipment from Termotechnik, the detailed instructions that are attached to each model will help. It is useful for every owner to read the manual in order to avoid mistakes and breakdowns.

It is especially important to read the instructions before diagnosing or repairing. For example: the burner goes out and it is impossible to immediately determine why this is happening - there can be about a dozen reasons for such a problem.

Before turning on the boiler, all the manufacturer's requirements for the premises used for the installation of the equipment must be fulfilled. You also need to correctly connect and configure the device.

All installation and adjustment work must be carried out by specialists who have a special permit to perform work. The first ignition is carried out after the completion of installation and piping. Be sure to check if the equipment is installed correctly.Make sure that all fasteners comply with fire safety regulations.

It is forbidden to place flammable materials near the heaters. It is forbidden to place gas appliances near windows - this will disrupt their operation. When mounting the equipment, you need to keep an eye on the case - it should stand level, distortions are unacceptable.

When the equipment is installed, you need to connect cold water to it by removing the plugs from the nozzles. Filters are installed at the inlet to prevent dirt particles from entering the system. Ball valves should be installed on each branch pipe used for piping. It is especially important to correctly install the gas pipes - you should not do it yourself, invite a specialist.

Requirements for the premises

The room intended for the installation of Termotechnik heaters must have a constant flow of air. The room is equipped with a ventilation hood.

Gas appliances can be mounted only at non-combustible walls, retreating from them by 15 cm. Hard-flammable walls must be covered with steel sheets - they are attached to asbestos sheets, the thickness of which is 5 mm. The dimensions of the sheet should be 10 cm larger than that of the heater. The passage in front of the facade should be more than one meter.

If the heater is mounted on a wooden floor, an asbestos sheet is laid first, and then a metal sheet.

Price range

The cost of the Zhukovsky AOGV 23 boiler depends on the specific model and is in the range of 20-24.4 thousand rubles. This price does not include the chimney. When buying, you should immediately clarify the complete set of the unit so that you do not have to urgently look for the necessary components.

In addition, additional costs will be incurred for the conclusion of the warranty agreement.

It is not recommended to neglect this action, since a much higher amount can be spent later on repairs..

NOTE!

Many users rely on their own skills and knowledge, intending to repair the boiler on their own. It must be remembered that unauthorized actions with gas equipment may entail administrative liability.

Equipment for the gas valve Econom ZhMZ. General description of the block.

Catalog / Instructions for the repair of gas boilers AOGV Zhukovsky

Publication date 10/14/2014.

The ZhMZ Economy gas valve is unique. The Economy valve - the Soviet own version for the gas valve - is hard to say, but 1974-1977, I think. Somewhere within these limits. Since then, the principle of its operation and the aggregate components have remained unchanged. Although, for some reason, the plant itself decided to stop producing boilers equipped with a similar valve. This does not in the least detract from its significance and does not affect the honor of the valve, since it was invented by the people who launched Gagarin into space. There are no such people at the plant for a long time. Knowing that the main requirements for any design of those times were primarily reliability, we will consider the operation of the valve from this point of view.

What makes the Econom valve unique?

1. The Econom valve is completely non-volatile. Works where there is no electricity (or is often turned off, or not at all and never will be). Boilers equipped with such a valve are installed and operate in any conditions, whether it is working on liquefied gas from cylinders or a gas holder, or natural gas, which was supplied, but there is no electricity or while it is "delayed".

2. The valve equipment is extremely simple and affordable. The composition of the tooling is produced by the plant to this day. Gaskets, thermocouple, solenoid valve, thrust sensor, temperature sensor (bellows-thermal bulb assembly), igniter assembly - any spare part is available.

3. The design of the valve itself is so simple that there is practically nothing to write about it. There is nothing there.

4. Maintenance of the Economy valve (although the word “maintenance” does not turn out to be pronounced) does not exist. Let me explain. The phrase “These are the boilers that we serve” or “do not serve” sounds especially cheerfully.The summary is: "No one has ever serviced or serviced any boilers." And stop listening to this nonsense.

5. Everything is always before your eyes. To carry out repairs, we do not need to go into the jungle, completely disassembling the boiler. Any detail is available within a couple of minutes.

Why do Econom valves on different ZhMZ boilers look different?

A long time ago, when the plant carried out the State Planning Commission for the produced products, it was also necessary to provide and report not only on the output, but also on the improvements and novelties among the manufactured products necessary for the country's progress. So the valve, made initially, was taken and turned upside down. And ... they reported on the new product! Then he was turned sideways, placed slightly higher or slightly lower, and again the report. After such "progress" we have several different valves, which, of course, have the same operating principle, but, unfortunately, each one fits only its own boiler according to the year of its production. In connection with the "progressive" circulation of the unit, we end up with a whole bunch of ZhMZ thermocouples, of different lengths, and differently bent, igniters and igniter units, bellows units, overheating sensors, etc.

If you have a boiler with an Economy unit installed, take a closer look at the photo. Shown here is the gas valve Econom of the gas boiler AOGV-11.6... You may have a different power and variant of the arrangement of the boiler block. It's not scary. Everywhere, both in this boiler, and in the other, and in your AOGV, the same principle of equipment is used. To understand what is what we give by the numbers of the names of the elements. This will greatly help you in quickly acquiring the skills to repair it yourself.

Part 1. General idea of the equipment of the gas kapan Econom ZhMZ.

1. Gas valve body Economy A little later we will move on to its structure. Now purely for informational purposes ... But who needs to immediately go to the valve device - here.

2. This is the nut of the tube leading to the draft sensor. There is nothing special about this tube. This is the electrical contact of the solenoid valve, which goes to the thermoplate (which is the thrust sensor). Heated up, the contact opened, and the boiler turned off, it does not heat up more than it should be, - the boiler is working for itself. We will return to this plate in detail. It falls apart over time (from condensation, etc.) or contacts oxidize. This is the reason why the boiler does not turn on. If you want to immediately learn about the work of thermoplate - here. If you need to quickly find out why the boiler turns off or does not turn on at all - here.

3. Thermocouple nut. The thermocouple is heated at the bottom by the igniter flame. The most common malfunction: thermocouple burnout, or poor contact of the thermocouple with the solenoid valve, or simply a thermocouple malfunction. All this leads to the fact that the boiler does not turn on at all and the solenoid valve button is clamped purely mechanically with something and the boiler has been operating in this state for years. If you want to learn how to check a thermocouple - here. If you need to quickly find out why the boiler does not work - here. What if it's a thermocouple ?! And if you need to replace the thermocouple with a new one - here?

4. Bellows-Thermal Bulb Assembly Capillary (sensor, temperature controller). In this tube, as in the bellows itself, there is a kerosene mixture. In gas boilers AOGV Zhukovsky, the temperature regulator is called the bellows-thermocylinder assembly. If you want to know how the bellows-thermal bulb works - here. If you want to see how the thermo-bellows changes to a new one - here.

5. Boiler nut of the bellows-thermal bulb assembly... It is she who holds the balloon inside the boiler. Usually, in old boilers, the cylinder is located directly in the body of the boiler, in the coolant. In newer versions, after 2002, the cylinder body is installed in a dry casing. If you need advice on all variants of bellows assemblies that the Zhukovsky plant produced and is producing - here.

6. Temperature regulator nut... Moreover, not just a nut, but with a tuning screw, in case, when replacing a unit, the degrees of tuning were knocked down. You can always tweak it. In general, this detail is characteristic only for the AOGV-11.6 Economy boiler. It is difficult to say why the bellows assemblies for more powerful boilers do not need to be adjusted after replacing the bellows assembly, but is there such an option for AOGV-11.6? (in developing)

7. Ignition tube nut. Gas flows through this tube to the igniter when the solenoid valve start button is pressed. Moreover, gas flows through this tube (when the button of the solenoid valve is pressed) bypassing virtually the entire gas block. And it is possible to turn off its supply only with a tap installed at the entrance of gas into the house... Please bear this in mind.

8. The solenoid valve itself... It "feeds" the EMF generated by the thermocouple when heated from the igniter flame. If nothing comes to it, no matter how long you hold the button, it will not stick. How to replace the solenoid valve with a new one - here. How to get rid of the fact that the button does not hold at all - three eternal malfunctions !!!

So far, this is the first and main thing that we should know. Often, people who have been using the boiler for 10 years do not know this !!! Study carefully the fittings of the gas valve of your boiler. If you haven’t understood yet, no one will do it for you. And winter always, until you get used to it, promises to be cold and gloomy. There is only one motto: "The more you know, the better you sleep!" Oh! More precisely, "you sleep warmer!"

It's all.

- Solenoid valve (Magnetic box) Products] JSC "Zhukovskiy machine-building plant" (Russia) [/ anchor]

Learn more about the product

Price: 2200 rubles

Add to cart