DIY steam generator. How to make a wood-fired steam generator with your own hands

13 April 2014

A steam generator is a device that produces water vapor in varying amounts, depending on the place of use. Often, such devices are used in industrial plants. However, the steam generator has found its application in everyday life, where it is most often installed in shower cabins and bath rooms. Thanks to such a device, you will always breathe fresh and humid (not dry) air, which is especially appreciated by true sauna lovers.

However, before choosing a steam generator, you need to pay attention to the price. Their cost is measured not even in hundreds, but in thousands of US dollars. Therefore, with a cut budget, you have to look for other ways, namely, to make a steam generator with your own hands. How to do this, see this article.

Features of assembling a solid fuel steam generator for a house on wood or coal

For the assembly of the classic, metal pipes of different diameters are used. This is somewhat reminiscent of a layered cake with the widest layer at the bottom, this will be the loading chamber.

Some masters say that the efficiency of a potbelly stove is much higher than the efficiency of electric steam generators. But this is not the case. It's just that the assembly of such a boiler is less expensive. The next layer is a water tank, it is located directly above the firebox. An adapter with a pipe is welded to it, through which steam will flow to. If you want to know more about how to make a solid fuel steam generator with your own hands, watch this video.

What is a steam generator?

First, let's take a closer look at all the features of this device. It is a device that significantly expands the functionality and capabilities of a modern bath room or shower. With the help of such a device, you can easily revive the ancient traditions of ancient Roman baths, and all this is only thanks to the steam generator.

In terms of its dimensions, this apparatus is not too large, it is distinguished by its special compactness, which allows it to be placed almost anywhere in the bath room. Even in small saunas with an area of 9 square meters, there is a place where to install it.

How to make a steam generator for a bath?

Since the cost of these devices is not affordable for most owners of backyard saunas, the most effective solution would be to make them yourself. So, let's figure out how to make a steam generator yourself.

A propane cylinder should be used as a base. Its dimensions should be selected based on the amount of steam that needs to be generated for the room. Also, do not forget about safety rules - before starting work, the cylinder must be completely empty. To do this, simply unscrew the brass valve. Next, the container is thoroughly washed. The inside is treated with dish detergent until the smell of gas disappears completely. After the cylinder is dry, start installing the heating elements. This should be done using a welding machine. Mount for heating elements is developed separately. However, here it is necessary to take into account that the heating element must withstand a pressure load of at least 6 atmospheres. Do not weld the tubular electric heater to death - install it in such a way that you can easily dismantle and install this element in the event of a burnout. These electric heaters are selected with the calculation of a power of 3 kW per 10 liters of water.If you are making a wood-fired steam generator, it is not necessary to mount heating elements with your own hands and carry out any calculations. However, we note right away that using these units is extremely inconvenient (especially if this device is in the house), so it is best to design electrical devices.

The principle of manufacturing a steam generator

It is best to make a steam generator from dishes with a hermetically sealed lid. The ideal option would be a pressure cooker, since the function of steam generation is incorporated into the design from the very beginning.

The dimensions of the container for heating water will directly depend on the volume of steam that you want to receive. Otherwise, the device will have to work continuously, which will negatively affect its service life.

Often, when distilling thick mash, the thick burns, badly affecting the aroma and taste of the drink. Steam distillation of the mash allows to prevent deterioration of the quality of the distillate. Making a steam generator at home is relatively simple - you need another container (pressure cooker, alembic, can), connecting hoses and a gas pipe.

Welding the tubes

How to make a steam generator with your own hands next? Four threaded tubes are additionally installed in the upper part of the cylinder. Then the automation elements are screwed onto them, as well as the steam generator filling valve and the pressure relief valve. But that is not all. A pipe with a ball valve should be welded on the side. In this case, the location of this element should be at a distance of no more than 10 centimeters from the top point of the cylinder. The ball valve tube will serve as a liquid level and will open as soon as a certain amount of water has entered the container. As soon as the liquid begins to flow from it, this process must be stopped.

How to make a steam generator for a bath from a gas cylinder with your own hands

This type of assembly is the most popular among craftsmen. Firstly, the balloon itself is made of high-quality sheet iron. Finding one is almost impossible. The metal can withstand almost any temperature, it is resistant to pressure drops. How to make a steam generator with your own hands from a gas cylinder, you can watch in this video.

What tools and materials are needed for work

The welded seams of the cylinder can withstand sufficient pressure. The metal is not afraid of corrosion, resistant to high temperatures. The preparation of the cylinder consists of important stages: removal of gas and vapor residues (as we talked about above), sawing off the upper part and processing the ends.

Advice!

Prepare all consumables in advance: metal sheets, plates, pressure gauges, nozzles, ball valves, adapters.

Selection and preparation of a container for a steam generator

Why exactly a gas cylinder - we explain. The diameter of its base is universal and is suitable for the selection of a heating element from a conventional electric kettle. The heating element in this case is the heating bottom. This in itself is an innovative solution, as it saves money and time for installing a different heating system.

Comment

Repair and construction team leader

Ask a Question

“The size of the container is chosen exclusively on the basis of the planned volume of steam. If the made device gives out the amount less than necessary, then it will have to work continuously, at the limit of its capabilities, which will often necessitate its repair.

«

Before starting installation work, the cylinder must be freed from water and dried! All welding work should be carried out only after you are fully convinced that there are no gas vapors. Sniff, the cylinder must be completely free of the propane odor.

Installation of heating elements

Heating elements are an essential component of any steam generator.The main rule is that if you use heating elements, and not the heating surface as such (some models of electric kettles have heating elements under the bottom), they should not touch either the bottom or the walls.

It is important to maintain the distance, otherwise the bottom may burn out and be damaged. We recommend using at least two insulating washers with special heat-resistant silicone gaskets. Do not forget to provide valves for draining and supplying water. In some designs, to provide liquid injection, an additional tank is used, as a rule, of a larger volume, or it is connected to centralized networks.

Comment

Repair and construction team leader

Ask a Question

“The tank is located above the transducer to provide natural pressure. Usually, a special tube is made at the bottom of the working container to add water. Just it, on the contrary, should be below the level of heating elements.

«

The choice of heating element depends on the volume of water and the planned load on the unit. The choice of a device in terms of power should be based on the calculation for every 10 liters of liquid 3 kW heating element.

Installation of additional elements

For reliable fixation of cranes and automation, special fasteners are used. They are located at the top of the steam generator. This is a filling, pressure relief and ball valve, as well as squeegees.

All these elements must be selected in the most careful way, as they respond to the exchange processes of the balloon. Improper installation, in the wrong order, or at the wrong height can result in poor performance.

Valve revision

If you are using a gas cylinder, then most likely you still have a brass valve, which may well be used in the operation of the steam generator. It can be easily converted into a ball valve. To do this, the valve is disassembled, the pin is removed, a thread is cut into it, the valve is screwed in. Such a design will be required for the extraction of steam streams.

Steam generator safety check

The main condition for the operation of the steam generator is correct heating and water supply. For this, it is important to control the process at every stage. That is why most home-made steam generators are equipped with special automatic control systems.

It is important to organize a control circuit: when a certain pressure is generated, the heating element is turned off.

Valve revision

Also, during the work, the brass valve of the propane cylinder should be modified. To do this, it is sawn in half (in this case, the upper rod is removed, and all 15 mm holes are additionally reamed). Next, a thread is cut and a ball valve is screwed on. The latter will serve us for the selection of steam.

All dial gauges can be used as instrumentation for the steam generator. One of these sensors will monitor the temperature and the other will monitor the pressure. The devices must be connected in series. This is necessary so that when the limiters are triggered, the heating in the system is automatically turned off. The pick-up coil of the magnetic starter will be used as the load.

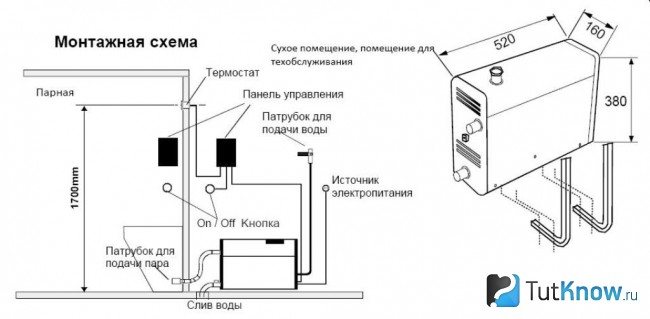

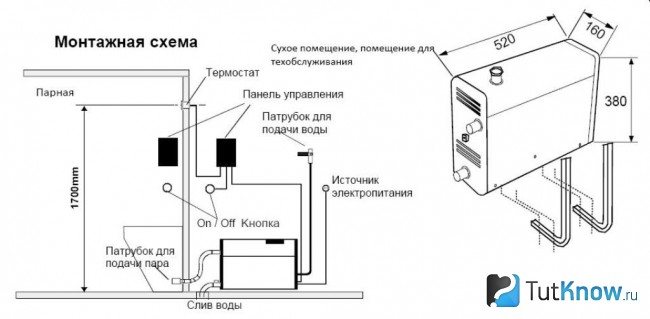

How to install a DIY sauna steam generator?

Particular attention should be paid to exactly where the steam generator will be located in the bath. Often this unit is installed near the steam room, but in a separate room. The place where the steam generator will be located must comply with the following rules - it must be dry and well ventilated. Also, in order to avoid condensation, the length of the steam line must be correctly calculated. It should be as short as possible - only then the risk of moisture formation will be minimized.

Do-it-yourself steam generator for a bath

Considering that the price of an industrial branded steam generator can fluctuate between 1-10 thousand dollars, it makes sense to build the structure yourself. There are two time-tested methods - a steam generator in an oven and a stand-alone steam generation unit. Let's consider further how to make a homemade steam generator in both ways.

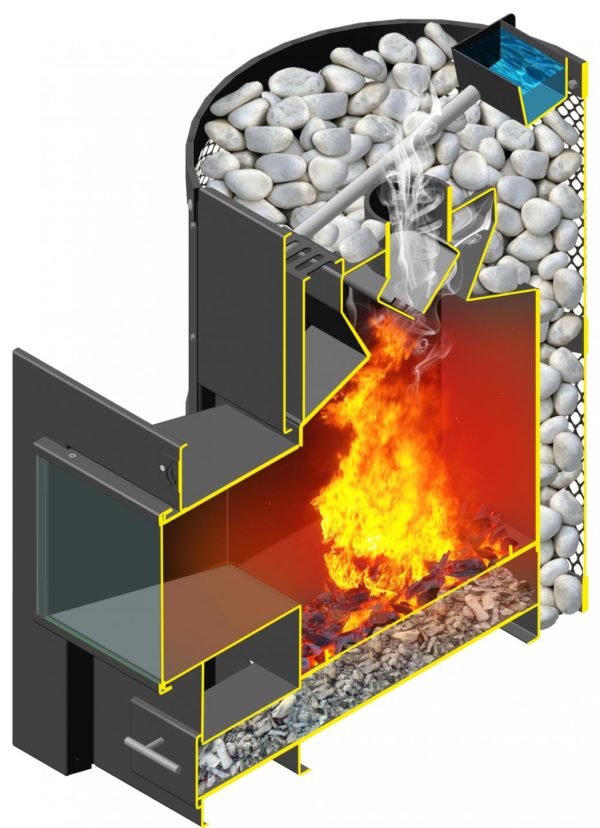

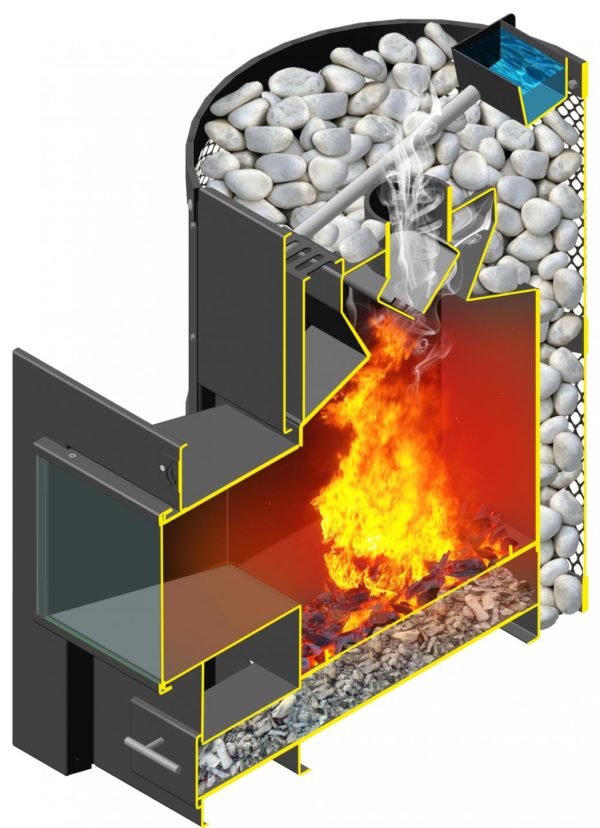

Instructions for creating an oven steam generator for a bath

True connoisseurs of steam bath do not recognize electric steam generators. Such lovers prefer to build steam generators directly in the sauna stove. We need the following materials: an economizer pipe (from 100 rubles apiece), magnesite sheets (from 340 rubles apiece).

A construction is made according to the following scheme:

- We increase the inertness of the steam room. To do this, you need to increase the weight of the stones. If the oven holds about 60–80 kilograms, we make an additional steel trough. We install it in the oven.

- We lay a layer of stones.

- Installing steam cannons.

- To get rid of hard infrared radiation, brick the oven.

- Cover the pipe with the economizer with magnesite sheets. First you need to hang them on the frame. To do this, we make duralumin blanks and screw the sheets onto the frame in such a way as to leave gaps between them. This ensures convection.

- We add another layer of stones in order to completely block the path to radiation.

Making a homemade electric steam generator for the oven

Steam generator wiring diagram

A unit constructed according to the diagram below will operate at high pressure. Therefore, care should be taken to ensure that the housing is of the appropriate thickness. To make a homemade steam generator, you can use a regular gas cylinder. It only needs to be slightly modernized.

Materials that will be needed in the process of work:

- Gas cylinder (from 4300 rubles);

- Heating elements (about 140 rubles apiece);

- Manometer (about 450 rubles).

Step-by-step instructions for creating an electric steam generator:

- We take a gas cylinder for the base. We release gas from it, remove the valve and thoroughly rinse the inside of the cylinder with warm water and any detergent until the smell disappears completely. We dry the balloon.

- We select heating heating elements for 10 liters of water - 3 kilowatts. We mount them in the lower part of our balloon. When creating a mount, keep in mind that the pressure must be at least six atmospheres, and the mount must withstand them.

- Next, we need to make 4 threaded tubes. A valve for collecting pressure, a valve for filling the steam generator with water and devices for the automation system will be screwed onto them.

- Then, on the side of the tubes and at a distance of 10 cm from the top, we weld a tube with a ball valve, which will control the water level. When water is collected, the tap must be opened and waited for water to flow from it. If the water has flowed, then there is enough of it, and the tap is closed.

- To create a steam extraction device, a brass valve from a cylinder is suitable for us. Saw it in half, remove the top bar and make a 15 mm hole. Then we cut the threads and screw on the ball valve.

- As sensors, you can use pressure gauges that will monitor temperature and pressure. Instruments and instrumentation will do. Connect the devices - and when the limit is triggered, the heating will automatically turn off. Use the coil of the magnetic starter for loading.

- We install the steam generator using a steam line.

Remember: the steam generator should not be placed directly in the steam room. It should be located in a separate room, but next to it. The room must be dry and well ventilated. The length of the steam line from the room with the steam generator to the steam room should be as short as possible. Take care not to form condensation and water pockets.

You will learn more about the operation of a steam generator for a bath from the video:

As you can see from the instructions, the device for a steam generator for a bath is not complicated, but rather laborious in the process of creation. In the production of steam generators, great attention should be paid to the safety system. After all, the steam generator runs on electricity, and the contact of an electrician with steam is a rather unsafe phenomenon.

How to choose the most suitable container

An example of an ultrasonic steam generator circuit

Modern housewives often use the process of water vaporization in the cooking process, for example, using pressure cookers. It is such a device that can be used without problems in creating a steam generator, in particular its body. Their main feature is that you can fix the cover as tightly as possible.

There is also a special valve that prevents an explosion in the presence of a pressure exceeding the norm. The advantage of such a container is that its walls are thick enough and able to withstand the highest possible pressure level.

Choosing a place for the heating process

After the container has been chosen, it is worth deciding on the place that will be used for high-quality heating of water.

The most common are the following:

- An ordinary electric or gas stove.

- High quality electric heating elements.

It is much easier to give preference to an electric or gas stove, then these are more dangerous options, especially when it comes to a gas stove with no gas supplied.

It is for this reason that it is worth giving preference to the method based on the use of heating elements. The variety of these devices on the market is large enough that it will allow you to purchase exactly what is required to heat the required volume of liquid.

It looks like a steam generator for a hamam

The offered models differ in size, shape and power level.

Heating element installation process

It is worth carefully determining the future location of the ten. Regardless of the type and type of this element, it is important to install it strictly at a height of 0.5 to 1 cm from the bottom of the selected container.

The heating element is installed as follows:

- At the indicated height, mark the marks on the outside of the dish;

- Holes of the required diameter are drilled as competently as possible;

- It is required to prepare the holes, that is, install a bolt or a special stud in each of them, insert washers on both sides and tighten, as far as possible, with nuts.

Important! It is worth taking care that hot water during the operation of this equipment does not seep through the holes made for installing the heater.

For this purpose, it is worth using a special heat-resistant silicone on both sides.

Organization of water inflow

After the sealing has been carried out, you can proceed to the main work - connecting the power.

For this purpose, a tube made of copper is located at the bottom of the heating element. With its help, fresh water will be supplied quickly and without interruption.

Installation of the device in a shower cabin

If this is a shower cabin, then you will need to ensure its maximum tightness and forced air convection. For this, a special sealed cap is mounted on top of the shower. Convection will be carried out by a conventional fan. You can install several devices at once, but it is not necessary to create a draft in the shower. The best option would be to purchase several 12-volt devices of the type used to cool computer blocks (coolers).

Next, you need to connect the steam generator with your own hands to electricity. But since the bathroom is the wettest and dampest room in the house, for the sake of safety, as in the previous case, place the device in a separate place or room (it is important that this is a dry place). If you decide to buy this device in a store, then before choosing a steam generator, pay attention to the types - automatic units are the most compact and practically do not take up space.

Why does the steam generator break down?

In general, this device fails quite rarely (due to its primitive design).In most cases, the steam generator breaks down due to poor water quality. The high content of impurities of iron, chlorine and salts leads to the rapid formation of scale, which is the reason for the breakdown of this unit. Therefore, even during installation, you should think about purchasing special fine filters. With them, the breakdown of the steam generator will definitely be excluded. And one more thing - in order for this unit to serve as long as possible, periodically drain the remaining water from it.

So, we figured out how to make a steam generator with our own hands and avoid its premature breakdown.

Comments (1)

Similar materials

Cars How to make do-it-yourself roof rails

Often, roof rails are compared to large four-wheel drive SUVs, as well as recreation and exciting travel. Although if you look at them more closely, it will not be difficult to determine ...

Home comfort How to make an ornament on the wall with your own hands?

When making repairs in a house or apartment, the owners strive to create a fashionable, interesting and original interior. Wall decoration can be done in different ways. If the owners want to make them unusual, decorate their homes ...

Home comfort How to make a hydrofoil for a boat motor with your own hands?

Many people cannot imagine modern hunting or fishing without such a vehicle as a motor boat. Most often, these vehicles are equipped with an outboard engine. Their power can vary ...

Home comfort How to make a roof on a garage with your own hands? Construction, materials, tools

When building a garage, few people choose complex and intricate designs. Simplicity, economy and reliability are in the first place. The erected roofs, as a rule, have a gable or single-pitched shape. Last …

Home comfort Plug for a socket from children: description, advantages, photo. How to make plugs for sockets with your own hands

If small children live in your house, then the use of this item becomes a necessity. What is it about? This is a plug for an outlet that is an effective protection against electric shock. If available, adults can ...

Home comfort How to make a lawn in the country with your own hands: step by step instructions

The meadow, which is distinguished by velvet grass, is able to create a certain atmosphere throughout the entire area. Emerald hues can define a design by combining colors, paths and alpine slides. How to make gas ...

Home comfort How to make a chimney deflector with your own hands?

The normal functioning of any heating unit presupposes the need for a chimney. At the same time, it is important to ensure good draft, which will guarantee the operability of the stove, boiler or fireplace. Many ...

Home comfort Do-it-yourself wattle in the country: master class. How to make a wattle fence in the country with your own hands?

Many craftsmen make wattle with their own hands at the dacha today. Recently, this has become the most common for the reason that the rustic style is gaining popularity in the exterior of the country landscape ...

Home comfort Cap on the chimney pipe: price and photo. How to make a cap on a chimney pipe with your own hands?

It is simply necessary to install a cap on the chimney pipe. This element acts as one of the most important components of a stove or fireplace. It is thanks to the hood that an unobstructed and constant drainage is ensured ...

Home comfort How to make a pond on a site with your own hands: step by step instructions

How pleasant it is to spend a few hours by a shady pond or lake in the hot summer season! Of course, it's great if there is one in the neighborhood. However, most often we spend free summer days at the dacha, and far from ...

How to make a steam generator for home and sauna with your own hands

Perhaps the main feature of each bath is high humidity.Most of us believe that steam in baths is generated by pouring water over hot stones.

But recently, the modernization of steam generation has reached the point that a special device is used for this purpose, namely a steam generator.

What is a steam generator

This is a special water tank, which consists of several elements:

Wherever the steam generator is installed, it will in any case be equipped with additional equipment: a couple of sensors and a steam line.

This will allow you to personally regulate not only the volumes of the incoming steam, but also the heating mode.

More modern models are equipped with D / U-remotes that provide remote control.

Also note that the steam generator is in any case used where the humidity is high. But is it safe? Naturally! Indeed, even in such conditions, the device has a special protection that covers all wires and cables.

The heating elements in the device quickly heat up to such a temperature that the trapped moisture evaporates almost instantly.

And the steam generated in this way is by no means ordinary - it is called light steam and it is quite difficult to get it naturally.

The case for a steam generator

- Saving water... Compared to a conventional stove, the steam from which leaves the steam room together with the smoke, the electric steam generator provides the required steam density with less water consumption.

- The convenience of use... Commercial steam generators are usually automated and can be programmed to deliver just the right amount of steam at the right time. This means that no one has to watch the stones and add water when they reach the right temperature. Even if the steam generator is home-made, its volume is usually enough for a full relaxation session in the steam room and there is no need to add water in the process.

- Maximum useful dry steam... If the generator is made correctly, "light" steam, consisting of very small drops, enters the steam room. Unlike the "heavier" steam of a conventional heater, it has no harmful effect on the cardiovascular system and does not cause discomfort. Even children can go to the steam room with a generator.

- Quick preparation of the steam room for work... In the stove, you need to wait until the entire mass of stones is heated to the desired temperature. With a steam generator, it takes only 15–20 minutes to prepare, since steam is generated in it due to the contact of water with a hot iron at the bottom of the furnace or with a heating element (in electric models). If you wish, you can equip a steam room only with a steam generator, completely abandoning the heater. However, in this case, it will be necessary to provide for an alternative heating system.

We start making a steam generator with our own hands

First, I would like to note that in fact, steam generators are used not only in baths - they are widespread in various industrial areas.

In addition, they disinfect all kinds of surfaces. They will allow you to completely eliminate the use of chemical cleaning agents.

And even though a wide range of such devices is presented on the electronics market, each of us can make a steam generator with our own hands.

What is required for this? First of all, a rather thick case - after all, the device will function at extremely high pressure.

In the role of the basis for our steam generator, we will serve as a regular propane cylinder.

Features of the steam system

There is no universal cylinder size, because it will be selected solely depending on our specific goals and capabilities, as well as on how much steam we need.

First of all, we must completely release the remaining gas from the cylinder (without forgetting to strictly follow the safety rules).

Then we carefully unscrew the brass valve.Next, we thoroughly wash the entire inner surface of the cylinder, using heated water and detergent for this.

Washing should continue until the gas aroma has completely disappeared.

At the end, the case should dry out a little.

We take the heating elements and carefully cut them into the lower half of the case. Regarding the mount, you choose the materials for it yourself (it is extremely important to take into account that this mount must withstand six atmospheres!) And install it so that in the future you can easily get to the heating elements.

And, finally, the heating elements themselves are chosen taking into account the fact that there are 3 kilowatts per 10 liters of water.

The four threaded pipes must be fastened to the upper half of the steam generator body.

We will attach to these tubes:

- Pressure control valve.

- The valve for filling the device with liquid.

- Automation.

After that, on the side of the steam generator, we weld another tube (this time with a ball mechanism), which should be ten centimeters from the highest point. This tube will serve us as the water level in the cylinder.

When we fill the body with liquid, then this tap will need to be opened, and if it flows from it, then this will be a sure sign that the water supply should be stopped.

The brass valve located on the body should be slightly modified.

To do this, we cut it in half. We remove the upper part altogether, and in the lower part we drill a hole up to fifteen millimeters in diameter. Then we cut the threads with the help of additional devices, we screw the ball valve here (if you have not yet understood it, we will use it as a steam extractor).

In order to properly control our steam generator with your own hands, it is necessary to install contact pressure gauges with arrows.

In our device, they will play the role of instrumentation and control devices. The first of them will monitor the pressure in the case, and the other will monitor the temperature.

It is best to connect such devices in sequence - this simple manipulation will allow us to instantly deactivate the steam generator in case one of the sensors informs us about exceeding the permissible rate.

As an additional load, we can use one of the elements of the magnetic starter - namely, its coil.

Some other recommendations for installing a steam generator

If desired, you can use the flavors that we mentioned at the beginning of the article.

Water with them will flow through the upper fitting, after which it will turn into steam, which, in turn, will come out of the adjacent fitting.

Do not forget about the safety of a homemade steam generator. We can provide it with an explosive valve not only reporting detected malfunctions, but also independently releasing excess pressure in the device.

Experts believe that it is best to install a steam generator somewhere nearby, and not in a steam room (of course, if it will be used in a bath).

Video tutorial on making a steam generator with your own hands

More information on the topic: https://boldproject.ru

How steam generators work

Before proceeding with the search for details and revisions, it is important to understand what we actually need to look for. A steam generator with your own hands can be assembled from rubbish - checked for yourself. Consider the device of a classic steam generator: any unit operates on water, respectively, we will need a container or a tank. By the way, it is best for the container to have exceeded strength and thermal insulation. Some craftsmen use an ordinary gas cylinder to assemble the steam generator. In fact, a steam generator can even be made from a metal flask.

Comment

Ask a Question

«

If you plan to use a gas cylinder as a container for a steam generator, then it is necessary to carry out a procedure for cleaning it from gas.To do this, it is necessary to very carefully and carefully remove the valve, release the remaining gas from the cylinder, fill it with water, and repeat the procedure several times. And only after that proceed to sawing the body.

«

In addition, you need to find, pick up, assemble or borrow a heating element. In this we will be helped by out-of-order old household appliances, for example, electric.

For the successful implementation of the project, it is necessary to prepare drawings of a steam generator assembled by hand. It is important to take into account and calculate the power and the required volume of the container. You will also need a steam and water pump. Especially if you need to make a steam cannon for a bath with your own hands. Remember that in order for the device to work for a long time, it is necessary to ensure a constant supply of cold water, which, by the way, will additionally cool the entire system. In order for and, you can install special sensors. If you plan to connect the device to a centralized water supply system, then it is necessary to provide for a branch pipe.

In addition, do not forget that in any system it is imperative to drain water and clean the heating elements. Therefore, it is necessary to provide a drain valve, as well as constant access to the heating elements.

DIY steam generator

| [td]Steam generator - an integral part of the ironing system, which is designed to convert water into process steam. On the modern market, there are many steam generators that differ from each other in the power of heating elements, the volume of the water tank and, as a result, in performance and purpose. The main parts of the steam generator, without which its work is inconceivable, are:

Boiler 2. Heating element 3. Thermostat 4. Thermal fuse 5. Pressure switch 6. Safety valve cover 7. Steam valve Some steam generators are equipped with: 8. Steam regulator 9. Pressure gauge For proper operation of the steam generator, it is necessary to unscrew the safety valve cover (6) and pour water into the boiler (1) - a hollow cylinder for generating steam. Then the steam generator is connected to the mains (220V). Using the switches on the control panel, the heating element (2) is turned on. The water in the boiler begins to heat up, turning into steam, thus the pressure required for operation is created in the boiler (about 0.35 MPa) and after about 8 minutes the steam generator comes into full readiness. The pressure switch (5) is responsible for controlling the pressure in the steam generator, which turns off the heating element in case of excess pressure, and when it decreases, turns it back on. If the pressure switch does not work, then steam is automatically released through the safety valve cover into the atmosphere. To protect the heating element and boiler from overheating, a thermostat (3) and a thermal fuse (4) are installed on the steam generator. When the temperature exceeds the standard, the thermostat turns off the heating element by closing and opening the circuit contacts, and when the temperature drops, turns it on. In the event of a thermostat breakdown, a thermal fuse is triggered, which opens the circuit and cuts off the voltage supply to the steam generator; after such a shutdown, the thermal fuse should be replaced. After the signal lights on the control panel of the steam generator indicate that the steam is ready, you can start working. By pressing the microswitch (14) on the handle of the electric steam iron, the steam valve (7) turns on, which supplies steam to the iron. As long as the microswitch is pressed, it is fed through the heat and moisture-resistant steam line to the soleplate of the iron and exits (10) under pressure through the holes in the soleplate. Condensation can accumulate in the wire, which is solved with the help of a labyrinth steam chamber, in which the process steam is cleaned of water droplets and dried. Gradually, during long-term operation, as the water in the steam generator is exhausted, the steam pressure in the boiler begins to decrease, this can be controlled using a pressure gauge (9). In this case, it is necessary to add water to the boiler. To re-fill, it is necessary to disconnect the steam generator from the network, release the remaining steam from the boiler through the safety valve cover (slowly and smoothly unscrewing it) and a new portion of water. Then you need to screw the lid back on, wait for the water to heat up and continue working. |

Steam generator or steam gun - description, device, principle of operation, types

The healing properties of steam have been known for a long time, since it can have a healing effect on the human body if it is used in the optimal amount and at a certain temperature regime. If such a device is installed in the bath, then there is no need to regularly pour water on the stones in order for the required volume of steam to form in the steam room. Also, thanks to the steam gun, water is significantly saved. It does not take up much space, is easy to assemble and does not require a lot of expensive materials to create it.

Steam cannon for sauna stoves

Device

A traditional steam generator is a device that is equipped with an electric heating element. By the principle of operation, it resembles an ordinary electric kettle. Pour water into the steam generator, turn on the heater, the liquid boils and steam forms. The cover of the device is equipped with a special valve with which you can independently adjust the degree of pressure. As a result, we can independently "create" steam of the required temperature. Steam with a high degree of humidity will create the atmosphere of a traditional Turkish hammam, and hot and dry will make you feel like in a real Russian bath.

Furnace device with a steam generator

The steam generator can be used in conjunction with a stove - heater. As a result of this "contact", the steam produced by the device is additionally supplied to the stones for full heating. Thanks to this scheme, electricity is significantly saved and at the same time the temperature of the stones decreases, the load on the furnace decreases and its service life increases.

If you use a steam generator without a heater, the energy costs will increase significantly, but you will not need to build an expensive large brick oven. In this case, it will only be necessary to choose a heating system for the bath.

A typical store-bought steam generator consists of:

- Security sensor.

- Water tanks.

- Pump for the movement of water and steam.

- Preparatory block for water.

- Steam generation unit.

- Control panel.

Outside the device there is an indicator and a display that shows all information about the operation of the device and its programs.

Types and types

Such devices can have manual and automatic water filling. Automatic filling provides for the connection of the steam generator to the central water supply. Most modern steam generators are equipped with an automatic system that will itself control the temperature in the steam room. And also they can be ceramic and metal.

There are two types of steam generators:

- Industrial devices with voltages from 220 to 300 volts. Such devices are commonly used in large saunas and public baths.

Industrial steam generator for a bath

- Household steam guns have a power of 4 to 16 kilowatts and are intended mainly for small domestic baths and saunas.

Household steam generators for baths, saunas and hamam

For a steam room of 10–13 m3, a steam gun of 8–9 kW can be used. In a room of more than 15 m3, it is recommended to install 12 kW devices. For a small steam room up to 5 m3, it will be enough to make a 5 kW steam generator.

Devices that have a power of more than 9 kW have a three-phase connection system.

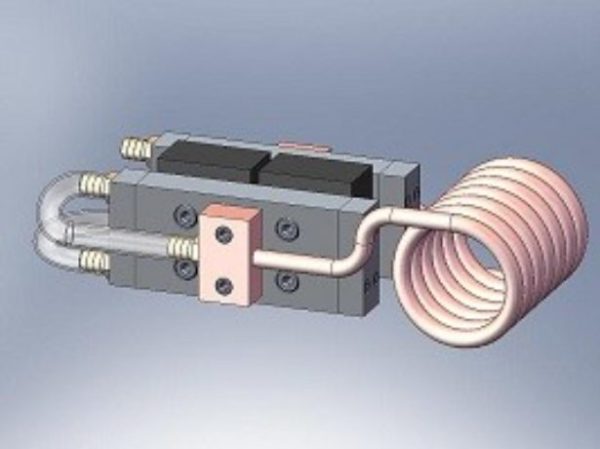

Steam generators can have three types of water heating:

- Electrode. In this case, the current passing through the electrodes through the water heats it to a certain temperature.Such a heater has a simple design (ordinary metal rods act as electrodes) and does not overheat, since it simply will not work without water. But since the electrodes tend to dissolve over time, they will have to be changed periodically.

Electrode heating elements

- Heating elements. Devices of various power levels are used to heat water.

TEN for heating water

- Induction. The water is heated in the same way as in a microwave oven. In this case, the water is quickly heated, since the alternating electromagnetic field allows you to immediately heat the entire container in which the liquid is located.

Induction heating element

Self-installation and assembly of the steam generator

The device of the electric steam iron itself is similar to the device of a steam generator. It consists of:

10. Iron soles 11. Heating element 12. Thermostat 13. Thermal fuse 14. Microswitch 15. Thermostat

The thermostat (15) can change the temperature of the ironing soleplate. The required temperature is set by turning the thermostat until the temperature indicator on the iron handle aligns with the symbol printed on the thermostat dial. The heating element of the iron (11) turns on and off automatically, i.e. closing and opening of the thermostat contacts (12) when the sole reaches the temperature set by the thermostat.

Modern industrial irons must meet safety requirements, so many manufacturers equip them with a cork handle to prevent slipping during operation and a hand guard to prevent burns.

There are electric irons, which differ in electric steam in that the semi-finished product is moistened not with the help of a microswitch and holes on the sole of the iron, but manually by spraying water on the surface of the fabric to be treated or by pre-moistening.

[/ td]

SITE OF THE OFFICIAL REPRESENTATIVE OF SILTER COMPANY IN RUSSIA all rights reserved © Welltex 2015

How to make a steam generator with your own hands: good advice for home craftsmen

They are the main constituents of limescale. This is done like this:

Give the water that you will use in the steam generator for analysis. Then, with the results of the water analysis, contact the company that deals with the water treatment systems (they often do the water analysis). They will select the filter you need. Installing a filter will significantly reduce the likelihood of lime scale formation.

Distilled water must not be used as it does not conduct electricity, and all steam generator sensors operate at low currents.

Those. with such water, it will not turn on.

Contaminated water does not affect the purity of the steam. Boiling water turns into steam, but impurities remain in liquid water and do not enter the steam room with steam. Contamination affects only the performance and duration of the unit operation without cleaning.

→ You can find a steam generator for a hamam here

How to make a steam generator for washing the engine with your own hands - the nuances

Very often steam engines are used by professional ones. The steam effectively removes dirt and germs. These machines are some of the noisiest such special devices in the state (due to the running compressor).

Usually this is a unit on wheels, somewhat reminiscent of a vacuum cleaner, water is supplied to it. The operator works like a gun. In this case, steam is supplied under sufficient pressure. But a home-made steam generator for a car can be used to blow off the engine, heat the hoses.

steam generator for car wash