Types and technical characteristics of foil insulation

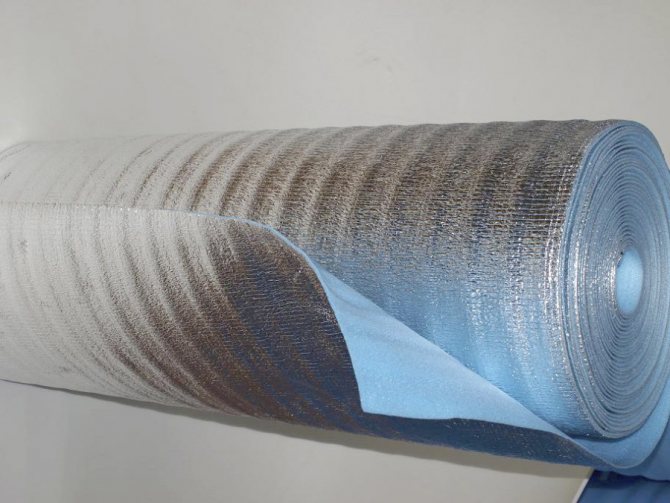

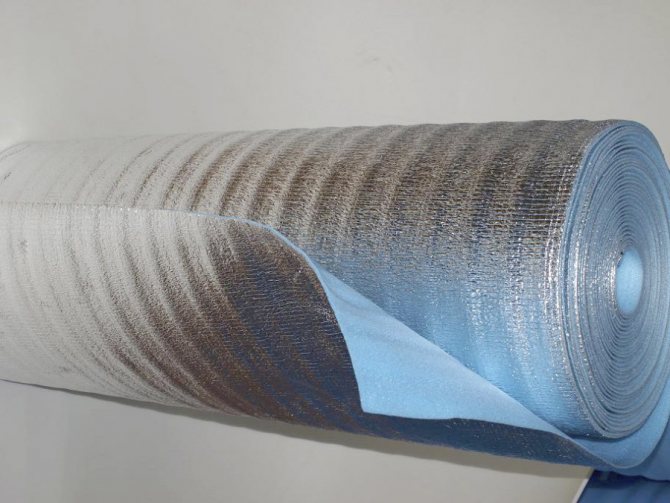

In the construction market, foil insulation is presented in several types:

- Foamed polyethylene foam: roll-up self-adhesive material. It is mainly used for the device of a heat-insulating layer in technological equipment, pipes and air ducts

- Foil mineral wool: Available in slabs, cylinders and rolls. Due to its high degree of fire resistance, the material is widely used for insulating chimneys, roofs, walls of saunas and baths

- Foil polystyrene foam (with double-sided foil): resistant to temperature fluctuations in the range (-170 - +170 degrees Celsius). Most often it is used when installing a heat-insulating layer in warm floors. Foil polystyrene can be used to insulate the space under the roof

- Foil-clad basalt thermal insulator: the most resistant to aggressive environments among all foil-clad heaters. Does not change its properties under the influence of temperature differences from -190 to +600 degrees Celsius. Mainly used in the heat and power industry, aircraft construction, in the construction of gas stations

Despite the difference in the composition of foil insulation, they are united by a number of technical characteristics:

- Resistant to temperature fluctuations

- Moisture repellent properties

- High vapor permeability (0.001 mg / m.h.Pa)

- High efficiency of reflection of thermal radiation (average thermal conductivity is 0.037 W / m ° C)

- High sound insulation properties (sound absorption - up to 68%)

Foil reliably protects all types of insulation from solar and radon radiation. In addition, thermal insulation materials of this kind do not require additional treatment with chemical agents, which has a very positive effect on the level of their environmental friendliness.

Manufacturers position foil insulation as a durable material that can last up to 95 years. However, it is very problematic to verify this statement.

A wide variety of materials can be found from thermal insulator suppliers. Any buyer immediately asks the question "How to insulate the house from the outside?" Perhaps one of the most popular materials is rock wool, as it has excellent resistance to high temperatures.

Minwatoi also insulate the roof. We advise you to familiarize yourself with the types and installation of mansard roof insulation in this article. The roof must be insulated.

Can polypropylene pipes be poured with concrete? what conditions are necessary for this

Carrying out overhaul in premises for housing of multi-apartment or private houses takes into account the replacement (modernization) of components of the heating system. The need is associated with reducing the cost of paying for energy sources for further use and giving a beautiful appearance to the rooms.

Sometimes the owners decide to hide the heating pipes under the floor covering or in the walls of the room. Therefore, they are concerned about the possibility of using plastic pipes for these purposes and the question of whether it is possible to use a polymer pipe flood concrete? How long does the working term of the communications placed under the screed exhaust?

Hidden pipe arrangement

Characteristics and use of PP pipes

To determine the possibility of installing polypropylene pipelines under the screed, it is necessary to refer to their properties.

Recall that polypropylene is one of the types of polymeric material, the components of which are connected by derivatives of ethylene gas.

The material is resistant to interaction with an aggressive environment and alkaline solutions, while the operating conditions declared by the manufacturer allow a difference in operating temperatures from -10 to +110 degrees.

- the period of application under thermal loads without changing the quality and external is at least fifty years, and when organizing cold water supply, it is twice as long;

- the operating system pressure of water supply or heat supply reaches 20 bar;

- systematic contact with the water mass of the inner part does not provoke the formation of scale;

- the noise background of flowing water is absorbed by the walls of the products;

- propylene has the characteristics of low thermal conductivity, which prevents the appearance of moisture on the outer walls;

- the product weighs little and provides for installation even by one person;

- when using special tools, the products are connected and installed in regular places in a short time;

- plasticity helps to give the turns the given bends;

- after the installation work of the products, additional maintenance is not required;

- democratic cost of the product and fasteners.

On the construction services market there are polypropylene

pipes of various colors. This fact does not determine the characteristics of the material from which they are made, except for black - which helps to protect against the influence of ultraviolet radiation. The properties of the product are determined by the markings applied to the surface:

- РРВ. The defining characteristic is a very high mechanical reliability due to the reinforcement technology during manufacture. The use is recommended for heating communications and water supply, plus a concrete screed.

- RRH. Marking is applied to products of significant diameters, their size makes it possible to use them in ventilation systems, sewage, cold water supply.

- RRK. A much more used brand of polypropylene products. It can be used in cold and hot water supply systems, heat supply systems. It easily transfers thermal and mechanical loads.

The main thing! Price PP pipes

and elements for profiles in each region of the country is different. Therefore, before buying, it is recommended that you familiarize yourself with the parameters presented at the points of sale of products and select copies that are good in quality and cost.

Usage specifics

Manufacturing technology PP pipes does not exclude a linear increase in the product when exposed to high temperatures. Compensating for this disadvantage will be made possible by a good choice of pipes with the desired characteristics and the installation of supports with the organization of expansion joints.

Any system includes branches from the central pipeline, direct connection and the creation of turns at all possible angles, while differences in pipe diameters cannot be ruled out.

The use of connectors facilitates the solution of these problems, which are divided into the following options:

- flange type;

- crimping device;

- using a fastening connection in the form of a thread;

- welded structure.

Polypropylene connectors are used for pipe connections of the same and other materials. A similar result is achieved by placing chromium-containing or brass inserts in the interior, which determine the technical possibility of connecting to plumbing devices and creating transitions.

Practice shows that the main reasons for the manifestation of ruptures of heating pipes under the screed are a gross violation of the installation technology and low-quality soldering of connectors at the joints of products.

The soldering process is not difficult for DIYers. The device for pipe connections is represented by a soldering iron with marked nozzles of different diameters.

Before industrial brazing, it is suggested to carry out a trial thermal connection of materials on small pipe pieces and unused connecting elements.

Using combined connectors, it is possible at the design stage to ensure a suitable pressure in all parts of the heating structure, while preventing unnecessary costs for using pipes of a larger than necessary diameter.

Soldering PP pipes

The main thing! Compound PP pipes

with external placement of a metal amplifier requires its retraction for the immersion length in the abutting component. Otherwise, all parts to be soldered must be dust-free. Degreasing is recommended.

Installation technique

A separate category is allocated polypropylene pipes for organizing heated floors. Their characteristics allow laying in a concrete screed without fear that the system will rupture. The basis for such a statement is the pipe-laying technique, in which the joints are above the floor surface, and only one-piece pipeline parts are silted up with a mixture.

The sequence of installation when laying a warm water floor is represented by the following measures:

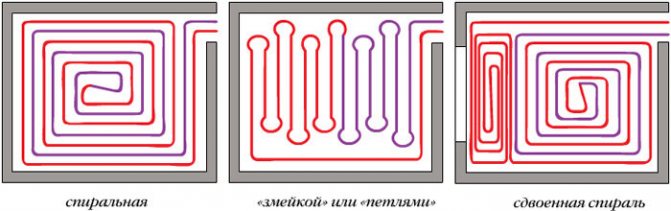

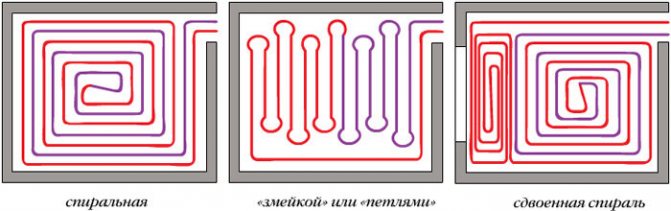

- It is reasonable to carry out a full calculation of the material that will be required and things and draw up a laying scheme PP pipes... When calculating the number of products, take into account the form of laying (serpentine, spiral and other good for this room).

- The surface of the primary screed is cleaned of debris caused by construction work.

- Gradually, the waterproofing barrier is laid, after which the material for thermal insulation is installed.

- A metal mesh is laid in the form of a base throughout the entire area of the room, covered by the heating circuit. Products are specifically fixed to it using PVC clamps or metal wire.

- Connect all heating circuits to a pre-formed collector. They test the system with parameters much higher than the working ones. The temperature to the operating temperature is raised slowly.

- After checking, fill in the final screed and lay the floor covering.

READ ALSO: Pnd pipe: characteristics, varieties, installation

Underfloor heating

The main thing! When there are signs of pipe breakage under the screed, it is possible to identify a local section of the floor surface where the pipe was damaged, using the installation scheme, open the surface. Dry the damaged area and carry out measures related to the repair.

The above information suggests that the use of polypropylene products during the installation of autonomous space heating systems is a reasonable and correct decision.

Compliance with the installation rules and high-quality soldering at the joints of the elements for the profiles ensures a very long period of trouble-free operation.

The technical specifics of polypropylene components, which determine their reliability, make it possible to place communications in the voids of the walls and under the concrete screed.

One of the types of styling PP pipes presented in the material below.

Video 1. The process of installing pipes made of plastic heating.

Price and quality

Foil insulation is more expensive than usual, so the price is one of the main selection criteria. But you should not get too carried away with the economy, forgetting about the quality of the material.

On the market you can find fabulously cheap foil insulation under the wallpaper. Before you buy it, think about how the manufacturer was able to release such a cheap product? And the answer is very simple: instead of real foil, he applied aluminum spraying to the insulation. The material shines just like the real one, but the quality, alas, leaves much to be desired. The point is that the sprayed layer is too thin to trap thermal radiation. So, most likely you will pay more than for ordinary insulation, but you will not win in quality.As a result - an unjustified overpayment.

The average cost of high-quality foil insulation is:

- 60 - 80 rubles / sq. m - with a thickness of 3 mm

- 120 - 140 rubles / sq. m - with a thickness of 10 mm

Here are examples of prices for the most popular types of insulation:

- The price of Penofol insulation (foil on one side) 3 mm thick - a roll of 36 sq. m costs 1600 rubles

- A roll of Penofol with the same area, but 5 mm thickness will cost 1900 rubles

- Foil insulation Izodom 15 mm thick costs 100 rubles / sq. m

- The price of foil self-adhesive Penofol 2000 with a thickness of 5 mm - the cost of a roll is about 2300 rubles. The roll width is 600 mm, the number of meters in it is 30

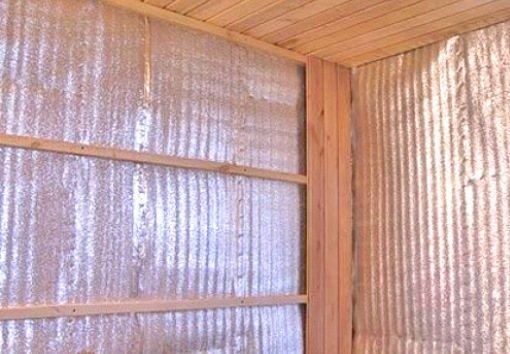

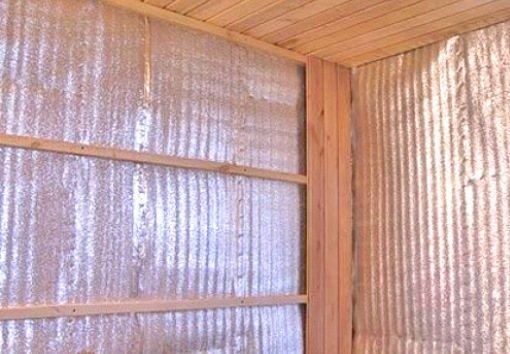

We insulate the bath

To maintain heat in baths and saunas, and especially in steam rooms, reliable thermal insulation of the walls is required. It is quite difficult to do this, since these establishments are characterized by high humidity. Unprotected insulation is quickly saturated with moisture and loses its heat-insulating properties. This problem is solved by using foil for baths: you just need to cover the walls and ceilings of the room with it. Moreover, this foil can be used without insulation: the polished surface of the foil reflects the heat recovery back into the room (thermos effect).

Sauna foil is sold in rolls of 10 meters. The thickness of the material is 40 microns. The price of foil insulation for a bath is about 40 rubles / sq. m.

Video about foil insulation

Comparison of foil-clad insulation Penofol and its analogs.

polypropylene screed

Among other things, it is this material that determines the service life of the created structure. If the adhesive dries up, the pipe will simply flake off and no longer hold hot water.

Of the minuses, it is necessary to highlight the relative complexity of self-bonding of pipeline segments (at home, laser or ultrasonic welding, as a rule, is not used). If you "underpress" a little, leaks will appear. If on the contrary - "pinch" - then the deformed part will have to be cut off and a new fitting applied.

In conclusion, it should be noted that the ideal technical solution for arranging a warm floor is the use of copper pipes. Among their advantages, experts point out an impressive margin of safety and the same durability. And the heat transfer and the permissible bending radius of copper pipes elevate them to the rank of an absolute leader. However, due to the high cost, not every our compatriot can afford to mount a warm floor on their basis.

Selection of pipes Screed pipes Polypropylene pipes Polyethylene pipes Reinforced-plastic pipes

Progress does not stand still. This also applies to heating systems. The most convenient and economical methods of heating the home are being developed. The leader in this matter is the installation of underfloor heating, which helps to create the most comfortable conditions in the premises. The heating pipes in the floor first warm up the floor itself, and then the heat, rising, heats the entire room. This heating method is considered to be the most efficient.

Types and technical characteristics of foil insulation

1) Insulation consisting of foamed polyethylene (polyethylene foam). The thickness of such insulation can be from 2 to 10 mm. One side of it is covered with a layer of aluminum foil. Most often, such insulation is supplied in rolls, has a low rate of thermal conductivity and water absorption.

They are used for floor insulation, usually as the last layer in front of laminate, linoleum, parquet. Another application of this insulation is thermal insulation of water pipes and sewers, saunas and steam baths. In order to save heat once again, it is worth installing foamed foil insulation between the wall and the battery, not forgetting to leave a gap of 15-20 mm. It is not uncommon to see shoe insoles made of polyethylene foam to keep the shoes warm even at the lowest temperatures.Moreover, this type of insulation perfectly insulates sound. It is for this reason that sewer pipes in houses are covered with it, in order to reduce noise, thereby creating a comfortable environment for residents.

Features and procedure for laying floor heating pipes

Scheme of laying pipes for underfloor heating.

Before starting to lay the heating pipes in the floor screed, attention must be paid to the insulating layer. The floor in rooms that are located directly above cold basements must be supplemented with insulating panels, otherwise part of the heat given by the heating pipes will be absorbed by the floor slab and not flow into the room, for which everything is arranged for heating.

The most popular method for laying heating pipes in a screed is known as wet laying. As a result of the embedding of products in the screed layer, high heat transfer is guaranteed. In this case, the pipes are mounted on a home-made or factory-made reinforcing mesh.

In order to ensure uniform heating, it is necessary to ensure that the underfloor heating in the room is arranged in the form of a snake or a spiral with the same distance between zigzags or turns.

Before the final pouring of the prepared concrete screed system, it is necessary to check the tightness of all products and transitions again. Be sure to leave expansion joints in the screed so that the pipes can expand freely during heating.

Price and quality

Foil insulation Tepofol, type "A"

The cost of foil insulation varies from 60 to 85 rubles / sq. m for a 3 mm layer and from 120 to 145 rubles / sq. m per layer of 10 mm. For example, let's take the prices of a well-known insulation - penofol (only one side is covered with foil). 36 sq. m of this insulation with a thickness of 3 mm will cost 2,160 rubles. Absolutely the same, but with a thickness of 5 mm - 2500 rubles.

Self-adhesive Penofol will be more expensive - 2900 rubles per roll of 5 mm thickness. The roll has a length of 30 m and a width of 0.6 m, which is quite convenient for installation.

Of course, foil insulation is an expensive option for thermal insulation, but do not forget about such factors as quality, durability and reliability. This can be neglected and spend your money by buying wallpaper insulation. But the fact is that in fact it is not foil. Instead of foil, aluminum spraying is used in wallpaper insulation. The appearance will not always give it away - it also shines brightly and beautifully, but it is not able to reflect heat. Therefore, before making such a purchase, think about: is this savings worth it?

Installation of floor heating pipes

Floor heating pipes installation diagram.

For a screed that will be laid on top of heating pipes, it is best to use high grade concrete with a fine fraction of gravel. The screed thickness should be 30-40 mm. The total thickness of the concrete screed and underfloor heating must be no more than 60 mm. The screed can be reinforced with a reinforcing mesh. Before and after pouring the concrete solution, the electrical parameters of the heating cable (insulation resistance of the heating cable and the resistance of the central core) are checked without fail.

The time for complete hardening of the concrete screed depends on the mixture used - usually 3-4 weeks. You cannot turn on the underfloor heating sections until the concrete has completely hardened.

To lay heating pipes in a screed, you will need the following tools and materials:

- concrete;

- crushed stone;

- roulette;

- level;

- pliers or pliers;

- pipe wrench;

- a set of ordinary wrenches;

- Phillips (curly) and flat screwdrivers;

- pipe welding machine (soldering iron);

- grinder;

- pipe cutter;

- gas-burner.

The methods of attaching the underfloor heating system to the base largely depend on which pipe you decide to use for heating.However, it is necessary to try to prevent the appearance of connecting joints or to reduce their number to a minimum, since the durability and strength of the joints is in any case inferior to the strength of a solid pipe. Choose heating pipes of such length that the system can be installed without joints.

One of the characteristic features of plastic products is, as already mentioned, their ability to return to their original shape after deformation. Therefore, when forming a heating system, immediately after bending the products at the required angle, they must be fixed on the base.

Copper and multilayer products, unlike elastic polyethylene pipes, do not have such a memory. They can be easily bent in different directions. The shape of the underfloor heating pipe will remain unchanged.

As a fastening of heating pipes on the base, clips, paper clips, strips with cutouts, special nets, foam insulation with special grooves for such products are used, which securely fix them.

To facilitate the installation of pipes and observe the required intervals when creating their bends, manufacturers offer a layout of heating pipes - a raster grid. By following this scheme, you can easily create a heating system that will evenly heat the entire floor.

Sometimes, in order to save money, ordinary foam sheets, covered with an insulating film, are bought and used as a basis for fasteners. A steel mesh is laid on top of the film, on which the entire heating structure is attached using wire or clips. When installing the flooring, choose foam sheets with a minimum density of 20 kg / m³.

Installation of foil insulation

- During installation, it is important to strengthen the foil insulation with foil inside, because it is this side that will reflect heat, thereby preserving it.

Shiny side inward to reflect heat

- Lay close to each other to avoid heat loss. Fastening will be carried out by means of usually a construction stapler. If you are going to insulate the walls, the material should be placed between the crate guides.

- The joints of polyethylene foam will help to close the special metallized tape.

Bonding joints with special tape

- It is necessary to leave an opening of 20-25 mm between the foil insulation and the final finish.

Large linear expansion

If you are going to make heating with polypropylene pipes, then immediately lay down their use only in hidden installation. All pipes you will need to hide in the walls and screed, and preferably in insulation.

The main problem with polypropylene is its linear expansion. It is approximately 2.5 mm per one running meter. If you have installed straight pipes, then during operation they will surely "float" somewhere. Even if they are often fastened. If these pipes are located outside, then you are unlikely to appreciate such a picture.

It will be useful: Polypropylene pipe (ppr) reinforced with aluminum

We insulate the bath

Baths and saunas are places where you especially need to keep warm. The whole difficulty in insulating these rooms is that they have high humidity. Ordinary insulation will very quickly absorb moisture and cease to retain heat, which is pretty bad. But this problem can be solved. There is a special foil for baths, which is used to cover the walls and ceilings. Moreover, the foil can be used without the insulation itself, because the heat will be reflected by its surface. This is called the thermos effect.

You need to think about insulating your home even at the stage of its construction, because this will help you save most of your energy resources. But what your insulation will be, you must decide for yourself.Also, it will not be superfluous to consult with specialists who can analyze the place of insulation and choose a decent insulation for you.

A few words about polypropylene pipes

Polypropylene pipes are widely used in engineering systems for various purposes: water supply, heating. They are suitable for laying in the ground, in channels, in shafts, in walls under plaster or in the open. Their main advantage is in the method of joining together, when the pipes after thermal welding turn into a monolith. For this, special equipment is used - a welding machine, which is popularly called a soldering iron. It is quite simple to use, soldering takes only a few minutes.

Use a special soldering iron, then the pipes after heat welding turn into a monolith.

Other advantages of these pipes are high mechanical strength and resistance to defrosting. Even if water freezes in the pipe, then nothing threatens its integrity. It will expand and, after it thaws, will take on its original shape.

At the operating temperature of the pipes plus 75 degrees and a pressure of 7.5 atmospheres, they are guaranteed to last at least 25 years. The highest temperature that they can withstand is plus 95 degrees, but then their service life will decrease.

The use of polypropylene pipes for underfloor heating is economically beneficial, because they are much cheaper than any others, for example, metal-plastic ones. This is especially true for connecting parts.

Polypropylene (PP) - physical properties and characteristics

PP is a plastic polymer with resistance to aggressive chemicals, flexibility and low vapor permeability.

Polypropylene products are made in 5 main ways:

- injection molding;

- extrusion;

- rotational molding;

- blowing out;

- foaming.

The material obtained by foaming polymer granules has found wide application in heat, steam and sound insulation of building structures and pipelines. To give it special properties, plasticizers, flame retardants, antistatic and other substances are added to PP granules. Porous or expanded polypropylene (PPP) is molded in the extrusion process.

The main characteristics of heating pipes

In the modern market, a variety of heating pipes are available that can be used in a floor screed: these are metal-plastic, and polyethylene, and reinforced concrete, and copper structures.

The material that you choose as the main material for floor heating will determine how long and efficiently the entire system will serve.

Regardless of the type, when choosing heating pipes that are suitable for each specific case, you need to be guided by the values that characterize the thickness of the pipe walls and the outer diameter of the pipe.

Choosing high-quality and inexpensive heating pipes that could be used in a floor screed is a rather difficult task. As already mentioned, the market for modern pipes is very wide.

Heating pipe device diagram.

When choosing heating pipes that are planned to be mounted in the floor screed, it is better to limit the choice to metal-plastic pipes or cross-linked polyethylene products. Prices for heating pipes that can be used in a floor screed differ and depend on the production technology, diameter, country of origin and other parameters.

The list of quality characteristics of floor heating pipes is really very long. Here are the most important indicators that you need to focus on in the first place:

- durability (almost all polymer floor heating pipes have a service life of up to 50 years);

- thermal conductivity (it depends on how quickly the coolant cools down);

- resistance to electrochemical processes (heating pipes for the floor must not corrode);

- the level of sound insulation (the audibility of the water flow or other heat carriers depends on this).

Table of hydrodynamic characteristics of pipes.

As already mentioned, the choice of a heating pipe for the floor is reduced to metal-polymer and polymer products (cross-linked polyethylene). Floor heating pipes made of XLPE are robust structures that are resistant to temperature influences. Compared to products made of polyethylene or polypropylene, products made of cross-linked polyethylene are manufactured in accordance with a special technology: they are processed under high pressure, as a result of which additional cross bridges are formed. This method is called stitching.

There is such an indicator as the crosslink density, and you also need to pay attention to it. Distinguish between high density cross-linked polyethylene, medium density and low density. The cost of a cross-linked polyethylene heating pipe of different density is also different. Crosslinking as a method for the production of polyethylene pipes is aimed at obtaining the thermal stability of the material under pressure. For example, for high-density polyethylene products, the possibility of implementing long-term loads at a temperature of +60 degrees is extremely rare. After stitching, the temperature can reach 110-120 degrees.

Properties of insulating materials based on PPP

Expanded polypropylene has the lowest thermal conductivity in its class. The gas-filled polymer has a density of 40 kg / m3, its closed pores provide moisture resistance and high strength. The elastic material does not deform during operation. It belongs to products with low flammability, does not emit dangerous toxic gases during combustion.

Synthetic insulation is environmentally friendly and safe for health; contact of polypropylene with food is allowed.

The cellular structure helps to absorb sound and vibration; the use of PPP is recommended for soundproofing buildings. To enhance the properties of the insulation, it is laminated with foil or lavsan threads. Composite products can be coated with non-expanded polypropylene. The most famous material with EPP lavsan and foil coating. It is produced in the form of rolls of 15, 25 m, the thickness of the web is from 2 to 10 mm. The size of the sheets is 1 × 1, 2 × 2 m, the thickness is up to 20 mm. The insulation is easy to cut and easy to install.

Standard sizes, varieties and colors

Expanded polypropylene sheet in its pure form is extremely rare on sale. The most popular is composite EPP - in this case, PPP is supplemented with a layer of foil or lavsan threads, or is located between sheets of ordinary polypropylene (i.e. lightweight PP).

Each of the EPP manufacturers has established their own standard sizes. For example, OOO Penotherm, the first in Russia to foamed PP, sells expanded polypropylene in rolls with a standard width of 1.2 m. The length differs depending on the thickness of the material: 2, 3, 4, 5mm - 25 running meters, 8, 10mm - 15 running meters.

Standard sizes of lightweight PPP sheets of various manufacturers (thickness 10 - 20mm): 1 × 1, 2, 3, 4, 5m; 2 × 2, 3, 4, 5 m, 1.5 × 3 m, 1.5 × 4 m.

The color of expanded polypropylene without dyes is milky. The following colors are also available - green, gray, blue. Color selection is possible upon individual order.

Applications of PP-based insulation

The main characteristics of the material: low thermal conductivity, sound absorption, resistance to moisture and decay, have determined the area of its use.

Insulation materials made of polypropylene are used to insulate roofs, walls, floors, loggias and balconies, as well as pipelines and heating mains.

They do not require the installation of additional hydro and vapor barrier. EPP is used for the manufacture of thermal containers used in everyday life and for the transportation of medical products that are sensitive to temperature changes.

Foamed polypropylene foam is widely used in rooms with high humidity and sudden temperature changes. One of the popular brands is "Penotherm", developed for the insulation of baths and saunas. The reflective layer of insulation prevents the release of infrared waves and reduces the heating time of the steam room by 3 times. Its thermal insulation characteristics and moisture resistance are higher than those of similar materials based on polyethylene.

Porous insulation is used to create a sound-insulating layer of partitions and interior walls. Lavsan-coated material is in demand as a substrate when installing a "warm floor" system.

Underfloor heating types

Recesses are prepared for laying the heating electric cable

Before starting installation, you need to decide on the type of heating system. It can be electric or water. The choice depends on the area of the house, the presence of a standard heating structure, and the owner's preferences.

Electric

The electrical option provides for laying a cable in the tie, which heats up when connected to the network. It is effective, but it cannot be used everywhere. Another option for this design is mats with an electric cable. The infrared warm floor in the form of carbon rods or film deserves special attention.

Each type of electrical system is reliable, durable, and requires a dry base during installation. When arranging, do not forget about insulation and grounding. A thermostat is used to control the heating temperature. These systems are installed in apartments under the tiles.

Water

Grooves for reinforced plastic pipes in a finished screed

A water-heated floor is suitable for a private house. Such a system becomes an alternative to standard structures, as it is capable of heating the floor and the entire room. This option is a little more expensive to install, but its cost pays off already in the first years of operation. Heating occurs due to the circulation of the hot coolant through the pipes.