What is polypropylene

It is an organic synthetic polymer - thermoplastic and non-polar. In 1957, this material was polymerized using a Ziegler-Natta catalyst, and its industrial production was launched.

Although the material is plastic under the influence of high temperatures, it has high strength in its normal state, is chemically inactive, practically does not absorb moisture, and does not allow electricity to pass through. It is suitable for the distillation of food liquids.

What are fittings for?

The device of any pipeline assumes the presence of various branches, connections and turns. The possibility of their device is provided by fittings. They are divided into several types, differing in the method of fastening, materials and purpose. By the way of connection, they can be:

- flanged;

- crimp;

- threaded;

- welded.

Fittings made of polypropylene are welded and threaded. On their surface there are special notches that help determine the position of the fitting during welding. They have the same advantages as polypropylene pipes, and it is impossible to do without them when installing water supply and heating systems.

Fittings markings correspond to pipe markings - PN10, PN16, PN20 and PN25. Manufacturers produce:

- tees;

- bends;

- couplings;

- sliding and fixed supports;

- stubs;

- knee (turns);

- flanges;

- contours;

- Ball Valves;

- valves and more.

Electrofusion fittings are also commercially available, which are designed with electric heaters. They are used when butt welding does not work. As a rule, this happens when repairing damaged areas, in cramped or difficult weather conditions.

Polypropylene fittings join together not only polypropylene pipes. For connection with pipes made of other materials, various adapters, couplings and squeegees are available. Fittings with chrome or brass inserts allow you to easily connect to absolutely any plumbing fixtures. It is worth noting that fittings and pipes must be made by the same manufacturer, otherwise hardly anyone can guarantee the quality of the connections.

The main advantages of polypropylene pipes:

- practically do not corrode;

- excellent resistance to mechanical and bioactive influences;

- practically do not create noise and vibration;

- fittings are installed easily and into any part of the given material;

- almost absolute safety for human life and health;

- heat resistance and low heat loss when transferring hot water;

- durability of operation, which is several times longer than the service life of steel alloy pipes;

- ease.

About Chinese products

The Chinese manufacturer cannot yet boast of the ability to maintain quality indicators at a high level. But even in this country there are manufacturers who deserve the attention of every buyer.

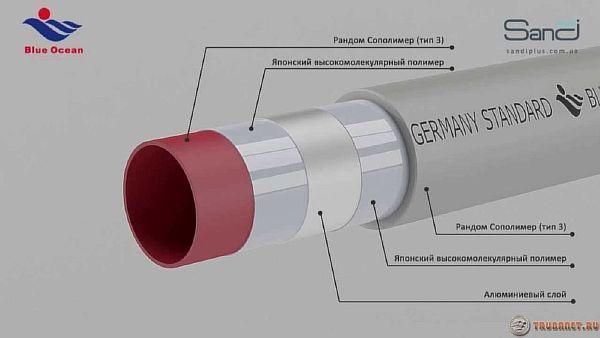

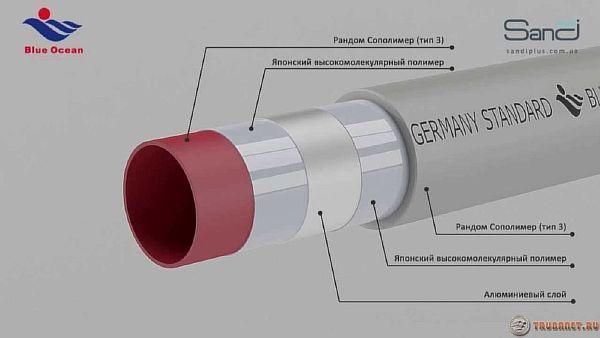

For example, Blue Ocean is a subsidiary of a British concern. It is engaged in the production of not only high-quality pipe products, but also fittings.

Polypropylene from China does not cause problems during soldering, which can be attributed to the advantages. The main thing is to use a nozzle with an inner rounding when processing the top layer. The disadvantage is the inconsistency of the indicators of external diameters.

Dyzain is known for its wide range of products. They do not require additional cleaning and preparation.Thanks to this, dismantling and installation work becomes much easier to carry out.

For hot and cold water supply, pipes with additional reinforcement are produced. Expansion in the linear plane due to heat is no longer a problem.

Polypropylene pipes marking

1. Single layer. Stamps:

- PPH. Manufactured from homopropylene. Used in industry for ventilation and cold water transmission;

- PPB. Made from block copolymer. They are used for laying pipelines that have to withstand strong pressure and external forces - floor heating, water supply under strong pressure;

- PPR. Made from random copolymer. The main feature is the even distribution of the load. They are used in underfloor heating and water supply installations. Protection from the sun (UV rays) is required if used outdoors;

- PPS... They are resistant to ignition. Working temperature - no higher than 95 degrees. Used in fire hazardous conditions.

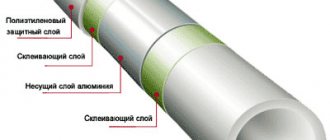

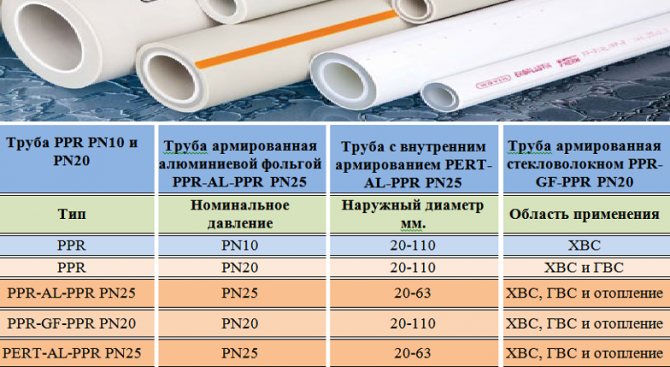

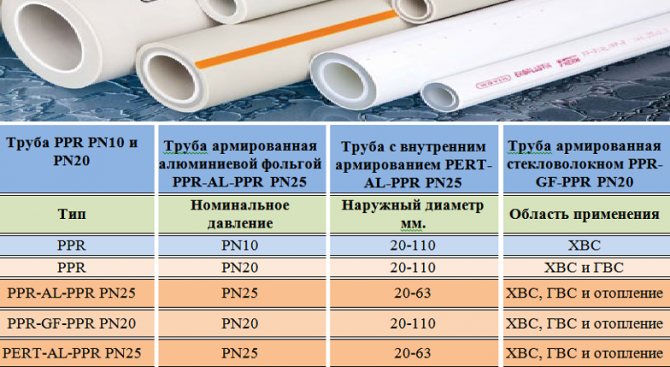

2. Multilayer. They have increased strength and reduced coefficient of thermal expansion when compared with their single-layer counterparts. They can be reinforced with aluminum foil and, accordingly, smooth or perforated. Fiberglass reinforcement is also possible. Stamps:

- PN10... The number in the marking after the letters indicates the maximum working pressure. Working temperature - 45 degrees;

- PN16. Working temperature - 60 degrees. Used for arranging cold water supply with high pressure;

- PN20... Working temperature - 95 degrees. Used for the installation of heating systems, including centralized ones;

- PN25. Working temperature - 95 degrees. They are used for installation of heating systems, floor heating and hot water supply.

Polypropylene pipes have become part of the water supply system. Plumbing is the primary communication system, which begins the improvement of any home, be it an apartment or a country house. Indeed, without water, neither sewerage, nor heating, nor water intake household appliances can function.

Today, domestic manufacturers produce a wide range of pipeline products, which differ in both technical parameters and cost. Knowledge of what classification is and which polypropylene pipes for heating can be used in a residential area becomes an indispensable tool for a modern designer.

Polypropylene pipes for heating and water supply differ from their steel counterparts in their affordable price, low weight, high resistance to corrosion and external influences, therefore they are widely used for domestic and industrial water supply. Every year, the number of households who connect the heating of their home with strapping with polypropylene pipes is growing.

Polypropylene pipes, classification and marking

Polymeric products are produced and labeled based on the operating conditions:

- PN 10 - manufactured for cold water supply with a liquid temperature not exceeding + 20˚С;

- PN 16 - also designed for cold water, but with increased pressure;

- PN 20 - universal pipes for hot (up to + 80˚C) and cold water supply;

- PN 25 - manufactured with fiberglass, aluminum or an additional layer of polymer reinforcement. They are characterized by high tensile strength and minimal coefficient of thermal expansion. This brand is bought when polypropylene pipes are needed for heating.

The marking of polymer pipes also includes other letter designations that indicate the presence of plasticizers and additives that determine the technical characteristics and properties of polypropylene:

- RRN - polypropylene homopolymer.Designed for cold water supply and ventilation systems, as it is not able to withstand high temperatures;

- RRV - block copolymer of polypropylene with a polyethylene content of up to 30%. Possesses considerable flexibility, resistance to low and high temperatures;

- PPR - static (random) polypropylene copolymer with a crystalline molecular structure. He is not afraid of water hammer, high temperatures and pressure in the line. In addition to plumbing, they are used in the installation of water heating and underfloor heating;

- PPs - fire retardant and high strength type of polypropylene with flame retardant. It differs from other types of polymers by a high indicator of the maximum permissible temperature (95˚С).

Polypropylene pipes for water supply - advantages

Manufacturers of polypropylene pipes give a guarantee for their products for more than 50 years, since this material has been widely used on an industrial scale since 1960, while many pipelines are still in stable operation.

Thanks to the unique production technology, polypropylene pipes have a high threshold of heat resistance and strength, withstanding pressure in the pipeline up to 10-20 atmospheres.

Polypropylene pipes for water supply are not afraid of the effects of aggressive reagents and significant temperature changes, even when they freeze and thaw, they do not lose their integrity.

Another advantage of such pipes is simple installation, which does not require special skills and profile specialization. To install the water supply, you will need additional components (fittings, shut-off and control valves), as well as special equipment for heating and welding polypropylene.

We suggest that you familiarize yourself with how best to choose polypropylene pipes for water supply. To figure out which is better, which pipe is intended for what. We watch the video review.

Polypropylene pipes for a reliable water supply system

Traditional steel pipes are hardly ever installed in modern residential buildings. They were replaced by more reliable technologies using polypropylene pipes, which ensure high tightness in hot and cold water supply systems.

Polypropylene pipes are easy to install, do not rust, withstand high water pressure and water hammer, are lightweight and affordable.

For the manufacture of polypropylene pipes, an environmentally friendly type of plastic is used, in which there are no decomposable components. Pipes are classified according to their application for products intended for cold water, hot water and drinking water.

There are many similar products on the market that differ in diameter, plastic thickness, and the presence or absence of a reinforced layer. In order to select the right pipes for each specific case, you need to consult with specialists.

The advantages of polypropylene pipe products:

- lack of harmful substances; - deposits do not appear inside; - not subject to corrosion; - the connections are hermetically sealed; - no need for staining; - ease of installation; - low cost; - can be used to supply drinking water; - service life exceeds 50 years; - resistance to mechanical stress; - good flexibility; - low weight.

The disadvantage of polypropylene plastic pipes is that they elongate significantly as a result of the thermal expansion of the material. To solve this problem, manufacturers suggest using reinforced pipes in hot water supply systems.

Fiberglass or aluminum foil is used as a reinforcing layer. Fiberglass reduces the temperature elongation by several times, due to which the pipes retain their dimensions under strong heating.

In cold water supply systems, there is no need to use reinforced pipes. In this case, you can install simple polypropylene products, which gives significant savings and makes the installation process easier.

The difference between fiberglass-reinforced pipes and aluminum-lined pipes is that the former are more convenient to install. When pipes with an aluminum reinforcement layer are installed, the foil makes the cutting process difficult. When cutting pipes, you need to get a neat end, and because of the presence of foil, this is much more difficult.

Installation of polypropylene pipes

When installing polypropylene pipes, traditional metal welding is not used, so sparks do not fly out in the room, which increases the safety of work. Pipe connections are made using a special device that melts the plastic at the very end of the pipe, allowing you to create a monolithic and completely sealed interface. In this case, you can do without rubber gaskets and all kinds of seals.

Polypropylene pipes significantly surpass steel products in terms of ease of installation, reliability of systems, as well as decorative and operational indicators. Unlike steel pipes, plastic pipes are not prone to vibration. Solids do not adhere to their inner surface, which eliminates the problem of reducing the diameter and reducing the throughput.

Polypropylene pipes are equally well suited for creating durable and sealed water supply systems in apartment buildings, country houses and cottages.

The economic benefit from their use is that they have an affordable cost, do not require much effort during transportation, are very quick and easy to install, serve for many decades without requiring expensive repairs. Thanks to the high-quality installation of such pipes, the likelihood of flooding your home and neighbors' apartment is much lower than when using ordinary metal pipes.

Russian-made pipe products

The combination of quality and low price are the main advantages, for which they love the products produced by Russian manufacturers. PRO AQUA is one of the companies that has become popular not only among ordinary buyers, but also among real professionals.

Such structures continue to work quietly even at temperatures up to +95 degrees and more. There is a long service life, the ability to resist corrosion, aggressive chemicals.

PRO AQUA are suitable for those who need to maintain system performance at pressures up to 79 atmospheres.

Reinforcement with aluminum in the middle of the wall is a distinctive feature of the RVK brand. But their size is unstable, which is the main drawback.

Heisskraft manufactures products that help meet consumer demand. They are available in gray, but this shouldn't be surprising. During the manufacturing process, carbon black is added to the composition. It becomes a stabilizer for the structure.

The average level of quality is a distinctive feature of the assortment of the manufacturer Politek, which can undoubtedly be considered a disadvantage.

Video: choosing pipes for the water supply

Specifications

The marking is deciphered as follows: PPR - polypropylene random (improved third type), PN - nominal pressure. PPR PN 20 pipe specifications:

- Linear expansion coefficient (1 / ˚С) - 12.7 * 10-5.

- Thermal conductivity coefficient (W * m / ˚С) - 0.238.

- The maximum allowable temperature is 80˚С (to increase the service life of products, it is recommended not to exceed the mark of 70˚С).

- The maximum allowable pressure is 2 MPa (1 MPa = 10 atmospheres).

- The wall thickness with a product diameter of 20 mm is 3.4 mm.

- The mass of one meter of a product with a diameter of 20 mm is 170-175 g.