Principle of operation

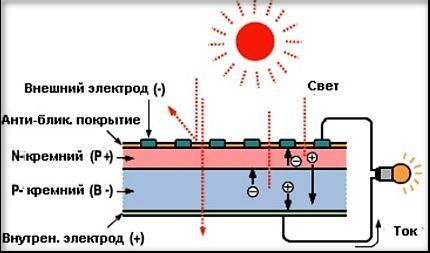

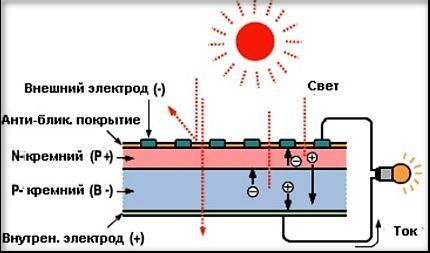

The design of many solar cells is made on the principle that they are, in the physical sense, photovoltaic converters. The power generating effect is manifested in the place of the “p – n” junction.

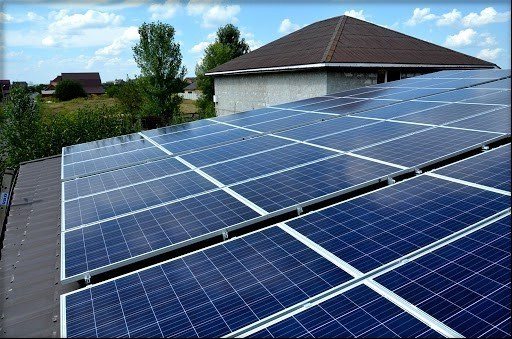

To concentrate solar energy in themselves, semiconductors are made in the form of panels. For this reason, these structures have received the same name, regardless of their shape (flexible or static) - solar panels.

What is the principle of solar panels and systems based on them? The panel includes 2 flint plates with distinguishable properties from each other. The process of generating electricity is as follows:

- Exposure to sunlight on the first leads to a lack of electrons.

- When exposed to the second plate, it receives an excess of electrons.

- Copper strips, conducting current, are connected to the plates.

- The strips are connected to voltage converters with built-in batteries.

The base is silicon wafers. But in order to use this structure as an uninterruptible power supply (and not only during the solstice), not cheap batteries are connected to it (with their help, objects connected to the network consume energy at night).

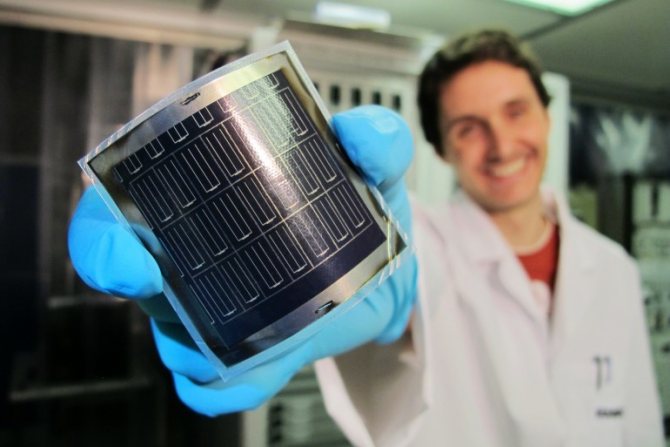

In industry, the structure for absorbing solar energy is made of multiple laminated photovoltaic cells connected to each other and placed on a flexible or rigid support.

The efficiency of the structure is calculated based on the application of various factors. The main ones are the purity of the silicon involved and the placement of the crystals.

The process of purifying silicon is rather complicated, and it is not easy to arrange crystals in a single direction. The complexity of the processes responsible for increasing the efficiency translates into a high price for such equipment.

Solar panels are a promising direction in the energy sector, so billions of dollars are being invested in researching new projects in this area. PV conversion increases every quarter due to manipulation of conductors and structural elements. At the same time, not only silicon can be taken as a basis.

How the solar battery works

Two layers of silicon with different physical properties form a thin plate. The inner layer is monocrystalline pure silicon with p-type conductivity, which is covered on the outside with a layer of "contaminated" silicon. This can be, for example, a phosphorus impurity. It has n-type conductivity. The back side of the plate is covered with a solid metal layer.

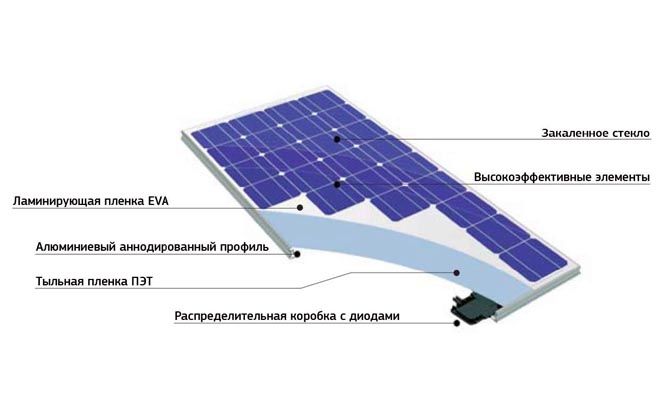

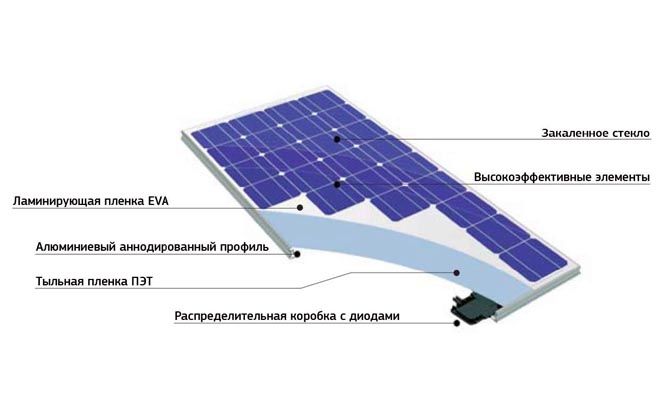

In the frame, the photocells are fixed in such a way that a broken one can be replaced. The entire structure is covered with tempered glass or plastic, which protects it from the negative effects of external factors.

Types of photovoltaic converters

In industry, there is a classification of solar cells according to the type of device and the photovoltaic layer used.

By device they are divided into:

- panels from flexible elements, they are flexible;

- panels made of rigid elements.

When deploying panels, flexible thin-film ones are most often used. They are laid on the surface, ignoring some uneven elements, which makes this type of device more versatile.

By the type of photovoltaic layer for subsequent energy conversion, the panels are divided into:

- Silicon (single crystal, polycrystal, amorphous).

- Tellurium – cadmium.

- Polymeric.

- Organic.

- Arsenide – gallium.

- Indium selenide - copper - gallium.

Although there are many varieties, silicon and tellurium-cadmium solar panels have the lion's share in consumer turnover. These two types are chosen because of the efficiency / price ratio.

Solar battery device and principle of operation

The principle of a solar cell is the photovoltaic effect, or the semiconductor effect. It is the ability to convert the sun's rays into electrical current.

The most efficient of all known semiconductors is silicon. The top layer / plate is made from it (n-layer (-) and p-layer ()).

The work of the structure begins with the fact that sunlight enters the photocells. The silicon wafers heat up, and electrons begin to be released, which are captured by the atoms of the lower wafer. Then the electrons are sent along the conductors to the batteries, and then they return to the top again.

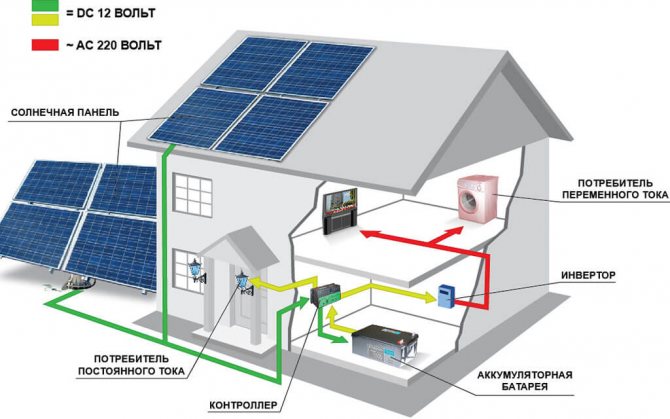

Solar cell device:

- 1. Panel body - for fastening the structure.

2. Conversion units - silicon solar cells (solar panel). Convert the rays of the sun into current. Connect in parallel-serial way. This contributes to obtaining the highest power and voltage in the mains.

3. Batteries - main and backup. Accumulate electric current. The main battery immediately supplies the house with current, and the backup battery saves a resource and turns on when the voltage drops.

4. Additional devices - controllers, diodes. Supervisors monitor the battery charge level. Diodes protect against overheating.

| Solar cell device Solar panel connection |

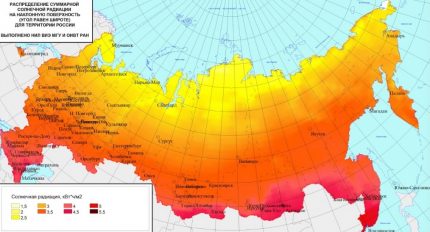

Often, faced with the need to install solar panels, a person asks about the feasibility of an enterprise. Because in most cases, the percentage of sunny days is significantly inferior to the analogous value of cloudy.

A similar ratio is typical for the regions of the middle zone, and the climate of the northern regions is characterized by an even greater number of cloudy days.

The insufficient number of sunny days is directly related to the efficiency of the devices that process the energy of the earth's luminary. As a result, the penetration of sunlight onto the surface of the battery is reduced. This process is called insolation.

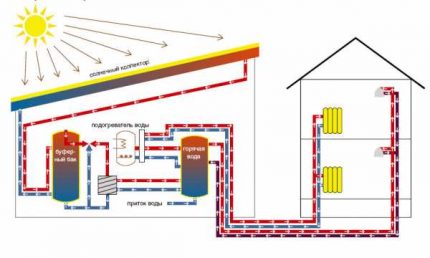

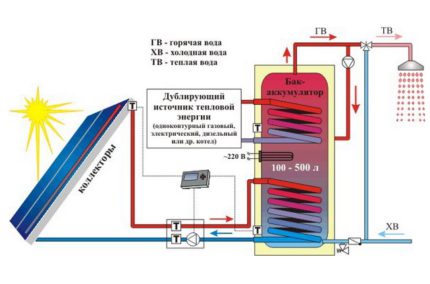

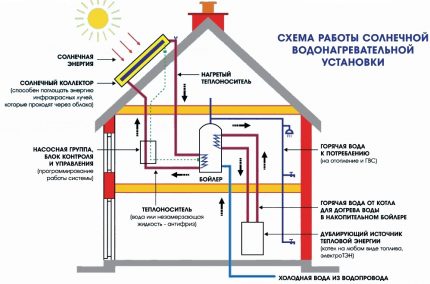

Solar panels can be used in heating systems as a supplier of heating medium or energy to power appliances

Its essence lies in the fact that any plane, regardless of its purpose, takes on a certain amount of solar energy. In the southern regions, this amount is naturally higher, which makes the installation of solar panels more relevant.

However, as practice shows, the market for technological equipment in the field of solar energy synthesis is constantly improving its products, therefore modern solar cells in solar panels function perfectly even in areas with a low level of insolation.

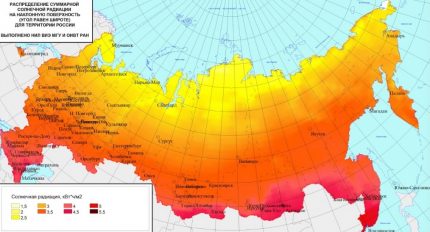

Distribution of solar activity on the example of a map of Russia. A higher coefficient is typical for the southern regions ()

Solar panels are considered to be a very efficient and environmentally friendly source of electricity. In recent decades, this technology has been gaining popularity around the world, motivating many people to switch to cheap renewable energy. The purpose of this device is to convert the energy of light rays into electrical current, which can be used to power a variety of household and industrial devices.

The governments of many countries allocate colossal amounts of budget funds, sponsoring projects that are aimed at the development of solar power plants. Some cities make full use of electricity from the sun. In Russia, these devices are often used to provide electricity to country and private houses as an excellent alternative to centralized power supply services.

As mentioned earlier, the principle of operation is based on the semiconductor effect. Silicon is one of the most efficient semiconductors currently known to mankind.

When the photocell (the upper silicon plate of the converter block) is heated, electrons are released from the silicon atoms, after which they are captured by the atoms of the lower plate. According to the laws of physics, electrons tend to return to their original position. Accordingly, electrons from the bottom plate move along the conductors (connecting wires), giving up their energy to charge the batteries and returning to the top plate.

The solar array device is quite simple and consists of several components:

- Directly photocells / solar panel;

- Inverter converting DC to AC;

- Battery charge level controller.

Batteries for solar panels should be bought taking into account the necessary functions. They store and release electricity. Storage and consumption occurs throughout the day, and at night the accumulated charge is only consumed. Thus, there is a constant and continuous supply of energy.

Overcharging and discharging the battery will shorten its useful life. The solar charge controllers automatically suspend the accumulation of energy in the battery when it has reached its maximum parameters, and disconnect the load of the device when it is strongly discharged.

(Tesla Powerwall - 7kW solar panel battery - and home charger for electric vehicles)

On-grid solar inverter is the most important design element. It converts the energy received from the sun's rays into alternating current of various powers. As a synchronous converter, it combines the output voltage of an electric current in frequency and phase with a stationary network.

Photocells can be connected in series or in parallel. The latter option increases the parameters of power, voltage and current and allows the device to work even if one element loses functionality. Combined models are made using both schemes. The service life of the plates is about 25 years.

Characteristics of silicon solar cells

Quartz powder is a raw material for silicon. There is a lot of this material in the Urals and Siberia, therefore, it is silicon solar panels that are and will be in greater use than other subtypes.

Monocrystal

Monocrystalline wafers (mono – Si) contain a bluish – dark color, evenly distributed over the entire wafer. For such wafers, the most purified silicon is used. The cleaner it is, the higher the efficiency and the highest cost of solar panels on the market for such devices.

Single crystal advantages:

- Highest efficiency - 17-25%.

- Compactness - the use of a smaller area in comparison with polycrystal for the deployment of equipment in conditions of identical power.

- Wear resistance - uninterrupted operation of power generation without replacing main components is ensured for a quarter of a century.

Disadvantages:

- Sensitivity to dust and dirt - settled dust does not allow batteries to work with light from a luminary and, accordingly, reduces efficiency.

- The high price equals the increased payback period.

Since mono – Si require clear weather and sunlight, the panels are installed in open areas and raised to a height. As for the area, preference is given to areas in which clear weather is common, and the number of sunny days is close to the maximum.

Polycrystal

Polycrystalline plates (multi-Si) are endowed with an uneven blue color due to the multidirectional crystals. Silicon is not as pure as in the mono-Si used, so the efficiency is somewhat lower, along with the cost of such solar cells.

Positive Polycrystal Facts:

- The efficiency is 12–18%.

- In unfavorable weather, efficiency is better than that of Mono-Si.

- The price of this unit is less, and the payback period is much lower.

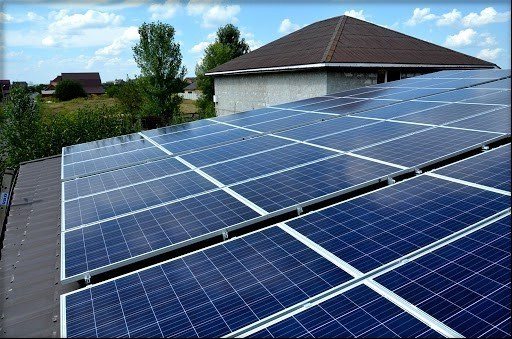

- Orientation to the sun is not critical, so you can place them on the roofs of various buildings.

- Duration of operation - the efficiency of energy absorption and storage of electricity drops to 20% after 20 years of continuous operation.

Disadvantages:

- The efficiency is reduced to 12–18%.

- Demanding to the place. A normal power generation plant requires more space to deploy than a single crystal battery.

Amorphous silicon

The panel production technology differs significantly from the previous two. Cooking involves hot vapors that descend onto the substrate without the formation of crystals. At the same time, less production material is used and this is taken into account when determining the price.

Benefits:

- The efficiency is 8-9% in the second generation and up to 12% in the third.

- High efficiency in less sunny weather.

- Can be used on flexible modules.

- The efficiency of the batteries does not drop down as the temperature rises, which allows them to be mounted on any surface with a non-standard shape.

The main disadvantage can be considered a lower efficiency (when compared with other analogs), and therefore requires a large area to obtain a comparable return from the equipment.

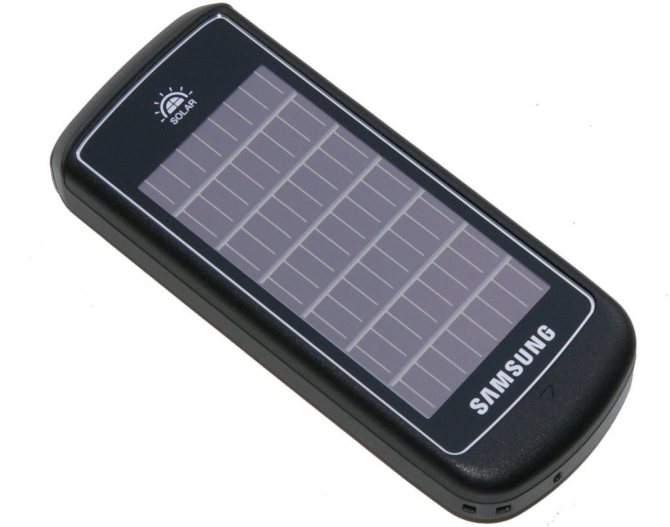

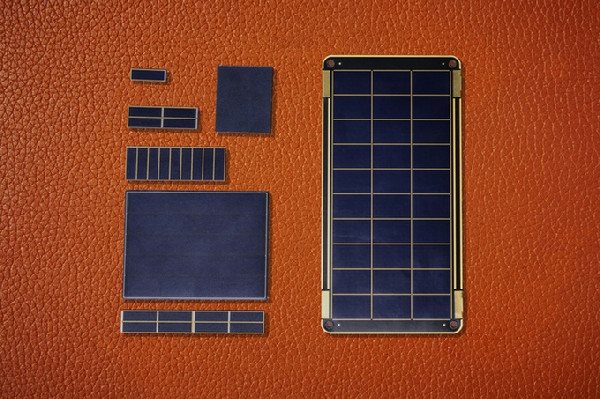

Portable solar battery - especially for tourists

Everyone nowadays has electronic gadgets. Not the point that someone has fewer, but someone more. All of them need to be charged, and this requires chargers. But, this issue is especially acute for those who find themselves in places where there is no power supply. The only outlets are solar panels. But, prices for them remain high, and the choice is small. The best option, as is commonly believed, is the products of the Goal Zero company (although there are both Russian and Chinese products - as always in doubt).

But it turned out that not everything is bad that is made in China or Korea. Particularly pleased with the solar battery company YOLK from Chicago, which began production of a compact solar paper Solar Paper - the thinnest and lightest. Its weight is only 120 grams. But there are other advantages as well - modular design allows for increased power. The solar panel is like a plastic box, similar in size to an iPad, only half as thin. There is a solar panel on its front side. There is an outlet for a laptop and USB ports on the case for connecting other solar panels, as well as a flashlight. Inside this miracle box are the batteries and the control board. You can charge the device from an outlet, and at the same time it can be a phone and two laptops. Of course, the device is also charged from the sun. As soon as light hits it, the indicator lights up. In field conditions, the solar panel is simply irreplaceable: it successfully charges all the necessary devices - phones faster, laptops.

Portable solar panels are compact in size: they even come in the form of key chains, which can be attached to anything. They were developed so that you can take them on a fishing trip, on a hike, etc. They must have a flashlight so that at night you can illuminate the road, tent, etc., mounts that make it easy to place them on backpacks, kayaks, tents ... It is very important that such a device has a built-in battery that allows you to charge devices at night.

Overview of non-silicon modules

Solar panels made from more expensive analogs reach a coefficient of 30%; they can be several times more expensive than similar systems based on silicon. Some of them still have lower efficiency, while having the ability to work in an aggressive environment.For the manufacture of such panels, cadmium telluride is most often used. Other elements are also used, but less often.

Let's list the main advantages:

- High efficiency, from 25 to 35%, with the ability to reach, in relatively ideal conditions, even 40%.

- The photocells are stable even at temperatures up to 150 ° C.

- By concentrating the light from the luminary on a small panel, the water heat exchanger is powered, resulting in steam, which turns the turbine and generates electricity.

As we said earlier, the disadvantage is the high price, but in some cases they are the best solution. For example, in equatorial countries, where the surface of the modules can reach 80 ° C.

Installation instructions for solar cells

Solar panels. We wrote about how to collect them in this article (will open in a new window). You can buy a ready-made solar array for your home, but to save money, you can buy polycrystalline solar cells and assemble solar panels for your home with your own hands.

Inverter. Solar panels generate direct current, close to 12 or 24 volts (depending on the connection), the inverter converts it into alternating current 220 V and 50 Hz, from which all household appliances can be powered.

Battery. Even their system. Solar energy is not constantly produced. At peak hours, it can be oversupplied, and with the onset of dusk, its production stops altogether. Batteries store electricity during daylight hours and release it in the evening / night. How to choose a battery for a solar power plant is written in this article (opens in a new window).

It is important to know. It is not recommended to use ordinary car batteries for these purposes - they become unusable after 2-3 years of operation (they are designed for such a service life)

Controller. Provides a full charge of the battery and protects it from overcharging and boiling. We wrote about which controller to choose in this article (it will open in a new window).

Solar panels are gradually becoming cheaper and more efficient. They are now being used to recharge batteries in street lamps, smartphones, electric cars, private homes, and on satellites in space. They even began to build full-fledged solar power plants (SPP) with large volumes of generation.

A solar battery consists of many photovoltaic cells (photoelectric converters FEP) that convert the energy of photons from the sun into electricity

Each solar battery is designed as a block of a certain number of modules that combine semiconductor photocells connected in series. To understand the principles of the functioning of such a battery, it is necessary to understand the operation of this final link in the solar panel device, created on the basis of semiconductors.

There are a huge number of FEP options from different chemical elements. However, most of them are early stage developments. So far, only silicon-based solar panels are currently being produced on an industrial scale.

We suggest that you familiarize yourself with the composition of wood decay

Silicon semiconductors are used in the manufacture of solar cells due to their low cost, they cannot boast of a particularly high efficiency

When photons hit the PVC between these semiconductor layers, due to the inhomogeneity of the crystal, a gate photo-emf is formed, resulting in a potential difference and an electron current.

Silicon plates of photocells differ in manufacturing technology for:

- Monocrystalline.

- Polycrystalline.

The former have a higher efficiency, but their production cost is also higher than that of the latter. Externally, one option from another on a solar panel can be distinguished by its shape.

Monocrystalline PVCs have a homogeneous structure, they are made in the form of squares with cut corners. In contrast, polycrystalline elements have a strictly square shape.

Polycrystals are formed by gradual cooling of molten silicon. This method is extremely simple, therefore such photocells are inexpensive.

But their productivity in terms of generating electricity from sunlight rarely exceeds 15%. This is due to the "impurity" of the resulting silicon wafers and their internal structure. Here, the purer the p-layer of silicon, the higher the efficiency of the photovoltaic transformer from it.

The purity of single crystals in this respect is much higher than that of polycrystalline analogs. They are made not from molten, but from an artificially grown solid silicon crystal. The coefficient of photoelectric conversion of such PVC already reaches 20-22%.

Individual photocells are assembled into a common module on an aluminum frame, and to protect them from above, they are covered with durable glass, which does not interfere with the sun's rays.

When the sun's rays fall on the photocell, nonequilibrium electron-hole pairs are generated in it. Excess electrons and "holes" are partially transferred through the p-n-junction from one semiconductor layer to another.

As a result, tension appears in the external circuit. In this case, a positive pole of the current source is formed at the contact of the p-layer, and a negative pole at the n-layer.

The potential difference (voltage) between the contacts of the photocell appears due to a change in the number of "holes" and electrons from different sides of the p-n-junction as a result of irradiation of the n-layer with sunlight

The photocells connected to an external load in the form of a battery form a closed circle with it. As a result, the solar panel works like a kind of wheel, along which the proteins "run" together with electrons. And the rechargeable battery is gradually gaining a charge.

Standard silicon photovoltaic converters are single junction cells. The flow of electrons into them occurs only through one p-n-junction with a limited in photon energy zone of this transition.

That is, each such photocell is capable of generating electricity only from a narrow spectrum of solar radiation. All other energy is wasted. That is why the efficiency of FEP is so low.

To increase the efficiency of solar cells, silicon semiconductor elements for them have recently begun to be made multi-junction (cascade). There are already several transitions in new FEPs. Moreover, each of them in this cascade is designed for its own spectrum of sunlight.

The total efficiency of conversion of photons into electric current in such photocells ultimately increases. But their price is much higher. Here, either ease of manufacture with low cost and low efficiency, or higher returns coupled with high cost.

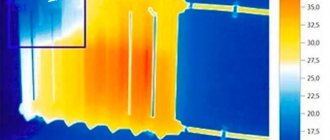

The solar battery can work both in summer and in winter (it needs light, not heat) - the less cloudiness and the brighter the sun shines, the more the solar panel will generate electric current

As a result, one and the same model of a solar battery generates less current in the heat than in the cold. Photocells show maximum efficiency on a clear winter day. There are two factors here - a lot of sun and natural cooling.

Moreover, if snow falls on the panel, it will still continue to generate electricity. Moreover, the snowflakes will not even have time to lie down on it, melting from the heat of heated photocells.

Panels belonging to the "flat" class are desirable to be installed in the summer season, when the level of insolation is higher. This will be the best option for the ratio of price and energy received, which means that the purchase of such solar collectors will fully justify all the funds spent.

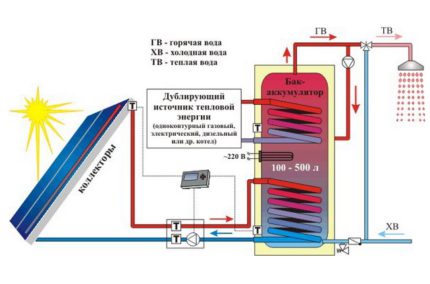

One way or another, the energy potential of the equipment allows it to be used in hot water supply and heating systems.

The energy conversion process is extremely sensitive to temperature extremes. This should be taken into account during installation.The first step is to make sure that the dwelling is thoroughly insulated, otherwise unforeseen failures in the operation of the system may occur.

The heating system with solar panels is a closed loop with a coolant circulating through it

For each region, there is an optimal installation option for equipment. The calculation is based on the degree of the same insolation. According to the rules of use, the collector must be positioned so that the angle of incidence of sunlight on its surface is 90 °.

Only in this case will the efficiency of the system be maximized. You can achieve absolute accuracy when installing panels by measuring the latitude of the area.

An important factor will be the direction in which the panels are positioned. Due to the fact that the highest power level is achieved mainly in the middle of the day, it is worth orienting the panels in a southerly direction. Some deviations are allowed during the installation process, in the east or west direction, but not too much.

In addition, there is often a decrease in efficiency when shadows from trees hit the collector panel. In winter, it is recommended to increase the angle of inclination of the solar panels, this will improve the level of system performance.

The efficiency of collectors primarily depends on the angle of the panel in relation to the horizontal surface. For optimal light absorption, it is recommended to keep the tilt around 45 °.

The optimal tilt angle of the solar panel depends on the season. It is good if the device is equipped with a device for correcting the angle.

The azimuth must be kept at 0 ° (direct south). Some deviations of 30-40 ° are allowed for better insolation. To increase rigidity, there is a special. aluminum structures.

This is primarily typical for the installation of collectors on an inclined roof. They will prevent changes in the set parameters due to weather conditions, and the quick installation speed, using fastening hooks and profiles, will save time.

At the first stage, all heating components are installed: boilers, compressors, heat conductors, etc. For convenience, it is recommended to place the system elements in an easily accessible place. When installing the expansion tank, take into account that there are no obstacles between it and the manifolds.

The temperature inside the tank is measured with a temperature sensor. It should be attached to the bottom of the tank.

The next step will be the organization of the ventilation system. When installing the circuit, it is necessary to create an air outlet leaving the expansion tank. The best solution would be to bring communications to the roof. This will contribute to the regulation of pressure drops inside the heating system.

Solar panels are part of the heating system, which must also include boilers, centrifugal pumps, piping, etc.

Polymer and organic batteries

Modules based on polymer and organic materials have become widespread in the last 10 years, they are created in the form of film structures, the thickness of which rarely exceeds 1 mm. Their efficiency is close to 15%, and their cost is several times lower than their crystalline counterparts.

Benefits:

- Low production cost.

- Flexible (roll) format.

The disadvantage of panels made of these materials is the decrease in efficiency over a long distance. But this issue is still being researched and production is constantly being modernized to eliminate the disadvantages that may appear in the existing generation of this type of battery in 5-10 years.

Body and glass

Solar panels for home have an aluminum casing. This metal does not corrode, with sufficient strength it has a small mass. A normal body should be assembled from a profile in which at least two stiffeners are present. In addition, the glass must be inserted into a special groove, and not fixed from above. These are all signs of normal quality.

There should be no glare on the case

Even when choosing a solar panel, pay attention to glass. In normal batteries, it is textured rather than smooth. To the touch - rough, if you run your nails, you can hear a rustle. In addition, it must have a high-quality coating that minimizes glare. This means that nothing should be reflected in it. If the reflections of the surrounding objects are visible at least from any angle, it is better to find another panel.

How to make the right choice?

For home owners located on the European continent, the choice is quite simple - it is a polycrystal or a monocrystal made of silicon. At the same time, with limited areas, it is worth making a choice in favor of monocrystalline panels, and in the absence of such restrictions - in favor of polycrystalline batteries. When choosing a manufacturer, technical parameters of equipment and additional systems, it is worth contacting companies that are engaged in both the sale and installation of kits. Keep in mind that regardless of the manufacturer, the quality of the systems from the "top" manufacturers is unlikely to differ, so do not be fooled by studying the pricing policy.

If you decide to order a turnkey installation of a "solar farm", keep in mind that the panels themselves in the package of such services will take only 1/3 of the total cost, and the payback will come close to about:

- A budgetary but effective choice will be panels from Amerisolar, the polycrystalline model is called AS-6P30 280W, has a size of 1640x992 mm and produces, respectively, 280 W of power. The module efficiency is 17.4%. Of the minuses - the warranty is only 2 years. But the cost is ∼7 thousand rubles.

- The RS 280 POLY module from the Chinese Runda will be similar in capacity, the cost is even lower - about 6 thousand rubles.

- If space is limited, you should pay attention to the product of LEAPTON SOLAR - LP72-375M PERC, the efficiency is 19.1%, and with dimensions 1960x992 mm we get 375 W of energy at the output. The cost of such a battery will be around 10 thousand rubles.

- Another effective option with smaller dimensions, 1686x1016 mm, will be a new product from LG - NeOn 340 W. "Not he" boasts an efficiency of 19.8%, but cannot boast of a cost, it will be more than half higher than the previous sample - about 16 thousand rubles ...

- For those who want to turn their attention to the premium segment, the Taiwanese company BenQ has launched the SunForte PM096B00 333W monocrystal module on the market, producing 333 W of power at the output, having a nominal efficiency of 20.4% with dimensions of 1559x1046 mm. This module received an impressive cost of almost 35 thousand rubles.

Video. How to calculate the required amount of solar panels for your home

The video clearly shows the procedure for calculating the area of solar panels for a private house. Useful for those who want to take into account all the costs of building an autonomous solar power supply system already at the planning stage.

We select a battery for a solar power plant Power Bank with a solar battery - calculating for illiteracy Is it profitable to buy a set of solar panels for summer cottages Windmill for a private house - a toy or a real alternative

A good 12 volt solar cell should have 36 cells, and a 24 volt battery should have 72 photocells. This amount is optimal. With fewer photocells, you will never get the stated current. And this is the best option.

Do not buy dual solar panels - 72 and 144 cells, respectively. Firstly, they are very large, which is inconvenient for transportation. Secondly, at abnormally low temperatures, which we have periodically, they are the first to fail. The fact is that the laminating film greatly decreases in size during frost.

4V solar panel has 7 elements

Second factor. Large panels should have more thickness of the case and glass. After all, windage and snow loads increase. But this is not always done, since the price increases significantly.If you see a double panel, and the price for it is lower than the two "regular" ones, you better look for something else.

We suggest that you familiarize yourself with the Description of birch for children. Description of birch leaf

Once again: the best choice is a 12 volt solar panel for your home, consisting of 36 solar cells. This is the best option, proven by practice.

Why is efficiency so important?

Efficiency gains great importance when calculating the area that you can use for a solar array system. With comparable sizes of the described modules from Amerisolar AS-6P30 280W (1.63 square meters) and NeOn 340 W from LG (1.71 square meters), the difference in power per square meter at the output will be 15.6%. On the one hand, this may not seem very effective, given the more than twice the price difference, but in the case of limited space or a more aggressive environment, it may shift your choice in favor of this well-known manufacturer.

The increased efficiency emphasizes not only the efficiency of the manufacturing technology, but also the quality materials used in the manufacture. This can affect the life of the devices, the resistance of the panels to the so-called degradation. Do not forget also about the manufacturer's warranty obligations. With representative offices and warranty services in almost all corners of the world, LG will be able to boast of a more loyal approach to customers and fulfillment of its obligations.

Specifications: what to look for

In certified solar panels, the operating current and voltage are always indicated, as well as the open circuit voltage and short circuit current. It should be borne in mind that all parameters are usually indicated for a temperature of 25 ° C. On a sunny day on the roof, the battery heats up to temperatures well above this figure. This explains the higher operating voltage.

An example of the technical characteristics of solar panels for a home

Also pay attention to the open circuit voltage. In normal batteries, it is about 22 V. And all would be fine, but if you carry out work on the equipment without disconnecting the solar panels, the open circuit voltage will damage the inverter or other connected equipment that is not designed for such a voltage.

What are solar panels made of?

The structure is a system of interconnected elements, in the structure of which the principle of the photoelectric effect is used. Depending on the manufacturer and type of installation, ready-made solar panel kits for a private house contain the following components:

- Semiconductor material located under tempered glass. It consists of two layers of materials with different conductivity. Some have an excess of electrons, while the other has a deficiency. They are separated by a thin layer of the element to resist mixing.

- Power supply.

- A battery that stores and stores energy.

- Solar panel charge controller.

- Inverter-converter.

- Voltage regulator.

- Connecting wires.

How does a solar panel work?

Previously, solar cells were used only in space as the main source of energy for satellites. Currently, solar panels are increasingly included in our lives, but few people know how they work. It is worth finding out how the conversion of rays into electricity occurs. Without complicated technological details, the principle of a solar panel for a home is described as follows:

- There are photovoltaic cells, consisting of semiconductor material, packed in a common frame.

- When rays hit their surface, they heat up, partially absorbing energy and thus releasing electrons inside.

- With the help of an electric field, free electrons move in a certain direction, which forms a current.

- It travels along the copper strands covering the battery and travels directly to its destination.It can be an electronic device or a battery that stores current.