What is a laminate underlay used for?

The following functions are assigned to the underlayment under laminate flooring:

- Soundproofing. If you do not use a laminate underlay, all walking sounds will be amplified due to the contact of the material with the base. To eliminate this problem, an additional softening layer is needed;

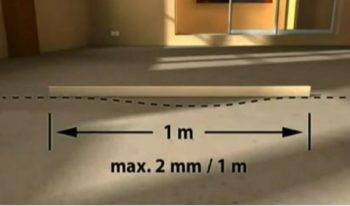

- Leveling the surface. The material used will also cope with this task. If you do not level the surface as much as possible, then the locks that hold the lamellas together will loosen over time, which will cause a squeak;

Base leveling

- Waterproofing. This flooring is based on fiberboard, due to this, during operation, the material can increase in size and, as a result, deform. This is due to the ingress of water. The substrate increases the moisture resistance of the material;

Waterproofing

Attention! Before laying the floor, make sure that the concrete screed, which forms the basis of the subfloor, is well dry. This happens after about a month. After this period, polyethylene is spread on the surface of the screed for the night. If in the morning there is no fumes on it, then work can begin.

Concrete screed

- Thermal insulation. Laminate underlays increase thermal insulation, especially if foiled. However, a layer placed above the warm floor will reduce its thermal conductivity.

Substrate thickness

The substrate should be chosen correctly from the very beginning so that it fully complements the laminate. This material differs in thickness, composition and level of sound insulation. Before choosing the final version, it is recommended to determine your needs and scope of work. In addition, the condition of the foundation is assessed:

- if the subfloor is even, then thin material will do;

- if there are small irregularities on the surface (up to 2 mm), then a thicker material should be put in front of the laminate flooring.

Some people think that the thickest backing material should be used for laminate flooring. Often not one, but two substrates are purchased at once, and stacked in two layers in order to increase the effect of sound and heat insulation of the floor.

Important! If the material under the flooring is too thick, it will interrogate, causing the boards to deform or even break.

If you purchase a substrate that is thicker than necessary, the laminate locks will become damaged over time. And if the locks are deformed, then the boards themselves will soon bend, and the floor will begin to creak strongly.

Material thickness

Attention! Do not bother and purchase a substrate from the same company as the laminate. If you put material from another manufacturer under the flooring, nothing terrible will happen.

Materials for the manufacture of substrates

Izolon (base - polyethylene)

Foamed polyethylene is not very strong, and under increased load it simply deteriorates or breaks. Therefore, izolon, which is based on polyethylene, is considered a cheap and unreliable option today.

Izolon

Isolon advantages:

- polyethylene is not afraid of excessive moisture;

- not susceptible to infection by fungi and mold, rodents do not eat it;

- provides a good level of sound insulation;

- fits easily and hassle-free, connects with ordinary tape;

- there are options when izolon is produced with aluminum-based foil, which reflects heat;

- material of this type smoothes out unevenness of the base, prevents deformation of the floor covering;

- not affected by chemicals.

Negative qualities of isolon:

- short service life - after about a couple of years, polyethylene loses its original shape and ceases to hold the lamellas well;

- polyethylene, which has been under the sun for a long time, becomes dry and brittle;

- the main disadvantage of foamed polyethylene is the accumulation of static electricity, which creates discomfort during the operation of the “warm floor”.

You should not use polyethylene foam if finances allow you to purchase another material. Once you save money, you can regret it many times later. If you wish, you can buy polyethylene of foreign production, with higher quality indicators.

Cork backing

Positive aspects:

- The cork material has excellent resilience; when compressed, it returns to its original shape in a short time. Therefore, even if the laminate is laid in a children's room, the substrate does not deform with constant increased loads;

- Due to the low level of thermal conductivity, the cork provides a good level of thermal insulation, which makes it popular with consumers;

- Cork is an elastic material, therefore, the substrate from it extends the life of the laminate, additionally protecting its locks;

- Working with such a substrate is very simple;

- Although natural, cork is not susceptible to rotting and pest infestation.

Negative qualities:

- Products of this type are hygroscopic, they allow moisture to pass through, which can pass under the boards and accumulate under them;

- Dense cork material must not be laid on uneven surfaces and substrates, therefore additional leveling work is required before laying the floor covering.

Cork option

Attention! The cork backing is not suitable for use in rooms with constantly high humidity, in this case the material for the laminate is better to choose a material based on a rubber base.

Foil backing

Such a basis for a laminate is used today quite often due to its ability to retain heat as much as possible. On the construction markets, there are different options that differ in the number of layers and cost.

Important! Foil underlay for laminate flooring is suitable for rooms with high humidity.

Foil material

Advantages of the material:

- The level of thermal insulation of the room in the case of using such a substrate under the laminate increases significantly;

- The floor gets an additional layer of waterproofing;

- The laminate, under which such a substrate is located, is not afraid of moisture, due to which it is not necessary to additionally use polyethylene;

- Fungus and mold will not appear when using such material.

The foil substrate under the laminate also has a drawback - it cannot be restored if deformed.

laminatepol.com

Foil for water heated floors

When installing a water floor, a screed from a concrete mixture is traditionally poured. A layer of cement is poured onto the foil substrate, thus the board is in close contact with the foamed polyethylene insulation material and the foil layer. In this case, the use of materials does not give any effect, except for the minimum insulation from the foil layer - 0.5%.

The structure of the foam backing and the thickness of 0.05 cm is insignificant, but a 5 cm screed per square meter of floors weighs about 120 kg. This mass flattens the air insulation and nullifies its expected performance.

Cement tends to corrode the foil layer. You can verify this by leaving a piece of foil in the cement screed for several days.

If the floors are made of wood, then the screed is no longer needed, and the effect of the substrate with foil will be greater. But only if a layer of air remains in the composition of the materials.

Insulation with a foil surface for wooden houses will be useful, but you should not expect it to save money on paying bills. Before starting work, it is worth deciding on the floor covering, having estimated the expected benefit as a percentage of the cost of the arrangement.

Installation of foil insulation

Foil insulation has a fairly wide range of applications, it is used for insulating pipes with cold and hot water, for insulating walls, as a substrate when laying parquet or under a laminate, for insulating hives, soundproofing a room, roofing, insulating ventilation ducts, insulating industrial equipment.

This insulation is used to sheathe the walls from the inside of the room behind the batteries to reduce heat loss, since it is heat-resistant. The following brands are represented on our market: Alufom, Ursa, Penofol, Folgoizol, Izolon, Knauf, Lavsan, Magnel, Megaflex, Penoplex, Ecoteplin, the most popular type is with foil and foamed foam.

How much does this material cost? It all depends on the manufacturer you prefer, the price ranges from $ 1 to $ 4 per meter2. Let's try to take a closer look at how to properly lay this material on various surfaces.

On the wall

Often, the walls are insulated with a similar material in baths, saunas, on balconies, in this case, a material based on a polyethylene base is used. It is recommended to use insulation with a thickness of at least 10 mm, such material can be covered with foil both on one side and double-sided.

If we consider the options for what it can be attached to, a construction stapler, double-sided tape is best suited, you can also use a special rubber-based glue, the joints of the sheet are glued with tape. If we are talking about the insulation of the balcony, then you need to lay an additional heat-insulating layer, for example, foam, basalt material or others.

Is it possible to insulate without them? Of course, yes, but you will not get the desired result. In order for the insulation to fulfill the task assigned to it, it is necessary to figure out how to properly lay it. The distance between the material and the skin should be approximately 20 mm, this will create a kind of air gap that will serve as an air barrier.

- Attach the styrofoam to the previously prepared surface.

- Fix the foil insulation on top of it.

- Then install the wooden blocks on top, then sew up everything with the selected material (gypsum, siding), sew up the joints with foil tape.

To the ceiling

As a rule, the maximum thickness of the insulation is chosen for the ceiling, since all the heat rises up, and its maximum losses occur there. Due to its reflective surface, the insulation is able to reflect up to 90% of heat, thus increasing the overall efficiency of the insulation system by 60%. These characteristics will be obtained subject to the installation rules.

- Construction stapler.

- Small nails.

- A hammer.

- Insulation material.

- Aluminum tape.

Such a product is sold in rolls; for ease of installation, cut it into the required lengths. And which side to lay it on? Installation must be done so that the foil surface is inside the room (with the silver side facing you). So, let's figure out how to nail this material.

The gap between the finishing material and the insulation should be about 20 mm, this buffer zone protects the room from heat loss.

When fixing to the ceiling, fix it using a stapler, the fixing should be joint to joint, and glue the mounting seams with aluminum tape to ensure hydro and thermal insulation.

On the floor

Perhaps the installation process on the floor is the most laborious, and there are more possible variations, since you can lay under linoleum, parquet, laminate, underfloor heating system (not only water floor). All this is possible thanks to its non-combustible basis, since there is a reflective foil on one side, and foam rubber on the other.

Some manufacturers have variations where there is foam rubber on both sides. So, we will describe in more detail the process of installing a wooden floor. To do this, we need the following: a construction knife, insulation, aluminum tape, meter, grinder, antiseptic primer, putty.

For this type of work, it is better to give preference to material with an adhesive base, however, you can get out of the situation with double-sided tape.

- Prepare the base, remove the skirting board, grind the floor, if there are irregularities, remove them using putty.

- Treat with an antiseptic liquid. After drying, take measurements and cut into desired pieces. Lay a sheet, there should be foam rubber inside, and foil outside.

- Seal the seams using metallized tape.

- Then lay parquet, laminate.

If you are insulating a concrete floor, the technology is similar, however, it is better to use specialized rubber glue for gluing. Otherwise, the technology is the same. If you have a very cold floor, in such a case, wooden logs are stuffed onto the insulation, the niches in them are filled with insulation material, sewn on top with sheets of OSB plates, then the selected coating material is primed and laid.

Underfloor heating insulation: is foil necessary?

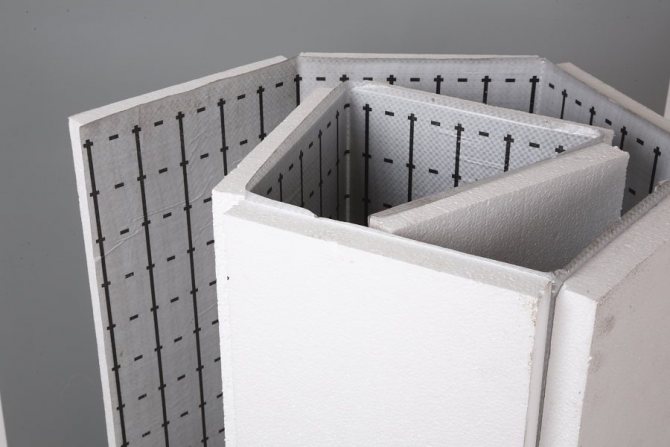

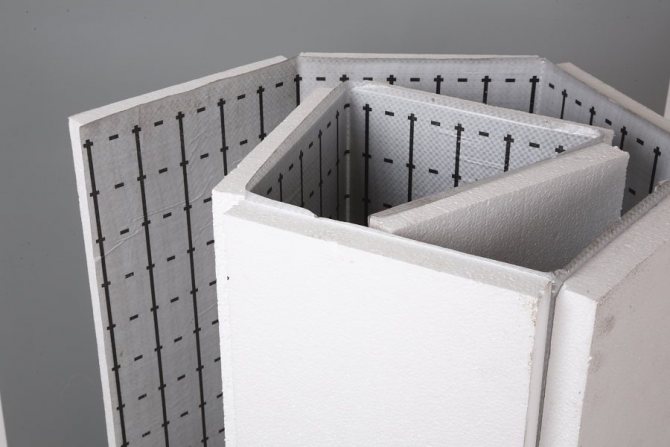

| Underfloor heating installation is performed according to the same recipe. First of all, the edge insulation is laid and the foam is laid. This is necessary for the heat to go up, i.e. so that pipes or cables heat your floor, and not heat the ceiling to neighbors. On top of the foam, some installation organizations advise to lay the so-called foil foam, i.e. polyethylene insulation covered with aluminum foil. The reason for this is that, firstly, the foam a few millimeters thick gives additional insulation, and secondly, the foil is needed to reflect heat rays upward from its surface. Is this really so and how advisable is the use of such a foil? Consider the first consideration: additional insulation with foam under the foil. The thickness of the main insulation - polystyrene or polystyrene, which is laid on the floor covering, should be at least 3 cm for interfloor floors, and 5-8 cm for floors on the ground or above basements. An additional 1-2mm foam under the foil will give an increase in heat transfer resistance of the order of 1-5%. Does it make sense to buy such insulation and pay for its flooring if the insulation improves so little? No. If there is such a need, then it will be cheaper to lay a thicker foam. The second argument: the foil in the screed acts as a mirror for "rays of heat", reflecting heat up and not letting it down. Thermos flasks are sometimes cited as an example, where a flask of hot water is lowered into another flask, which has a mirror coating from the inside. Let's consider this consideration. We'll have to remember a little physics, but we can handle it. Heat in nature can be transferred in three ways:

|

The key point required for the transfer of heat by radiation is as follows. The medium in which such heat transfer takes place must be transparent. The sun won't warm you underground (sorry for the dark analogy). Beams of any spectrum, incl. infrared, do not pass through concrete. There is no radiation heat transfer inside the concrete screed. Foil cannot reflect anything inside the underfloor heating structure. Therefore, by itself, the foil inside the floor screed does not make sense.

In addition, concrete very quickly corrodes zinc, foil, and metal in general. Do an experiment. Take a piece of such insulation and spread it with a thin layer of concrete, which can be easily wiped off with a rag after a couple of days. Take a look at what will be under the concrete in a couple of days. You will see that the foil is no longer there. The cement will eat away the entire reflective coating within a few days. Therefore, none of the above arguments in favor of the use of foil-clad penofol or its analogs stand up to criticism.

If our arguments seem insufficient to you, then look at another method of laying pipes for underfloor heating, which is offered by almost all manufacturers of components for underfloor heating.

These are polystyrene profiled plates with "hemp" between which the pipe is laid. On top of such mats, concrete is immediately poured, there are no reflectors there, and this is considered a better and more professional solution than just foam. Thus, you should not overpay for foil insulation when installing underfloor heating. Against the general background, its cost is not very significant, but since it is completely meaningless there, then you should not do this. And the wide open jaw of the installers when you tell them all this will give you a lot of pleasure.

Voila. You are gorgeous!

Varieties of material

- With foamed polyethylene, it looks like a roll of self-adhesive material, similar to a film with foil. The scope of application in various equipment, sheathing of pipes, shafts, roofs, since it has a high temperature range from -160 to +160 degrees, is fire resistant.

- Mineral wool with a foil coating, can be in the form of a plate, a cylinder. Also has a high degree of fire resistance.

- Expanded polystyrene, treated with foil on both sides. Also has a wide temperature range, the diameter can be 5mm, 10mm, 15mm.

- Basalt, just like the above materials, is made on the basis of foil-clad material, however, thanks to a unique technology, it can withstand temperature fluctuations from -200 +600 degrees, is resistant to aggressive chemical environments.

How to put insulation on pipes

As a rule, such a material has the form of a pipe "cocoon" made of mineral wool (withstand high temperatures) or expanded polystyrene (moisture resistant). And how to insulate them, the question disappears in itself, since they have the form of a "cocoon", which is put on top and fixed. There are main lines for chimneys of various diameters and temperature regimes.

However, if you decide to purchase a sheet of insulation, you may be faced with the question of how to glue it to the metal? Aluminum tape will come to your aid, which is wound on the insulation over the pipe. And, as in the above options, you must dress with the shiny side to yourself.

Is it possible to insulate the walls from the outside

To insulate the walls from the outside, perforated foil insulation is used. This material, which, among other things, has soundproofing qualities, is able to protect your home from moisture and wind, and also does not prevent moisture from leaving the room. This option is ideal for those who do not have the opportunity to do this kind of work indoors.However, such activities can only be performed during the warm season and in dry weather.

- If you had any covering on your wall, you need to get rid of it. Then treat the surface with an antiseptic solution. It is better to do this in hot weather, so that everything dries out well, especially carefully treat the lower part of the building. The surface will dry completely within two days.

- Next, build a frame from a bar, fix it with self-tapping screws. Lay Penafol, then leave the air tunnel, glue the joints, then mount the outer frame.

In conclusion, we suggest watching a video about the installation of Penofol thermal insulation:

boilervdom.ru

Description

Today on sale you can see various options for substrates. They all depend on the thickness and material that was used in their manufacture. Each product has its own pluses and minuses. Most often, foil-clad foamed polyethylene, polystyrene or cork is used for the installation of the protective layer.

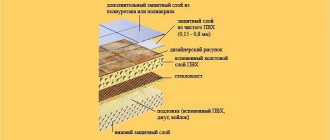

In addition to linings, which consist of one type of material, you can find combined coatings. They consist of several layers. One layer is aluminum foil, and the other is polystyrene or polyethylene foam. Both layers are glued together with a special glue. Thanks to this structure of the material, it is possible to increase its protective properties.

On the photo - foil underlay for laminate

The presence of a foil layer increases the thermal insulation properties of the floors by 30%. When laying the material, increased moisture resistance properties are achieved, so that there is no need for additional installation of a polyethylene film.

In addition, the foil lining is a reliable protection against the penetration of fungi and the formation of mold. The material is actively used when arranging the floor in those rooms where there is a high risk of moisture penetration into the screed. This includes the bathroom, kitchen and basement.

When choosing a protective layer for a laminate, it is necessary to take into account such a parameter as thickness. It can reach 2-10 mm. The optimum thickness is determined by the type of flooring and the degree of unevenness in the floor. In addition, it must be borne in mind that over time, polyethylene foam sags, so that with an incorrectly selected thickness, the quality of the laminate installation and the period of its use are reduced. For installation under a laminate, it is necessary to purchase a substrate with a layer thickness of up to 5 mm.

On video foil underlay for laminate:

Foil backing

In addition to pads made of one type of material, there are already several types of combined pads, consisting of two or three layers. These include the foil underlay for the laminate. As a base, polystyrene or polyethylene foam is used, on one side of which is coated with an aluminum foil film. Both materials are glued together with glue.

A layer of foil can increase the heat-insulating properties of the floor by about a third, besides, it is another layer of waterproofing. The use of a substrate under a laminate with foil allows you not to lay a waterproofing layer of a polyethylene film.

In addition, the foil-coated backing material protects against mold and mildew.

Today, this type of lining is increasing its popularity and demand. It will come in very handy for use in rooms with possible ingress of moisture into the subfloor from the floor located below, where, for example, a damp basement is located.

When choosing a backing layer for a laminate, it should be borne in mind what its thickness should be. It can be from 2 to 10 mm. The optimal thickness should be chosen based on the following factors:

- type of laminated coating, thickness of its panels, strength class;

- the degree of leveling of the base surface;

- room microclimate: humidity, temperature;

- backing material for laminate.

Advantages and disadvantages

The installation process of the laminate is carried out by a floating method. You do not need to use special adhesives for this. The installation of the coating slabs is carried out directly on the substrate, which performs its direct functions.

Thus, the following advantages of the material can be distinguished:

- Soundproofing... Due to the deformation that laminate boards undergo, various noises can occur when walking on the floor. A good quality foil backing can help prevent squeaks. This is achieved by absorbing sound waves and reliably supporting the laminate. On the photo - foil underlay for the laminate as sound insulation

- Steam and moisture insulation... When installing laminate boards on a base that was not completely dry, excess moisture and vapors begin to accumulate. If you install a foil lining, it is possible to protect the flooring from the negative effects of vaporization. On a photo-foil underlay for a laminate as a vapor and moisture insulation

- Long service life... You can enjoy the aesthetic beauty of flooring for more than 10 years. Thus, the foil lining should last even longer. Durability depends on the type of flooring used, the density and the load for which it is designed.

- Thermal conductivity. If underfloor heating systems are to be used, then high heat conductivity is one of the functions that the underlayment must fulfill. Due to thermal conductivity, heat will be evenly and efficiently transferred to the laminate. In this case, the concrete screed will not heat up.

Which side to put the substrate under the laminate and how to do it correctly is indicated in this article.

In which cases a 5 mm laminate underlay is used, this information will help to understand.

But what kind of underfloor laminate flooring should be used, and what is best to refuse, this information will help to understand: https://resforbuild.ru/paneli/utepliteli/podlozhka-pod-laminat-dlya-teplogo-vodyanogo-pola. html

But what is the cost of a cork underlay for a laminate and where to use it. described in this article.

Installation

The process of laying the underfloor underfloor heating is carried out with an overlap or butt-to-joint. The choice of a suitable mounting option is determined by taking into account the thickness of the material. It is clear that it is unrealistic to overlap a heat insulator with a large thickness, then the joint-to-joint method comes to the rescue.

The thickness of the foil backing can be 2-20 mm. Taking these parameters into account, the choice of the installation method is made.

For material with a thickness of not more than 6 mm, you can use the overlap method, that is, run on top of each other. Fix the formed joints with adhesive tape so that the made flooring is durable. It is unacceptable to shift it when installing pipes or brackets. If a laminate is used as a floor covering, then a not thick reflector can be used. If you use thick material, then a soft pillow will appear. It will negatively affect the top screed, which will be subject to deformations and cracks. How it looks and how the linoleum substrate is laid on a concrete floor can be seen in this article on the video. But how the coniferous substrate is laid under the laminate and how to do it correctly, you can see the whole procedure in the diagram in this article.

On video installation of a foil underfloor heating:

If auxiliary insulation is required, then sheets of extruded polystyrene foam must be laid under the thin insulating material. It also differs in thickness. And it depends on what kind of insulation power is needed.

Install a hydro-barrier under the reflector if you are not sure that the screed is equipped with waterproofing. Thanks to the laid dense cellophane, a reliable barrier is created.

When installing a foil lining under a warm floor, you must adhere to the following simple recommendations:

- It is imperative to use a lining with a foil layer. This is the only way to keep up to 98% of the heat and eliminate its loss in the room.

- For laminate flooring, the backing must have a soft backing. This will correct the unevenness of the board.

- For a linoleum base, you need to choose a solid thermal insulation material. Then the floor will not be squeezed under the influence of furniture.

- If there are significant irregularities in height on the floor, then a soft lining will be able to eliminate them, because it is plastic. When installing a foil lining on a surface with significant defects, a rigid configuration material must be used.

What a cork underlay looks like for a parquet board and how to use it correctly. described in this article.

But what are the substrates for the laminate and how to choose them correctly, is described in this article.

What thickness of the cork backing for the laminate should be and how to choose the right option is indicated in great detail with the photo here in the article: https://resforbuild.ru/paneli/utepliteli/tolshhina-podlozhki-pod-laminat-kakaya-luchshe.html

How the arbiton underfloor heating laminate looks and is used can be seen in this article in the photo.

Installation process

You can lay the foil backing yourself. The process is notable for its simplicity and speed. Consists of two stages - preparation and installation itself.

Training

Before laying laminate boards, you need to thoroughly prepare the floor surface. The durability of the flooring will depend on the quality of the preparatory work.

Preparation includes compliance with the following actions:

- The floor surface must be level, firm and dry. The first step is to dismantle the old coating and assess the condition of the existing screed. If there are many cracks and chips on it, it crumbles and exfoliates, then it must be dismantled and a new one created. If the defects are insignificant, then the existing chips and cracks should be eliminated with a putty, and the surface should be leveled.

- When choosing the material used for leveling the surface, it is necessary to take into account the depth of the irregularities.... Measure the floor with a building level and calculate the difference between the highest and lowest points. If the obtained value is more than 3 cm, then it is advisable to perform a traditional cement-sand screed. If the depth of the uneven does not exceed 1 cm, then you will have to use a self-leveling mixture.

- The screed must be completely dry before installing the laminate.... You will have to wait about 14 days. To check the readiness of the surface, you need to use a simple method: install a glass jar with the neck pointing down. Wait a day and inspect the glass. If moisture has settled on it, then you still need to wait, since the screed has not dried out.

- If the installation is carried out on a wooden base, then the condition of the surface must be assessed to detect the presence of irregularities, cracks and instability.... If the condition of the floor is unsatisfactory, then the boards will need to be rebuilt. Minor irregularities can be eliminated by applying the installation of fiberboard sheets.

- Preparatory activities end with a thorough cleaning of debris and dust... A vacuum cleaner will help to cope with this work.

The video shows the preparation of a substrate for a laminate with foil:

As for the shortcomings, there is only one. This is a high price, because of which not everyone can buy such a high-quality lining under the laminate.

Installation

It is necessary to lay the foil product in the direction in which the laminate will be mounted. Lay the backing so that the reflector is on top. Leave an allowance on the strip that is concentrated along the wall.It will be a few centimeters long.

Installation of all strips is carried out end-to-end, and fastened with foil tape. It must be glued very carefully so that there is no creasing of the edges of the material and cracks.

In order not to destroy the integrity of the flooring with the shoes, the process of laying the substrate should take place in stages.

The material is laid in a volume that will be sufficient for laying 2-3 rows of laminate boards. Then mount the floor covering and lay the next strip of backing. Allowances that are near the wall, after installing laminate boards, must be masked under the skirting boards.

On the video how to lay a substrate with foil:

In order for the installation process to be performed as accurately and efficiently as possible, you must adhere to the following recommendations:

- Do not select a thick substrate or lay it in 2 layers. To hide the strong unevenness of the floor, it is better to carry out preparatory work to level the surface as evenly as possible, and then lay thin insulation on the dried layer.

- When laying the lining, it is necessary to ensure that there is no coincidence of its seams with the joints of the floor covering.

- Installation of the roll substrate should be carried out with an overlap on the walls. Further strips are laid without overlap, fixing with masking tape.

- The insulating sheet is staggered and then secured with tape.

Perhaps you will also be interested in knowing what color of laminate to choose for an apartment.

But how to choose a high-quality laminate for an apartment and what criteria you should pay attention to, is described in great detail in this article.

It will also be interesting to know which class of moisture-resistant laminate is the best and which one should be used.

But what are the pros and cons of a coniferous substrate for a laminate, and what you should pay attention to, this article will help you understand.

For those who want to learn more about how to lay a substrate under a laminate, you should watch the video in this article.

Which side to lay

You can lay the foil backing yourself. The process is notable for its simplicity and speed. Consists of two stages - preparation and installation itself.

Training

Before laying laminate boards, you need to thoroughly prepare the floor surface. The durability of the flooring will depend on the quality of the preparatory work.

Preparation includes compliance with the following actions:

- The floor surface must be level, firm and dry.

The first step is to dismantle the old coating and assess the condition of the existing screed. If there are many cracks and chips on it, it crumbles and exfoliates, then it must be dismantled and a new one created. If the defects are insignificant, then the existing chips and cracks should be eliminated with a putty, and the surface should be leveled. - When choosing the material used for leveling the surface, it is necessary to take into account the depth of the unevenness. Measure the floor with a building level and calculate the difference between the highest and lowest points. If the obtained value is more than 3 cm, then it is advisable to perform a traditional cement-sand screed. If the depth of the uneven does not exceed 1 cm, then you will have to use a self-leveling mixture.

- The screed must be completely dry before installing the laminate.

... You will have to wait about 14 days. To check the readiness of the surface, you need to use a simple method: install a glass jar with the neck pointing down. Wait a day and inspect the glass. If moisture has settled on it, then you still need to wait, since the screed has not dried out. - If the installation is carried out on a wooden base, then the condition of the surface must be assessed to detect the presence of irregularities, cracks and instability. If the condition of the floor is unsatisfactory, then the boards will need to be rebuilt. Minor irregularities can be eliminated by applying the installation of fiberboard sheets.

- Preparatory activities end with a thorough cleaning of debris and dust

... A vacuum cleaner will help to cope with this work.

In the video - preparation of a substrate for a laminate with foil:

As for the shortcomings, there is only one.This is a high price, because of which not everyone can buy such a high-quality lining under the laminate.

Installation

It is necessary to lay the foil product in the direction in which the laminate will be mounted. Lay the backing so that the reflector is on top. Leave an allowance on the strip that is concentrated along the wall. It will be a few centimeters long.

Installation of all strips is carried out end-to-end, and fastened with foil tape. It must be glued very carefully so that there is no creasing of the edges of the material and cracks.

The material is laid in a volume that will be sufficient for laying 2-3 rows of laminate boards. Then mount the floor covering and lay the next strip of backing. Allowances that are near the wall, after installing laminate boards, must be masked under the skirting boards.

On the video how to lay a substrate with foil:

In order for the installation process to be performed as accurately and efficiently as possible, you must adhere to the following recommendations:

- Do not select a thick substrate or lay it in 2 layers. To hide the strong unevenness of the floor, it is better to carry out preparatory work to level the surface as evenly as possible, and then lay thin insulation on the dried layer.

- When laying the lining, it is necessary to ensure that there is no coincidence of its seams with the joints of the floor covering.

- Installation of the roll substrate should be carried out with an overlap on the walls. Further strips are laid without overlap, fixing with masking tape.

- The insulating sheet is staggered and then secured with tape.

You may also be interested to know about

The hidden underfloor heating system is an excellent option, both for creating additional comfort in the room, and for fully heating the house. If we look at the structure of the classic version of such heating in section, then you can see at least four separate layers. Each of them has its own purpose, and the exclusion of any of them will negatively affect the efficiency of the entire heating unit. One of these structural elements is a foil underfloor heating. And what is its purpose, we will tell you in this article.

Manufacturers and prices

Today, there will be no difficulties with the choice of a foil substrate for a laminate. It is present in every hardware store and differs in thickness, as well as the materials from which it was obtained.

Table 1 - Manufacturers and price of foil underlay for laminate

| Manufacturer | Ort-Plast Russia | Izolon Russia | Wicanders Portugal | Tuplex Finland | Alloc Norway |

| Price, rub./m² | 10 | 80 | 145 | 90 | 112 |

Read about other types of foil insulation.

Laying laminate boards cannot be done without first installing a material such as foil backing. Thanks to it, it is possible to increase the heat and sound insulation properties. The product is produced in a wide range of widths, so that it becomes possible to level the floor surface and eliminate minor defects.

resforbuild.ru

Reviews of domestic manufacturers

According to customer reviews, the 5-mm LMP Normaizol laminate substrate is of high quality. It is made by a domestic manufacturer. The structure of the cells of the material is closed. This guarantees high performance of the polyethylene backing. The cost of this material is approximately 800-850 rubles. per roll.

Another in demand. The company produces polyethylene substrates of various thicknesses. They can be mounted both under electric heating systems, and simply under a laminate. The cost of the production of this brent is about 750-850 rubles. per roll.

Another popular manufacturer is. In the manufacture of the substrate, innovative technologies are used.As a result, the highest quality material is supplied to the market. This backing is made of cross-linked polyethylene. His cells are closed. This increases the thermal insulation properties of the material. The cost of substrates is acceptable. It is about 700-750 rubles. per roll.

Another well-known manufacturer of universal laminate pads is. This domestic brand manufactures many varieties of materials for arranging the presented flooring. The average price of a foil substrate for a laminate of the presented brand is about 850 rubles.

What is foil insulation

The reflective layer is available on one or both sides

It is a combined material that consists of a layer of aluminum foil or metallized film, combined with a thermal insulation material. The reflective layer can be one-sided or two-sided. Differs in easy and quick installation due to its elasticity. Thinner than other thermal insulation materials.

The aluminum coating has the maximum heat reflection performance, but is destroyed by the action of alkalis in the concrete. The metallized coating is resistant to alkaline attack. Spraying practically does not fulfill its function.

In addition to retaining heat, it can be used as waterproofing, since it does not allow moisture to pass through itself. The thinner the foil layer, the better it allows heat to pass through itself.

Foil in thermal insulation materials

Installation of a warm floor is not complete without thermal insulation materials. Reducing heat losses during the operation of the heating system significantly saves the owner's finances spent on paying for heating or electricity. Foil underfloor heating is considered the most efficient in terms of energy saving.

When installing underfloor heating, you can use any substrate, with or without foil. But infrared film floor heating systems require exclusively foil surfaces as a substrate.

Heat-reflecting and other properties of foil, thanks to which it is so successfully used in installation work, are partially incorporated in the manufacture of materials that insulate heat. All of them are available in rolls, which is very convenient for installers.

The base is used from polyethylene, mineral, expanded polystyrene, basalt. The bubbly foam structure does not allow heat to pass through due to the large amount of air in the composition.

The use of materials with foil is safe from the point of view of fire hazard, environmentally friendly and harmless to human health.

Types of thermal insulation materials with foil

The modern range of building materials offers several basic (basic) insulation options with a foil layer:

- foamed polyethylene;

- traditional expanded polystyrene;

- mineral wool;

- folgoizolone;

- multi-foil;

- basalt insulation.

The most popular of all is foamed polystyrene foam. As a heat insulator, it is highly durable, resistant to temperature changes from 180 degrees of frost to 180 degrees of heat.

A substrate made of such a material is not afraid of the use of chemicals, is resistant to microorganisms and does not pose a threat to the health and well-being of the owner.

Types of heaters

There is a wide variety of foil-clad insulation.

They differ in the materials used in the manufacture.

The characteristics of heaters with a layer of foil are described in the table:

| № | Foil material | Characteristic |

| 1 | Expanded polystyrene | Tough, reliable insulation material, available in the form of rigid slabs. It is used for thermal insulation of water and electric underfloor heating. Operation in the temperature range from -180 to +180 degrees |

| 2 | Mineral wool | Environmentally friendly, fireproof material, 50-100 mm thick. Manufactured in slabs, rolls, cylinders.It is used in all areas of insulation work. |

| 3 | Foamed polyethylene | Available in rolls, covered with aluminum foil. The material has a small thickness from 2 to 10 mm. The bottom layer can be self-adhesive. |

| 4 | Foamed polyethylene | Available in rolls, covered with aluminum foil. The material has a small thickness from 2 to 10 mm. The bottom layer can be self-adhesive. |

When choosing, you need to take into account the requirements for the room and its functional purpose. The top layer should be covered with aluminum foil, not sprayed on.

Types of thermal insulation

Penofol

Thermostat for underfloor heating

Penofol is produced and sold in rolls.

Penofol is a foil-covered polyethylene foam. It is a soft and flexible material produced in rolls.

Thermal conductivity coefficient - 0.037 - 0.052 W / m × ° С.

Penofol is easy to install, easy to cut. A layer of foil effectively distributes heat over the entire surface of the heated floor.

However, this material also has a drawback: under the weight of the screed and floor covering, it can shrink, while the volume of air bubbles entering its structure will significantly decrease, which will entail a loss of thermal insulation qualities.

Important! As a rule, this material is used on the upper floors of apartment buildings, where there is a warm heated room under the heated floor, and the floor slab is sufficiently heated. ... For basements and first floors, as well as balconies and loggias, basements and garages, this material is not suitable

Sometimes, however, it is not possible to raise the floor a considerable distance, then the use of penofol may be justified.

For basements and first floors, as well as balconies and loggias, basements and garages, this material is not suitable. Sometimes, however, it is not possible to raise the floor a considerable distance, then the use of penofol may be justified.

Advice! When choosing floor insulation, look for foil materials with an aluminum foil thickness of at least 30 microns. We are not interested in lavsanny coatings with reflective properties, only thick foil!

Cork tree

Balsa insulator is sold in rolls, sometimes in the form of mats or slabs.

The thermal conductivity of balsa wood ranges from 0.035 to 0.05 W / m × ° С. As you can see, this characteristic is comparable to that of penofol.

However, it is believed that a 2 - 3 mm thick cork layer is sufficient to insulate a warm floor. This is certainly a controversial opinion.

The advantage of cork insulation is its naturalness. It consists of absolutely natural raw materials and does not emit toxic chemicals under any conditions.

However, there are also disadvantages:

- high material price;

- the possibility of rotting, a breeding ground for fungi and mold;

- damage from biological corrosion;

- the cork needs waterproofing.

Therefore, for cork, it can also be concluded that it is only suitable for floors with minor losses and warm heated floors. Most often, cork is used as a substrate for a laminate.

Expanded polystyrene

Foil polystyrene foam for thermal insulation of floors with markings.

Expanded polystyrene is the most suitable option for thermal insulation of floors.

This is due to a number of reasons:

- The material has a density sufficient for laying under a screed - more than 35 kg / m³;

- Expanded polystyrene plates have a sufficient thickness - 50 mm, thanks to which you can easily arrange an effective 100-mm thermal insulation of the floors of basements and basements, first floors, etc.;

- The material has a low thermal conductivity - 0.039 W / m × ° С, which, with a layer of 50 - 115 mm, gives complete insulation and reduces heat losses to nothing;

- Expanded polystyrene for floors is covered with a laminated foil layer from 30 microns thick, which makes this type of insulation optimal;

- The installation instructions assume simple do-it-yourself work, and the markings on the foil simplify the installation of heating elements;

- Plates do not shrink under the weight of the screed and maintain stable thermal conductivity values for many years;

- Polystyrene is chemically inert to solutions of salts, acids and alkalis;

- The material is biologically inactive and is not food for living organisms or a substrate for fungi;

- Does not change parameters and does not emit harmful chemicals in the temperature range from - 180 to +180 ° С.

Advice! When buying a heat insulator based on expanded polystyrene, look for exactly the floor material, since facade and other configurations may not be adapted to work near heating elements and emit harmful substances or change their parameters and shape.

Expanded polystyrene is especially convenient for warm water floors, if it is equipped with special locks for attaching pipes.

Important! According to most experts, it is extruded polystyrene foam with a density of 35 kg / m³ or more that is the best thermal insulation for warm floors, especially on basement floors and in the case of unheated rooms from below.

Properties

The materials used in production are most often environmentally friendly, safe for health and the environment.

Benefits:

- light weight;

- durability;

- resistance to loads;

- protection against moisture penetration;

- high rates of heat saving and sound insulation;

- resistance to temperature changes;

- ease of styling;

- high reflective properties.

Such insulation can be used in any room. In addition to the qualities described, it is capable of reflecting radiation radiation.

What is foil in warm floors for?

Under the floor heating system, the material is needed to direct the heat flow upwards, and not through the screed below. Such a system allows you to warm up the room stably and with equal heat fluxes without additional energy costs. Foil under floor heating has become extremely popular both in large cities of the Russian Federation (Moscow, St. Petersburg) and in the periphery.

Thermal insulation retains heat, especially if the material is made on a foil backing. Foam plastic 8 cm thick has the same thermal insulation parameters as polyethylene foam structure on a layer of foil.

Foil for underfloor heating must meet the following parameters:

- the quality of heat reflection;

- invulnerability to temperature changes;

- isolation of noise;

- high waterproofing characteristics;

- high-quality thermal insulation;

- ease and simplicity of installation;

- safety - environmental friendliness and harmlessness.

Almost all modern materials with a foil base meet these requirements, especially in the process of heat transfer - reflection of heat fluxes.

Laying methods

Consider which side to correctly lay the insulation with foil on the floor.

Heat-saving properties depend on how well the insulation is laid.

The foil reflects infrared radiation, therefore, the metallized layer must be laid so that it looks into the room.

Insulation of a concrete floor

Place the pad with the foil down

Most often, the roll material is fixed to a concrete base on a special glue made on the basis of rubber.

Installation sequence:

- Preparing the surface. We align the slab so that there is no large difference in height. We seal all cracks and cracks with cement mortar.

- We spread the material on the floor with a foil layer upwards, cut it to the required length. We move the strip aside, apply glue to the place of its laying. We stand for several minutes according to the instructions for the glue. We lay and press the material well. We put the strips close to each other.

- We fix the joints with foil tape, which is sold in hardware stores.

For additional insulation of cold floors, wooden logs can be laid on top, the space between which is filled with slab insulation. On top of it, floorboards or sheet material (OSB, fiberboard, chipboard) are placed. For an interesting comparison of foil materials, see this video:

You can fix the material on double-sided tape, glued around the perimeter, or dowels.

Thermal insulation of wood floors

The most convenient way to lay the material on the adhesive layer

It is most convenient to lay foil insulation on a wooden floor, which has a lower self-adhesive layer.

If you bought material without an adhesive base, then you need to fix it on staples using a construction stapler or on double-sided tape.

Laying sequence:

- We remove the skirting boards, remove debris and dust with a vacuum cleaner.

- If there are irregularities on the boards, we grind them with a special machine, if necessary, we perform scraping (remove the top layer of the board).

- All existing cracks are sealed with wood putty.

- We prime it with an antiseptic composition.

- We measure the room, cut out the roll, lay it up with foil. It can be easily cut to size with sharp sewing scissors.

- We lay out in strips end-to-end. We wait a day for the material to settle down and straighten out. If the heat insulator has a self-adhesive base, gradually remove the protective film and press it tightly to the surface. Lay the next strip end-to-end.

- The joints of the strips are fixed with foil tape.

Once the material has been installed, the selected floor covering can be installed.

Foil insulator for underfloor heating

When installing the insulator under underfloor heating, lay the material with the foil facing up so that it reflects heat into the room.

The base for underfloor heating should be flat without height differences and defects. All errors must be eliminated.

Stages of laying thermal insulation with a layer of foil:

- We lay out the foil material in strips end-to-end, glue the joints with special tape.

- On top we mount a system of electric or water heated floors.

- We lay hydro and vapor barrier material. It will prevent the concrete from leaking onto the floor heating elements.

- We fill a screed with a thickness of 30-50 mm, depending on the type of heating elements and the functional purpose of the room.

Warm floors can be turned on only after the screed is completely dry. It will take about a month.

Types of thermal insulation with foil

So, on the building materials market, you can find a variety of types of thermal insulation materials covered with foil; in particular, it can be:

- foamed polyethylene;

- expanded polystyrene;

- basalt insulation;

- mineral wool;

- multi-foil;

- folgoizolone.

Let's take a closer look at them. The most popular thermal insulation material used for underfloor heating is foamed polystyrene foam. Quite durable material that is not afraid of sudden temperature fluctuations. In general, he is able to cope with changes in air temperature from -180 to +180 degrees without prejudice to himself, but, of course, in domestic conditions, the floors do not exactly heat up to such an extent. Also, expanded polystyrene is not afraid of the effects of various chemicals. It is not afraid of rot, various pathogens do not settle on it, which also demonstrates the material as safe for human health.

Mineral wool is purchased and used much less often, even with a layer of foil. It is especially not suitable for laying a water heating system. The fact is that in the event of a liquid leak, the material is easily saturated with it and will lose all its qualities - it will not be able to retain heat. And mineral wool is not recommended for electric heated floors. The main reason for negative reviews is that this material, when heated, begins to release substances that negatively affect the body. Therefore, such insulation is often used only in industrial facilities.In fairness, it should be noted that mineral foil wool has an advantage - a low fire hazard class.

Foamed polyethylene is another commonly used type of underfloor heating. Durable, plastic, not afraid of moisture, it is not afraid of various chemicals, and pathogens do not settle on it. All these advantages make foil-clad polyethylene one of the best materials for thermal insulation. It can be used both under a water heated floor and under an electric one, and its useful life can be very long.

On a note! Foamed polyethylene does an excellent job of absorbing noise. Its main drawback is the fear of ultraviolet radiation, but under the flooring, sunlight will not reach the material.

Basalt insulation is not used in residential buildings. He is not afraid of sudden temperature changes and can easily withstand from -200 to +700 degrees, and therefore does not burn. This thermal insulation material is used in the aircraft industry.

Folgoizolone is often used in the construction / repair of saunas and baths, as it is not afraid of moisture or sudden changes in temperature. The service life of the material is quite long, it does not rot, has increased sound insulation properties, and is safe from an environmental point of view. But folgoizolon is very expensive, therefore it is practically not used in residential ones.

There is another type of insulation with a foil layer. It is known as multi-foil and consists of several layers. The foil layer is covered with a bubble, filled with air, then polyethylene and polypropylene film are laid. There is a special protective coating under the foil layer. If you use this type of thermal insulation, then heat loss will be reduced to a minimum. In addition, multifoil is not afraid of high humidity.

Attention! You should not use materials for the installation of the underfloor heating system, intended for the insulation of walls and other parts of the building. On the floor, they will experience strong mechanical stress, and therefore can quickly lose their properties.

Only use materials specifically designed for flooring.