Flushing the system before starting

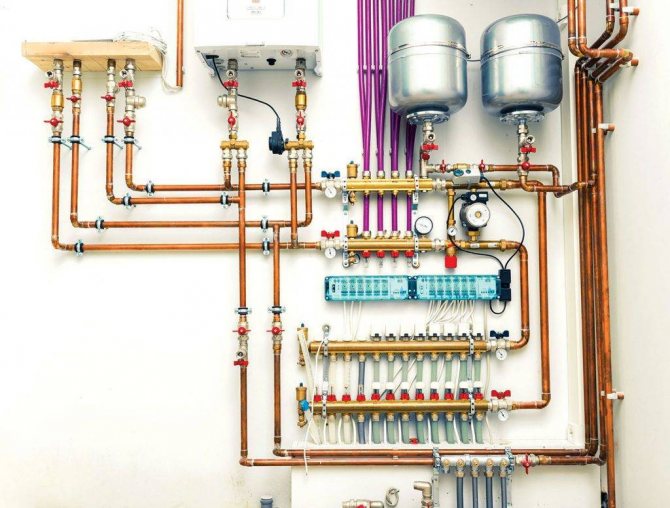

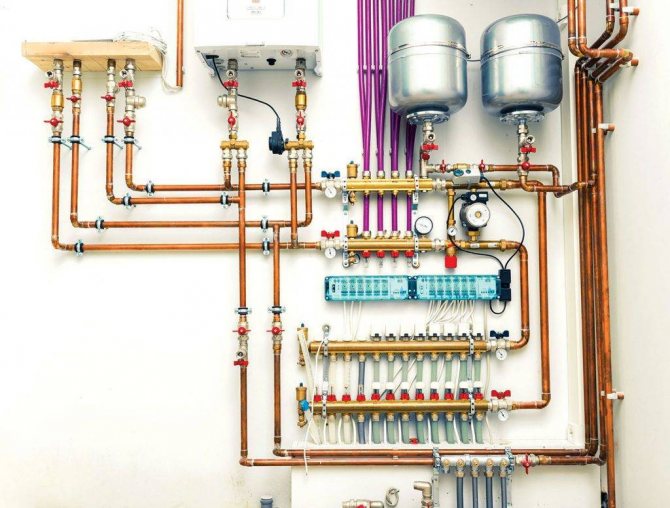

Water heating circuit.

If there is water in the heating system, it must be drained. Next, you should dismantle the heating radiators. Then connect the pipes for supplying water from the water supply system to the outlet of the system, and the drain pipe to the inlet to the system. All formed connections must be well secured with pre-prepared clamps. It should be remembered that the higher the pressure water is supplied, the better the cleaning will be (but not more than two atmospheres). A pump is usually used to generate pressure. You can sprinkle bleach on the water to achieve a disinfecting effect. On average, this procedure can take about two hours. At the end of the drain, pure water will flow without additional impurities.

Cleaning the heating system can be carried out using special chemicals: additives or anti-corrosion fluids

They should be treated with caution, since they are not suitable for all materials and can damage some elements of the system.

After cleaning, the radiators are mounted in the opposite direction of their dismantling. You should additionally check the tightness of the system by visual inspection and detection of leaks.

The main types of heat transfer fluids

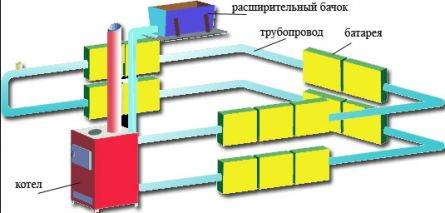

Heating system.

The principle of operation of the heating system is that the coolant moves from the heat source to the end point through the pipes, heating them. The type of heat carrier used depends on the type and design of the heating equipment, which can be liquids and gases.

The most popular are liquid coolants:

- Water is the most readily available and cheapest resource. According to statistics, about 70% of heating systems use water, which has a high density and heat capacity. In addition, this type of coolant has gained such popularity due to its properties such as low viscosity, high heat transfer coefficient, and simple temperature control. The main disadvantage is the ability to freeze at zero temperature. If water freezes in the heating system, this will lead to rupture of pipes and failure of all equipment.

- Antifreeze - this type of coolant is not as widespread as water, and its use is 5%. It is used for heating office buildings and residential buildings, where the heating system does not allow the use of water due to the increased risk of corrosion. The main advantage of antifreeze is freezing in frosts of 60 - 70 degrees.

The following gases are used as a heat carrier:

- Water vapor - mainly used in industrial buildings, as its use is prohibited in residential and public buildings. Water vapor maintains the temperature of heating devices at 100 degrees, according to sanitary standards, this figure should not exceed 80 degrees.

- Flue gases are toxic, therefore, recently they are used only for heating water and in order to save electricity to obtain a heat source.

- Air is characterized by a low heat capacity, therefore, to move it through the heating system, high energy costs are required. It is most cost-effective to use air as a heat carrier, provided that it performs two functions simultaneously: heating and ventilation.

At present, organic fluids are being introduced as a heat carrier, which have excellent freezing rates and have a low viscosity.However, they have not yet received wide distribution, due to their high cost and scarcity.

Filling the water supply system of a passenger carriage with water and draining water from it

It is carried out outside the car through filling pipes with connecting heads. The conductor is obliged to determine the amount of water in the system 5-10 minutes before arriving at the water filling station, to turn on the water filling alarm on the remote control. When the train stops at the station, warn the outfitter of the need to refuel. Check the refueling process. When draining water from the system, open all valves and taps and drain the water from the boiler.

Check the presence of water in the system in our carriage in the toilet from the working side view the Gauge glass of the small tank. In German from the non-working side

The principle of operation and design of the hot water supply system for a passenger car

The hot water supply system consists of a boiler unit located in the boiler room and a hot water piping system. A boiler system for heating water and cooking food consists of a boiler, a stove and a storage tank.

The hot water supply system operates in two modes - winter and summer. In winter mode, when the heating system boiler is operating, the water in the boiler is heated by hot water from the heating system, which flows into the coil directly from the boiler. In this case, the valves must be open.

In summer mode, when the boiler of the heating system is not working, the water in the boiler is heated by the heat obtained by burning fuel in the stove's furnace. In this case, the valves must be closed. The stove is powered by wood or charcoal.

Water from the water supply network is supplied to the boiler through the taps, fittings for supplying cold water to the boiler and a three-way tap, water drain taps. The boiled water is disassembled through the tap of the drinking water taps. The steam outlet pipe together with the sump pipe is brought to the weir with a warming funnel.

From a hot boiled water tank, which is poured through a funnel, water through a valve (enters the water cooler, the tank of which has an air outlet valve and a drain valve. Chilled water is disassembled through a valve installed in the niche of the boiler side corridor.

Wash bowls are supplied with cold and hot water, respectively, through taps and 93, 92, and sink through taps. Cold water flows to the toilet bowls through the flush valves The taps, the joint drain valve and the boiler fill valve are involved in the operation of the heating system

The device and principle of operation of the combined boiler

Boiler device: body

, at the bottom of which there is

firebox

with door and

ash pan

with a door. Inside the firebox there are

grate

and

flame arrester

.

Inside the boiler are two flasks

: for raw water (9 l) and for boiled water (17 l); with

water gauge glass

, according to which boiled water boiling is observed. There are two marks on it - 15 liters and 17 liters. The gauge glasses have valves at the bottom to shut off the gauge glasses in the event of a split.

Installed on the boiler body: demountable titanium faucet

;

alcohol thermometer

;

three-way valve

- for draining raw water from the boiler, has three positions: raw water; closed; boiled water;

sump filter

for purification of raw water from mechanical impurities;

raw water regulator

(inside which there is

float

(metal), the float has a lower needle that goes into the tube and an upper needle with a valve fixed on it - to block the access of raw water to the boiler).

The boiler can be with heating elements: with one or two - at the bottom; with three - 2 at the bottom, 1 from the lid.

According to sanitary standards, it is required Rinse the flask with raw water once every 5-6 days - fill and drain at least 2 times. If boiled water has stood unused for more than 12 hours, it is not recommended to use it for drinking - drain it.

⇐ Previous2Next ⇒

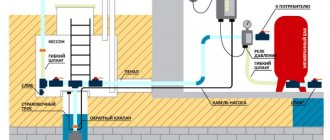

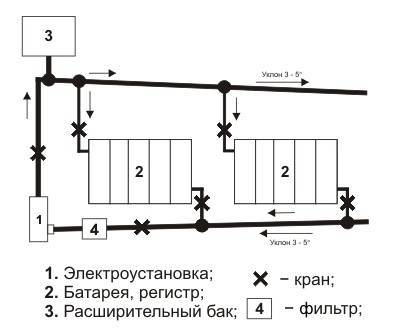

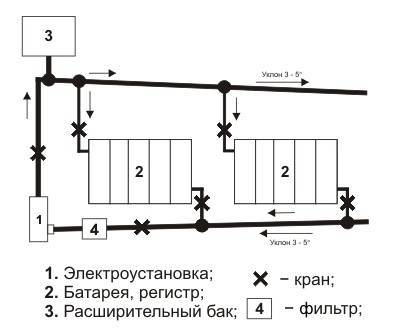

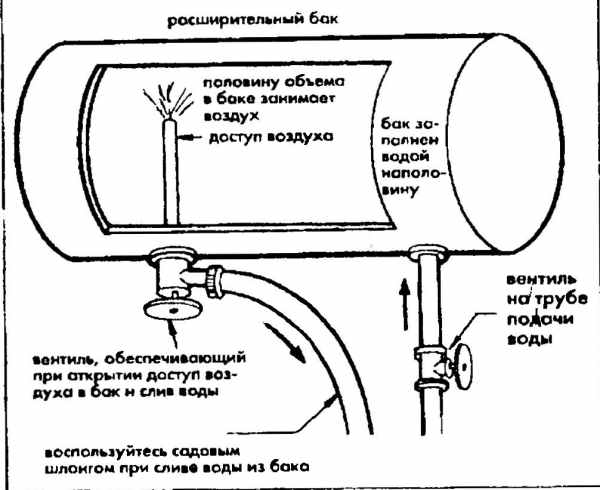

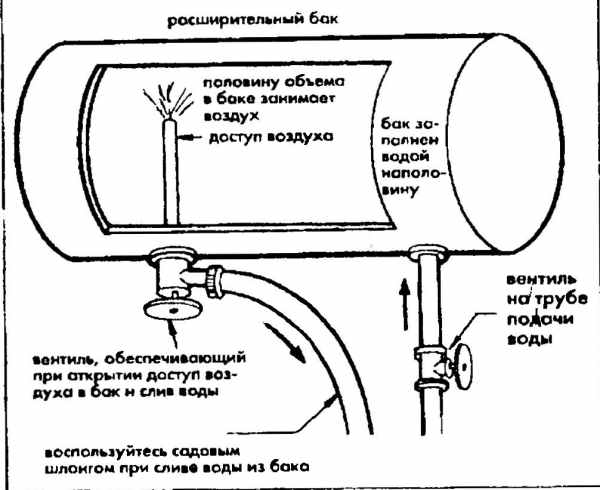

Open gravity heating system start-up process

In modern houses, open heating systems are rarely satisfied; such technologies have long been considered a relic of the past. But they still exist, so you should consider how to fill them with water. In any such heating system, there is an expansion tank at its highest point; it is designed to accumulate water after an increase in its volumes in the system with increased pressure during a rise in temperature. The tank is an open tank with or without a lid. Through the tank, the system is filled with water. Large volumes of liquid, of course, will be quite problematic to fill in small containers, moreover, to the highest point.

The most rational would be to use a conventional vibration pump for household use. To do this, prepare a capacious container, fill it with water. The previously prepared hoses are attached to the pump with clamps. Such a pump has a submersible type of structure. The hose through which water will be taken must be lowered into a prepared water tank. The hose from which the water will be discharged is immersed in an expansion tank. The pump is turned on, the pressure in the system should be from one and a half to two atmospheres. When lowering, add water to the prepared tank and lower the hose into it below. When the heating complex is full, water will be visible at the bottom of the expansion tank, the system can be considered filled.

Installation diagram of the hot water heating system.

Excess air will come out of the pipes at the first fire through the expander. It should be noted that during the heating season, when the system maintains a constantly high temperature, the water will gradually evaporate from the expander. It is necessary to make up by adding water to the expander to the required level. You should also monitor the temperature on the thermometer attached to the heating boiler. Upon reaching its level above 80 ° C, the water will soon begin to boil and splash out. In this case, it is necessary to block the access of oxygen to the furnace to reduce the intensity of combustion.

5.4.2 Water supply system

The water supply system for passenger cars is the most important sanitary equipment that provides the necessary conditions for passengers during their long journey. Regardless of the type, each passenger carriage is equipped with a gravity water supply system designed to provide passengers with drinking water, satisfy their domestic needs and replenish the heating system in the intervals between refueling. Two systems of water supply for passenger cars have been used in the carriage industry: domestic and those built by factories in Germany.

The domestic water supply system (Fig. 5.13) with a total capacity of 1000 liters provides hot and cold water to all consumers of the carriage. The cold water supply system consists of a large 77 and small 4 tanks with 5 pallets, united by a two-inch pipe, filling pipes with connecting heads located under the car on both sides, and a network of pipelines (shown in solid lines in the diagram) with various fittings.

A large tank 17 with a volume of 850 liters is located above the ceiling of the toilet and the corridor of the non-brake end of the car. It consists of a steel body, breakwaters and a cover. Two filling pipes and a vestibule pipe that limits the water level in the tank are welded into the body. At the ends, the tank is equipped with hatches for cleaning it. Small tank 4 with a volume of 80 liters is located above the ceiling of the toilet and the corridor of the brake end of the car.It consists of a steel body, a cover and is equipped with an inspection hatch, air pipe and water gauge glass. The inner surface of the large and small tanks is galvanized, and the outer is painted with enamel. The pallets are made of galvanized sheet steel and have a drain under the wagon. The drain pipes are equipped with heaters located at their ends. On the filling pipes, valves are installed to prevent water from spilling out of the tank during the movement of the car. The heads of the filling pipes are covered with casings that protect them from contamination and are equipped with electric heaters. The water level in both tanks, connected by a surge pipe, is determined by the water gauge glass installed on the small tank 4. From the tanks, cold water flows to the boiler 10, the water box of the heating system, to the toilets to 13 washbasins and 12 toilets, as well as to the service compartment for sink 14.

The hot water supply system consists of a hot water stove 8, an expansion tank b, located in the boiler room, as well as a hot water tank 11 located above the ceiling of the boiler end corridor of the car, and a hot water pipeline system (shown in dotted lines in the diagram). Hot water tank 11 with a volume of 45 liters consists of a steel body covered with thermal insulation, a cover, a coil and a pipe. For periodic monitoring of the water temperature, a thermometer with a remote temperature indicator is mounted in the tank. The surface coating of the hot water tank body is made in the same way as for cold water tanks. Expansion tank b consists of a body, an overflow pipe that does not allow water to rise above the set level, a water pipe and nozzles for connecting various pipelines. Valves 2, 7 and taps 3 are used to control the water supply system of the car.

The system under consideration has two modes of operation: winter and summer. In winter mode, when the heating system boiler is operating, hot water directly from the boiler enters the tank coil 11. In summer mode, when the boiler is not working, hot water enters the coil from the hot water stove 8. Before heating the hot water stove, as well as when it is already heated, the water level in the expander is periodically checked by opening the water sample tap, and, if replenishment is required, it is pumped up by a hand pump 9. Drinking water is boiled before use and enters the tank 16, and it is cooled by a water cooler 15.

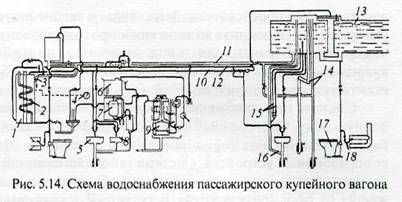

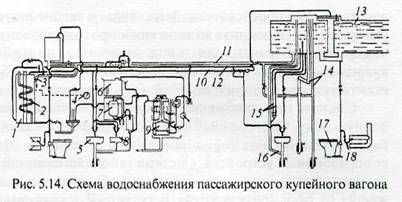

The water supply system in a passenger compartment car (Fig. 5.14) includes two interconnected tanks 13 located at the end of the car body. The total volume of the water supply system under consideration is 1050 liters. At the boiler end of the car there is a 50-liter flush tank, into which water is supplied from large tanks through pipe 11. In this system, water is heated in a special boiler 1 by coil 2 connected by a system of pipes and valves to the heating boiler. The water temperature in the boiler is controlled by a thermometer 4. The system is filled with water by means of filling pipes 14 located at the non-boiler end of the car: one from the compartment side, and the other from the corridor side. At the ends of these pipes there are connection heads for connecting inlet hoses, protected by covers. In winter, before filling the system, electric heaters are turned on in advance to defrost the heads of the filling pipes.

In the case of filling the system with one pipe 14, the other and pipe 16 are sentinels, not allowing the set level to be raised. When the filling of the system is complete, a white warning light comes on in the middle of the body on an electrical panel mounted on the side wall, after which filling stops and the signal switch on the service compartment switchboard is turned off.The main pipeline 11, which runs along the carriage, feeds the boiler 9 with cold water through a filter and a float chamber, and the heating system through a check valve. Boiled water from the boiler 9 is pumped by a hand pump into the tank 6, from where it enters the tank 7 of the refrigeration unit. The water cooled down to + (12-18) ° С is supplied through the pipeline to the drinking water tap installed in the niche of the wall of the boiler end corridor of the car. Wash bowls 5 located at both ends of the carriage, as well as sink 8, are supplied with cold and hot water. Cold water is supplied to the toilet bowls 17 from the cold water supply system, but hot water is supplied to them through the pipeline 18 from the heating system for thawing in winter. To connect the hose used when cleaning the toilet, a pipeline 3 with a valve is provided. Hot water enters the sinks 5 and sink 8 through pipeline 72, and returns to the boiler of unused hot water through pipeline 10. The water level in the tanks 13 is checked using control pipes 15 and taps installed in the toilet at the non-boiler end of the car.

Passenger cars of other types, such as restaurant cars, post cars, baggage cars, and others, are also equipped with a gravity water supply and heating system and differ from those discussed above by design solutions due to the purpose of the car. The dining car, for example, has two separate systems for supplying hot and cold water: the first for the kitchen with a dispensing compartment, the second for the boiler room with a toilet compartment. To supply the kitchen and cold water tap, there is an 800 liter tank located above the kitchen ceiling. From the tank, cold water is piped to the taps: the sink located in the dispenser, the sink and the sink located in the kitchen. From the same tank through a pipeline, a manual pump supplies water to a water heater and a hot water tank, the volume of which is 50 liters. From here, the water flows through the cleaning filter to the taps of the dishwashers and washbasin.

Both the kitchen and dispensing cold and hot water systems are filled through the connection heads located in the middle of the car on both sides of the body. The water filling system for the entire car is equipped with an electric tank filling alarm. When the filling of the system comes to an end, the lamp on the shield lights up, which goes out at the moment the filling stops. The filling pipes and the drain pipe of the wash basin are electrically heated. The water supply in the restaurant car for the boiler room and toilet is 130 liters. Cold water is piped to the heating boiler, wash basin and shower. Hot water from the water heater through the pipeline by natural circulation enters the hot water tank and returns back to the water heater. Hot water is consumed in the toilet, shower and washbasin.

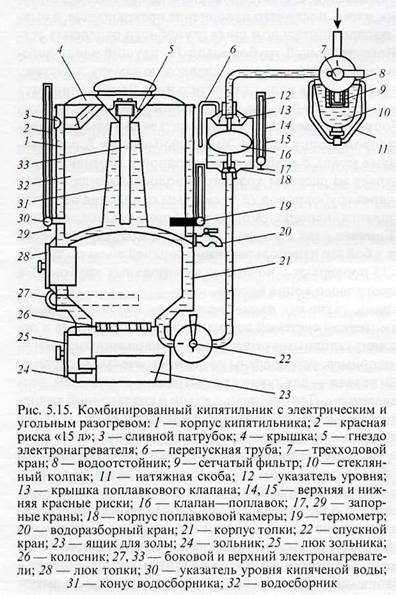

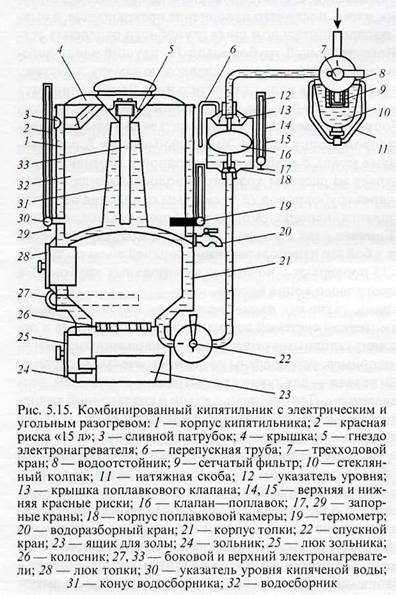

The water supply system for baggage and mail cars also has hot and cold water. The cold water supply system consists of a 300 liter tank located above the corridor in a niche in the service compartment, as well as pipelines and water taps. The system is filled with water from below from under the carriage through the filling pipes running in the corridor and compartment of the baggage distributors. The shower is supplied with hot water from the boiler expander, and the toilet is supplied from the heating system. On some models of mail cars, a 25 liter electric heater is installed to obtain hot water. Drinking water in passenger cars is prepared in continuous boilers (Fig. 5.15) with combined electric coal heating. It consists of a U body, a coal heating furnace 21, electrical elements: upper 33 and side 27, a water collector 32 of boiled water, a float chamber 18 with a valve 16, a filter 9, a boiled water level indicator 30, a thermometer 19 and fittings: three-way 7, water-folding 20 and 22 drain valves.

The space between the outer wall of the boiler body 1, the furnace body 21 and the conical pipe 31 of the water collector is filled with raw water. The inner wall of the boiler body and the conical pipe form a water collector 32 of boiled water, which is connected to the atmosphere by a drain pipe 3. Water from the water supply network enters the boiler through a three-way valve 7 and filter 9, a float chamber 18 and a valve 22.

When the water is heated to the boiling point, it overflows through the cone 31 into the collector 32, its level in the raw water chamber and the float chamber decreases, the float 16 drops and opens the water supply valve. Thus, the raw water replenishes the boiler, its level rises and the float with its upper shut-off needle shuts off the water supply. The float is adjusted so that the level of raw water cannot rise above a level that does not reach 40 mm to the upper edge of the cone 31, as a result of which it is excluded the possibility of it getting unboiled into the collector 32. The level of raw water is controlled by the indicator 12 of the level of the float chamber, on which there are two red marks 14 and 15. The upper risk indicates the maximum filling of the boiler with water, and the lower one indicates the maximum possible consumption of raw water and the minimum allowable level in the chamber. The filling of the reservoir with boiled water is controlled by the level indicator 2, on which there is also a red line, indicating the maximum filling of the reservoir. The performance of the boiler during normal operation is 1.1-1.4 liters of boiled water per minute.

The installation for cooling drinking water (Fig.5.16) consists of a compressor 18, a discharge valve 20, a condenser 16, a receiver 13, a shut-off valve 12, a filter 11, an automatic control valve 10 and an evaporator 8. Boiled water from tank 4 enters tank 6, is cooled in it, and then fed to the water tap 2.

The water is cooled due to the transfer of its heat to the refrigerant vapor in the evaporator 8. The operation of the refrigeration unit is as follows. From the compressor 18, the gaseous refrigerant through the discharge valve 20 enters the condenser 16 and becomes a liquid state. From the condenser, it is pumped into the evaporator through the receiver 13, the shut-off valve 12, the filter 11 and the automatic control valve 10 by the compressor 18. When it passes through the control valve 10, the liquid refrigerant expands, its pressure drops sharply and it goes into a gaseous state - it evaporates.

In the process of evaporation, the refrigerant removes heat from the water, and then its vapors are sucked in by the compressor 18 through the suction valve 19, and the cycle repeats. The level of water cooling temperature is set using thermostat 7 and can be regulated within + (12—20) ° С. The water cooler is located in a cabinet where there is a tank 4 for boiled water with a capacity of 40 liters, a tank for chilled water 6, a refrigeration unit 17, and in a niche there is 1 tap 2 for dispensing water.

How to pour water into an open heating system

In order to fill the open heating system of a private house with a coolant, a slightly different procedure is used. The main difference from closed networks lies in the internal pressure of the circuit: here it corresponds to atmospheric pressure, which makes it possible to use an expansion tank as the main control device. In open heating systems, it is mounted above all other elements.

- Draining the old fluid and cleaning the circuit. This is done in the same way as in the case of a closed system.

- To pour water into an open system, an expansion tank is used, which looks like an open tank. After removing the lid, they begin to pour water: filling a small circuit is usually carried out with a bucket. Filling large systems in this way is quite tedious, so it is best to use a domestic vibration pump.This will require a capacious tank with pre-prepared water. The pump is equipped with flexible hoses on clamps: one end is immersed in a container with water, and the other in an expansion tank.

Extended tank

- It is recommended to supply water slowly so that the air has enough time to escape. When using a vibration pump, it is necessary to ensure that the pressure in the circuit during filling is within 1.5-2 atm. When it is lowered, more water is added to the preparatory container so that it is possible to immerse the suction hose deeper. Shut off the water supply after it starts pouring out into the expansion tank.

- At the end of the procedure, it is necessary to free the circuit from air plugs. To do this, in turn, they open Mayevsky's taps on all available radiators, closing them only after the appearance of water. In order not to wet the floor, it is recommended to place a portable container under the taps. Having released the gas from all the batteries, they are topping up the water in the tank. As practice shows, the final release of the open system from air occurs through the expander after the first firebox.

During intensive use of open heating (most often in winter), the coolant will gradually evaporate through the expansion tank. This is explained by the high temperature of the coolant. To maintain the system's performance, it must be refilled periodically, making sure that its temperature does not rise above +80 degrees.

Feodosia reservoir began to fill with water

In order to fill the North Crimean canal at the beginning of May at a rate of five cubic meters per second, water from the Taigan and Belogorsk reservoirs was discharged into the bed of the mountain river Biyuk-Karasu, the total volume of which is now 21 million cubic meters of water.

“First, water flows for 55 kilometers along the Biyuk-Karasu River to the place where it flows into the North Crimean Canal,” explains Andrey Lisovskiy, head of the Crimean Basin Water Resources Administration, to explain the launched scheme. - In the Nizhnegorsk region, a hydraulic structure has been built, from where the water rises by 26 meters and is pumped into the North Crimean canal. Then the water flows for another 58 kilometers to pumping station No. 16, from where it is pumped to the Fedosiya reservoir.

Now at pumping station No. 16, three pumps have been launched, which supply water to the reservoir at a rate of four cubic meters per second. Moisture rises through pipes uphill and noisily pours into the Feodosiya reservoir, which has become seriously shallow in the last month.

“In a day and a half, we have already supplied 1.5 million cubic meters of water to the reservoir,” says Andrey Lisovsky.

According to the head of the Republican Committee for Water Management and Irrigated Agriculture Igor Vail, a unique project has been implemented in Crimea.

- All the tasks that the government gave to the Crimean water sector were completed a week earlier than it was prescribed by the schedules. A huge amount of work has been done by everyone - from excavators to engineering and technical personnel. It was difficult to adjust the rate of water supply, the operation of the canal, but now the entire system of water supply to the Feodosiya reservoir with a length of 113 kilometers is working reliably, - said Igor Weil. - We have achieved stable operation of the system, and no more intervention by the Vodkhoz is needed. And the quality of the water supplied from the Taiganskoye and Belogorskoye reservoirs is even higher than we received from the Kakhovskoye.

According to experts, by the end of June, the Feodosiya reservoir will be provided with the necessary water supply - about nine million cubic meters. Considering that the demand of Feodosia and Sudak is about 100 thousand cubic meters of water per day, the authorities are ready to pump over 250 thousand cubic meters of water daily.That is, 2.5 times more water is supplied to the southeast of Crimea than is required for the normal life of Crimeans and expected tourists.

“Today we can say with confidence that not a single region of Crimea has problems with drinking water,” said Rustam Temirgaliev, first deputy chairman of the Crimean Council of Ministers, who inspected the water facilities. - On May 20, the first water went to the Feodosiya reservoir. In addition, within a month, the reconstruction of the Feodosia-Sudak water pipeline begins, which will allow us to reduce water losses by 40 percent in a short period. Also, the design of a large 190-kilometer water pipeline has begun, which from the Novogrigoryevka and Novoalekseevka areas of the Nizhnegorsk region of the Crimea - this is Lake Sivash - next year will provide the region of Feodosia, Sudak and Kerch with clean drinking water.

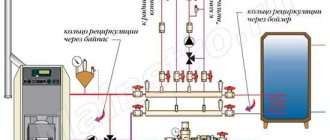

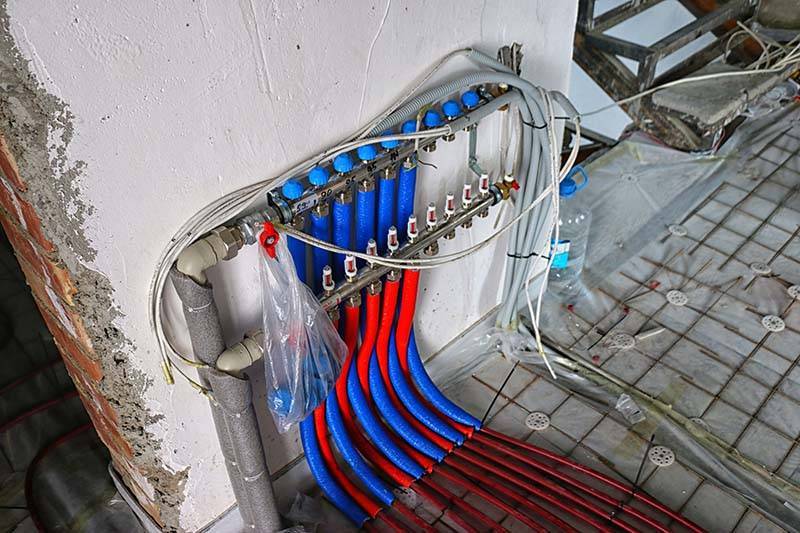

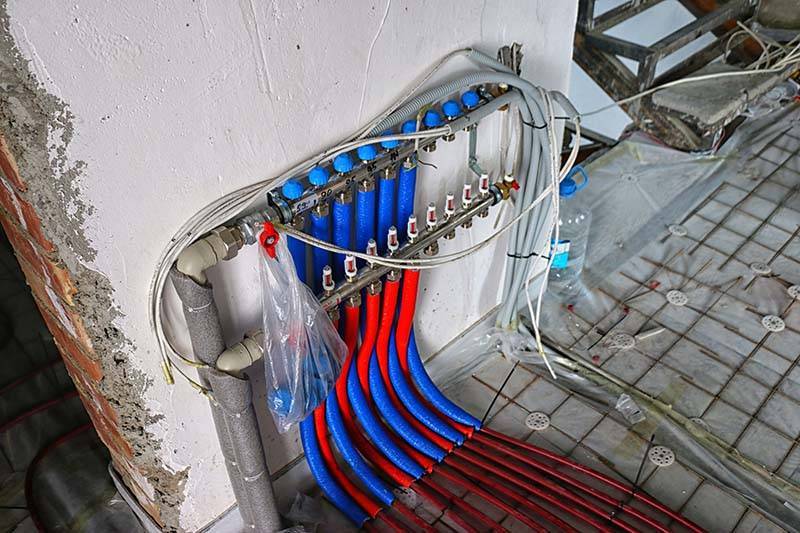

Filling underfloor heating

Warm floors have their own characteristics. They are not filled all at once, but one by one. If you fill everything at once (and they have different lengths), then there will definitely be air in the long circuits, which is almost impossible to remove from there. Therefore, we proceed as follows.

The collector is fully assembled. All circuits overlap on the return, except for one. The pump turns on, and through the supply of this circuit, the heating system is filled until a clean coolant without a sign of air flows from the drain hole. After this has happened, the circuit is closed. All others are filled in the same way.

Here, it is advisable to have another hose in order to direct it into a bucket with a coolant in order to avoid spills.

After that, the drainage hole is closed, all circuits are opened and the operation of the warm floor is checked.

It is important to pay attention to the fact that the radiator network system can be filled with coolant against its movement. You cannot do this with warm floors, you only need to fill it from the straight side, because otherwise the coolant will not move through the rotameters

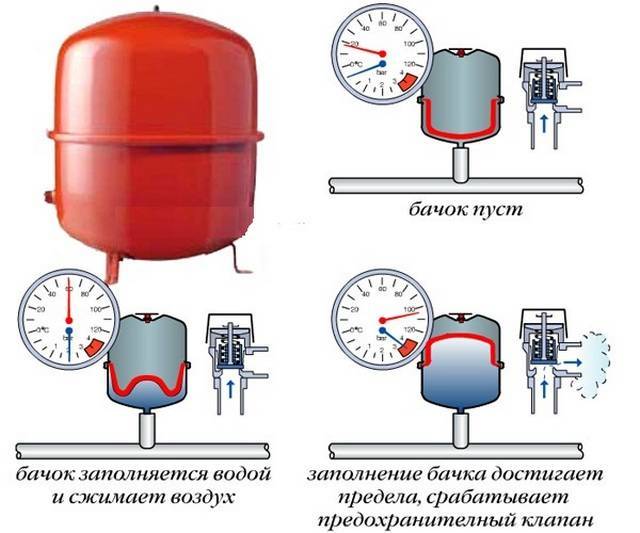

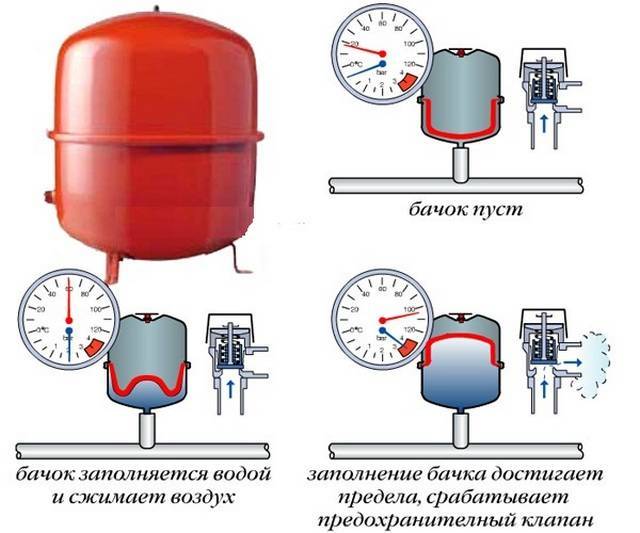

Selection of pressure values in the system and expansion tank

The higher the working pressure of the coolant, the less likely it is for air to enter the system. It must be remembered that the working pressure is limited to the maximum permissible for the heating boiler. If, when filling the system, a static pressure of 1.5 atm (15 m of water column) was reached, then a circulation pump with a pressure of 6 m of water. Art. will create a pressure of 15 + 6 = 21 m water column at the boiler inlet.

Some types of boilers have a working pressure of about 2 atm = 20 mWC. Be careful not to overload the boiler heat exchanger with an impermissibly high pressure of the heating medium!

The diaphragm expansion vessel is supplied with the factory set pressure of an inert gas (nitrogen) in the gas cavity. Its common value is 1.5 atm (or bar, which is almost the same). This level can be raised by pumping air into the gas cavity with a hand pump.

Initially, the internal volume of the tank is completely filled with nitrogen, the membrane is pressed against the body by the gas. That is why closed systems are usually filled up to a pressure level not exceeding 1.5 atm (maximum 1.6 atm). Then, having installed the expansion tank on the "return" in front of the circulation pump, we will not get a change in its internal volume - the membrane will remain motionless. Heating the coolant will lead to an increase in its pressure, the membrane will move away from the tank body and compress the nitrogen. The gas pressure will rise, balancing the coolant pressure at a new static level.

Expansion tank pressure levels.

Filling the system to a pressure of 2 atm will allow the cold coolant to immediately tighten the membrane, which will compress nitrogen also to a pressure of 2 atm. Heating water from 0 ° C to 100 ° C increases its volume by 4.33%. The additional volume of liquid must enter the expansion tank. A large volume of coolant in the system gives a large increase in it when heated.Too large initial pressure of the cold coolant will immediately use up the capacity of the expansion tank, it will not be enough to receive excess heated water (antifreeze)

Therefore, it is important to fill the system up to the correct defined pressure level of the heating medium. When filling the system with antifreeze, you need to remember that its coefficient of thermal expansion is greater than that of water, which requires the installation of an expansion tank of a larger capacity.

Conclusion

Filling closed heating systems is not just a standard final step before commissioning. Correctly or incorrectly performing this step can seriously affect the performance of the system, in the worst case even damage it. Compliance with filling technology is the key to obtaining a stable heating system.

How to implement alternative heating of a private house

Two-pipe heating system of a private house - classification, varieties and practical design skills

One-pipe and two-pipe heating distribution in a private house

Collector heating system of a private house - advantages and disadvantages

Heating system classification

To fill it out correctly, you need to know what type it belongs to. There is a classification of systems according to the method of pipe routing: from the top, from the bottom, horizontal, vertical or combined. According to the method of connecting devices using pipes, the systems are: one-pipe and two-pipe.

Also, in the system, water can circulate naturally or forcibly (if a pump is used). In terms of the scale of action, local and central heating systems are distinguished. In the course of the movement of water in the pipes - dead-end and associated. All these types are used in everyday life in a mixed manner.

When filling with heating medium

There are only two known situations that require the performance of this technological operation:

- commissioning of heating (at the beginning of the heating season);

- restarting after repair work.

Usually, the heating water is drained in late spring for two reasons:

- Water is inevitably contaminated with corrosion products (inside radiators, metal-plastic and polypropylene pipes are not subject to it). Leaving the old water for the new season, you risk breaking the circulation pump with solid impurities.

- Non-running flooded systems of country houses can "unfreeze" in the event of a sudden cold snap - such cases are not uncommon. In this sense, antifreeze coolant is preferable. The high-quality composition has high anti-corrosion properties, increasing the "inlet" interval up to 5-6 years. There are known cases of uninterrupted operation of heating on the same volume of antifreeze for 15-17 years. It is recommended to drain low-quality antifreeze after 2-3 years.

Antifreeze injection into the heating system.

Preparatory work

They are performed regardless of the state of the equipment.

Hydraulic test

Both old and new pipes must be flushed and tested:

- With the help of water, the strapping is cleaned of technological debris, scale. With the addition of chemicals it is possible to remove scale and rust. If the operating rules are followed (the coolant is not drained in the summer), this procedure is carried out with a break of two years.

- Testing is performed with air at high pressure. For crimping, the working indicator is multiplied by 1.25 (the value varies depending on the material and the volume of water). The pressure for the entire time of operation can drop by no more than 1%.

Overlapping reinforcement

After completing the inspection, it is necessary to tighten all the valves leading to the drain of liquid from the radiators, and also close the air valves.

Checking for problems

During hydraulic tests, the system is inspected for cracks and cracks, leaks. After that, you need to check the performance of the equipment: pump, expansion tank, boiler and others.

System pressure and make-up

Stable working pressure is the key to efficient operation of the heating system. Let's figure out why the pressure in the heating system drops. This is due to a decrease in the volume of the coolant, which is caused by inevitable leaks in the nodes and joints, the release of liquid from the air vents during the manual air release of radiators, etc.

An automatic make-up valve connected to the water supply will protect from a pressure drop below the required values. In small systems, a mechanical valve is installed, but in this case, the consumer needs to regularly check the pressure gauge readings and add the required volume of coolant manually.

Conclusion. The ability to properly fill a closed-type heating system will allow you to properly prepare it for the heating season and start it up after repair or maintenance work.

Related videos:

How to properly drain water from the water supply system.

From time to time, you may need to completely turn off all taps, fittings, sanitary equipment, even drain the water from the entire water supply network (if the house remains unheated for the whole winter). In these cases, the following operations must be performed: (given in the technological sequence). 1. Draining the water. Turn off the water supply to the house. Disconnect gas and electricity from water heating systems. In the presence of central heating, it is necessary to open the outlet valve located on the boiler or on the pipes (this is usually done using a hose). Then you need to open all the valves on the radiators. Starting from the topmost floor of the house (mansion), open all hot water taps in the shower, bathroom, etc. (don't forget to drain the toilet cistern). We emphasize once again: all water outlet taps on the heater and other equipment must be open. The last thing: it is necessary to open the taps of the outlet of the main water supply line so that all the remaining water is gone. If you leave the house (cottage) for the winter for a long time, do not be too lazy to go through again and make sure that all the water has left the system. Add salt or a glycerin tablet to the water remaining in the siphons as additional frost protection. This will protect the siphons from possible rupture and exclude the possibility of odors entering the room from the pipelines. 2. Filling the system with water. The first thing to do is close the drain valves on the main pipes. Then you need to close all the taps in the house (including the taps of the boiler and water heater. If there is a cold water heater, open the tap on the radiator and let air in. After that, slowly open the main valve of the system and gradually fill the system with water. Even before turning on the boiler, the batteries must be purged with air.At the final stage, turn on the gas and electricity to turn on the heater and boiler.

3. Measures against water freezing. There is a possibility of cold penetration from the street due to malfunctions in the heating system. In this case, it is very important to immediately take the necessary measures against freezing of pipes, because the water frozen in them will immediately burst the pipeline. In very cold weather, even those pipelines that have been laid without violating the requirements can freeze (this often happens with pipes for supplying heat to a garage or basement). What preventive measures can help here? If the country house is electrified, in the cold area where the pipe runs, turn on the electric heater or simply put a 100 watt lamp near the pipe. In emergencies, heat the pipe with a hair dryer. Autumn is good if you insulate the pipe before winter by wrapping it in newspapers and tying it with a rope. If the pipe is already frozen, wrap with rags (any cloth) the frozen section of the pipe and pour it with a thin stream of hot water so that the matter around the pipe remains hot at all times.

Closed heating system.How to fill with water correctly

Nowadays, many owners of apartments and private houses choose closed heating systems. A closed system is a scheme within which the movement of the coolant is carried out using the movement of the coolant - the pump, that is, forced. A special feature is a membrane-type expansion tank. Main elements. boiler, tank - membrane, radiators, pump, pipes, also fittings, fasteners and filtering equipment. But very often buyers of such a "closed heating" soon wonder how they can fill it and how to close the heating pipes. Below we will tell you how to properly fill a closed heating system with water.

The heating system is filled through the power supply to the boiler. This is done using an electric pump as well as a manual crimper. The system is filled with prepared network water or antifreeze made according to a special method - it is an anti-freeze coolant. At this time, air is deflated in the entire inner part of the system (taps, radiators, air vents, and so on). When the required pressure is reached, you can already start up the system. Sometimes it is difficult to create the ideal pressure. Closing the heating pipes will largely depend on individual wishes, the design solution of the room and the location of the pipes themselves in the apartment, their number and size.

Difficulties often arise when filling with water. If the system is closed, then the expansion membrane tank must also be closed (up to 6 bar pressure inside the tank), the safety valve up to 3 bar. Special valves should also be installed to release air in places of accumulation, as well as a valve for replenishing and filling pipes and heating equipment. The sequence of actions when filling a closed system is as follows:

Unscrew the screw on the pump. Unscrew the shaft of the pumping system with a screwdriver. Tighten the screw tightly. Open the charge screw. Fill the system so that the pressure is equal to approximately 0.5 bar. (you can start from 0.3 bar). It is imperative to check for leaks during this procedure! Raise the operating pressure in the system to 2 bar. Make sure that there is no leakage anywhere. Bleed the air in absolutely all internal places of the system. The next step is to make the pressure in the system about one and a half bar. This will be the most optimal pressure for a closed heating system. If the system is going to be cooled or heated, then the fluctuations should not be significant (from 0.1 bar to 0.5 bar). Watch out for the vibration range! Sudden changes threaten to break down all equipment, pipes and fittings!

There is no water level in such closed systems. The presence or absence of water is controlled by pressure. At a normal amount, it should be between one and two bar.

A closed heating system is easy to operate, less susceptible to corrosion and destruction, it is easy to replenish it and, if necessary, drain it. If you have any questions, or found faults in the heating system (freezing, leaking, etc.), then immediately contact the support service!

Heating boilers are one of the main types of heating equipment and are devices for heating up to a certain temperature of the heating medium entering the heating system. The heat carrier passes through a closed circle of the heating system.

Before you start looking for contractors to improve your own balcony, ask yourself one question: what do I want from glazing Perhaps you just want to use this room for drying.

Such cast-iron batteries, familiar to the majority of the population, installed many years ago, can no longer fully cope with the functions assigned to them for heating premises and have a rather unattractive appearance.

Solid fuel heating boilers are devices that heat a room using solid fuels (for example, wood, coke, briquettes or coal). Usually, such boilers are universal, as they can work on anyone.

Filling the water supply system with water.

PASSENGER CAR WATER SUPPLY SYSTEM.

SAFETY MEASURES DURING OPERATION.

COLD AND HOT WATER SUPPLY

All passenger cars are equipped with a gravity-fed cold and hot water supply system. The volume of the system is about 1200 liters at the rate of approximately 20 liters per person per day with an interval between refueling and replenishment of the system up to 12 hours.

Despite the different design, the basic structure of water supply systems of all types is practically the same.

The water supply system includes water storage tanks located on both sides in the upper part of the car, distribution pipelines, isolation and drain valves and taps.

Refueling with water (entering the tanks) is carried out from the bottom of the car through the refueling pipes, which are warmed up by hot water from the heating system in winter. The water supply system necessarily includes a vestibule pipe, which does not allow the tanks to overflow if the water filling is not stopped in time.

Principle of operation: From storage tanks, water flows by gravity to washbasins, toilets, a boiler and a hot water system; the heating system is filled with a pump.

The hot water supply system includes a hot water boiler in the boiler room, an expander, a tank above the ceiling of the boiler room and the corresponding pipelines. In winter, hot water enters the boiler from the heating system, in summer from a hot water boiler fired with solid fuel.

All tanks are equipped with water taps and gauge glasses.

Despite some structural differences between cold and hot water supply systems, the rules for their operation for all types of cars are the same. Control over the good condition of the water supply systems is entirely entrusted to the conductor. In winter, it is necessary to carefully monitor the serviceability of the heating filling pipes and the constant circulation of hot water in them. When filling the system with water from a stationary source, control the filling of the tanks. In the oblique corridor of each car, a diagram of the position of taps and valves is posted for each operation of the water supply system. In the books of the service timetables of each train, there is a list of stations at which water refueling is carried out.

Fig 1... Water supply scheme for a non-compartment carriage built by TVZ

(equipment numbering corresponds to that adopted in the manufacturer's documentation):

2 - valve of the combined drain; 3 - boiler filling valve; 6, 47 — valve and valve for shutting off the boiler heating coil; 61, 91 - valves for supplying cold water to toilets; 63, 85, 107 - pallets; 64, 65 - water gauge glass taps; 66 - a tank with a capacity of 80 liters; 67, 87, 100, 105, 136 - water drain taps; 68, 102, 138 - air outlet fittings; 69, 83 - valves for supplying cold water to washbasins; 70 - valve of the reserve filling head; 71 - valve for connecting a hand pump; 73, 92, 113 - hot water valves for mixers; 74, 93, 112 — cold water valves for mixers; 75 — mixer; 77 - boiler; 78, 79 - fittings for supplying cold water to the boiler; 80 - valve for shutting off the line; 81, 134 - hot boiled water tanks; 84 - boiled water supply tap to the water cooler; 86 - a tank with a capacity of 830 ... 850 liters; 89 - water taps; 95, 114 - toilets; 96, 99 - filling heads with water heaters; 97, 111 - wash taps; 98,110 — wash bowls; 103 - water cooler; 104, 106 - taps for analyzing drinking water; 108, 123 - weirs with a warming funnel; 109 - sink; 115, 116 - water heaters for drain pipes; 117 - reserve filling head; 118, 119 — toilet bowl flush valves; 120, 121 - water seals; 135 - compressor; 137 - tap for water supply from the boiler to the intermediate tank; 139 - locking device; 140, 141 - check valves on the filling pipes; 142 — tap for water sampling for domestic needs and fire extinguishing; 144 - boiler installation

WATER SUPPLY SYSTEM OF STANDBY CARS OF MODELS 61-425, 61-821 CONSTRUCTION OF TVZ.

The system diagram is shown in Fig. one.

The position of the taps and valves at different operating modes of the system should correspond to Table 1.

Filling the water supply system with water.

When the outside air temperature is below 0 ° C, the system should be filled after keeping the carriage in a heated room for at least a day or after filling the heating system and heating the air in the car to a temperature of at least 12 ° C

Water is poured into tanks 66 and 86 (see Fig. 1) from under the car, through filling heads 96 and 99. When filling the system with water, valves and taps 3, 61, 64, 65, 68, 69, 71, 78, 79, 80, 83, 91 should be open, the rest, as well as the mixer tap closed.

The filling of water into the system must be stopped when the warning lamp, located at the filling head on the wagons equipped with the water filling alarm, comes on, or when water appears from the front pipe and the opposite filling pipe. Taps 64 and 65 should be opened when determining the water level in the system. To prevent overflow of water onto the railroad track when filling the system, a locking device 139 is installed in the ceiling space in front of the end wall of the tank 86, and check valves 140 and 141 on the filling pipes in the toilet and the corridor of the non-boiler end.

Table 1

| Tap number, valve, node (fig. 1) | Appointment | Location | Position | ||

| during system operation | when filling the system | when draining water from the system | |||

| 2 | Joint drain valve | In the boiler room | — | — | + |

| 3 | Valve for filling the boiler with water from the water supply system | Also | — | + | + |

| 61 | Valve for supplying cold water to the toilet | In the boiler end toilet | + | + | + |

| 64, 65 | Gauge glass taps | Behind the ceiling of the boiler end toilet | + | + | + |

| 67 | Small tank drain cock | Also | — | — | + |

| 68 | Tank vent valve | In the boiler end toilet | — | + | — |

| 69 | Washbasin cold water valve | Behind the ceiling of the boiler end toilet | + | + | + |

| 70 | Reserve filling head valve | In the boiler room | — | — | + |

| 71 | Valve for connecting the hand pump to the water supply system | Also | + | + | + |

| 73 | Hot water valve for sink mixer | In the service department | + | — | + |

| 74 | Cold water valve for sink mixer | Also | + | — | + |

| 75 | Sink mixer | » | + | — | + |

| 78 | Valve for cold water supply to the boiler | In the boiler room | + | + | + |

Continuation of table. one

| Tap number, vent la, knot (fig. 1) | Appointment | Location | Position | ||

| during system operation | when filling the system | when draining water from the system | |||

| 79 | Boiler tap | In the niche of the boiler | + | + | + |

| 80 | Line shut-off valve | Behind the ceiling of the non-boiler end corridor | + | + | + |

| 83 | Washbasin cold water valve | Behind the ceiling of the non-boiler end toilet | + | + | + |

| 84 | Boiled water supply tap to the water cooler | In the service department | + | — | + |

| 87 | Tank drain valve | Behind the ceiling of the non-boiler end toilet | — | — | + |

| 89 | Water sample faucet | Also | + | — | — |

| 91 | Valve for supplying cold water to the toilet | » | + | + | + |

| 92 | Washbasin mixer hot water valve | In the toilet at the non-boiler end | + | — | + |

| 93 | Washbasin mixer cold water valve | Also | + | — | + |

| 97 | Washbasin faucet | » | + | — | + |

| 100 | Water drain valve from the water cooler | In the service department | — | — | + |

| 102 | Water cooler air outlet valve | Also | — | — | + |

| 104 | Chilled drinking water disassembly valve | In the boiler end corridor | + | — | + |

The end of the table. one

| Tap number, valve, node (fig. 1) | Appointment | Location | Position | ||

| during system operation | when filling the system | when draining water from the system | |||

| 105, 106 | Boiler taps | In the niche of the boiler | + | — | + |

| 111 | Washbasin faucet | In the boiler end toilet | + | — | + |

| 112 | Washbasin mixer cold water valve | Also | + | — | + |

| 113 | Washbasin mixer hot water valve | Also | + | — | + |

| 118 | Toilet flush valve | In the boiler end toilet | + | — | + |

| 119 | Toilet flush valve | In the toilet at the non-boiler end | — | — | + |

| 136 | Tap for draining water from the intermediate tank | In the boiler room | — | — | + |

| 137 | Water supply valve from the boiler to the intermediate tank | In the niche of the boiler | + | — | — |

| 138 | Air release valve from the intermediate tank | Also | + | — | + |

| 142 | Water drainage valve for domestic needs and fire extinguishing | In the toilet at the non-boiler end | — | — | + |

Note. "+" - open, "-" - closed.

At low outside temperatures, in the event of freezing of the filling heads 96, 99 or failure of the heaters, the system can be filled with water through the backup filling head 117, which is located in the boiler room above the spare water tank 66 and is not subject to freezing. In this case, the filling of the system is carried out using an inventory inlet hose with a length of about 4 m.

To prepare for filling the system, it is necessary to connect one of the heads of the inventory hose to the reserve filling head with the valve 70 closed. Before filling the system, the opposite end of the hose with the head must be brought out through the open door to connect to the inlet hose of the water column on the station tracks. After connecting the hoses, open valve 70. When filling the system, make sure that there is no leakage in the connection between the reserve head and the hose head. To observe the filling of the tank 66, the taps of the gauge glass 64, 65 should be opened. The moment of filling the tank 86 is determined by the appearance of a water leak under the carriage from the vestibule of the large tank.

After filling the large tank, it is necessary to close the valve 70, stop the water supply from the water column, then disconnect the inlet hose from the inventory hose and the last one from the reserve filling head. At the end of refueling, open valve 68.

The position of the rest of the system fittings when using the reserve head is the same as in the case of filling the system from under the car through the filling heads 96, 99.

Filling a closed heating system

A closed heating system is used most often. Its difference from the open one lies in the structure of the expansion tank. In a closed heating complex, the expander is hermetically sealed, and the filling of the system is done in a different way.

To begin with, prepare all the necessary materials and tools. Including: a volumetric tank, hoses for pumping water from the tank to the system, clamps for firmly fixing the hoses, pliers for installing clamps, a vibrating household pump to forcibly fill the system with water.

Diagram of air removal from the heating system.

Before pumping, it is necessary to tightly fasten the pump to the prepared hoses using clamps. Fill the prepared tank with water and place it near the system filling valve. The pump should also be located nearby. The hose that takes the water should be lowered into the tank, and the hose supplying the pumped-over water is fixed with a clamp on the filling valve. Taps and dampers for air release of the heating complex must be open. Turn on the pump and start supplying water to the pipes. The pressure on the pressure gauge should rise gradually. When the entire circuit is full, the pressure gauge should reach two atmospheres. Then the pump should be turned off. Disconnect hoses and turn off filler cock.

If it is not possible to use the pump to fill the heating complex, then you can use the water supply. The circuit is quite similar to the one described above.It is enough to attach one end of the water intake hose to the water tap, and the other end to the filling one into the system and gradually open the filling hose first and then the tap. In this case, the pressure will have to be monitored additionally with a separate pressure gauge.

The final operation of filling the system with water will be to remove excess air from its circuit. In modern installations, special devices are provided for this purpose. The system can be vented using this bypass device.

Filling the heating system will be most convenient when two people work, since it is necessary to simultaneously control the pressure level in the system and the operation of the pump, being near the injection valve, and monitor the tightness and the process of airing the heating radiators during the entire filling process.

How to fill the pool with water? How to pour water into the pool in the country?

A unique preparation PERKESENT is used for water disinfection (see description below).

You can also buy PERKESENT 0.7%, 3%, 27 and 37% from us. Check the cost with the dispatcher.

On hot days in the country you really want to plunge into cool water, but before that you need to fill the pool with water. This question worries many owners of summer cottages and household plots, who, with the arrival of summer, move from stuffy apartments to their suburban lands. It is very difficult for those whose summer cottages are located far from the river or other natural sources of water. An artificial reservoir (pool) must be filled with water before using it. It doesn't matter which pool you need to fill with water. There are many types of pools: inflatable, frame, reinforced concrete. The choice must be made based on the capabilities and size of the suburban area. But do not forget that the pool will need to be filled with water. Naturally, the larger the pool, the more water will be required to fill it. If there is a well or a well nearby, then there will be no problems in preparing the pool for the summer season. However, it must be borne in mind that it is necessary to drain unusable water and fill the pool with fresh water according to the rules. For example, if you quickly drain water from a concrete pool, then its bottom may deform. This is due to a change in pressure.

Use of the drug "Percesent" for water disinfection

When supplying water for the pool, our specialists, at your request, use a unique solution of the PERKESENT preparation, which provides a long-term effect of "pure water" even at high ambient temperatures. When ordering water, inform our dispatcher about your desire to add this preparation to the water. The cost of water containing Perkesent solution is about 25% more expensive than ordinary pure water, but this can guarantee that the pool will not bloom and that there is no need to use additional chemicals. The drug has no analogues.

Imanbaev Erken Madimarovich - Russian scientist, reference

The developer and creator of the PERKESENT drug is a Russian scientist, Doctor of Medical Sciences - Imanbaev Erken Madimarovich. Its formula allows the use of water containing Percesent solution for the treatment of long-lasting wounds, burns and even psoriasis. Just add the drug to your pool. In addition to relaxing and enjoying clean water, you will get rid of wounds, burns and dermatitis of various origins.

Of course, not everyone has the opportunity to maintain special staff for cleaning the pool, but if you have any questions or doubts about the operation of the pool, you can always call and consult with those who sold / installed / built it to you. For all types of artificial reservoirs in the country, it is important to properly fill the pool with water. For example, if you take water from a well, then it will take a week to fill a pool with a volume of 21m3.During this week of gradual filling and warming, the water in the pool will bloom. If you need to pour clean water into the pool, then you need to do it right away, at one time. In this case, no flowering or problems with deformation of the pool structure will arise. How to get out of the situation for those who do not have a water source in the immediate vicinity of the pool? We need to look for someone who will bring water by a water carrier. Some go to the fried parts and ask for a car to fill the pool with water. Usually, this is not so easy, because firefighters are not allowed to carry out such activities, so they agree to fill the pool with water in the country, as they say at their own peril and risk, and, of course, if they want to make money. But, judging by the reviews of those who ordered water in this way, this is not the best option. The water brought by firefighters blooms very quickly, has a strange smell and color. It is possible to fill the pool with water using a multi-meter hose, thus reaching the adjacent well. But this can be very labor intensive, especially if the hose needs to be extended up to 100 m. This requires time, patience and physical preparation, because it is quite difficult to stretch a hose of this length. How to fill the pool with water, without unnecessary stress? The easiest way to fill an inflatable or frame pool with water is to organize the delivery of water by special transport (water carrier or tank truck). Depending on the required volume, the price for the delivery of water and filling the pool will be calculated. Usually no one brings less than 1 ton of water. You can choose industrial or tap water, which will be brought by the car. What is the difference? Process water is water that can be used in various processes (in the heating system, in construction). Industrial water can be used quite safely in order to fill the pool with water, the price will be very affordable.

As mentioned above, industrial water, tap water, water from wells and wells, water from rivers and other natural reservoirs are suitable for the pool. But if children are swimming in the pool, then the water must be purified to the state of tap water. But you can do it easier and fill the pool with tap water right away. All you need to do is buy a water tanker. Our service will promptly deliver the required volume of water to your dacha. You don't have to worry about how to quickly fill your pool with water. The vehicles are equipped with special equipment. equipment, including hoses up to 50 m long, which allows you to quickly drain water into a tank or pool without even entering the territory of the summer cottage. To quickly fill your pool with water, you just need to call our service and leave a request for a tanker truck. All water meets sanitary and hygienic standards and GOST. Water can be used not only to fill swimming pools, but also for showers, toilets, at a construction site or a car wash, and so on. Indeed, quite often in the Moscow region, the owners of summer cottages, cottages, country houses experience problems with interruptions in water supply. If the water was turned off for a long time, and current needs require water, then the only way out is to call our rescue service. We accept applications and deliver water around the clock throughout Moscow and the Moscow region.

What water is better to pour into the heating system

There are several types of water poured into the heating circuit:

Plumbing. This can also include liquid taken from a well, well or the nearest body of water. The main advantage of this option is its cheapness. However, the quality of such a coolant is rather low: it rather aggressively affects the inner walls of the circuit due to salts and oxygen dissolved in it.

Boiled.Boiling allows you to remove from the water some of the oxygen and salts that precipitate. However, it is rather difficult to prepare water for the volumetric contour in this way.

Purified with reagents. To neutralize harmful impurities, instead of boiling, it is convenient to use special chemicals - reagents. Water prepared in this way needs to be thoroughly filtered before pouring into the system.

Distilled. It is sold in plumbing stores in containers of various sizes. Rainwater also has similar properties, which some owners of private houses specially collect for subsequent use in heating networks.

Antifreeze. They are used instead of water in cases where the heating system is prone to freezing (the crystallization temperature of antifreezes is much lower than that of water). Due to its high cost, this method of filling the heating circuit is rarely used.

Antifreeze for heating

Conclusion

Filling the heating circuit with water is a rather complicated and time-consuming procedure, which is recommended to be performed at least by two people.

During its implementation, it is important not to rush, carefully following all the recommendations

Particular attention should be paid to the preparation of water for pouring into the circuit: in cases where, for financial or other reasons, liquid from the water supply is used, it must at least be boiled. To remove sediment and rust particles that gradually accumulate in the coolant, it is recommended to equip the system with special mud filters

Why does the pressure drop in a closed heating system

There is only one reason why the pressure drops - the lack of tightness, that is, a leak. The question is to find her. A characteristic sign of a leak is a puddle in a certain place or a brown spot when the water has time to dry. During the search, you should inspect the following nodes and elements:

- pipe connections and fittings: it happens that cracks appear in the latter;

- automatic air vents: a faulty element with a stuck float will leak water;

- shut-off and control valves, safety valve;

- expansion tank: a crack in the membrane will cause a drop in pressure, air in the system and frequent shutdowns of the boiler.

To eliminate the leak, you cannot do without partial or complete emptying of the pipelines. At the end of the work, you will have to pour water into the system again, create the necessary pressure and monitor the pressure gauge for several days.

Operating rules

With the onset of cold weather, the conductors check the serviceability of the combined heating in the car and its preparation for the winter period, the following types of work are carried out:

boiler equipment is checked for malfunction; attention is drawn to the position of the taps and valves; the presence of grate bars and their serviceability are investigated in the firebox; the operation of pumps and measuring instruments is corrected; the water in the system is checked. Is it in sufficient quantity, the spare tank is also inspected for the presence of water; attention is drawn to solid fuels

In case of a shortage, it is necessary to inform the management about it; inventory for work with solid fuel is viewed; Also, the technical documentation on the rules for the use of mixed heating of cars is being put in order.

The lower part of the boiler of the second-class carriage

For the normal and uninterrupted functioning of the mixed heating, the equipment must be checked for each car, one hundred and ninety-eight heating heads that fit the water pipes.

Before starting the boiler equipment, it is necessary to check the serviceability of the ventilation system. To do this, you need to look at the position of the valve handle. It is located on the ceiling in the boiler room. When ventilation is running, the position of the handle will be turned to the word "Open"

Also an important requirement is to look at the fire damper. By the position of the drive handle, you can guess that it is open