Hydrogen is the most abundant chemical element in nature, as it makes up about 90% of the total mass of all elements in the universe. At the same time, it practically does not occur in its pure form. More often it can be found in the composition of various chemical compounds. Meanwhile, it can be an excellent environmentally friendly and harmless fuel for energy production. Thus, even your own home can be heated with hydrogen. Particularly encouraging is the fact that hydrogen fuel can be used if you convert a simple gas boiler to a hydrogen one. However, the main problem remains: where to get pure hydrogen? It is not freely available, you cannot buy it. The only way out is a home hydrogen generator. Fortunately, you can either assemble it yourself or purchase it ready-made. It remains only to decide on the type of generator, which differ depending on how hydrogen is obtained.

Obtaining pure hydrogen

Water electrolysis

Hydrogen can be obtained in a variety of ways. Here are just a few of them, which are the most accessible and common:

- Water electrolysis. The most effective way is high temperature.

- Chemical reaction of water and aluminum-gallium alloy.

- Hydrogen production during high-temperature processing of coal and wood.

- Garbage and household waste recycling.

- The release of hydrogen through the processing of biomass (manure, hay, algae and other agricultural waste).

Most of the methods are based on the use of high temperatures and, unfortunately, are not applicable in an ordinary household. However, there are several ways to get hydrogen at home.

Electrolytic hydrogen

The most affordable and most widespread way of producing hydrogen at home is through the water electrolysis reaction. A special piece of equipment called an electrolyser is fairly readily available in the market. At the same time, among the manufacturers there are both eminent giants (for example, Honda) and small manufacturers from China or the CIS countries. And if in the case of the former there is no doubt about the quality of the products provided to the attention, then the latter are often let down. At the same time, you should not pay much attention to their bright and promising advertising. An unscrupulous manufacturer does not need to declare that his product is of the highest quality, good and durable on the market. However, not everything he says will turn out to be true. The price should be especially alarming, since the generator cannot be too cheap. Cheapness may indicate poor quality materials used in the work, or savings in assembly. Installations are expensive for a reason, but also due to security. Since hydrogen is explosive, leaking it can cause a lot of trouble. Poor-quality hoses, a leaky storage tank - and that's it, an explosion is guaranteed. The quality of workmanship can sometimes "lame", so it is better one day do not stint and spend money on good equipment.

A good electrolyzer boasts quality, compactness and ease of use. It can be installed in any corner of the room and use ordinary tap water as fuel to obtain the coveted hydrogen. Typically, an electrolyser consists of a reformer, fuel cells, purification system, compressor and gas storage tank. Electricity comes from the power supply. The most modern models are equipped with solar panels at all.Such equipment will definitely quickly pay off due to the minimum cost of its use, even taking into account the not the smallest cost of the unit itself.

Hydrogen from agricultural waste

Often on the Internet you can find references to biogas plants. The point of their work is that manure is loaded into the generator, it is processed there and methane is obtained at the output. Of course, not only manure can be used, but any compostable material. However, clean manure is the most productive and affordable. The resulting biogas is then piped to the needs of the farm and is used as usual natural gas. However, this method of producing hydrogen has a couple of disadvantages:

- Hydrogen as such in this process is only a by-product. In order to separate it, additional processing of the obtained gas is required. As a rule, no one does this, and hydrogen safely dies in the arms of the flame along with methane.

- A continuous supply of raw materials is required. That is, manure must be supplied to the generator without stopping, and in large quantities. Obviously, an ordinary private economy will not be able to provide a constant flow of raw materials. And buying it on the side is not profitable. Conclusion: this method of producing hydrogen is only suitable for relatively large farms that are ready to provide such volumes. However, such an installation will not bring them benefits, unless it will allow them to get rid of waste with benefit for the economy.

In addition, the share of hydrogen at the outlet accounts for only 2-12% of hydrogen. That is, the bulk of the product is methane. To provide the economy with just hydrogen, an incredible amount of raw materials and huge production capacities will be required. So it is not profitable even for large farms to focus specifically on the release of hydrogen. They will either have to burn it together with methane, which is done in practice, or try to use it on the farm as well. However, additional equipment will again be required to separate and store hydrogen, which means additional costs. Thus, a biogas plant is by far the most disadvantageous method for producing pure hydrogen.

Differences between conventional electrolysis and modern polymer membranes

Modern SPE / PME polymer membranes are themselves an electrolyte, so they do not need water containing minerals to conduct current, and therefore have a huge technological advantage, long service life and are able to produce high concentrations of pure H2.

Due to the lower electrical resistance between the anode and the cathode in the polymer membrane, there is a lower voltage drop and a more efficient electrolytic H2 output. The increase in the service life of the membrane is due to the fact that the pH of drinking water practically does not change, therefore, there is no formation of mineral deposits on the electrodes.

Why is it important that the device has a proton exchange membrane / solid polymer electrolyte?

The water in the device is not an electrolyte, electrolysis takes place inside the membrane, water is only saturated with pure hydrogen. Distilled water or reverse osmosis water is recommended. This allows the membrane to work for a long time, without the need for flushing.

Are there devices that separate hydrogen and oxygen during electrolysis, but without a proton exchange membrane?

Yes, even the earliest U-tube electrolysis devices produced hydrogen and oxygen separately. But the electrolyte in them is a solution of salts in water, and in addition to hydrogen and oxygen, other compounds will be released. There are also devices with a membrane that separates hydrogen, but the membrane is not a solid polymer electrolyte.These devices require the use of water with salts, therefore the membrane becomes clogged and requires frequent flushing. Check if the instrument can handle distilled water to see if it uses an SPE / PEM membrane.

Making an electrolyser with your own hands

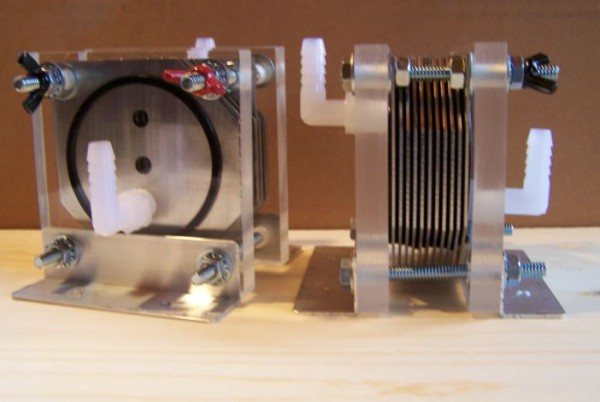

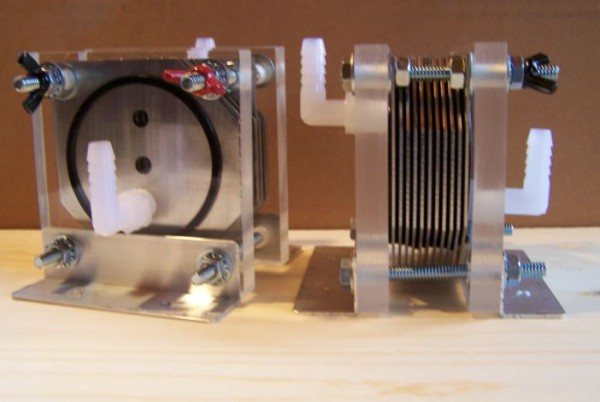

DIY electrolyzer

Prices for expensive foreign equipment often scare away ordinary owners of small farms. Once burned in an inexpensive electrolyzer of not very high quality, or even deciding not to risk it at all, the craftsmen think about making a home hydrogen generator on their own. In general, the task is feasible, subject to possession of certain knowledge and skills.

In order to make your own electrolyzer, you will need to purchase all the components of the installation, which were listed above. Moreover, the process does not end at the stage of fuel extraction. After all, it is still necessary to separate hydrogen from oxygen and water vapor, to ensure its constant current, accumulation in the required volume and supply. As a result, the final calculation will show that self-assembly will not cost much less than a purchased generator, but an incredible amount of effort and time will be spent. And it is not known whether the result obtained will meet expectations and cope with the task at hand.

Hydrogen cost

Hydrogen cost

Hydrogen production technologies affect its cost. So, the cost of hydrogen per 1 kg as it increases is:

- 130 rubles - by the method of high-temperature electrolysis at nuclear power plants;

- 200 rubles - by the hydrocarbon conversion method;

- 320 rubles - by the method of chemical reaction (from a nuclear power plant);

- 350 rubles - by extraction from biomass;

- 420 rubles - by electrolysis;

- 700 rubles - by the method of reagent recovery.

Thus, it is obvious that the cheapest method of producing hydrogen is the first, by electrolysis at nuclear power plants with the participation of high temperatures. The fact is that high temperatures at NPPs are a side effect of production, there are no additional costs for their receipt. However, so far none of the methods for producing hydrogen as fuel energy is fully recoupable. After all, even if you buy the most inexpensive and at the same time efficient installation, even if you do not take into account its high cost, electricity is still required to generate hydrogen. The electricity used is generated in local stations and transmitted by wires. In this case, inevitable energy losses occur.

Negative sides of hydrogen-type building heating

[sticky-ad id = 13532]

In discussions on the feasibility of using hydrogen fuel for heating systems, skeptics give weighty arguments:

- High cost: even in the most efficient electrolysis plants created to date, producing hydrogen requires 2 times more energy than its subsequent combustion.

- Explosion hazard: people were convinced of the ability of hydrogen to explode easily during the crash of the Hindenburg airship, the cylinder of which was filled with just this gas.

- The complexity of the preparatory process: getting hydrogen from water is half the battle. For efficient use in heat generators, it must be supplied at a stable pressure, which will require a compressor and an additional reservoir with a reducer. In addition, water vapor will need to be disposed of, requiring the use of a dehumidifier.

It is quite easy to make a plant for the extraction of hydrogen from water on your own. According to its characteristics, it will not be much inferior to the purchased one, but it will cost much less. Let's consider sequentially the stages of creation.

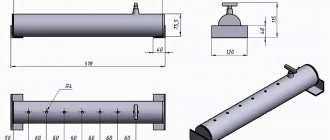

Project (drawing)

To manufacture a generator, you will need a hermetically sealed container, which will be filled with water before hydrogen production begins.

The electrodes located inside will look like a set of plates (16 pieces are needed) installed with a gap of 1 mm.

To ensure this, nylon spacers must be placed between the plates (any other dielectric is allowed).

A distance of 1 mm is optimal: if you increase it, you will have to increase the current strength; as the gap decreases, it will be difficult for gas bubbles to escape. The plates will alternately connect to the anode and cathode of the 12 volt power supply. In this case, they must be put on an axle, also made of dielectric material.

When the electrodes are attached to the holder, it will need to be attached to the bottom of the housing cover.

To select the gas mixture, a tube from a conventional dropper is cut into the housing cover. In addition, two more holes must be drilled in it through which the wires will be passed. After assembling the unit, all holes in the cover will need to be sealed with silicone or glue.

An important component of the generator is a water seal. To make it, you will need a small container (a regular bottle will do), where you will need to pour water before using the device. In the hermetically sealed cover, you need to drill two holes: in one we pass the tube from the generator (it must be lowered to the very bottom), and in the second - another tube through which the gas mixture will flow to the burner. The openings in the water seal cover must also be sealed. Water should be poured into the bottle by ¾ of its volume.

Selection of electrodes

The material from which the electrodes will be made must have a low electrical resistance and be chemically inert with respect to oxygen and substances present in the solution.

If the second requirement is not met, a chemical reaction will take place with the participation of electrodes connected to the cathode pole, as a result of which the solution will become saturated with foreign substances.

That is why copper, one of the best conductors, cannot be used in aqueous solution. It is recommended to use stainless steel instead. The optimum thickness for electrode plates made of this material is 2 mm.

Read more: What filters to choose for water purification

Container

Considering the risk of explosion, the generator housing should be made of durable and plastic material that is resistant to high temperatures. Steel meets these requirements best of all. It is only necessary to completely exclude the contact of wires or electrodes with the case, which will result in a short circuit.

Enrichment of the fuel-air mixture with hydrogen helps to reduce fuel consumption. According to some motorists, fuel savings can be up to 30%.

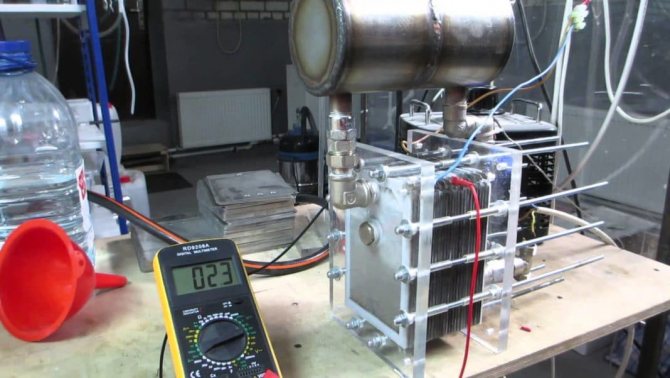

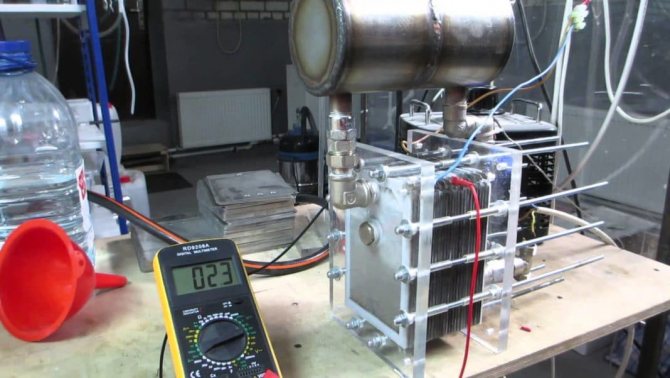

The device that was described in the previous section is taken as the basis for an automobile hydrogen generator. The difference lies in the absence of a hydraulic seal (the resulting hydrogen is immediately sent to the intake manifold) and the presence of a control unit. The latter will regulate the current between the electrodes depending on the engine speed.

Self-production of such a unit is only possible for those who are fluent in radio electronics, so we recommend using the purchased option. Moreover, prefabricated units take over all the work on regulating the hydrogen generator's performance without requiring the user's participation.

System elements for a car generator

All that will be needed is for the very first time to manually select the value of the current strength (optimal) for the "idle" and "maximum load" modes, and then the control unit will itself vary the performance of the installation within the specified limits.

All connections must be sealed very carefully: leakage of hydrogen can lead to fire.

It is best to check the tightness of the structure with soapy foam: leaks, if any, will manifest themselves as constantly appearing and growing bubbles.

The body of an automobile hydrogen generator can be made from a tap filter, which is quite durable. Its volume is small and so that the installation does not have to be refilled too often, it can be additionally equipped with a tank for storing a stock of solution. It is connected to the working container by two pipes.

The self-made device schematically represents a container with water, where electrodes are placed to convert water into hydrogen and oxygen.

In order to make such a device with your own hands, you will need:

- Stainless steel sheet 0.5-0.7mm thick. Stainless steel brand 12X18H10T is suitable.

- Plexiglas plates.

- Rubber pipes for water supply and gas discharge.

- Gasoline-oil-resistant sheet rubber 3 mm thick.

- Voltage source - LATR with a diode bridge to obtain direct current. It should provide 5-8 amps of current.

First, the stainless plates are cut into rectangles 200x200mm. The corners on the plates must be cut off in order to then tighten the entire structure with bolts. In each plate we drill a hole with a diameter of 5 mm, at a distance of 3 cm from the bottom of the plates, for water circulation. Also, a wire is soldered to each plate to connect to a power source.

Before assembly, rings with an outer diameter of 200mm and an inner diameter of 190mm are made of rubber. You also need to prepare two plexiglass plates with a thickness of 2 cm and dimensions of 200 × 200 mm, while you must first make holes in them on four sides for tightening bolts M8.

DIY hydrogen generator

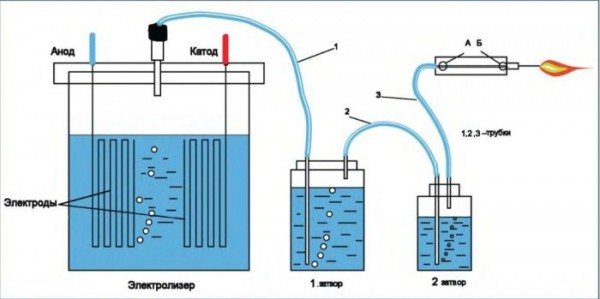

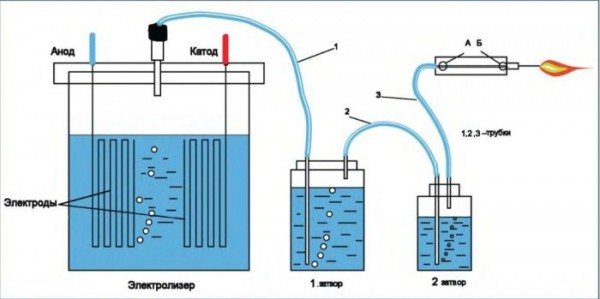

In order to prevent the gas from getting back into the gas generator, it is necessary to make a water seal on the way from the generator to the burner, or even better, two valves.

The design of the shutter is a container with water, into which the tube is lowered into the water from the side of the generator, and the tube that goes to the burner is above the water level. A schematic of a hydrogen generator with gates is shown in the figure below.

Hydrogen generator circuit with water gates

In an electrolyzer - a sealed container with water with lowered electrodes, when voltage is applied, gas begins to evolve. Through tube 1, it is fed to gate 1. The design of the water seal is arranged in such a way, as can be seen from the figure, that the gas can only move in the direction from the electrolyzer to the burner, and not vice versa.

This is hampered by the different density of water, which must be overcome on the way back. Further along the pipe 2, the gas moves to the gate 2, which is intended for greater reliability of the system: if suddenly, for some reason, the first gate does not work. The gas is then fed to the burner via tube 3. Water seals are a very important part of the device, as they prevent the gas from flowing in the opposite direction.

If gas gets back into the electrolyser, the device may explode. Therefore, under no circumstances should the device be operated without water seals!

The welding generator is currently the only practical application for electrolytic water splitting. It is impractical to use it for heating the house and here's why. Energy costs during gas-flame work are not so important, the main thing is that the welder does not need to carry heavy cylinders and fiddle with hoses. Heating the home is another matter, where every penny counts. And here hydrogen loses to all currently existing types of fuel.

Serial welding generators cost a lot of money because they use catalysts for the electrolysis process, which include platinum. You can make a hydrogen generator with your own hands, but its efficiency will be even lower than that of a factory one. You will definitely succeed in obtaining combustible gas, but it is unlikely that it will be enough to heat at least one large room, let alone the whole house.And if that's enough, you will have to pay fabulous electricity bills.

Is there a benefit

Is it profitable?

There is a misconception that heating a home with hydrogen fuel costs a penny. In fact, this idea is being spread by manufacturers of electrolysers and other hydrogen production facilities. In a word, those who benefit from such an opinion. They say that you only have to spend money on the purchase of this wonderful machine once, and live your life further happily and carefree. However, is it really so?

One has only to think for a minute to understand that in reality things are not so rosy. First, the installation itself is very expensive. Even if you assemble the unit yourself, the cost of components will not be so cheap. That is, the initial costs are very high, and the prospects for recoupment are vague. Secondly, for the operation of the electrolyzer, tap water is needed, which is also not free. And thirdly, it is necessary to consider the cost of electricity in the event that the generator is not running on solar panels.

Thus, there are practically no benefits in using hydrogen as a fuel for household needs. Perhaps, only after a decade or two, when the technologies become more advanced, the use of hydrogen fuel will be more profitable than the currently existing alternative sources. However, so far this method is almost 4 times more expensive. And this is taking into account not the highest tariffs for electricity and water. Even if we take the average and minimum values for Russia and the CIS countries, the cost of the resulting fuel is unreasonably high. Therefore, the use of this method of heating your home will only appeal to ardent defenders of nature, because hydrogen plants are absolutely environmentally friendly.

be careful

be careful

After installing the generator, as well as during, one should not forget about safety precautions. Hydrogen is an odorless, flammable, explosive gas, so its leakage is extremely dangerous. To avoid this, it is necessary to carefully check all components of the electrolyzer for leaks: tubes, pump, reservoir. This is especially true for self-assembly devices. They are the most dangerous. In addition, it is not known how high-quality fuel they will eventually supply. Of course, the likelihood of marriage can be high for purchased models, especially unknown or unverified manufacturers. Therefore, it is always better to give preference to a more expensive but also more reliable manufacturer of this equipment. It sounds like an advertisement, but the fact remains: you have to pay extra for quality. Although the rule does not always work that the more expensive the better. It is ideal if the buyer, making his choice, relies on knowledge in this area. And, most importantly, trust, but verify. After all, even the most famous brand can produce a marriage.

Exploitation

After assembly, you can start testing the device. To do this, a burner from a medical needle is installed at the end of the tube and water is poured into it. Add KOH or NaOH to the water. Water should be distilled or melted as a last resort. A 10% concentration of an alkaline solution is sufficient for the device to work.

Read more: Connecting ouzo and difavtomats: principle and diagrams

After that, a LATR with a diode bridge is connected to the electrodes according to the scheme. An ammeter and a voltmeter are installed in the circuit to monitor the operation. They start with the minimum voltage and then constantly increase, observing the gas evolution.

Pre-work is best done outdoors outside the house. Since the installation is explosive, all work should be carried out with extreme caution.

During the tests, observe the operation of the device.If there is a small burner flame, then there may be either a low gassing in the generator, or there is a gas leak somewhere. If the solution becomes cloudy, dirty, it must be replaced. It is also necessary to ensure that the device does not overheat and that the water does not boil.