In order for the selection of a pump for the water supply of a private house to be carried out correctly, it is necessary to approach this point "mathematically" - to choose according to a previously compiled algorithm. What is this algorithm and why the selection of a pump for the water supply of a private house should be carried out according to it - see this material.

Before starting the selection of a pump for the water supply of a private house, we sit down at the table, take a pen and paper and begin to fill in the tables and draw diagrams. Further, moving in steps, from the very initial to the final, we can use the selection algorithm to choose a pump for the house.

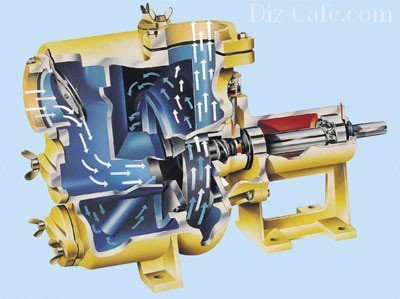

General principles of pump design

Each type of pump has its own design features, but the general principle of operation for all pumping devices is the same. When the electric motor is turned on, a vacuum is created inside the housing. Due to the low pressure, water is sucked into the vacuum chamber, moves to the outlet and is forcefully pushed through it into the hose or pipeline. The force of "squeezing out" the water determines the pressure in the system. It must be high enough to overcome the hydraulic resistance.

All pumps work on the principle of drawing in water through the inlet and ejection through the outlet, they differ only in the way of creating a vacuum

Pump designs can vary significantly depending on how a vacuum is created in the device, according to this feature, pumps are divided into:

- centrifugal;

- vortex;

- vibration (the second name is electromagnetic).

Depending on the location of the pump relative to the water tank, surface and submersible models are distinguished. By design and functionality, the devices are divided into well, borehole, drainage, motor pumps. A more detailed explanation is given in the video below:

What you need to know when choosing a pump

Daily water consumption

One of the main characteristics that influences the choice of a pump for a well is the number of devices in the house. It is important to determine how many units can be turned on at the same time and the duration of continuous operation. All these factors determine the required volume of water that needs to be supplied to the pump into the water supply system.

These data are found out from the passport attached to a particular device. To obtain the value of the maximum water intake, add the data for each of them and add the water demand for irrigation.

It should be understood that all existing consumers in the house will not work at the same time, but only for a certain period of time. Thus, it is necessary to determine the short-term water consumption per minute and the long-term one in a few hours (most often, no more than 6 hours).

Accurate source depth

Determine the depth of the well

The pump's passport data indicates, among other characteristics of the device, the maximum depth for which this model is designed. It is important to find out the correspondence of the technical capabilities of the equipment with the real depth of the well.

In the absence of accurate data, the well depth is measured independently. For this purpose, the load is secured on a rope or twine, followed by its immersion into the well cavity until the moment when this object reaches the bottom. Then the load is removed, and measurements of the wetted section of the rope and its dry section are carried out. The height of the water column will be equal to the length of the wetted section, and the distance from the water surface to the top of the shaft will correspond to the dry section. Their sum will give the depth of the well.

Well filling rate with water

Well productivity indirectly characterizes its type and static water level. More important is the well flow rate, which is the volume of water that can be withdrawn from it without lowering the level below the critical one. The unit of this parameter is the number of liters pumped out per hour.

The result of calculating the flow rate, obtained on the basis of only the depth of the well and the water level in it, will be erroneous. It is possible to obtain data close to the actual state of affairs only empirically. To obtain a reliable result, water is pumped out by a powerful pump for a sufficiently long time.

Casing diameter

Pipe diameter

The size of the well diameter largely determines the choice of pumping equipment capacity. If the drilling was carried out by a specialized organization, then the data is contained in the well certificate. If such information is absent, then they can be easily obtained independently, and the result obtained can be converted into inches.

Typically, the pump is sized for 4 ”wells. Much less often, the device is designed for operation in three-inch wells. This circumstance may require the selection of a pump from the catalog.

Pressure

The choice of a pump for a well will be incorrect if it is made without taking this parameter into account. It is determined by adding the number 30 to the borehole depth (in meters). The result is the height of the water column. It is recommended to increase the result obtained by 10%, and in accordance with the obtained figure, the equipment is selected.

Well drilled quality

When drilling a well with your own hands or in doubt about the quality of the drillers' work, a pump specially designed for wells may be required. The cost of universal pumping equipment is lower, and its efficiency is often insufficient.

Water sources that are built by non-professional drillers or wells that have been in operation for a long time run the risk of being washed out by sand. This circumstance adversely affects the operation of the equipment and leads to its clogging, as well as shortens the life of the pump. A unit designed specifically for wellbore conditions is less susceptible to the negative impact of well degradation.

The cost

It is important to consider the likelihood that water may run out at the horizon of the pump location. A device model that does not have protective systems will inevitably fail.

With comparable parameters of well flow rate and pump power, the latter must necessarily have the possibility of emergency shutdown in automatic mode. This is due to the fact that a newly drilled well has an abundance of water, but over time the flow rate decreases. Pumping equipment with a higher cost necessarily have protection; in cheaper models it may not be.

Well pump selection criteria

When selecting a borehole pump, you should be guided by two main criteria.

- the pump must provide the necessary water flow to meet the needs of the consumer, taking into account the depth of the well and the distance to the point of water intake (usually a membrane hydraulic accumulator);

- at the same time, its average flow rate should not be more than the productivity (flow rate) of the well.

The second condition is very important, since if the pump flow rate exceeds the well flow rate during its long-term operation, the water level will drop so much that the pump will partially come out of the water and will run dry. And this is a direct path to breakdown.

Therefore, it is impossible to thoughtlessly select a borehole pump according to the principle of the more powerful, the better. This is the case when you spoil the porridge with butter.

Application of surface and submersible pumps

All water-lifting equipment can be divided into surface and submersible.Pumps of the first type are installed near hydraulic structures or reservoirs from which water is taken. The latter are immersed in water. Designs differ in performance, type and location of inlet nozzles, acceptable installation conditions. Surface models are usually cheaper and are capable of working when the water layer is below 80 cm. Submersible pumps must operate at a depth of at least 1 m below the surface of the water.

Surface models are a good choice for watering

A surface water pump for a garden or vegetable garden is ideal if you need to organize watering from a natural reservoir or volumetric reservoir. If necessary, it is easy to dismantle and move it to another place, put it away for storage. It is well suited for summer cottages. Such a pump can be installed to take water from a well or a shallow well (up to 9 m), an Abyssinian well. In this case, the owner does not have to select the device by diameter, because only the hose is lowered into the well, and the pump itself is installed next to the production pipe.

Pumping stations belong to surface water-lifting equipment. They are multifunctional systems that combine a pump and a hydraulic accumulator

The only caveat is that for mounting a surface model, you need to prepare a room where the device will be protected from moisture, and the noise from its operation will not interfere with anyone. Install the device either on the ground or on a special floating platform if you need to take water from an open source. When installed in leaking pits, the bottom is not poured with concrete, but covered with gravel. Bulk materials absorb excess moisture that may appear when water seeps through the seams of concrete rings or masonry.

When calculating the required power, you need to remember that the ratio of the vertical and horizontal length is 1: 4, i.e. 1 m of vertical pipeline is considered as 4 m of horizontal. For the organization of water supply, it is better to use plastic pipes, rather than rubber hoses. When pumping fluid through flexible hoses, they can shrink and bend due to pressure changes. Water will not pass through the narrow opening normally, resulting in interruptions in the flow.

With the help of surface equipment, it is easy to organize watering of the plants from the pond. To do this, when choosing a model, it is necessary to take into account that the water will come with particles of dirt and sand.

Submersible equipment for water supply at home

The best pump for water for a house or a summer residence where they live for a long time is a submersible. It is well suited if you plan to install a water supply system from a deep well (over 9-10 m). A common household model raises water from a well up to 40 m deep, and for deeper structures, you can find a more powerful device. Problems rarely arise with the selection of pumps for wells up to 80 m. the assortment is extensive. All submersible models are equipped with automatic dry-running protection.

It is possible to install a submersible pump if it does not touch the bottom, and the height of the water layer above it is at least 1 m. This is necessary for several reasons. First, there must be enough water for the engine to cool properly. Secondly, the water level in the well or well is not stable. It may change depending on the season. It is important that the pump does not get too close to the water mirror in this case, otherwise difficulties with the water supply may arise. The pump should not reach the bottom by 2-6 m, so that dirt and grains of sand from the bottom do not fall into the inlet pipe.

A distinctive feature of drainage pumps is the ability to pump both clean water and dirty water with solids. A grid is provided on the inlet pipe of such a pump. Devices can be connected to water supply systems

Features of the work of vortex-type structures

The device works due to a vortex wheel, which is a metal disk with blades that create centrifugal force. Due to its structural features, water swirls in spirals that look like a vortex. The main advantage of vortex pumps is their powerful head. With the dimensions, weight, wheel dimensions and the number of revolutions equal to the centrifugal pump, the vortex provides a stronger head. Therefore, the dimensions of the vortex model body can be significantly smaller than that of the centrifugal one.

Due to the high pressure created by vortex pumps, they are successfully used for watering gardens and vegetable gardens. They are perfect for installation in water supply systems for summer cottages and private houses, if there is a need to increase the pressure in the network. Unlike centrifugal models, vortex models normally transfer large air bubbles entering the pipeline. The compact dimensions expand the scope of this pump type. Among the disadvantages is sensitivity to suspended particles in water. If there are a lot of them, the pump will work intermittently and quickly become unusable.

Due to their compact size and high power, vortex pumps are well suited for installation in deep wells with small diameters.