To create the required level of comfort in residential and industrial premises, it is necessary to supply hot water. There are several ways of forming, but in recent decades, systems that use heat exchangers for hot water supply and heating have gained popularity. They are reliable, economical and efficient units, characterized by compact dimensions.

These installations are made for the exchange of heat between carriers, one of which is heating. This solution is called a closed type of DHW. The device is the main element for preparing hot water in the system. The heat exchanger and burner are the main working elements of the boiler.

Device and principle of operation

Modern heat exchangers are units whose operation is based on different principles:

- irrigation;

- submersible;

- brazed;

- superficial;

- collapsible;

- ribbed lamellar;

- mixing;

- shell-and-tube and others.

But plate heat exchangers for hot water supply and heating differ favorably from a number of others. These are flow-through heaters. Installations are a series of plates, between which two channels are formed: hot and cold. They are separated by a steel and rubber gasket, so mixing of the media is eliminated. The plates are assembled into one block. This factor determines the functionality of the device. The plates are identical in size, but located at a turn of 180 degrees, which is the reason for the formation of cavities through which liquids are transported. This is how the alternation of cold and hot channels is formed and a heat exchange process is formed.

Recirculation in this type of equipment is intensive. The conditions in which the heat exchanger for hot water supply systems will be used depends on the material of the gaskets, the number of plates, their size and type. Installations that prepare hot water are equipped with two circuits: one for DHW, the other for space heating. Plate machines are safe, productive and used in the following areas:

- preparation of a heat carrier in hot water supply, ventilation and heating systems;

- cooling of food products and industrial oils;

- hot water supply for showers at enterprises;

- for the preparation of the heat carrier in underfloor heating systems;

- for the preparation of a heat carrier in food, chemical and pharmaceutical industries;

- pool water heating and other heat exchange processes.

Varieties of heat exchangers for hot water systems

Let's look at some examples of circuits. The gaskets can be either steel or rubber. Very easy to implement and relatively inexpensive.

A significant disadvantage: the high cost is twice as compared to a parallel circuit. Thanks to this, they are compact in size, which does not affect the usefulness and performance in any way.

As in the case of parallel, it requires the mandatory installation of a temperature controller, and is most often used when connecting public buildings. The connection of plate heat exchangers can be carried out in accordance with three main schemes: parallel, two-stage mixed, two-stage serial. The main advantage and plus of working with collapsible structures is that they can be modified, modernized and improved, from there to remove excess or add new plates.Conclusion As practice shows, the modern plate heat exchanger is still slightly inferior to the old shell-and-tube heat exchanger in one criterion.

In IHP Dependent heating connection with automatic heat consumption control.

It is also worth servicing the VET on time, carrying out systematic cleaning with your own hands. Such a scheme is the easiest to implement, but for sufficient heating it is necessary that the coolant moves actively.

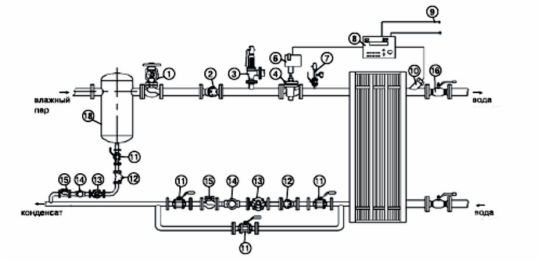

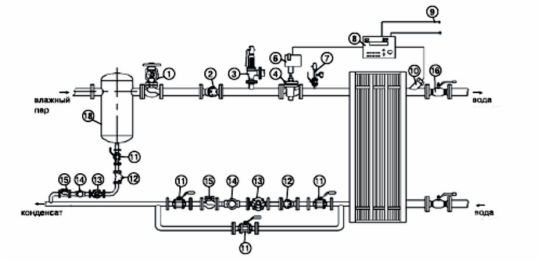

The principle of operation of a two-stage sequential scheme: the incoming stream is divided into two branches. Collapsible, that is, consisting of several separate tiles. DHW through a plate heat exchanger What did the cleaning lead to citric acid Best recipes

See also: Energy passport

Connection diagrams

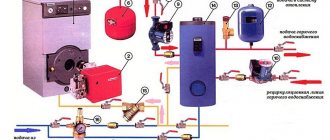

If you decide to use a plate heat exchanger for heating and hot water supply in the system, then before selecting a specific model, you need to consider the type of connection diagram. There are three options:

- Independent configuration of the connection from the heat supply (this is how the boiler is connected).

- Parallel or 1-stage configuration involves the installation of equipment in parallel with the heating communication. Regulation is carried out by one valve. The process is a constant fixation of the set temperature of the medium. This is a simple structure that provides sufficient heat exchange, but consumes large volumes of coolant and involves the connection of pumping stations. This circuit is economical to install.

- The two-stage configuration guarantees efficient use of backflow energy. Liquid preparation is carried out in 2 units. The first heats the water up to 40 degrees, the second continues the procedure and brings the indicators to the specified rate. This is +60 degrees. The second DHW plate heat exchanger can be connected in parallel or in series, depending on the chosen engineering scheme. This method is characterized by low heat carrier consumption - up to 40% and high efficiency. This arrangement will provide operational savings.

Operating costs and whether people will receive a sufficient amount of hot water depend on the competent choice of the connection scheme. But in order for the circuits to be efficient, it is necessary to correctly select a heat exchanger for heating. The parameters take into account the combination of the hydraulic regime of water supply and heating.

How to calculate a model for a specific building

In order for the heat exchanger to be effective in the heating and hot water supply system, the following parameters must be taken into account when choosing:

- number of consumers;

- the volume of water required by 1 consumer per day (for information, according to SNiP, the limit is set at 120 liters per person);

- heating of the coolant, in central networks its temperature averages 60 degrees;

- the device is constantly in use or will be turned off - operation mode;

- average temperature values of cold water in winter;

- permissible heat loss, standard value - 5%;

- the number of plumbing fixtures to which the DHW is connected.

For calculations, other data will also be required, depending on the situation and conditions. The result of this calculation will be a model that will be able to supply the required volumes of hot water for a specific dwelling.

Use of plate-type heat exchangers to provide DHW

Heating water through heating networks is economically useful, since heat exchangers, when compared with classical boilers on electric or gas energy, work only for the heating system, and for nothing else. As a result, the cost of hot water per liter will be much lower.

Plate-type heat exchangers use heat energy in heating systems in order to heat ordinary water from the mains.Heated by the heat exchange plates, hot water penetrates into all points for parsing water, including mixers, taps, showers.

It is also important to take into account the fact that heated water and water, which is a heat carrier, do not interact with each other in any way within the heat exchanger. The media for the flow of water are separated by plates placed in the heat exchanger, therefore, heat exchange passes through them.

It is impossible to use the water in heating systems to provide domestic needs, it is harmful and irrational. Explained by the following reasons:

- 1. Processes for preparing water for equipment and boilers are expensive and, most often, a complex procedure that requires special knowledge, experience and skills.

- 2. In order to soften the water and make it less hard for the heating system, reagents and chemicals are used that adversely affect human health.

- 3. For many years, a large amount of deposits accumulates in heating pipes, which are also harmful to humans and their health.

Nevertheless, no one prohibits the use of such water not for its intended purpose, but indirectly, because the heat exchanger for hot water is distinguished by high efficiency rates.

Selection of heat exchange equipment for hot water supply

If the engineering calculation of heat exchangers for heating and hot water supply was done correctly, and a correctly selected model of equipment is installed in the building, taking into account the operating conditions, you can count on the reliable operation of the equipment for 15 years. Do not neglect the services of professional craftsmen, this will form additional guarantees of system performance and security.

On the Russian market, there are installations from well-known brands and Russian-made plate heat exchangers, the latter are no less reliable, but affordable. So, the heat exchanger for the Ridan hot water supply system (Danfoss group of companies) is in demand, even wealthy consumers prefer to buy it. Therefore, it is better to choose a device not according to the brand name, but according to the parameters of a specific structure and technical characteristics of the device. Better if done by a professional.

Choosing a heat exchanger for receiving hot water from heating

Comfortable conditions at home and at work depend not least on the availability of hot water. On the heating equipment market today there is a wide selection of columns, boilers and other installations, but heat exchangers for hot water supply, which are selected taking into account the characteristics of the equipment and the customer's requirements, are considered the most efficient and at the same time economical.

Competent calculation of a heat exchanger for hot water supply and its installation is a guarantee of uninterrupted hot water supply and a long service life of the equipment. The devices differ in design and shape, but the principle of operation is the same - heat transfer. The coolant heated in the system is supplied to the elements of the heat exchanger and heats the tubes. Cold water is directed along parallel pipes, which heats up from contact with heat.

The choice in favor of the decision to buy a heat exchanger for water is dictated by economic benefits. Compared to standard water heaters using electricity and gas, no additional electricity consumption is required. The final price of hot water is significantly reduced. The heated water is transferred further to kitchen mixers, separate taps, to the shower room, etc. The resulting water does not come into contact with the coolant, since the media in the heat exchanger are separated hermetically.

Some consumers use hot water directly from the heating system in order to save money. This is impractical due to expensive water treatment, the presence of chemicals and harmful substances accumulated inside over the years of operation.What will be the price of a specific heat exchanger for hot water from heating depends on the brand and type of equipment. Regardless of the price, the benefits of using it are obvious.