Connecting the boiler (installation-piping-installation) is NOT the next stage after buying a solid fuel boiler, it is important to decide who will install it and how, determine in advance, and NOT buy a solid fuel boiler without installation, especially in Minsk. After buying, you can still crookedly establish, and then what is the meaning of a solid fuel boiler, you should approach it with all seriousness and responsibility. Tying a solid fuel boiler requires specific knowledge, skills and abilities. It is unlikely that it will be possible to tie a solid fuel boiler on its own. Yes, and this is a dangerous idea. So, if you nevertheless decide to entrust the connection of a solid fuel boiler to a specialist, then our advice: try to understand this process and at least try to figure out the nuances of installing the boiler yourself (you will use it for many years in the future and operate the heating system, by the way, the boiler is on wood is most often used and has more nuances for strapping).

- Training

- Security

- Schemes

- A photo

- Video

- Let's summarize

Piping - a set of works on connecting equipment to the engineering system (boiler piping). There are straps: safety sports and for industrial mountaineering, strapping the foundation with boards.

We will try to list some of the nuances when connecting a solid fuel boiler. The installation of heating boilers begins with the preparation of the floor and the extraction of smoke:

- preparation of the base for installing a solid fuel boiler - it must be strictly horizontal. Because a solid fuel boiler has not a small weight, then the floor screed, poured under it, should be 7-10 cm. The dimensions of the base should correspond to the dimensions of the boiler, increased by 10%.

- also, any heating boiler (except for an electric one) requires a chimney to be connected. It can be either indoors (not insulated) and go out vertically through the roof, or initially go out horizontally through the wall and rise along the wall of the house above the ridge (insulated). Any chimney must be cleaned annually and monitored.

How to properly tie a solid fuel boiler

The piping of a solid fuel boiler requires the provision of certain safety measures for the heating system:

- installation of an emergency valve (or boiler safety group). In the event of a rise in pressure in the heating system, an emergency discharge of the coolant into the sewer will occur. And this will prevent the boiler from exploding.

- installing a cooling circuit on a solid fuel boiler will save you from a boiler explosion, as well as from the need to recharge the heating system in the case described above.

- connecting an uninterruptible power supply UPS to the boiler and pumps will allow the heating system to work properly even in the event of a power outage, which we often hear about in the news in many settlements of Belarus.

- the connection of a solid fuel boiler according to fire regulations must be made only with a metal pipe (ferrous metal, galvanized, stainless or carbon steel), any option will do. As for the diameters, we most often connect boilers up to 30 kW with a 1 1/4 ″ pipe, boilers up to 50 kW - 1 1/2 ″, and boilers up to 100 kW - 2 ″ or 2 1/2 ″.

- in the connection diagram of a solid fuel boiler and, accordingly, when tying a solid fuel boiler, it is necessary to provide an open or closed expansion tank (depending on the heating system). The volume of the expansion tank is calculated using a simple formula:

V tank = V system: 10The solid fuel boiler connection diagram requires an expansion tank to be installed on the return line. This will extend the life of the tank membrane.

- connect a solid fuel boiler (up to 70-80 kW), preferably not using welding, but on threaded connections. In the future, this will simplify the maintenance of the entire system, and will also allow replacing any failed unit without any problems.

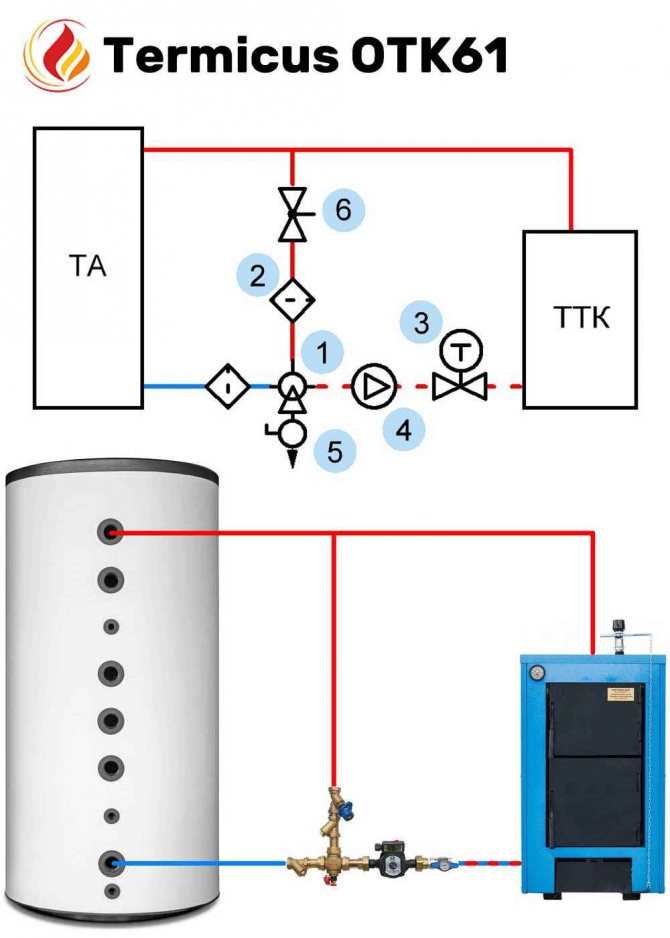

- the connection diagram for a solid fuel boiler implies the presence of a thermostatic mixing valve (for steel boilers it is protection against excessive condensate, and for cast iron - protection against cold return flow, under the influence of which the boiler section can burst).

These are just some of the nuances, the observance of which, when connecting a solid fuel boiler, you need to pay close attention to. The safety of a home heating system is the first thing that begins with heating design.

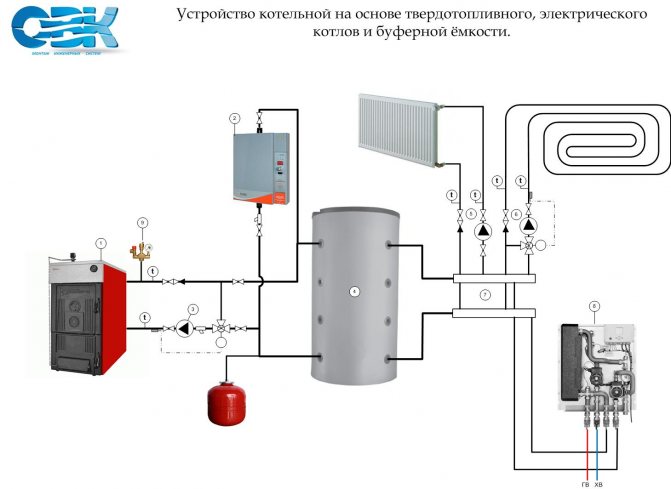

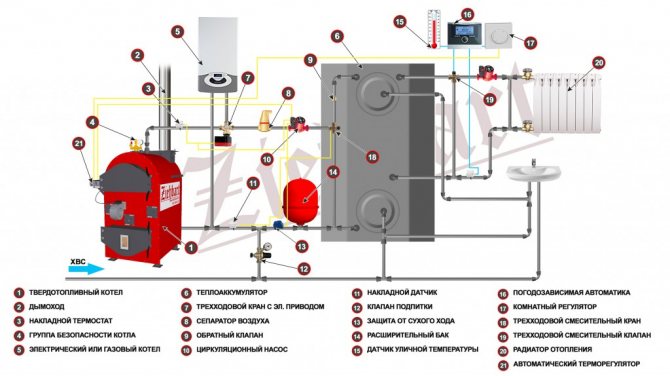

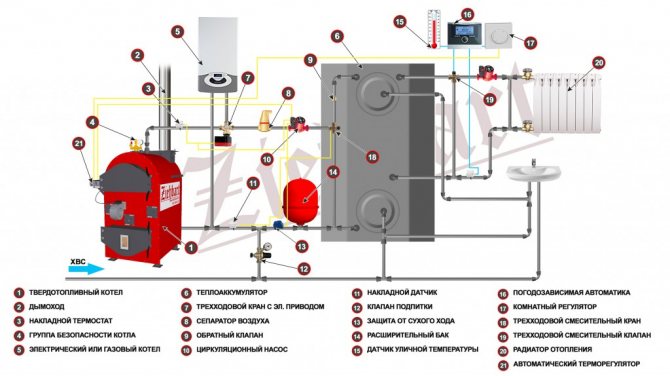

Heat storage circuit

All heating gradually warms up, and the valve completely closes the bypass - all the coolant circulates through the unit. Thus, the thermal circuit is protected from sudden changes, which allows maintaining a constant temperature regime in the house. Connecting pipes and safety elements Adhering to the connection diagram, insert a complete safety group for this type of boiler, which is installed before the shut-off valves. First, a primary closed ring is created, along which the coolant moves in a circle under the influence of a circulation pump.

Usually it looks like this: while the owner of the house is awake, he devotes time to a wood-burning heat generator, at night a different type of heater is turned on.

We use a primary and secondary ring system. But, so that the work of one of them does not affect the work of the other, check valves are installed at the outlet of each of them, after the taps.

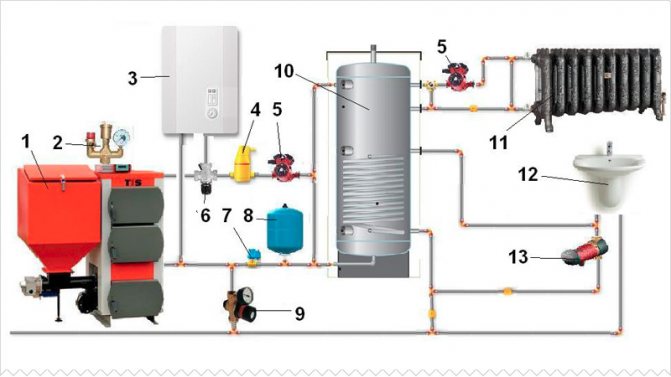

If necessary, programming devices can be included in the boiler diagrams, which make it possible to regulate the operation depending on the outside temperature. Of course, the scheme of parallel connection of a gas and solid fuel boiler through a buffer tank will work most efficiently.

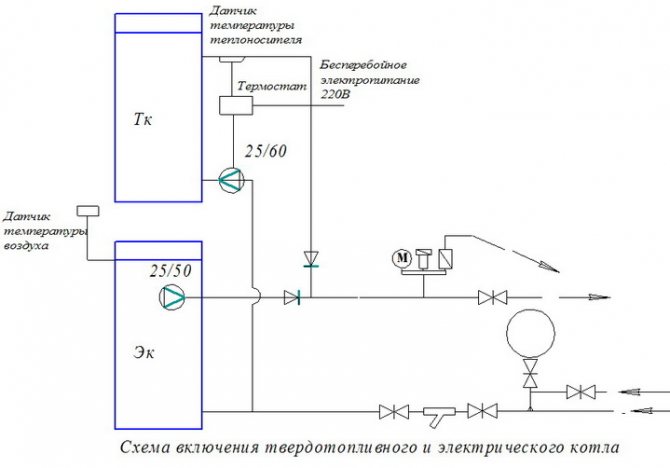

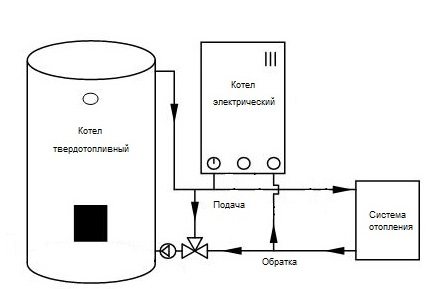

Application of the method of primary and secondary circulation rings allows for joint piping of the TT of the unit and the electric boiler.

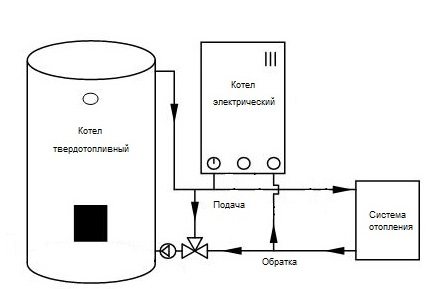

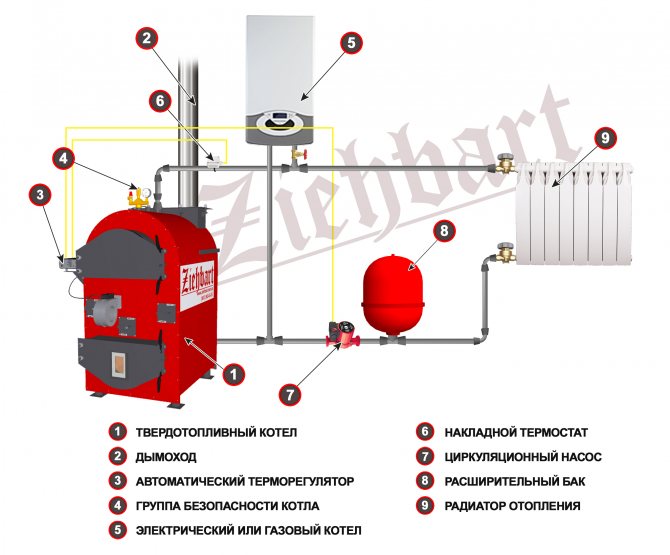

This is possible if the electric boiler runs all the time and maintains the temperature in the heating system. The basic scheme, where there is a small boiler circuit and a three-way valve, shown in the figure, is mandatory for use when working together with other types of heat generators. This is a common scheme for budgetary piping of a solid fuel boiler. An example of heating a private house, part 1

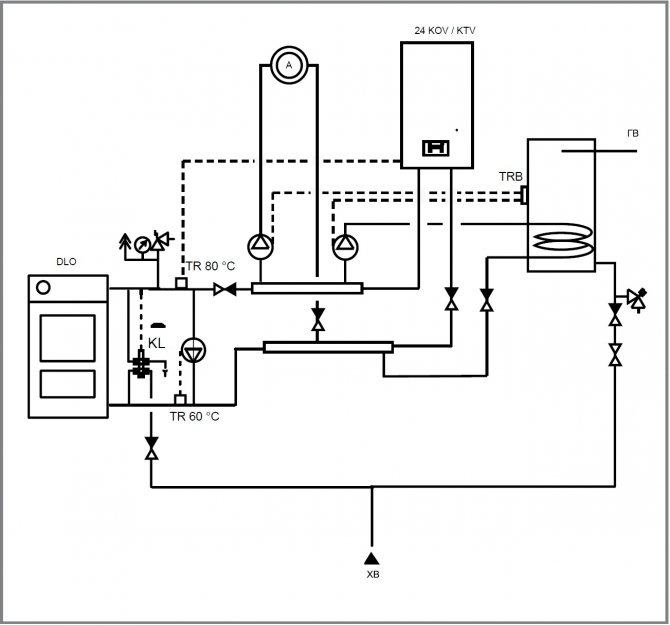

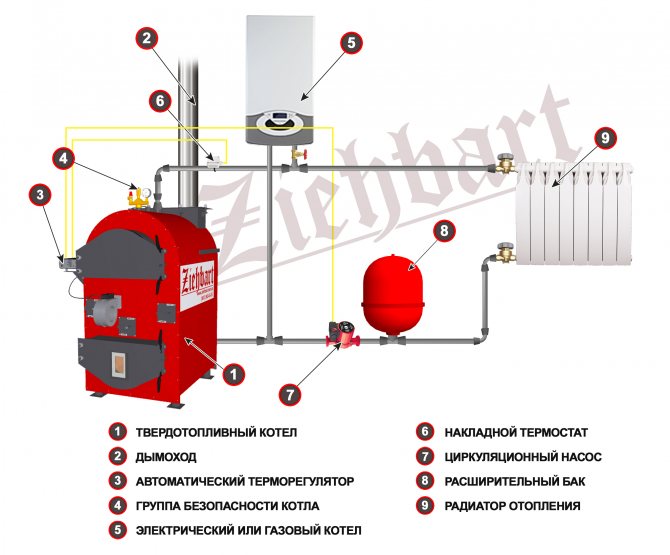

Boiler connection diagrams for general presentation

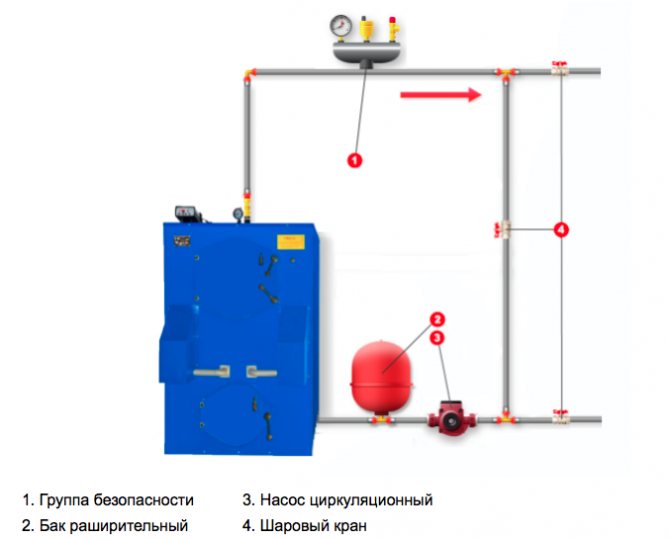

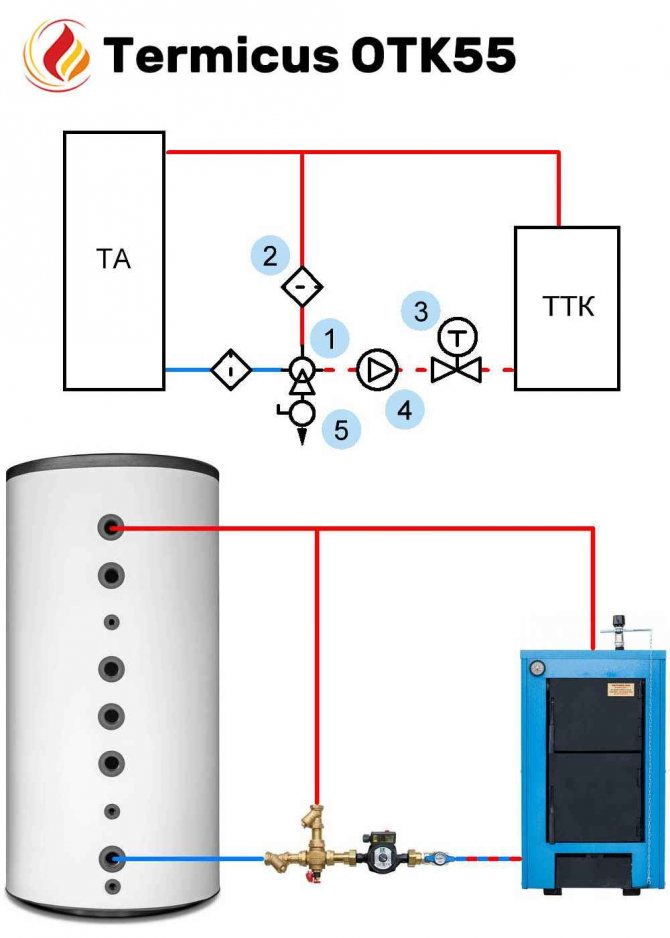

Let's analyze the harness in the diagrams. Simple boiler piping includes:

- circulation pump (1) to ensure the movement of the heat carrier (water) in the pipes and equipment of the heating system,

- the expansion tank (2) takes excess water (heat carrier) from the system when it is heated and gives it back to the system,

- the boiler safety group (3) with a safety valve, when the boiler boils, throws excess water into the sewer.

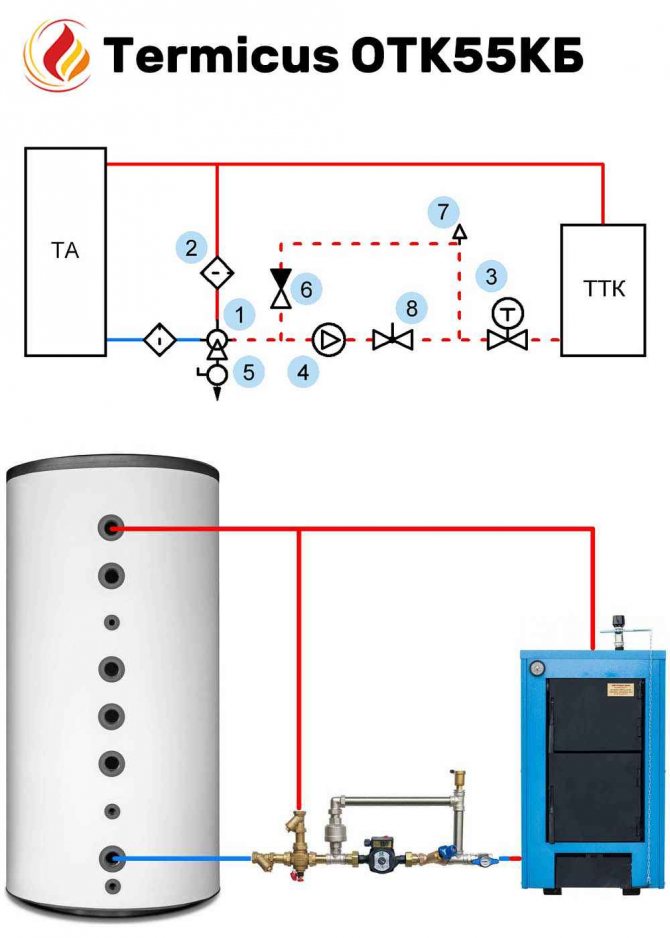

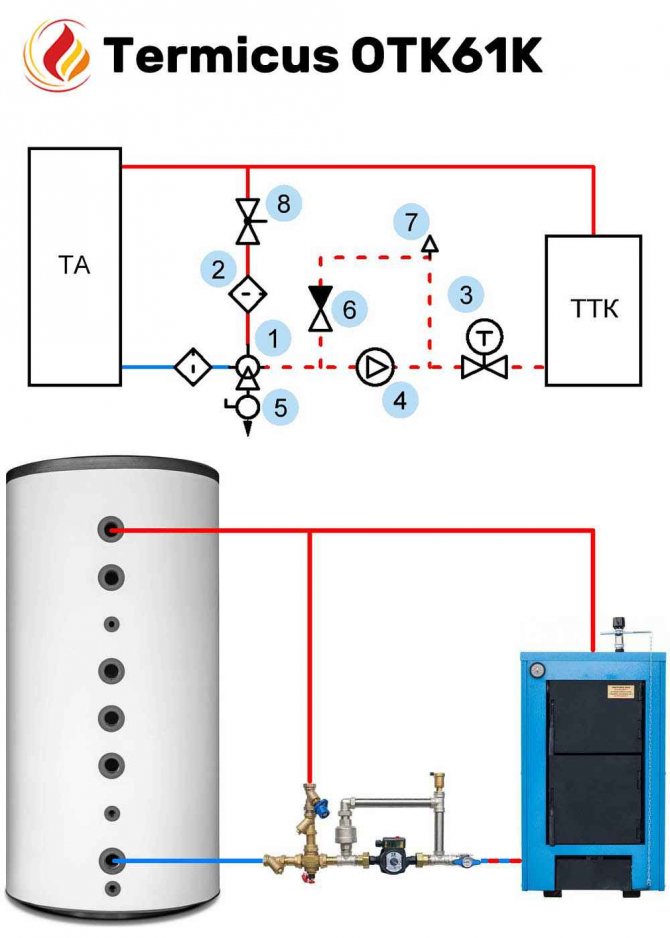

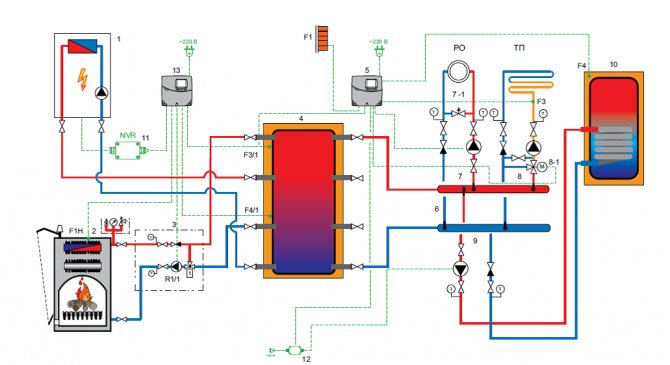

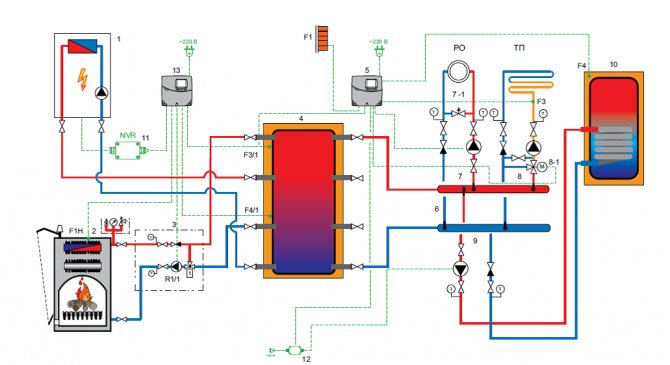

Next are the safety systems for people and the boiler itself. We protect the boiler heat exchanger from excessively cold water getting on it, which puts it out of action ahead of time. We put a 3-way thermostatic mixing valve (8) - if a cold one comes from the return flow from the heating radiators, it is more than useful for the boiler heat exchanger, the valve will turn on the hot water admixture.

Now we protect people from explosion and burns. A feature of the piping of a solid fuel boiler is: the combustion of solid fuel in the boiler is completely uncontrollable as in gas and electric boilers. Therefore, it is imperative for piping the heating system with a solid fuel boiler to prevent excessive overheating of the water up to 95 degrees. in pipes and radiators of heating to temperatures dangerous to human touch.And for this there are 3 separate ways of cooling water to heating radiators, which can be used at the same time.

Option 1: The mixing valve (7), as required, adds cooler water to the pipe to the heating radiators from the return water from the heating radiators. Looks simple enough.

Option 2: 4-way valve for emergency cooling of the heat exchanger (4) with a remote sensor when overheating up to 95 degrees. through the return flow, it will launch cold water from the water supply into the boiler, and throw overheated water from the boiler into the sewer. Since this is possible when there is a power outage in the house. The boiler pump stops, but also the pump in the well. Therefore, cold water for cooling the boiler is taken from the hydraulic accumulator of the water supply system and it may not be enough: we install an additional accumulator (5) with a check valve (6) to disconnect it from the water supply.

Option 3: Emergency gravity circuit with a check valve (9) - the diagram shows it as an option, however, the circuit requires specificity, a certain low pressure and temperature, it may contain a heating radiator for these purposes.

Option 4: Use multiple methods at the same time.

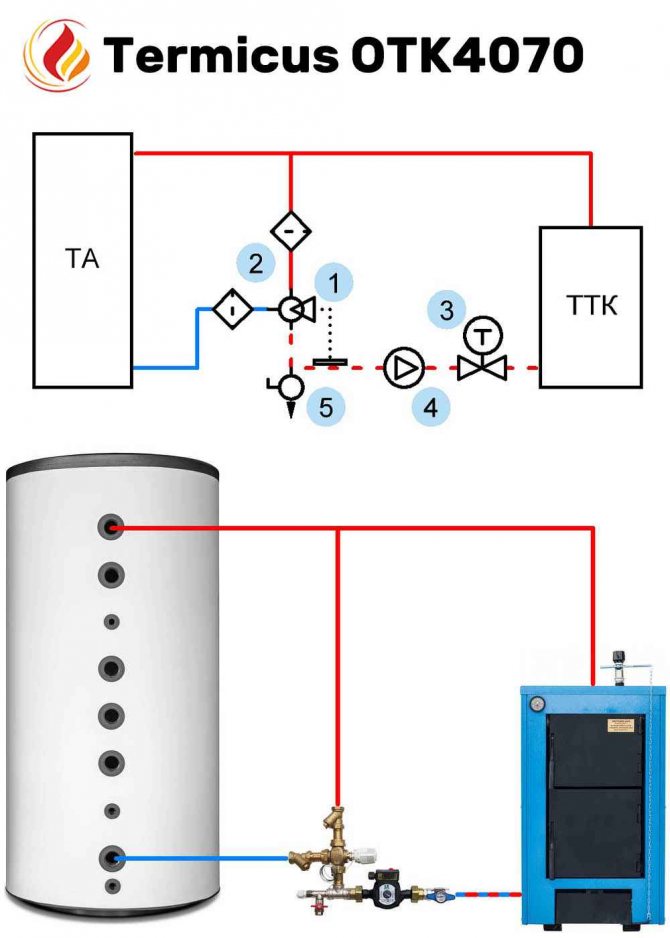

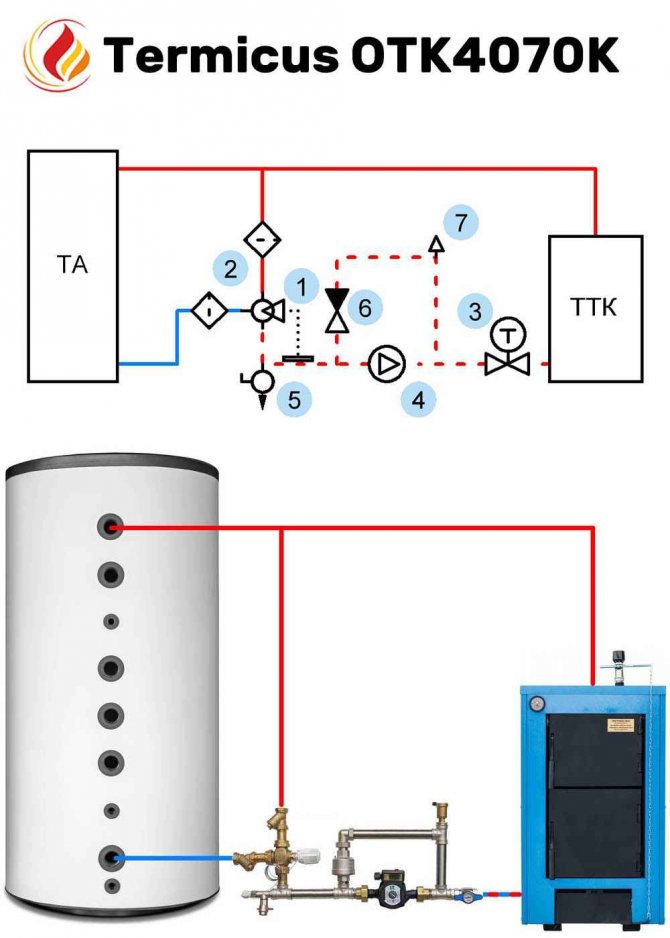

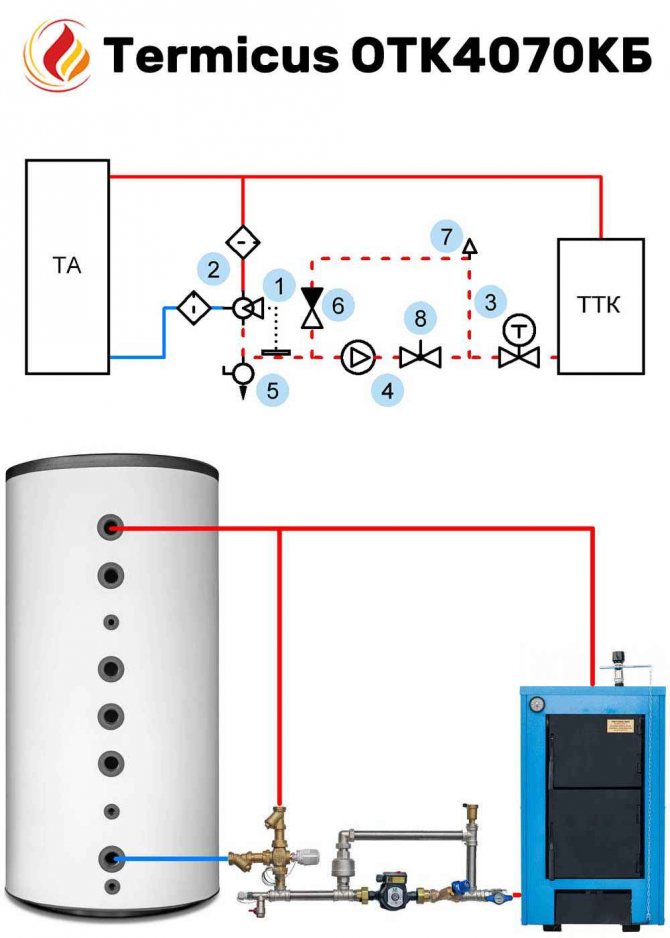

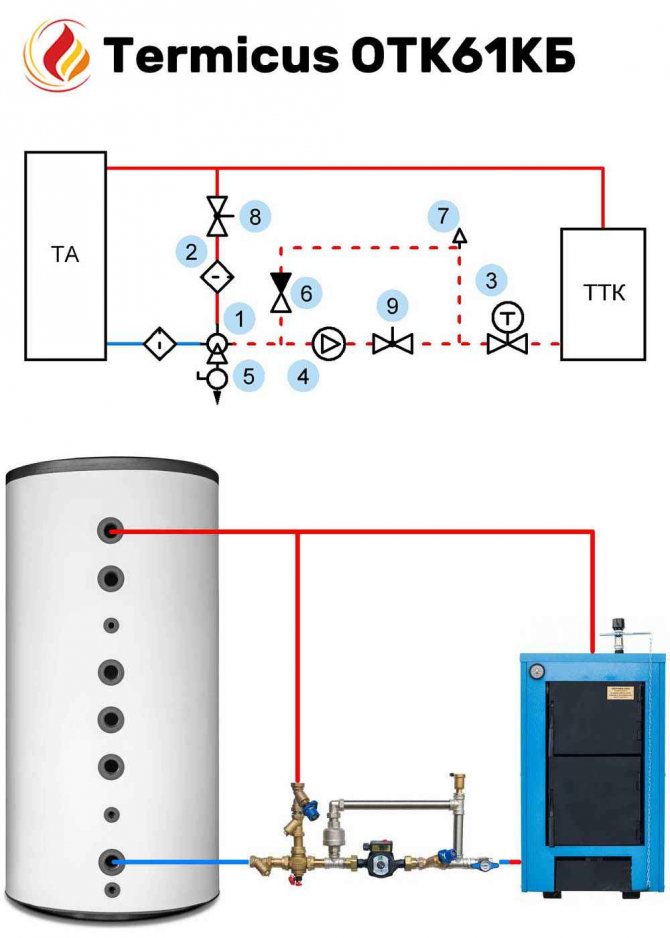

Application diagrams of ready-made strapping Termicus OTK

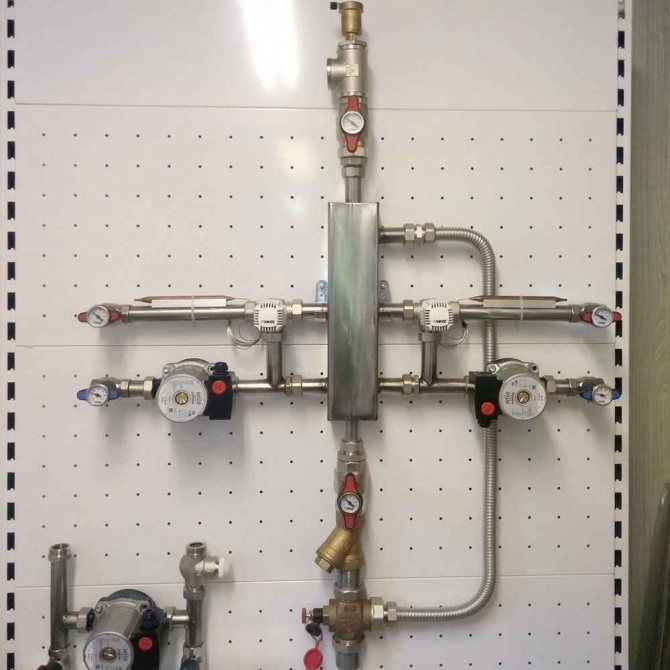

Also, there are strapping systems with hydraulic dividers and mixing assemblies made of stainless steel. In the photo there is a boiler piping with two independent circuits and boiler protection against condensation.

Pump module for switching on a backup electric boiler in the heating circuit with a solid fuel boiler. Provides timely connection of the electric boiler. A feature of this scheme is the absence of electricity consumption for heating the boiler circuit (or others), all the generated heat goes to the consumer.

Send us the boiler passport data, we will help you choose the required piping configuration.

Solid fuel boiler piping

Solid fuel boiler connection diagram

The piping of a solid fuel boiler connected to a closed circuit of the heating system necessarily contains a boiler safety group, an expansion tank and a circulation pump. Solid fuel boilers do not have a number of safety functions; therefore, the piping of a solid fuel boiler must include the specified safety systems in addition. Safe connection of the boiler is the safety of life and health of households and must ensure the minimum operating temperature of the coolant at the boiler inlet at a level of at least 60 ° C. The heat exchanger should not be exposed to large thermal fluctuations - this will prevent unwanted metal deformations and the formation of tar and soot in your boiler. This condition is ensured by the installation of the mixing unit. It will maintain the required temperature of the coolant at the entrance to the solid fuel boiler.

Installation of solid fuel boilers and piping of a solid fuel boiler should be carried out exclusively by specialists. Installing a solid fuel boiler on your own with your own hands is extremely dangerous, especially since such a boiler installation will most likely not be accepted by firefighters. This material on how to connect a solid fuel boiler is aimed at acquainting you with the topic so that your choice and control of the installation specialists is more competent.

Photo heating installation - Minsk region, Dzerzhinsk

Heating installation: Minsk - drawing of the scheme, Dzerzhinsk - piping of the boiler on site, installation of the chimney. Yes, we start with a pencil drawing of a diagram of a future home heating system with real heating equipment: a 58 kW SAS solid fuel boiler, a S-Tank buffer tank / heat accumulator of 2000 l, an expansion tank of 300 l, a 32-60 grundfos circulation pump. By the way, like everyone else, the client chose chimneys for the Buy Boiler House.

The installation of a solid fuel heating boiler in the photo was carried out by the House of Boilers Bai, Minsk.

Schemes: TT boiler

Also, such a boiler is able to withstand a high and long-term temperature load, has a longer service life.

This is due to the fact that liquefied gas is heavier than air, and if it leaks, it will go down. Without it, the operation of such heaters is simply prohibited. The device should be located at some distance from the side surfaces: at least cm from the front and more than 50 cm from the side walls.

It includes samples with various configurations, depending on the energy carrier and functional features of the apparatus. This does not suit many private home owners.

How to reduce the cost of piping The basic scheme for connecting a solid fuel boiler provides for the use of a three-way mixing valve equipped with a thermal head and an attachment sensor. But it has a significant drawback - high cost.

More on the topic: Make an estimate for an electrician

Connecting the boiler to power supplies

Most models can be controlled using convenient remote controls or panels. Violation of this point will reduce the life of the unit and lead to unnecessary pollution. The circuit is very simple and can be assembled at home. When operating a solid fuel boiler, there is always a risk of overheating of the coolant, especially at modes close to maximum power.

The simplest option is to connect two heat generators in parallel through a heat accumulator, which will additionally function as a low loss header. Otherwise, the increased pressure in the pipes can lead to their rupture. If the distance from the ridge to the chimney does not exceed a cm, then it is necessary to make an outlet 50 cm above the highest point. The boiler is connected to the cold water system with a flexible hose. The device requires the installation of several devices at once to organize the circulation of the coolant.

leave a comment

Ventilation of the boiler room For normal operation of the boiler, the boiler room must have a ventilation system, not only exhaust, but also supply. The fuel supply scheme in such boilers can be automated, electronic control.

After that, you need to install the boiler on a solid base, taking into account all distances, adjust the horizontal and vertical position of the apparatus. After that, the heating pipes should be connected, it is advisable to connect through shut-off valves, while carefully sealing the joints with flax or plumbing tape. The boiler is connected to the cold water system with a flexible hose. After that, it is necessary to check the location of the grates, dampers, plugs, fireclay stones. Hermetically sealed system, the heat carrier does not evaporate. Solid fuel boiler. Simple strapping.

Collaboration with electric boilers

Very often, wood-fired or coal-fired water heaters become the second heating unit in the furnace room, where there is already a gas or electric installation. They will need to be correctly connected to each other for correct joint operation, so that one unit insures the other. This is very convenient, for example, when all the coal burns out in one of them. Then the electric or gas water heater is automatically switched on. A typical piping scheme for a solid fuel boiler and an electric boiler is shown in the following figure. It is assumed that the electric heater has its own circulation pump.

Strapping schemes

Let's start with two simple positions:

- The first concerns the device of the solid fuel heating boiler itself. Remember - you will never find built-in circulation pumps and expansion tanks in any of its models and modifications. They are selected separately. The first one is according to the power of the heating unit and the area of the heated premises. The second is only based on the volume of the coolant.By the way, the volume of the expansion tank is always 10% of the total volume of the used coolant.

- The second position is, in fact, a question from consumers who believe that there is no point in fussing about this. The connection of a solid fuel boiler is simple - through two nozzles, one of which is connected to the supply circuit of the heating network, and the second to its return circuit.

The second position correctly sets connection tasks for installers. But this is the simplest scheme. By the way, the one who decided to install a solid fuel boiler with his own hands chooses this particular connection and piping option. And why bother if there is a simple and efficient scheme.

But let's face it. The aforementioned strapping scheme is not the only one. There are more complex options based on one very important rule. By the way, almost all manufacturers of solid fuel boilers indicate this rule as a warning in the operating instructions for heating units.

It states that the temperature of the hot water in the return circuit at the entrance to the solid fuel boiler should not be lower than + 60C.

Why are there such tight restrictions?

- Firstly, this is the only way to avoid the large temperature difference inside the heat exchanger, which has a positive effect on its service life.

- Secondly, this is the only way to avoid condensation of wet vapors inside the boiler furnace. The appearance of even a few drops of water on the walls of the combustion chamber gives rise to the formation of tar on the walls of the furnace. Soot and moisture have this negative effect.

Now we are interested in the question - how to make sure that all these processes do not arise, and the temperature in the return line does not fall below + 60C? There are several options.

First option

This is the simplest thing with regard to the complex piping of solid fuel boilers. To do this, it is necessary to embed a so-called mixing unit into the heating system. Many people might think that this not only complicates the design, but also increases its cost. In fact, the mixing unit is an ordinary pipe jumper that connects two circuits of the heating system - supply and return. It is usually cut with one end into the area between the circulation pump and the expansion tank, and with the other, into any point of the supply circuit.

Why is this jumper needed? It plays the role of a mixer, where hot water enters from the supply circuit and goes to the return. Thus, if necessary, you can increase the temperature of the coolant on the return section of the heating network. A shut-off valve must be installed on the jumper.

That is, the heating works in normal mode until the temperature in the return line begins to drop. As soon as it reaches a critical level, the automation system is triggered and the jumper opens. If you have installed a simple solid fuel boiler in your house without a complex automation system, then you will have to control the temperature of the coolant yourself and manually mix the media by opening and closing the shut-off valve. Therefore, the installation of a thermometer at the entrance to a solid fuel boiler is a prerequisite.

Second option

Solid fuel boiler in the heating system

How does a simple solid fuel boiler usually work without an automatic fuel supply? You manually load firewood, peat, coal and so on into the furnace. That is, you are completely attached to the heating unit. We were a little late with the bookmark, and we can assume that they immediately reduced the temperature regime inside the premises of the house.

What options do the experts suggest to make your life easier and reduce your addiction? This problem can be solved by installing a buffer tank. What is it, and where does the piping of solid fuel boilers have to do with it?

To begin with, the buffer capacity acts as a thermal energy accumulator. It contains water that is heated from the supply circuit of the heating network.As soon as the fuel burns out in the boiler furnace, and you will not notice this, the coolant will begin to lose its temperature. So the installed buffer tank, or rather, the hot water in it, begins to give off its heat to the coolant. This extends the operating time of the heating system.

How will the boiler piping scheme differ from the previous options? The tank installed in the circuit divides the entire heating system into two sections:

- In the first one there is a heating boiler.

- The second contains the radiators of the heating system.

And now the most important thing with regard to the piping of the boiler with a buffer tank. Everyone knows that TT boilers are difficult to control and regulate. It is almost impossible to manage them. Moreover, when you forget to carry out the exact fuel filling. For this, it is recommended to install another mixing unit. That is, one is already installed in the first section and is designed to increase the temperature in the return circuit of the heating system. The second unit must be located in the second section after the buffer tank. Its purpose is to reduce the temperature of the coolant at the time of the peak of the solid fuel boiler.

What do we get in the end? We have one piping diagram where a buffer tank is installed. So it may or may not have a jumper in it. It all depends on how often you add fuel. If you are the owner of a boiler with automatic fuel supply to the combustion chamber, then you can do without a jumper. In general, in this case, you can use the simplest strapping scheme.

Emergency circuit

Emergency wiring diagram

We return to the position that the management of solid fuel boilers is the number one problem. In them, overheating of the coolant is a common thing, so all manufacturers, without exception, are trying to find ways to cool hot water before it starts to turn into steam. What are they using? Which methods are effective and which ones are not very effective?

Consider three main methods for cooling the coolant:

- Two heat exchangers are installed in the combustion chamber of the boiler, which are in close contact with each other. One works to heat the coolant, and the second is used as a refrigerator. Its inlet pipe is connected to the water supply network, and the opposite pipe is connected to the sewage system. If it is necessary to lower the temperature of the coolant, you just need to open the valve on the water supply pipe and run cold tap water into the second heat exchanger. This is how it works.

- The scheme is practically the same. But only the second heat exchanger is installed inside the first one. With this arrangement, the decrease in the temperature of the coolant occurs several times faster and more efficiently.

- And the last option. It does not have a second heat exchanger. Its branch pipes - inlet and outlet - are connected to two pipes, which on one side are connected to the water supply system, and on the other - to the sewage system. A valve is installed at the junction of the pipes, which opens or closes the access of cold water to the heating system of the house. Of course, this coolant in heating becomes more, therefore, the outlet pipe is connected to the sewer system.

Let's face it - the temperature reduction scheme is rather strange. But it is surprising that boilers with such a design are present on the market, and service centers have even been organized for them.