Recently, a material such as heat-insulating paint has become popular in the construction market.

Insulating paint received its recognition due to its cheap cost.

With the help of this heat-insulating material, you can save electricity, and therefore your money.

Thermal insulating paint is divided into different types and before buying it is necessary to familiarize yourself with the characteristics of each and with the scope of their application.

In contact with

Varieties

Thermal insulating paint has several varieties:

- The first type is water at the base of the paint. Environmentally friendly paint. The material does not burn.

- Acrylic based paint.

- Thermal insulating paint that is used for painting walls and ceilings.

- Thermal insulating paint suitable for painting water pipes and gas pipes.

- Thermal insulating paint - used for painting outside the house, as it is waterproof and heat resistant.

The main properties of thermal insulation materials for pipelines

Among the main properties of modern heaters for heating pipes are:

Types of thermal insulation

- The ability to reduce heat loss in the pipeline, especially when it comes to hot water supply systems.

- Insulation for heating pipes must prevent the possibility of accumulation of condensate on the surface of the pipes.

- The insulation provides a certain temperature range on an insulated surface, according to safety regulations, and also prevents stagnation of water in pipes (freezing) in winter.

- Resistant to moisture. Moisture accumulates in the structure, as a result of which corrosion of the metal develops rapidly, this significantly reduces the thermal insulation properties, removes the pipeline from normal operation.

- The insulation must have a long operational period and have reliable protection against any kind of corrosion.

Such properties are characteristic of the following insulation materials:

Among modern heat-insulating materials, polyurethane foam is popular.

- Polyurethane foam;

- Mineral wool and fiberglass;

- Foil penofol;

- Styrofoam;

- Heat insulating paint.

What does it consist of

First of all, thermal insulation paint contains water. It also contains acrylic dispersion (adding various stabilizers to acrylic acid) - it is one of the main elements of any paint, thanks to this component, the paint retains its color, saturation and shine for a long period of time. Acrylic dispersion protects the surface from various environmental influences.

Perlite is added to the heat-insulating paint. Perlite is used to improve sound and heat insulation functions.

And also heat-insulating paint includes fiberglass, foam glass, microspheres made of ceramics - all these components of this paint are aimed at warming a dwelling.

Heat-insulating paint, when applied to the surface, lays down 5 millimeters thick.

Note: the main advantage of this material is the uniform application of paint over the entire painting surface. This advantage will help hide all defects and irregularities in the wall or ceiling.

Thermal insulating paint is available in the form of a thick mixture. It is either white or gray.

Composition and features of insulating paint

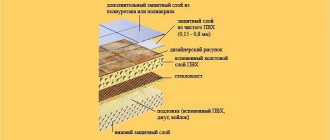

The material has a pasty consistency, it contains the following components:

- water;

- acrylic dispersion;

- fillers: perlite, foam glass, ceramic hollow balls, silicone spheres.

The thermal insulation properties of the paint directly depend on the amount of fillers; the more hollow spheres, the better the structure is protected from frost.

The color of the composition is white, but it can be matte and shiny. The consistency allows you to use a special spray for application. Small rooms can be treated with a soft roller or brush. Heat-saving paint has high adhesion to any material: metal, concrete, wood, plastic, brick, drywall, cinder block. Its insulating properties depend on the thickness of the applied layer, usually it reaches 3-4 mm.

The substance is evenly distributed over the surface of the walls and effectively replaces the usual thermal insulation, especially in relief areas.

It is recommended to apply the insulating mixture in three layers, and it is necessary to wait until the coating is completely dry. This will take up to 24 hours.

Benefits

Thermal insulating paint has a number of advantages:

- huge service life (service life can reach up to 45 years);

- the paint can withstand temperatures up to 280 degrees Celsius;

- you can insulate any room, even in those places where it is difficult to do it;

- the possibility of painting metal objects;

- the procedure for applying thermal insulating paints is very simple and does not require certain abilities, absolutely any person can work with this building material;

- the material from which the paint is made does not burn and does not emit toxic particles;

- in the future you will be able to save on electricity;

- many areas of application of thermal insulation paint;

- has increased moisture resistance;

- the surface where the paint is applied does not lend itself to rust.

Modern energy-saving paints

At present, energy-saving paints are produced by many, JSC "Gomelstroymaterialy", etc.). Such paints have many varieties, differing from each other in type, composition and some performance characteristics - these can be energy-saving paints containing glass and ceramic microspheres; aerosol paints; paints containing insulating putty, etc.

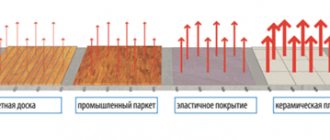

Modern energy-saving paints are antistatic, non-allergenic, do not require labor-intensive installation work, are resistant to precipitation and ultraviolet radiation, have high decorative properties and have a long service life - from 10 years and more. Such paints can be applied to various types of surfaces: drywall, wood, metal, brick, concrete, etc. At the same time, a 1 mm thick layer of energy-saving paint has the same thermal insulation properties as an insulation consisting of 2.5 cm thick mineral wool.

Distinctive features

In total, there are four features of heat-insulating paint:

- heat-insulating paint has a protective property, it protects against the release of heat or the entrance of cold, prevents the appearance of corrosion and wet substances;

- items on which heat-insulating paint has been applied increase their validity period;

- paint saves heat, you will be able to save electricity, therefore, your money;

- the material from which the insulating paint is made is completely environmentally friendly, without emitting any toxic and other harmful substances.

These four points distinguish thermal insulation paint from other materials used for painting objects.

It is interesting! Do-it-yourself wooden door insulation: types of insulation and procedure

Selection Tips

There are several tips to help you when purchasing thermal insulation paint.

Let's take a look at them:

- Attention: since the painting consumes too much material, it is necessary to calculate everything in advance and purchase the required amount of heat-insulating paint. You need to calculate like this: first you need to find out the material on which the paint will be applied (metal, wood, and others). Then you need to mark all the irregularities or bulges of the surface, decide what thickness of heat-insulating paint you will apply, measure the surface to be painted.

- Remember: it is important to choose several manufacturers at once and compare the characteristics of each - this will help you choose the required material.

- Sold separately for interior paint, and separately - for exterior, remember this.

- If painting is carried out outside the room, then you need to choose a paint with high water resistance and heat resistance. You also need to know the weather forecast for the day when the painting will be carried out.

- If painting is carried out indoors, then before buying, you should familiarize yourself with the composition of the paint and make sure that it does not contain toxic or other harmful elements.

- If water pipes or gas pipes are being painted, the thermal insulation paint must have the highest temperature resistance.

- It is best to use a spray gun when painting the surface - it will help you distribute the paint evenly.

- If the area of the room is small, then an ordinary roller is also suitable for painting the surface.

- The thermal insulation paint must be applied in several layers (three layers).

It is interesting! How to choose a spray gun - types of electric spray guns

Who produces quality thermal insulation paints

The production of heat-insulating paints was mastered at the beginning of the 2000s, and today a number of serious industrial enterprises are already producing their own lines of thermal paints. Some companies produce only one universal type of paints that can be used for insulation of interior walls, facades and plinths, as well as for insulation and corrosion protection of pipelines. A number of enterprises produce thermal paints only for a specific purpose for use in a specific area of insulation, but there is no doubt about the quality of all these products.

Table. Leading manufacturers of thermal insulation paint

| Firm | Insulation paint name | Features of the |

| GOODHIM (Russia) | GOODHIM TERMO | Universal heat-insulating paint designed for insulation and protection of facades, plinths, as well as protection against condensation and corrosion of heating pipes, hot and cold water supply. Suitable for indoor wall covering, protects against heat loss. Consumption of 1 liter per 1 sq.m. Packaging in 5 and 10 liter buckets (3.5 and 7 kg) |

| CORUNDUM (Russia) | CORUNDUM | Ultra-thin heat-insulating paint is available in three modifications: Classic - to protect walls and internal pipelines from heat loss. Facade - to preserve heat, protect against freezing, condensation, fungus, mold Facade Lotus - for finishing after processing the walls with the Facade. All modifications are characterized by high vapor permeability and do not impede air circulation. Packing in buckets of 5, 10, 20 liters. |

| VGT (Russia) | HEAT BARRIER VDAK 1180 | Thermal paint for thermal insulation of facades, interior walls with disinfection mode. To reduce heat loss, protect against condensation and corrosion of cold, hot water supply and heating pipelines inside and outside buildings. Do not process surfaces in contact with food and drinking water. Packaging in containers of 2 and 9 liters. |

| INNOVATIVE TECHNOLOGIES (Russia, Kazan) | RE-THERM | Modifications are made Standard, Inhibitor, Antifreeze, Vertical, Frost Each of the modifications has special fillers that allow the use of thermal paint in different conditions and on different surfaces. They are designed for thermal insulation, protection against corrosion, mold and mildew formation, fire protection, use in extremely high temperatures. Packing buckets 3, 10, 20 liters |

| AKTERM ( Russia) | AKTERM | Produced in different modifications: Standard, Anti-condensate, Metal, Concrete (facade), Nord, Volcano, NG (non-combustible) High quality thermal paints designed for use in different conditions and for different surfaces. Universal thermal insulation paint Standard is suitable for reducing heat loss, protecting against condensation, corrosion, mildew and mildew. The rest of the modifications have their own specific application. Packaging plastic, metal buckets of 3, 5, 10, 20 liters |

| PROMSNAB (Russia) | BARRIER | The company produces modifications of liquid heat-insulating paint: Standard, Facade, Anticondensate, Anticor, Nord. Standard paint is universal, protects against heat loss, mold and mildew, condensation and corrosion on pipes, reduces humidity in rooms. The rest of the modifications are designed for the processing of certain surfaces and metal products. Packing in buckets of 10, 20 liters. |

Note: In addition to the companies indicated in the table, many more Russian companies produce heat-insulating paint, their products also do not differ from European counterparts and have proven their quality and efficiency. But, unfortunately, we have to note that there are a lot of fakes on the market now, so when choosing, you need to carefully check the offered thermal paint, buy only from trusted retail outlets and from trusted manufacturers, confirming their name with quality certificates.

For painting pipes

Pipes are covered with various other insulation materials, but they do some harm to human health. When using these malicious materials, you also get a very short lifespan. Therefore, practically no one uses them for thermal insulation of pipes.

Heat insulating paint will help you keep your funds, health and warmth. This paint fully meets the parameters that are needed for pipe insulation. Heat will be stored for tens of years until the service life of this material (heat-insulating paint) ends. This is the best option for insulation.

Main manufacturers

Thermal insulating paint can be purchased on absolutely every construction market.

There are many different manufacturers of this popular insulation, but let's discuss the most important ones:

- Thermal insulating paint from. Mostly paint from this manufacturer is used for heating equipment. Indoors it is used as a decorative element. It is an excellent insulation material for any surface. offers customers four types of heat-insulating paint.

- Thermal insulating paint produced by Astratek. The paint is water-based. It is completely environmentally friendly and harmless material. The thickness of the applied paint layer reaches 3 millimeters. The service life is 30 years. The paint from this manufacturer is capable of withstanding temperatures up to 170 degrees Celsius. "Astratek" gives customers a choice of only three types of heat-insulating paint.

- Heat insulating paint from. This industrial paint is most often used for painting pipes with various media (water, gas and other liquid streams). The most widespread paint "Bronya" received in the industrial sphere. Bronya provides three types of heat-insulating paint for buyers in the construction market.

It is interesting! Do-it-yourself wall insulation with ecowool: advantages and disadvantages, installation stages

Foil penofol

Foiled penofol is an excellent thermal insulation coating that has advantages

The material consists of two layers: polyethylene foam and aluminum foil.

The result is an excellent thermal insulation coating that has the following advantages:

- Low coefficient of thermal conductivity;

- Ease of installation directly on site;

- Maintainability;

- Chemical resistance to environmental influences.