Features of the

This innovative thermal insulator creates a barrier to energy conservation when insulating a building. By the method of application, it is similar to conventional coloring compositions. As a result of polymerization of the composition, a matte elastic coating is formed, endowed with special thermophysical properties. It is it that becomes the barrier that easily tolerates temperature changes and does not allow heat to come out.

The insulation includes the following components:

- filler (microscopic balls made of glass, ceramics, polymers, filled with rarefied air);

- a binder (most often acrylic or latex);

- additives.

Depending on the composition, the properties of the liquid insulator, the requirements for the base to be treated, and the application technology change.

One of the most effective materials is Astratek liquid thermal insulation.

Varieties of thermal insulation Astratek and application technology

Astratek can be easily sprayed with a spray bottle.

The price of thermal insulation does not differ much, but there are nuances in the composition that should be considered before use. First you need to familiarize yourself with the types of liquid thermal insulation of Astratek, reviews of which only push you to purchase this material for protection. Varieties:

- facade;

- metal;

- decor acoustics;

- station wagon.

"Facade" is used for insulation of apartments or private houses, for wall cladding outside and inside. It is used for walls and facades of buildings that are characterized by high humidity. Also used on any plastered surface. Earlier, we have already talked about how to independently insulate the facade of a house.

In rooms with high humidity, it is recommended to use Astratek Metal, which perfectly protects against corrosion.

Liquid insulation Astratek decor-acoustic has a special feature - it absorbs and scatters sound waves by almost 40%. This type is used mainly for interior wall decoration. Astratek universal is suitable for insulating any surface: wood, metal, concrete, brick and other materials. Suitable for both outdoor and indoor use. Provides thermal protection in the range from -60 to +200 degrees.

Astratek insulation is applied using the following technology:

- the surface is being prepared;

- padding;

- coating is applied;

- the time is expected until the material is completely dry;

- application of the following layers (up to 15 are allowed).

To prepare the coating, remove any visible dirt. It can be dust, or pieces of plaster falling off. If there are cracks on the wall, then they must be covered with putty. After it dries completely, everything is thoroughly rubbed and cleaned. Priming is essential to improve adhesion. For this, a primer is used, which is applied to the surface with a brush or roller. For reliability, 2 layers are applied. After the preparatory work, Astratek is diluted with water in a 1: 5 ratio and mixed thoroughly. Then the insulation is applied to the wall with a paint brush. The technology is similar to using conventional paint. Ceiling insulation with this material can be viewed in the video:

It is recommended to apply the material in one direction only. Harsh strokes in different directions will bring the mixture back to the brush. The layer should not exceed 0.5 mm. After complete drying of the material, a second layer is applied. It must be remembered that each subsequent layer is applied only after the previous one has completely dried.

The two main advantages that polypropylene pipes for heating are endowed with are technical characteristics and ease of installation.

Where tees for heating pipes are used and for what purpose is described here.

About the brand

Liquid thermal insulation of the Astratek brand is produced by OOO NPP Termalkom. For more than 10 years, this company has been promoting innovative building materials and technologies on the domestic market. It is a leader in the design and manufacture of heat insulators, the main component of which is composite compositions with hollow microspheres.

Thermalkom was one of the first to offer domestic consumers a unique material - American-made liquid ceramic thermal insulation. Due to the high prices for it, the company began to develop a domestic high-tech product that is not inferior in quality to foreign counterparts, but has a lower cost. The result of this work was the liquid thermal insulation of the Astratek brand.

LLC "Termalkom" is an enterprise that promotes the latest technologies to the domestic market. The company's product is not only liquid thermal insulation, but also high quality paints and primers (GROSS brand).

Today "Termalkom" is a well-established production, which is equipped with the most modern devices, they provide a high level of productivity and accuracy of adherence to the entire technology. The company's products are made from high-quality raw materials of Russian and foreign production.

ASTRATEK® - liquid ceramic thermal insulation

Liquid ceramic insulation

О - manufacturer of liquid thermal insulation Astratek®.

LLC "Termalkom" was one of the first in Russia to enter the market with a completely new product - liquid ceramic heat-insulating materials made in the USA. The first material of this type was Thermal-Coat (TC Ceramic). The next step was cooperation with Mascoat Products Inc. - the world's leading manufacturer of thermal insulation coatings. This company has created a range of original products for various applications (Industrial - for industrial and energy applications, WeatherBloc - liquid thermal insulation for facades, Marine - special thermal insulation coatings for shipbuilding, AC - anti-condensation coatings).

1mm between warm and cold

Studying the market and gaining practical experience (technical and marketing), I could not help but pay attention to the growing interest of consumers in the use of liquid thermal insulation. However, this interest was held back by high prices for American products, which made it difficult to market them. That is why in 2004 it was decided to develop a domestic material similar in quality to American coatings, but more competitive in cost. The work was carried out with the assistance and under the guidance of specialists from the Department of Chemistry and Technology of Elastomer Processing of the Volgograd State Technical University. The task was not just to create an analogue of overseas products, but to offer the consumer a new high-tech product that meets all market requirements. The result of these works was the patent for the invention "Anticorrosive and heat-insulating coating based on hollow microspheres" (RF patent No. 2374281, priority dated 12.24.2007).

Product quality

Today it is a modern production facility equipped with equipment from Netzsch (Germany), SMC (Japan), Dellmeco (Great Britain), which ensures high productivity and accuracy of all technological processes.

The release of high-tech products provides for the use of the best domestic and foreign raw materials. For the production of complex multicomponent thermal insulation materials ASTRATEK, the stability of the quality of raw materials and the stability of production processes play a particularly important role.The thoroughness of the preparation of raw materials and the control of this process, which require high experience and technological discipline, greatly affect the quality of the final product. All products manufactured by Termalkom LLC undergo complete quality control at all stages: incoming quality control of raw materials and auxiliary materials, control of production processes, final acceptance of finished products - each batch of ASTRATEK thermal insulation coatings is tested in its own laboratory according to a specially developed program.

Objects of application of Astratek thermal insulation The quality management system is certified for compliance with the requirements of the international standard ISO 9001: 2008, which guarantees complete quality control at all stages of production and is a serious competitive advantage of the products manufactured.

is a leader in the development and production of heat-insulating polymer coatings - highly filled composite compositions based on hollow microspheres (syntactics). In addition to liquid thermal insulation ASTRATEK, the company produces high-quality paints and special primers under the GROSS trademark.

is included in the regional register of innovative enterprises of the Volgograd region.

Advantages of ASTRATEK liquid thermal insulation:

- It is applied to the surface of any shape and to hard-to-reach places;

- The possibility of thermal insulation without interrupting the production process;

- Isolates "cold bridges" (shut-off valves);

- Does not create an additional weight load on the supporting structures;

- Permanent access is possible to inspect insulated surfaces without the need to stop production;

- Eliminates freezing of walls;

- The coating is resistant to UV radiation;

- Short coating time reduces labor costs compared to traditional insulators (easy and quick to apply with a brush or spray gun);

- Maintainability of the coating;

- The material does not support combustion;

- Environmentally friendly, non-toxic, does not contain harmful volatile organic compounds;

- Prevents thermal deformation of metal structures;

- Resistant to alkalis;

- The polymerization time of one layer is 24 hours;

- Thermal conductivity at 20 ° C is 0.001 W / m ° C;

- Fully certified in Russia.

The material "ASTRATEK" is designed for use in industrial and civil construction, industry and energy, urban utilities.

Liquid ceramic thermal insulation Astratek

Liquid thermal insulation Astratek is a composition based on polymer dispersion, special lightweight fillers and modifying components. Thermal insulation is a homogeneous liquid suspension (mastic) that can be applied to the insulated surfaces with a brush or spray. After the liquid thermal insulation dries, a durable elastic coating with an ordered microporous structure is formed, which has heat-shielding and anticorrosive properties.

Thermal insulation polymer coatings ASTRATEK® are modern thermal insulation materials based on polymer binder, special lightweight fillers and targeted additives.

ASTRATEK coatings are a liquid suspension (mastic), which allows them to be applied to objects of any configuration with a brush or spray.

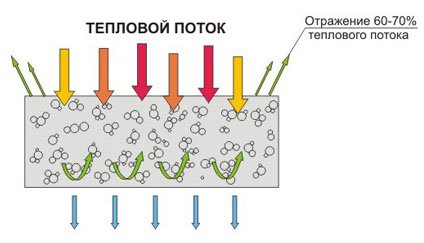

ASTRATEK is a highly porous heat-insulating material that works by implementing a blocking mechanism (creating a high thermal resistance) of 3 types of heat transfer - convection, conduction and radiation. The microporous structure of ASTRATEK heat-insulating paint reflects and dissipates more than 76% of the input thermal radiation during heat transfer.Due to the low thermal conductivity, there is a "weakening" of the heat flux in the thickness of the material, the low emissivity reduces the level of the output heat flux and provides a decrease in heat loss. Check out the Astratek video.

Heat paint "Astratek"

Ultra-thin thermal insulation of the Astratek brand has earned a lot of positive feedback from consumers. The Astrakhan Institute of Metrology, Certification and Implementation, after conducting all the studies, presented a conclusion on the thermophysical characteristics of the heat paint.

The heat insulator of this brand is a high technology product. It is water-based and consists of ceramic balls with a vacuum inside. Acrylic polymers act as a binder.

Scope of use

The area of application of Astratex liquid thermal insulation is the energy and construction industries. As for the latter, this type of insulation is used to protect facades, roofs, internal surfaces (walls, floors, including basements), loggias, balconies, concrete structures, pipelines.

The mixture of this brand can be used for processing concrete, polymer, brick and metal surfaces.

Challenges and benefits

The purpose of Astratex thermal insulation is to create a protective layer that protects against the formation of condensation and the development of corrosion processes.

The popularity of the material is explained by its many positive characteristics:

- safety for people and the environment (does not emit toxic substances);

- fire safety (at temperatures from +2600 ° С it charred, from +8000 ° С it self-extinguishes);

- protection of surfaces from the appearance of fungus and the formation of mold, icing, condensation.

Unlike traditional insulation materials (mineral wool, foam), the brand's liquid insulation protects the treated structures from corrosion. The installation process does not require special skills. It is applied like a regular paint and, accordingly, does not take much time.

With its help, you can completely protect the treated area, while there will be no thermal gaps. The super-thin coating formed as a result of work will save usable area, "will not eat" precious centimeters.

Liquid thermal insulation of the Astratek brand is an optimal combination of price and quality. The use of this material for processing the facades of buildings for various purposes leads to a decrease in heat loss and financial costs for air conditioning in the warm season.

Astratek liquid thermal insulation

Liquid ultra-thin thermal insulation Astratek

Astratek Is a new liquid ceramic thermal insulator, a high-tech water-based composite material consisting of evacuated ceramic spheres in a mixture of acrylic polymers. This combination makes the material lightweight, flexible, stretchable and has excellent adhesion to the surfaces to be coated. The material resembles ordinary paint in consistency, it is a white suspension that can be applied to any surface. After drying, an elastic polymer coating forms, which has unique thermal insulation properties and provides anti-corrosion protection.

Operating principle thermal insulation of ASTRATEK can be called "thermal mirror effect". In a fully polymerized coating, the concentration of evacuated voids (foam glass microgranules) is about 80%. Thermal insulation ASTRATEK allows you to both reflect the heat flow and retain it inside yourself. The material merges with the protected surface, filling all micropores, and completely eliminates the contact of the surface with the environment.

ADVANTAGES

- Can be applied to metal, plastic, concrete, brick, PVC and other building materials.

- It is impermeable to water and not affected by an aqueous solution of salt.

- Effectively reduces heat loss and increases corrosion protection.

- Protects the surface from condensation.

- Coating layer with a thickness of 1 mm provides the same insulating properties as 40-60 mm mineral wool insulation or brickwork 350-380 mm thick.

- It is applied to any surface shape.

- Does not create additional load on the supporting structures.

- Prevents thermal deformation of metal structures.

- Reflects up to 85% of radiant energy.

- Does not deteriorate under the influence of UV radiation.

- Fast coating procedure reduces labor costs compared to traditional insulators (easy and quick application by brush, trowel or airless spray).

- Easily repaired and refurbished.

- Does not support combustion. At a temperature of 260 ° C it charred, at 800 ° C it decomposes with the release of carbon monoxide and nitrogen oxide, which slows down the spread of the flame.

- Environmentally friendly, non-toxic, does not contain harmful volatile organic compounds.

- Resistant to alkalis.

- PH value 8.5 - 9.5

- Time for complete drying of one layer 24 hours

- Thermal conductivity at 20 ° С - 0.0011 W / m ° С

- Astratek can be coated with any alkyd or acrylic paint, wallpapering, tiles, plastering, putty, any facade decorative systems are allowed.

- The service life of the polymer coating Astratek 15 - 25 years (depending on operating conditions).

APPLICATION AREA

- Thermal insulation of building facades, ceilings, floors, roofs, attics

- Thermal insulation in the "warm floor" system

- Protection of building structure elements with the elimination of "cold bridges" and freezing

- Protection of building structures from freezing of walls, condensation, the appearance of fungus, mold

- Protection of internal slopes of windows from freezing and frost formation

- Thermal insulation of industrial equipment

- Hot and cold water supply pipelines, incl. underground

- Thermal insulation of oil and gas pipelines, tanks and cisterns, oil storages

- Coating of air ducts of ventilation and air conditioning systems

- Coating of refrigerators and freezers

RANGE OF HEAT-INSULATING COATINGS ASTRATEK

| Heat insulator name | Description and purpose | Benefits |

| Astratek station wagon | An original base composition for thermal insulation of any objects and structures made of brick, concrete, metal, plastic, wood and other materials. For indoor and outdoor use. Apply by brush or spray. Color: white, gray. Packing: plastic buckets 20L, 10L, 3L. | Versatile material. Environmentally friendly, non-toxic and free of harmful volatile organic compounds. Safe for indoor use. Water-thinnable. Operating mode: - 60 + 200 ° С (maximum peak load + 260 ° С for 1-2 hours). |

| Astratek metal | A special compound with increased anti-corrosion properties and improved adhesion for thermal insulation of objects and structures operated in conditions of high humidity and exposure to weak corrosive environments. For indoor and outdoor use. Apply by brush or spray. Color: gray. Packing: plastic buckets 20L, 10L, 3L. | Free from organic solvents, safe for indoor use. Increases the service life of metal objects, prevents the formation of rust. The ultra-thin heat insulator is resistant to UV radiation and chemical compounds (oil products, solutions of acids, salts, alkalis). Operating mode: - 60 + 200 ° С (maximum peak load + 260 ° С for 1-2 hours). |

| Astratek facade | Special composition with high viscosity and solids content for thermal insulation of building facades. It is characterized by high rates of adhesion, weather resistance and durability. Designed for indoor and outdoor use. Apply by brush, spatula or spray.Basic color: white, can be tinted in pastel colors. Packing: plastic buckets 20L, 10L, 3L. | Free from organic solvents, safe for indoor use. The ultra-thin thermal insulation coating can be applied in layers, 0.8 - 1.2 mm thick, on plastered, brick and concrete surfaces. Differs in high water-repellent properties. It has excellent vapor permeability - "breathing" ability. |

| Astratek decor-acoustician | A special decorative and textured composition for additional thermal insulation of walls, which has properties that significantly improve the acoustics of the room. It is characterized by greater elasticity, which provides additional decorative properties. Designed for indoor use. Apply by brush, spatula or spray. The material is produced in two basic versions: A and C. Base A - white for tinting in pastel colors. Base C - colorless, for tinting in dark saturated tones. Packing: 20L plastic buckets. | Free from organic solvents, safe for indoor use. The thermal insulation coating is applied in layers, 0.4-0.5 mm thick on non-absorbent surfaces and 0.8-1.0 mm on porous absorbent surfaces. Possesses significant thermal insulation properties, the ability to reduce the reverberation time of sound waves, providing comfortable room acoustics. |

| Astratek VS station wagon all-season works up to -30оС | A special composition of liquid thermal insulation for insulating the enclosing structures of buildings, structures, pipelines at negative temperatures. It is characterized by high rates of adhesion, weather resistance and durability. Designed for outdoor use. The coating is applied in layers with a brush, airless spray. Basic color: white, can be tinted in pastel colors. Packing: metal buckets 20L. | Contains organic solvents. Observe safety precautions during transport and use. The thermal insulation coating is applied in layers, the theoretical consumption is 1 - 1.1 liters. per sq. m. with a finished coating thickness of 1 mm. Operating temperatures from - 60 ° С to + 150 ° С. Application temperature from - 30 ° С to + 10 ° С. |

| Astratek NG non-combustible | A special composition for use in cases where it is necessary to use a material with a fire hazard class KM0. It is characterized as non-flammable, temperature-resistant, weather-resistant, vapor-permeable. For indoor and outdoor use. Apply by brush or spray. Color: white, gray. Packing: 20L plastic buckets. | It is used at facilities requiring the use of materials of the NG group: pipelines, air ducts, steam lines, steam boilers, stove pipes, chimneys and other industrial equipment. Environmentally friendly for indoor residential use. Operating temperature: - 60 ... + 200 ° С. Application temperature from +5 to + 120 ° С. |

All ASTRATEK products are also manufactured in "Frost-resistant" modifications. Material marked "frost-resistant" can be transported and stored at temperatures up to -40 ° C for one month. 5 freezing cycles of liquid thermal insulation are allowed. The "frost-resistant" ASTRATEK recipe does not impair the adhesion characteristics and heat-insulating properties of the material, it is safe for the environment and human health.

RECOMMENDATIONS FOR USE

Thermal insulation polymer coatings ASTRATEK are applied in layers. The thickness of one applied layer of ASTRATEK liquid thermal insulation should not be more than 0.5 mm. ASTRATEK facade on plastered concrete and brick surfaces it is allowed to apply thermal insulation in layers up to 1 mm thick. If a thicker coating is applied, the formation of a continuous film of liquid thermal insulation occurs faster than water evaporates from it (water is part of the material), and the remaining water deteriorates the thermal insulation properties of the material.

ASTRATEK should be applied in successive thin layers, each layer of liquid thermal insulation should be dried beforehand. The time for complete drying of each layer with a thickness of 0.5 mm at a temperature of 20C and an air humidity of 65% is 24 hours.

Consumption rate material with a single-layer coating 1 liter per 1.5 - 2 sq. m.

Auxiliary products for surface preparation before applying Astratek:

- Means for removing mold GROSS Antisept

- Primers GROSS facade, GROSS metal

Finishing decorative protective coatings brand GROSS

For each specific technical task, a preliminary calculation of the required thickness of the insulating layer and the consumption of ultra-thin thermal insulation ASTRATEK is made in accordance with SNiP 2.04.14-88 *, SNiP 23-01-99, SNiP II-3-79 *, SNiP 2.08.02.-89 * and Reference book of the designer "Designing of heating networks".

For getting heat engineering calculation the cost of covering Astratek, you must fill out an application form:

Application form (for BUILDINGS)

Application form (for PIPELINE)

Application form (for TANK)

You can find detailed information on the use of each type of ASTRATEK thermal insulation polymer coating by clicking on the link https://astratek.ru/production/

Jump to section: FREQUENTLY ASKED QUESTIONS (briefly)

Errors when applying thermal insulation coating Astratek

Questions and answers on the use of Astratek (full version)

Customer Reviews

You can buy liquid thermal insulation (Kirov) from the ICT company. We have a wide range of products from well-known manufacturers at an affordable price. If you have any questions, call us, we will be happy to advise.

Operating principle

This ultra-thin coating can be applied to any surface, it tightly envelops them. The composition works in the same way as most composite thermal insulation materials.

After it dries, the heat insulator turns from a liquid material into a film that is strong and elastic. It is she who protects the structure from heat loss, being a kind of thermal barrier. Liquid thermal insulation can be applied in several layers, but the thickness of each layer should not exceed 0.5 mm.

An exceptional feature of the Astratek heat insulator is that the 1 mm coating it forms is as effective as layers of conventional roll insulation 50 mm thick.

Application

Ultrathin thermal insulation "Astratek" has a number of nuances in the technology of application and operation. A similar composition is used to treat clean, dry surfaces, free from dust and debris, old exfoliated materials, paints not affected by fungus. Loose areas are removed, deep cracks, cracks are sealed with putty.

The prepared substrates must dry completely. After that, they are sanded with coarse and medium-grained sandpaper. Then the surface is treated with a deep penetration primer mixture.

Work with a liquid composition can be carried out at a temperature of the treated surface from +5 ° C to +60 ° C. This should not be done in windy, rainy weather, fog or frost.

The mixture is thoroughly mixed before application. If necessary, it can be diluted with a little clean water.

Apply thermal insulation with a natural bristle brush, roller, trowel or spray, letting each layer dry completely (within 24 hours) before applying the next one. Before work, the brush is moistened with water. For high-quality application of the composition of the movement, the tool is directed in one direction. The recommended thickness of each layer is 0.5 mm. On concrete, brick or plaster substrates, up to 1 mm of the composition can be applied.

The coating becomes moisture resistant in a day. After complete drying, acrylic facade paints can be applied to the thermal insulation.

The service life of the material is at least 15 years.

Production technology and material features

Unlike some products also of domestic production, Astratek paints are among the hundred best materials for thermal insulation in the country, while the production technology is patented and leaves no doubt about the high quality of the final product.

Coatings are an example of a successful combination of thermophysical and operational characteristics against the background of significant economic efficiency. For the manufacture of the product, the manufacturer uses modern high-precision equipment from Japan, Germany and Great Britain, uses raw materials from leading brands made in Germany, the USA and Switzerland.

If we compare liquid thermal insulation with ordinary mineral wool, previously used to insulate interior and exterior walls, then the former can be considered a huge step forward, both in terms of performance, and simplicity, duration of use.

One layer 1 mm thick will be enough to reduce heat loss by at least three times, not to mention the fact that paint can be applied to surfaces of any type, including relief shapes, with high temperatures, a layer of rust or regularly formed condensation ...

The finished coating based on liquid thermal insulation is characterized by elasticity, excellent heat-shielding and anti-corrosion properties. If we compare Astratek's products with analogues, then its advantages become more than obvious. Firstly, the material lasts up to 30 years, while the declared term of heat insulators of other brands is no more than 15 years.

Secondly, the products are presented in the widest range, which allows you to select liquid thermal insulation, taking into account the characteristics of the surface and its operational purpose.

Where can I buy?

You can buy the Astratek heat insulator at any hardware store or through online stores, where specialists will answer all your questions and advise on the technological conditions and operating features of such a composition.

Choosing liquid thermal insulation compounds, you make your home warm and cozy, create a favorable microclimate in it, provide yourself with comfortable living conditions and at the same time save your own finances when paying bills for gas and electricity.

Recommendations for the application of thermal insulation polymer coating ASTRATEK metal

| 1. Preparation surfaces | The insulated surface must be cleaned from rust, scale, dirt by a mechanized method or manually with metal brushes, degreased and dust-free. When applying to a previously painted surface, it is necessary to remove the old paint in places of peeling and peeling. If necessary, use medium to coarse sandpaper. |

| 2. Priming | To improve adhesion and increase the service life of the finished coating, it is recommended to prime the metal metal surfaces before applying the ASTRATEC thermal insulation coating. When covering "cold" metal surfaces (not lower than + 5 ° С), it is recommended to use a GROSS metal primer (1 - 2 layers) or another high-quality acrylic metal primer. For a non-ferrous metal surface, it is necessary to use a special primer for non-ferrous metals, such as VL-023. When covering hot (more than + 80 ° С) metal surfaces, it is recommended to use 20 - 25% aqueous ASTRATEK as a primer layer. |

| 3. Application coverings | 3.1. It is recommended to apply the coating at a temperature of the insulated surface within the range from + 5 ° C to + 120 ° C. 3.2. It is not recommended to apply ASTRATEK metal coating on the surface, in strong wind, rain, fog, frost. 3.3.When applying the ASTRATEK metal heat-insulating coating, you should pay attention to the following points: It is recommended to apply ASTRATEK metal on “cold” metal surfaces at an ambient temperature of + 5 ° C and a humidity of no more than 65%. The lower the relative humidity, the faster the material dries and, accordingly, the higher the humidity, the longer the drying time. On clean, polished metal surfaces, steam condenses into moisture at a humidity of more than 90%. On rough or uncleaned surfaces, condensation occurs even at a humidity of 65 - 70%. In addition, condensation can settle on the surface even at low humidity, if the temperature of the metal is lower than the air temperature. Therefore, the surface must be dried naturally or forcibly before application. It should be remembered that when the temperature drops below + 20 ° C and the humidity rises to 85%, the drying time increases. Therefore, it is necessary to increase the time between application of layers by at least 2 - 3 times. For example, a material that has dried at low temperatures appears to be ready after the formation of a film, although the film will become completely strong only after all the water has evaporated and the film formation is completely completed. High ambient temperatures significantly accelerate water evaporation and curing. In this case, only the top layer can dry out and "preserve" water vapor inside, which, in turn, will worsen the thermal insulation and operational characteristics of the finished coating. At the same high temperature of the ambient air and the surface, this, as a rule, does not happen, therefore, in the summer, it is recommended to carry out work only in the morning in order to avoid a significant difference in metal and air temperatures. Drying of the applied layer with a directed jet of heated air on the surface of the coating is also unacceptable. Before using ASTRATEK, the metal must be thoroughly mixed until a homogeneous mass is obtained. With mechanical stirring, the rotational speed should not exceed 300 rpm. If necessary, dilution with clean water of 3-7% of the total volume is allowed. The resulting composition must be periodically mixed during operation. 3.4. The coating is applied in layers with a brush, air or airless spray, subject to the interlayer drying technology, at a temperature of t = 20 ± 2 ° C and above and a relative humidity of no more than 65%. The thickness of the applied layer should not exceed 0.5 mm, the final thickness of the ASTRATEK metal heat-insulating coating is determined by the method of heat engineering calculation. The time for complete drying of each applied layer with a thickness of 0.3-0.5 mm is 24 hours. The time for complete drying of the finished coating depends on the number of layers, temperature and humidity of the ambient air. If necessary, the interlayer drying time should be increased by 2-3 times. The cover is resistant to rain after 24 hours. 3.5. Brush application. It is recommended to use a non-natural bristle brush for applying interior or facade paints, as well as for painting small surfaces and correcting color imperfections. Moisten the brush with water immediately before applying the material. When applying with a brush, the movements should be directed in one direction to obtain a good coverage. For advice on air or airless spray coating, as well as the necessary advice on the selection of the necessary equipment, please contact our technicians. Rinse working tools with water after application. The finished coating can be coated with GROSS facade acrylic paint or other high-quality acrylic paints. For additional protection of the finished coating from constant contact with aggressive media, we recommend applying Ureplen polyurethane coating on top. |

| 4. Consumption | The consumption of ASTRATEK metal heat-insulating coating depends on the method of application, the shape of the surface and is more accurately determined by a trial application. Average consumption is: 1 - 1.3 l / m2, depending on the method of application and the properties of the insulated surface (with a finished coating thickness of 1 mm). |

| 5. Measures precautions and disposal | Heat-insulating polymer coating ASTRATEK metal is fire-safe and explosion-proof, does not contain solvents, does not require special precautions in handling it. In case of contact with eyes, rinse immediately with water. Do not allow to enter waste water. Keep out of the reach of children. Carry out work in a ventilated area. Dispose of material residues after drying as household waste. The material is water-soluble, the addition of organic solvents is not allowed. |

| 6. Storage and transportation | Thermal insulating polymer coating ASTRATEK metal should be stored in a tightly closed container at temperatures from + 5 ° C to + 35 ° C, away from direct sunlight. Material marked "frost-resistant" can be transported and stored at temperatures down to -40 ° C. 5 freezing cycles are allowed. |

| 7. Warranties manufacturer | The manufacturer guarantees that ASTRATEK metal heat-insulating polymer coatings comply with the technical characteristics when following the rules of transportation, storage, preparation and application, which are given in these recommendations and technical descriptions for each specific type of coating. The guaranteed shelf life in original unopened packaging is 12 months from the date of production. The manufacturer is not responsible for the improper use of the material, as well as for its use for other purposes and conditions not provided for in the technical documents. |