Alkaline batteries

Unlike acidic ones, alkaline batteries do an excellent job with deep discharge and are capable of delivering currents for a long time by about 1/10 of the battery capacity. Moreover, it is strongly recommended to discharge alkaline batteries completely so that the so-called "memory effect" does not occur, which reduces the capacity of the battery by the amount of the "unselected" charge.

In comparison with acidic ones, alkaline batteries have a significant - 20 years or more - service life, give a stable voltage during the discharge process, can also be serviced (flooded) and unattended (sealed) and, it seems, are simply created for solar energy. In fact, no, because they are not able to charge the weak currents that solar panels generate. A weak current flows freely through the alkaline battery without filling the battery. Therefore, alas, the lot of alkaline batteries in autonomous power systems is to serve as a "bank" for diesel generators, where this type of storage is simply irreplaceable.

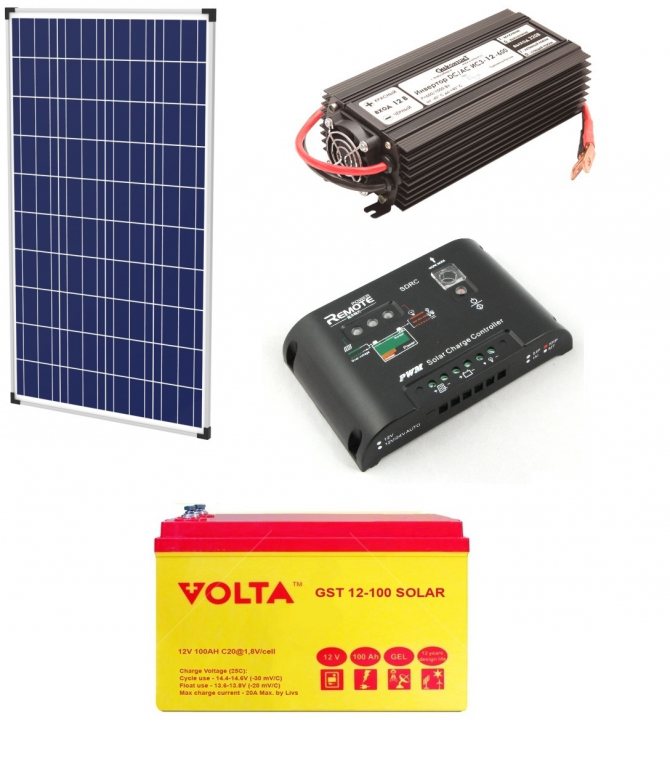

What is an inverter?

The simplest question in this article is what is an inverter. The voltage inverter is a converter of 24 Volt DC voltage to 220 Volt AC stabilized voltage on one phase.

In addition to uninterrupted power supply of a country house and a summer residence, it can be used in galvanic isolation, for voltage conversion and stabilization.

What to present the appearance let's look at inverters with an output power of 3 kW from the company newet.ru. The photo shows an inverter system for a rated load power of 3000 W: DC / AC — 24 / 220V — 3000BA — 3U.

The dimensions of this device are not large. In the marking, you see the designation 3U. This is the height of the device in mounting units. 3U = 13.335 cm. Width and depth of the device 480 × 483 mm. Among installers, such dimensions are commonly referred to as a 19 Inch 3U rack.

As you can see, for the declared possibilities of converting the voltage of 24 V to 220 V AC and with a power of 3 kW, the dimensions are quite small.

Li-ion batteries

Batteries of this type have a fundamentally different "chemistry" than batteries for tablets and laptops, and use the lithium iron phosphate reaction (LiFePo4). They charge very quickly, can give up to 80% of the charge, do not lose capacity due to incomplete charging or long storage in a discharged state. Batteries withstand 3000 cycles, have a service life of up to 20 years, and are also produced in Russia. The most expensive of all, but in comparison with, for example, acidic ones, they have twice the capacity per unit of weight, that is, they will need half as much.

Lithium batteries for autonomous power supply at home

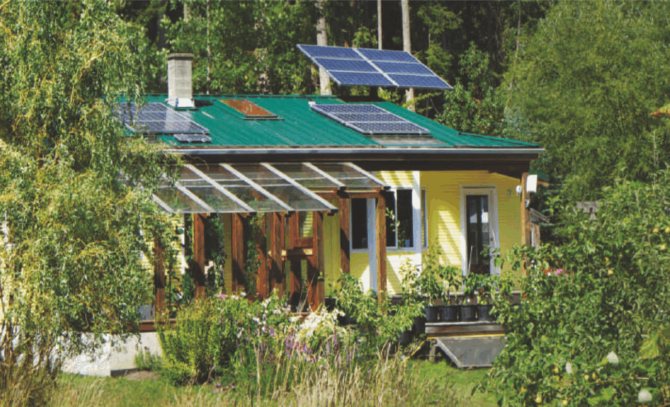

Melinda and Ezra Aerbakhi moved to Laskety Island in 1970. The island had no electricity at all and gradually, the Aerbachs went from a kerosene lamp and candlesticks to a dishwasher and wi-fi.

“Our workload is more than average. We use the Internet all day long, the ventilation system and in addition to our own refrigerator, we additionally supply electricity to two of our neighbors' refrigerators, and of course, we use electricity for cooking and heating water for the shower, ”says Ezra.

Main technical characteristics of the battery

The characteristics and requirements for batteries are determined based on the characteristics of the operation of the solar power plant itself.

Batteries must:

- be designed for a large number of charge-discharge cycles without significant loss of capacity;

- have a low self-discharge;

- maintain performance at low and high temperatures.

The key characteristics are considered to be:

- battery capacity;

- full charge and permissible discharge rate;

- conditions and service life;

- weight and dimensions.

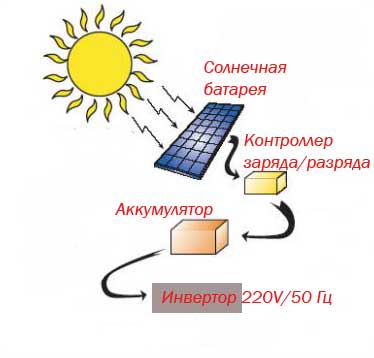

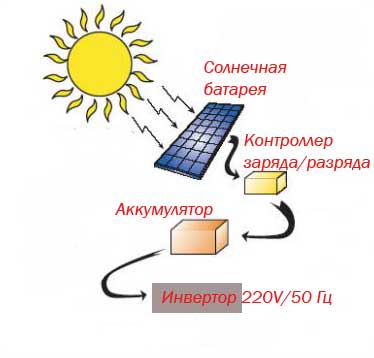

How voltage inverters work

Any inverter is powered by a lead acid battery, in this example, with an output voltage of 24 Volts. The battery wires are connected to the input terminals of the inverter. A single-phase voltage of 220 volts is taken from the output terminals of the inverter.

Let's look at the most general principle of operation of a voltage inverter with a sinusoidal voltage at the output (pure sine).

At the first stage of conversion, the device raises the voltage to almost 220 V.

Further, electricity is supplied to the bridge converter (inverter module or modules), where it is converted from DC to AC. After the bridge, the voltage waveform is close to sine, but only close. It is rather a stepped sine wave.

To obtain a voltage waveform in the form of a smooth sine wave, which is important for the operation of pumps, heating boilers, LED TVs, motors, multiple pulse-width switching is used.

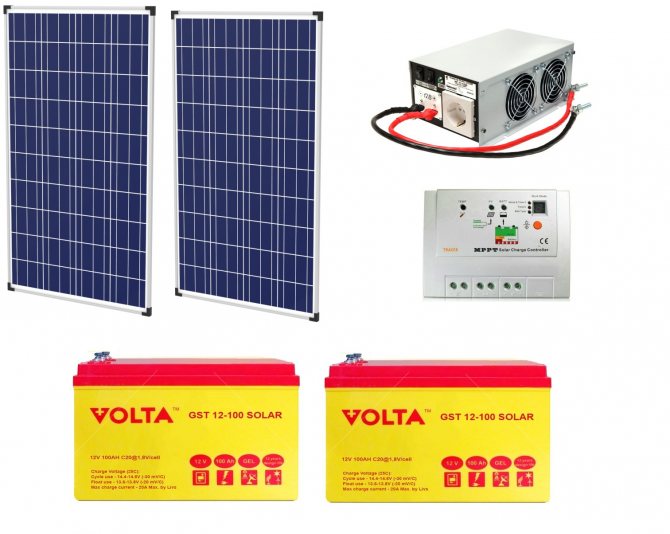

How to calculate and choose the right battery

Calculations are based on simple formulas and tolerances for losses that arise in an autonomous power supply system.

The minimum supply of energy in the batteries should provide the load in the dark. If from dusk to dawn the total energy consumption is 3 kWh, then the battery bank must have such a reserve.

The optimal energy supply should cover the daily needs of the facility. If the load is 10 kW / h, then a bank with such a capacity will allow you to “sit out” 1 cloudy day without any problems, and in sunny weather it will not discharge by more than 20-25%, which is optimal for acid batteries and does not lead to their degradation.

Here we do not consider the power of solar panels and take it for the fact that they are able to provide such a charge to batteries. That is, we are building calculations for the facility's energy needs.

The energy reserve in 1 battery with a capacity of 100 Ah with a voltage of 12 V is calculated by the formula: capacity x voltage, that is, 100 x 12 = 1200 watts or 1.2 kW * h. Therefore, a hypothetical object with a night consumption of 3 kW / h and a daily consumption of 10 kW / h needs a minimum bank of 3 batteries and an optimal one of 10. But this is ideal, because you need to take into account the allowances for losses and equipment features.

Where energy is lost:

50% - permissible discharge level conventional acid batteries, so if the bank is built on them, then there should be twice as many batteries as a simple mathematical calculation shows. Batteries optimized for deep discharge can be “drained” by 70–80%, that is, the capacity of the bank should be higher than the calculated one by 20–30%.

80% - average efficiency of an acid battery, which, due to its peculiarities, gives off energy 20% less than it stores. The higher the charge and discharge currents, the lower the efficiency. For example, if an electric iron with a power of 2 kW is connected to a 200Ah battery through an inverter, the discharge current will be about 250A, and the efficiency will drop to 40%. Which again leads to the need for a two-fold reserve of the bank's capacity, built on acid batteries.

80-90% - average efficiency of the inverter, which converts DC voltage into AC 220 V for the household network. Taking into account energy losses, even in the best batteries, the total losses will be about 40%, that is, even when using OPzS and even more so AGM batteries, the capacity reserve should be 40% higher than the calculated one.

80% - the efficiency of the PWM controller charge, that is, solar panels will physically not be able to transfer to batteries more than 80% of the energy generated on an ideal sunny day and at maximum rated power.Therefore, it is better to use more expensive MPPT-controllers, which ensure the efficiency of solar panels up to almost 100%, or to increase the battery bank and, accordingly, the area of solar panels by another 20%.

All these factors must be taken into account in the calculations, depending on what constituent elements are used in the solar generation system.

Batteries for autonomous and backup systems

Additional equipment → Batteries

The catalog of batteries for solar systems and backup systems is here

An accumulator (Latin accumulator) is a buffer for the accumulation of electrical energy through reversible chemical processes. This reversibility of chemical reactions taking place inside the battery gives it the ability to operate in a cyclic mode of constant charges and discharges. To charge the battery. it is necessary to pass a current through it in the direction opposite to the direction of the current during the discharge. Batteries can be combined into monoblocs, and then they are called rechargeable batteries. The main parameter that characterizes the battery is its capacity. Capacity is the maximum charge that a particular battery can accept. To measure the capacity, the battery is discharged within a certain time to a certain voltage. Capacitance is measured in pendants, joules and Ah (ampere-hours). Sometimes, mainly in the USA, the capacity is measured in Wh. The ratio between these units is 1 W * h = 3600 C, and 1 W * h = 3600 J. Proper battery charging takes place in several stages. In most cases, these are 4 stages: the stage of accumulation (bulk), stage of absorption (absorbtion), stage of support (float) and stage of equalization (equalization). The leveling stage is relevant only for open-type batteries (they are also called flooded), they are performed according to a specific schedule. This operation is akin to "boiling" the electrolyte in a battery, but it allows you to mix the electrolyte, which stratifies over time. Ultimately, proper alignment will increase battery life. The main reason for battery failure is the sulfation of the working plates. The formation of oxide on lead plates is called sulfation. Battery manufacturers report that this cause accounts for up to 80% of all battery failures. In addition to stirring the electrolyte, leveling cleans the plates of sulfates, and subsequently the load on the plates is evenly distributed. During the equalization process, a significant amount of an explosive mixture of oxygen and hydrogen is released. Therefore, you need to pay serious attention to the ventilation of the battery room. There are modern industrial open-type batteries in which the electrolyte is forcibly circulated. In addition to batteries with liquid electrolyte, there are also sealed batteries. In such batteries, equalization is not necessary, and in the remaining stages of charging, gassing does not occur.

The energy of many energy sources is needed not when it is available (first of all, this applies to solar panels), which is why it has to be stored. The work of the load should not depend on the illumination of solar panels, and therefore, even in the daytime, the presence of a battery is necessary. Of course, in this case, there must be a balance between the energy coming from the SB and the amount of energy going into the load. Batteries used in various energy systems differ in: nominal voltage, nominal capacity, dimensions, type of electrolyte, resource, charge rate, cost, operating temperature range, etc. Batteries in photovoltaic systems must meet a number of requirements: / discharge), small self-discharge,as high charging current as possible (for hybrid systems with liquid fuel generators), wide operating temperature range, and minimal maintenance. Taking these requirements into account, deep-discharge batteries have been created for various power supply systems. For solar systems, there is their solar modification. Such batteries have a huge resource during cyclic operation. Starter batteries are of little use for operating in such modes. They "do not like" deep discharges and discharges with small currents, they have a large self-discharge. Their service life in such conditions is short. Their normal mode is a short-term discharge with a high current, immediately restoring the charge, and waiting for the next start of the starter in a charged state. If we draw an analogy with sports, then a starter battery is a sprinter, and a specialized battery is a marathon runner. The most popular today are lead-acid batteries. They have a lower unit cost of 1 kW * h than their counterparts produced using other technologies. They have more efficiency and a wider operating temperature range. For example, the efficiency of a lead-acid battery lies in the range of 75-80%, and the efficiency of an alkaline battery is no more than 50-60%. In some respects, alkaline batteries are still superior to "lead". This is their huge survivability resource, the ability to recover by replacing the electrolyte, and work at a very low temperature. But some points make them of little use in FES. These include low efficiency and low susceptibility to low current charging. This leads to an irretrievable loss of a significant part of the energy that comes with such efforts. In addition, it is very difficult to find a charge controller for an alkaline type battery, and controllers with adjustable charge modes are expensive.

Now let's move on to a more detailed consideration of the batteries most often used in uninterruptible and autonomous power supply systems. The three main types are AGM, GEL and Flooded technology.

- GEL technology Gelled Electrolite appeared in the middle of the 20th century. SiO2 is added to the electrolyte, and after 3-5 hours the electrolyte becomes jelly-like. This jelly has a mass of pores that are filled with electrolyte. It is this consistency of the electrolyte that allows the GEL battery to work in any position. The battery of this technology is maintenance-free.

- AGM technology Absorptive Glass Mat appeared 20 years later. Instead of electrolyte thickened to jelly, they use glass mat, which is impregnated with electrolyte. The electrolyte does not completely fill the pores of the glass mat. Gas recombination takes place in the remaining volume.

- Flooded - batteries with liquid electrolyte (flooded) are still widely used. Equipped with recirculation valves, they become a low-maintenance battery. Such valves prevent gas emission, and the electrolyte level needs to be checked only once a year. This removes restrictions on indoor placement of Flooded batteries. Open-type batteries are more durable than maintenance-free batteries, their specific Ah cost is lower and they lend themselves better to balancing.

Each of the above-described battery types has a subclass of armored batteries. A distinctive feature of such batteries are lattice plates and tube-shaped electrodes. This technology significantly increases the number of charge-discharge cycles. Moreover, deep discharges are up to 80%. Electric forklifts, FES and other power electrical engineering widely use such batteries. They are labeled OPzS and OPzV.

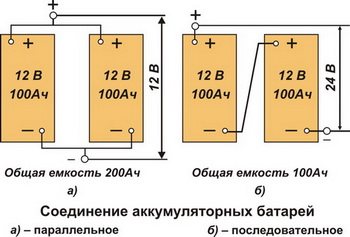

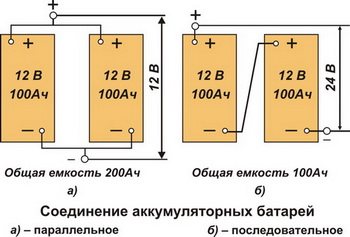

The increase in battery capacity is achieved by the fact that battery monoblocks are combined by parallel, serial or parallel-serial connection. To connect the batteries in series, you must use batteries of the same capacity.In this case, the total capacity is equal to the capacity of one battery, and the voltage is equal to the sum of the voltages of individual batteries. When the battery is connected in parallel, on the contrary, the capacities are added and the total capacity increases, and the voltage of the unit is equal to the initial voltage of the individual battery. Parallel-serial switching leads to an increase in both voltage and capacitance of the unit. Only identical batteries can be combined in one unit. Those. they must be of the same voltage, capacity, type, age, manufacturer and, preferably, of the same production batch (the difference is not more than 30 days). Over time, batteries connected in series, and especially in series-parallel, are subject to imbalance. This means that the total voltage of the series batteries corresponds to the standard for the charger, but in the chain itself, the voltages of single batteries differ significantly. As a result, some of the batteries are overcharged, while the other part is undercharged. This significantly reduces their resource. Special balancing devices help to minimize this harmful phenomenon. In extreme cases, it is necessary to charge each battery individually 1-2 times a year. For series-parallel connection of batteries, it is recommended to make jumpers between the midpoints (this somewhat contributes to self-leveling), as well as to remove power in a balanced way: the plus must be "taken" from the nearest battery, and the negative contact from the diagonally located one. To make the batteries convenient to maintain and mount, they are placed on metal racks.

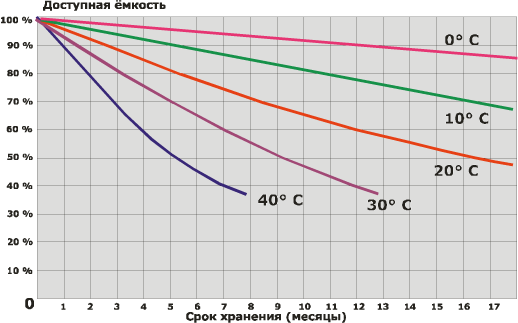

Any 12-volt monoblock consists of 6 blocks of 2V each. In this regard, in order to collect a block of high-capacity batteries, it is recommended not to parallel connection of 12-volt monoblocks, but to serial connection of 2-volt high-capacity blocks. The resource of such an "assembly" is much higher. In addition, most manufacturers do not recommend parallelizing more than 4 chains. This is due to the problem of imbalance and the consequent varying degrees of aging of individual batteries. But for example, the German concern Sonnenschein allows switching up to 10 chains in parallel. When calculating the FES, such a battery capacity is usually laid so that after autonomy for a given number of cloudy days in the absence of a charge from outside, the depth of discharge of the battery does not exceed 50%, but preferably 30%. However, these figures are not dogma, and everything depends on the specific project. You can read more about this in the section "Calculating a PV system". Correct use of the battery implies compliance with:

1) The values of charging and discharging currents are not higher than their nominal value. Discharge of the battery with an unacceptably high current will lead to rapid wear of the plates and premature aging of the battery. Charging with a high current reduces the volume of electrolyte. Moreover, in sealed batteries, electrolyte boil-off is irreversible - the battery dries up and dies.

2) Depth of discharge of the battery. Deep discharges, and even more systematic ones, are the reason for the frequent replacement of batteries and the rise in the cost of the system. A typical graph of the relationship between the depth of discharge of the battery and the number of charge / discharge cycles is located below.

3) The magnitudes of the voltages of the charging stages and the introduction of temperature compensation into these voltages at an unstable temperature in the battery room. This is described in more detail on the Charge Controllers page. It is impossible to accurately determine the battery charge level from the battery voltage, but an estimate of the charge level can be made. The table below shows this relationship.

| Battery type | 25% | 50% | 75% | 100% |

| Lead acid | 12,4 | 12,1 | 11,7 | 10,5 |

| Alkaline | 12,6 | 12,3 | 12,0 | 10,0 |

The voltages of the various charging stages are also temperature dependent. Manufacturers indicate the temperature coefficient in the product documentation. Usually this coefficient is in the range of 0.3-0.5V / degree:

| Battery temperature, Co | Voltage, V |

| 0 | 15,0 |

| 10 | 14,7 |

| 20 | 14,4 |

| 30 | 14,1 |

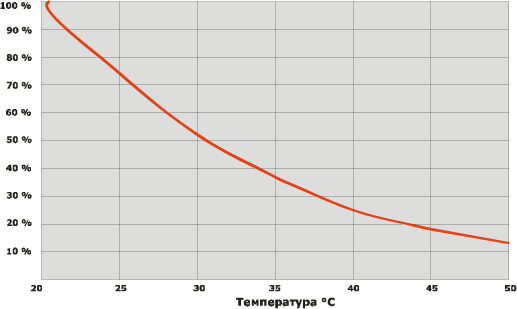

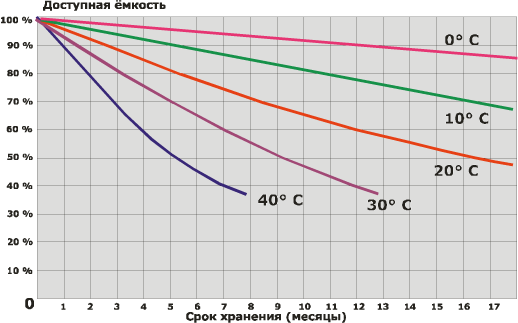

The ambient temperature has a significant impact on the parameters of the battery. Battery operation at high temperatures will dramatically reduce battery life. This is due to the fact that all negative chemical processes are accelerated with increasing temperature. An increase in the battery temperature by only 10 ° C accelerates corrosion by 2 (!) Times. Thus, a battery operated at 35 ° C will live 2 times less than the same exact battery at 25 ° C. The following graph shows the dependence of the battery life on its temperature.

Do not forget that the battery heats up when charged, and its temperature can exceed the room temperature by 10-15 ° C. This is especially noticeable when there is an accelerated charge with a high current. Therefore, it is not recommended to place the batteries close to each other, making it difficult for natural airflow and cooling.

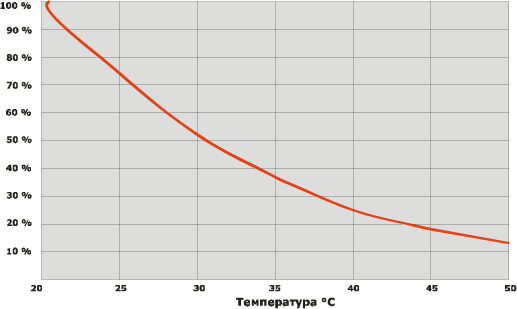

The next parameter of lead-acid batteries is self-discharge. When stored under standard conditions (20 ° C), batteries typically discharge at a rate of 3% per month. Long-term storage without recharging leads to sulfation of the negative plates. Recharging once or twice a year is sufficient to keep the battery in good condition. The increased temperature accelerates the self-discharge. The following graph illustrates the dependence of self-discharge on temperature.

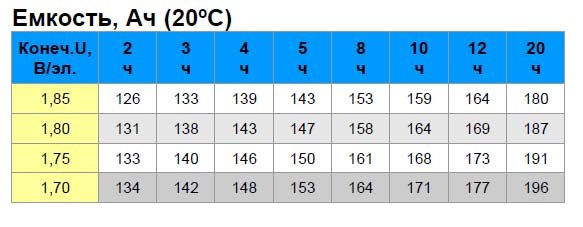

When calculating the system, you need to remember that the discharge characteristics of the battery are non-linear. This means that discharging the battery with a current of 2 times higher current will not reduce the load time by 2 times. This dependence is true only for low currents. For high currents it is necessary to use the table of discharge characteristics provided by the manufacturer for the calculation. Below is an example of one of these tables.

Battery testing in a nutshell. The simplest are the CTZ (control training cycle), checking the electrolyte density with a hydrometer and a test using a load fork. More modern methods include all sorts of capacity testers. All methods have their pros and cons. CTC is time-consuming, and besides, the battery must be taken out of service. Checking the level and density of the electrolyte does not give a complete picture. High-quality testers test the battery in 3-5 seconds, there is no need to discharge the battery, but such testers are very expensive. Depending on the purpose of the system, we use in our practice batteries from such manufacturers as Sonnenschein, Fiamm, Haze, Rolls, Trojan, Ventura, Shoto, Delta. These companies produce a very wide range of products and it is possible to choose a battery for any project.

In connection with a significant decrease in prices for solar panels over the past 2-3 years, batteries have become the most expensive PVP element that has them in its composition. Their initial cost is high and, moreover, they are practically consumable. It follows from this that you need to pay special attention to the choice of batteries for the project, as well as their subsequent correct operation. Otherwise, the cost of the system will snowball. Usually, in the documentation for the battery, manufacturers indicate the service life in the buffer mode and under ideal operating conditions (temperature 20 ° C, rare shallow discharges, constant optimal charge). Even in a backup system, such conditions are very difficult to provide. And in offline mode, the picture is completely different. Continuous charge / discharge is a very harsh environment.

Summarizing all of the above, we list the factors that reduce the battery life

• Recharge. It is dangerous by boiling off the electrolyte. This will not be allowed by the charge controller or inverter charger; • Systematic undercharge. It is necessary to charge the battery at 100% 1-2 times a month; • Deep discharge. There is no need to deeply discharge the battery. This can prevent the charge controller or inverter from setting the generation cut-off voltage or other third-party device. A deep discharge is not as terrible as storing a discharged battery.The battery must be charged immediately after deep discharge; • Discharge of the battery with exorbitant currents. Loads with inrush currents must be taken into account when calculating the battery capacity. Otherwise, the plates inside the battery become unevenly thinned and the battery will become unusable prematurely; • Charging the battery with excessive currents (more than 20% of its capacity) "dries up" the battery and shortens its service life. GEL batteries are especially critical to this. Check out the manufacturer's recommendations in this regard; • High operating temperature. The optimum temperature for the battery is 20-25 ° C. At a temperature of 35 ° C, the battery life is reduced by 2 times.

To make an attempt to restore the "killed" batteries, it is recommended to charge them with a very low current (1-5% of the capacity), and then discharge them with a high current (up to 50% of the battery capacity). This procedure destroys the oxide layer on the plates and there is a small chance to restore part of the battery capacity. Such cycles must be carried out at least 5-10. "Catalog of accumulators" offered by us is located here. During the discussion of the order, other brands of batteries that are not included in the catalog may be proposed.

Take good care of the batteries and they will serve you for the prescribed period, and will not end up in a landfill ahead of time!

Battery operating rules

Serviced batteries emit gases during operation, therefore it is forbidden to place them in residential premises and it is necessary to equip a separate room with active ventilation.

The electrolyte level and the depth of charge must be constantly monitored to avoid battery damage.

With year-round operation, in order to avoid deep discharge of batteries on cloudy days, it is necessary to provide for the possibility of recharging them from external sources - a network or a generator. Many inverter models can realize this automatic transfer.

How to choose an inverter for a summer residence: protections and other additions

Let's face it, an inverter is such a thing that one cannot do without automatic protection and limitation (there are too many factors of its operation that a person will have to control without them). By default, all devices of this type are equipped with such protections, but, as they say, there are exceptions. When choosing an inverter, you need to pay attention to the presence of the following protections.

- From excessive load - without it, the device may burn out. If, of course, you connect too powerful electrical appliances to it.

- Overheat protection. This is a standard option found on most modern electrical appliances.

- Battery full discharge protection. Motorists know what the risk of a voltage drop in the battery below the permissible level.

- Protection against entanglement of input terminals. Due to ignorance or inattention, a person can confuse plus and minus, and without this protection, some components of the device may burn out.

This is with regard to the protective mechanisms of the inverter. In addition to them, we can separately mention the additional equipment. In particular, it should be noted the presence of a cooling system, which is a conventional cooler - in some inverters they are turned on all the time (regardless of whether the device is warming up or not), while others have an intelligent system for turning them on. Coolers start up only when they really need to work - such inverters work quietly, and if they are not overloaded, we can say that they are generally silent.

Brief summary

To correctly calculate the capacity of the battery bank, you need to determine the daily energy consumption, add 40% of the fatal losses in the battery and the inverter, and then increase the calculated power depending on the type of batteries and controller.

If solar generation will be used in the winter, then the total capacity of the bank must be increased by another 50% and the possibility of recharging the batteries from third-party sources - a network or a generator, that is, with high currents - should be provided. This will also affect the selection of batteries with certain characteristics.

If you find it difficult to make independent calculations or want to make sure that they are correct, contact the specialists of Energetichesky Center LLC - this can be done via an online chat on the Slight website or by phone. We have vast experience in the assembly and installation of solar generation systems at various facilities - from cottages and country houses to industrial and agricultural facilities.

Manufacturers offer such a wide range of equipment that it will not be difficult to assemble a solar power plant according to your requirements and financial capabilities.

How to choose an inverter for home and summer cottages: we study the characteristics

The most important indicator of this type of device (of course, after the output waveform) is its power. Let's just say - if you buy an inverter with a power of 500W, then it will not work to power the same electric kettle through it, which consumes from 2kW and above. At the very least, protection will work and the device will turn off. It will burn out as much as possible, and it is for this reason that devices of this type provide a mass of all kinds of protections, which we will talk about later, but for now let's return to our power.

Today, for some reason, they began to denote it not by the standard letters W or W, but by such an abbreviation as VA - it means the current-voltage characteristic. In fact, if you do not take into account the reactive power that occurs when devices such as an electric motor operate, this is the same as the classic Watts. If we are talking about a complex load, which takes into account active and reactive power consumption, then this indicator is less than standard watts. That is, if we are talking about 1000VA, then when converted to W, it turns out that the power of the same inverter is less than 15% percent. It is this moment that manufacturers forget to indicate - you just need to take it into account when selecting an inverter for a summer residence.

The second point (or rather the characteristics of the inverter) that must be taken into account when choosing it is the value of the input voltage. There are two options here.

- Inverter converting 12V to 220V.

- Inverter converting 24V to 220V.

Everything is quite simple here - if we are talking about low-power sources of autonomous or backup power supply at home, the power of which does not exceed 2-4 kW, then 15V inverters are quite suitable. If we talk about more serious loads, it is better to give preference to an inverter designed to convert a voltage with a current of 24V. In general, if the energy consumption from an autonomous source exceeds 2000W, then it is already better to give preference to the second option. The fact is that there is such a moment as a reserve of capacity - more energy can be stored in 24V batteries.