The efficiency (efficiency) of a heating boiler is the ratio of the amount of fuel consumed to the amount of heat generated. The efficiency of even the most efficient modern models of hot water boilers cannot be 100% due to heat loss inside the boiler, insufficient thermal conductivity of metals or imperfections in the operating principle. In addition, the efficiency of the same model of a gas boiler also depends on the load: the efficiency specified in the passport is not realistic in the entire range of heat output.

In the article, we will analyze how to correctly calculate the efficiency, what it depends on and how to increase the efficiency of an already purchased boiler on our own.

Gross efficiency and net efficiency

Not all of the heat generated during fuel combustion is directed to heating the coolant, a certain part is spent on the boiler's own needs: a turbine, a fan or a smoke exhauster, a circulation pump, the operation of automation and an electronic display, the operation of an electric drive (as you already understood, all types of received energy are used in the calculation , including electricity, if the boiler is volatile).

With this in mind, it is customary to divide the boiler efficiency by the generated heat (Gross efficiency) and released heat (Efficiency-net).

This classification makes it possible to single out the degree of technical perfection of the boiler - gross efficiency or economy of fuel and electricity consumption - net efficiency.

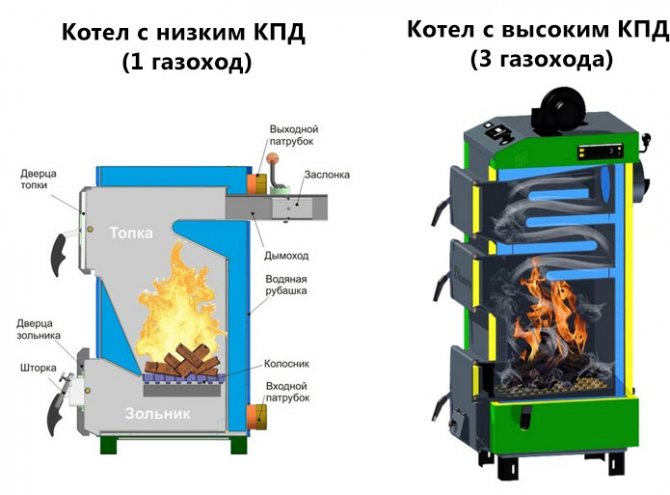

How to increase the efficiency of solid fuel heating technology

Today, many consumers, having a solid fuel boiler at their disposal, are trying to find the most convenient and practical way to increase the efficiency of heating equipment. The technological parameters of heating devices, laid down by the manufacturer, lose their nominal values over time, therefore, various methods and means are sought to increase the efficiency of boiler technology.

Consider one of the most effective options, the installation of an additional heat exchanger. The task of the new equipment is to remove heat energy from volatile combustion products.

The video shows how to make your own economizer (heat exchanger)

To do this, we first need to find out what is the temperature of the smoke at the exit. You can change it with a multimeter, which is placed directly in the middle of the chimney. Data on how much additional heat can be obtained from volatile combustion products is necessary to calculate the area of an additional heat exchanger. We do the following:

- we send a certain amount of firewood to the firebox;

- we note how long a certain amount of firewood will burn out.

For example: firewood, in the amount of 14.2 kg. burn for 3.5 hours. The smoke temperature at the boiler outlet is 460 0 С.

In 1 hour we burned down: 14.2 / 3.5 = 4.05 kg. firewood.

To calculate the amount of smoke, we use the generally accepted value of 1 kg. firewood = 5.7 kg. flue gases. Next, we multiply the amount of firewood burned in one hour by the amount of smoke obtained during the combustion of 1 kg. firewood. As a result: 4.05 x 5.7 = 23.08 kg. volatile combustion products. This figure will become the starting point for subsequent calculations of the amount of thermal energy that can be used additionally to heat the second heat exchanger.

Knowing the value of the heat capacity of volatile hot gases, as 1.1 kJ / kg., We make a further calculation of the heat flux power if we want to reduce the smoke temperature from 460 0С to 160 degrees.

Q = 23.08 x 1.1 (460-160) = 8124 kJ of thermal energy.

As a result, we get the exact value of the additional power provided by volatile combustion products: q = 8124/3600 = 2.25 kW, a large figure, which can have a significant impact on improving the efficiency of heating equipment. Knowing how much energy is wasted, the desire to equip the boiler with an additional heat exchanger is quite justified. Due to the inflow of additional thermal energy for heating the coolant, not only the efficiency of the entire heating system increases, but also the efficiency of the heating unit itself increases.

How to calculate the efficiency of a heating boiler

There are several ways to calculate values. In European countries, it is customary to calculate the efficiency of a heating boiler by the temperature of the flue gases (direct balance method), that is, knowing the difference between the ambient temperature and the real temperature of the flue gases. The formula is pretty simple:

ηbr = (Qir / Q1) 100%where

- ηbr (read "this") - boiler efficiency "gross";

- Qir(MJ / kg) - the total amount of heat released during fuel combustion;

- Q1 (MJ / kg) - the amount of heat that was accumulated, i.e. use to heat the house.

For example, if Q1 = 22 MJ / kg, Qir = 19 MJ / kg, then the “gross” efficiency = (19/22) * 100 = 86.3%. All measurements are carried out with an already established, standard boiler operation.

The direct balance method does not take into account the heat loss of the boiler unit itself, underburning of fuel, deviations in operation and other features, therefore, a fundamentally different, more accurate calculation method was invented - the “reverse balance method”. Equation used:

ηbr = 100 - (q2 + q3 + q4 + q5 + q6)where

- q2 - heat loss with flue gases;

- q3 - heat loss due to chemical underburning of combustible gases (applicable to gas boilers);

- q4 - losses of thermal energy with mechanical underburning;

- q5 - heat loss from external cooling (through the heat exchanger and the body);

- q6 - heat loss with physical heat of slag removed from the furnace.

Heating boiler net efficiency according to the reverse balance method:

ηnet = ηbr - Qsnwhere

- Qs.n - total consumption of heat and electric energy for own needs in% expression.

The actual efficiency will almost always differ from that declared by the manufacturer, since it depends on the correct installation of the boiler and heating system, smoke removal system, quality of power supply, etc. It is measured, respectively, already in place.

So what is the real efficiency of the boiler?

Thus, if the efficiency of your boiler is indicated in the passport of 90%. Then you need to understand that this is the efficiency that can be achieved if the boiler operates in the nominal mode, and good fuel with low ash content is burned in it. If we take into account other factors that the owner of the boiler encounters during its operation, then the real Boiler efficiency can be reduced to 65-70% (!!!)

How to get as close as possible to the nominal efficiency?

There are small tricks that you need to know and about which we will talk in the next article, which will not keep us waiting long.

- in frosts, in winter, as a rule, the draft in the chimney increases, thereby increasing the amount of excess air (excess air that does not take part in the combustion process) in the boiler burner. Eliminate the appearance of excess air in the boiler, which carries out all the heat from the boiler through the chimney. To do this, install a draft limiter on the chimney. This is not an expensive device (its price will not be higher than 3000 rubles), but you will save a lot of money on it, because it is it that increases Boiler efficiency.

thrust limiter

The draft limiter is installed on the boiler chimney. Its main purpose is to maintain a constant pressure at the flue gas outlet from the boiler. It works in automatic mode and does not require electricity for its operation. Set it up, set it up and forget it.But what is the use! Buy it online or at a suitable store.

Install turbulators in the flue pipes of the boiler. They look like metal plates curved in some places along their length, or (at some manufacturers) like metal spirals. They increase the heat exchange between the hot flue gases flowing inside the boiler and the heating medium behind the boiler wall.

Turbulators can be more expensive than a draft limiter. Their price reaches 9,000 and 20,000 rubles, depending on the power of the boiler. You won't be able to buy them in the store. At least I haven't seen it. Well, but the manufacturers of boilers will be happy to offer them to you. Ask and install. How they look - see the picture.

turbulator

With this sorted out, move on.

What determines the thermal efficiency of boilers

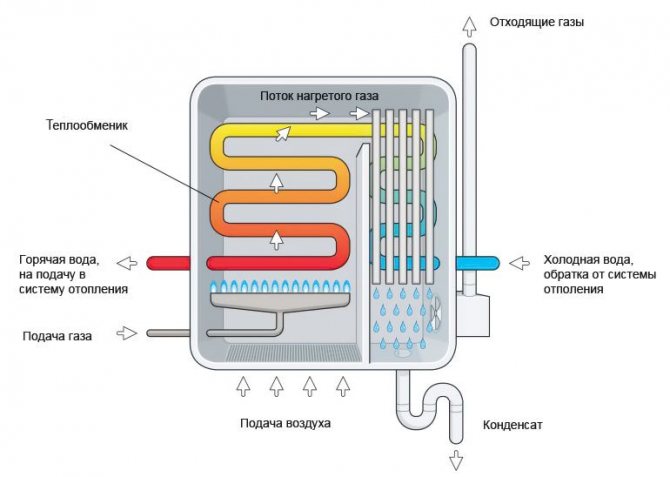

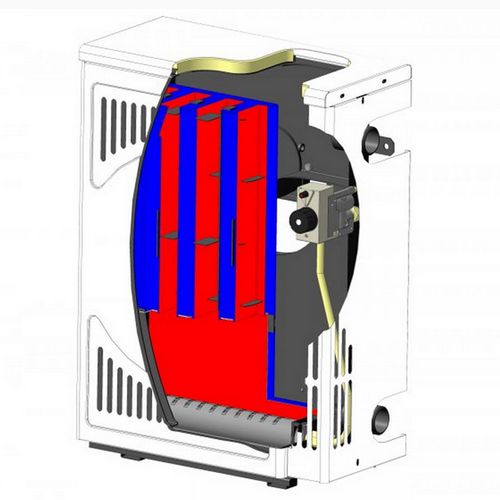

The principle of operation of the classic floor gas aspirated.

The efficiency of heating boilers is not equal at any power, there is a proportional dependence on the load: an increase in heat load (quantity of fuel burned) also increases heat loss through the body or chimney. In the same way, operation at minimum power does not always ensure complete combustion of the fuel, which leads to a decrease in efficiency.

For example, in the service instructions for gas boilers Protherm Wolf KSO with a capacity of 12.5 kW and 16.0 kW, it is indicated that when operating at maximum power (12.8 kW and 16.3 kW, respectively), the efficiency is 92.5%, while while operating with minimum load (4.5 kW and 5.8 kW), it will decrease and amount to only 78.4%.

This is one of the main reasons why it is worthwhile to consciously approach the choice of the power of the boiler unit. The most optimal performance in most models is achieved at a load in the range of 60-90% of maximum power.

Otherwise, the efficiency depends solely on the technological perfection of the model aimed at reducing the above-described q2-6 (lowering the temperature of the exhaust gases, efficient fuel combustion, modulating burners, thermal insulation, etc.), as well as on the quality of maintenance and operation of the boiler unit. The cleanliness of the coolant, regular cleaning and flushing - all this, over time, seriously affects the efficiency.

How to choose a room thermostat and save up to 30% per month on heating

Factors on which the efficiency of boilers depends

Boilers with a high efficiency value are currently represented by the following heating technology:

- units fired with coal and other solid fossil fuels;

- pellet boilers;

- devices of the pyrolysis type.

The efficiency of heating devices, in the furnace of which anthracite, coal and peat briquettes are fed, averages 70-80%. Significantly higher efficiency of pellet devices - up to 85%. Loaded with pellets, heating boilers of this type are distinguished by their high efficiency, giving out a huge amount of thermal energy during the combustion of the fuel.

On a note: one load is enough for the device to work at optimal conditions for up to 12-14 hours.

The absolute leader among solid fuel heating equipment is a pyrolysis boiler. These appliances use firewood or wood waste. The efficiency of such equipment today is 85% or more. The units also refer to highly efficient long-burning devices, but subject to the necessary conditions - the moisture content of the fuel should not exceed 20%.

Values of modern boilers depending on the type of fuel

| A photo | Boiler type depending on the fuel burned | Average efficiency,% |

| Gas | |

| - Convection | 87-94 | |

| - Condensing | 104-116* | |

| Solid fuel | |

| - Wood burning | 75-87 | |

| - Coal | 80-88 | |

| - Pellet | 80-92 | |

| Liquid fuel | |

| - On diesel fuel | 86-91 | |

| - On fuel oil | 85-88 | |

| Electric heating elements | 99-99,5 |

*From the point of view of physics, the efficiency cannot exceed 100%: it is impossible to obtain more thermal energy than is released during fuel combustion. However, it all depends on how you count. There are two definitions:

- net calorific value - heat obtained during the combustion of fuel, when the combustion products are simply removed through the chimney;

- gross calorific value - heat, including the energy contained in water vapor - one of the combustion products of combustible gases.

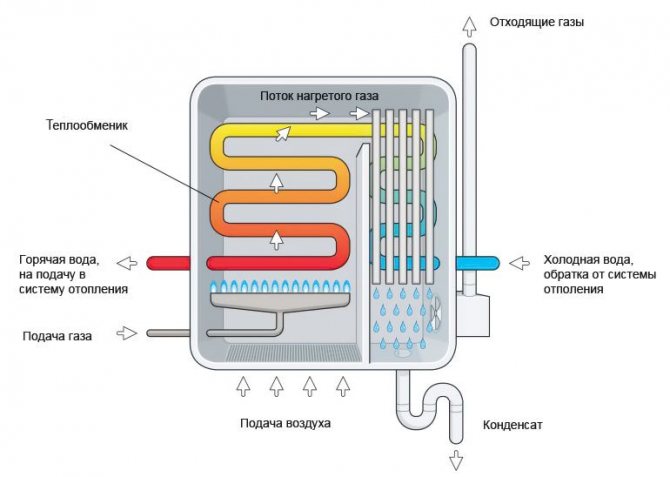

Gas condensing boilers additionally accumulate thermal energy of condensate formed from gas combustion products and deposited on an additional heat exchanger. Thus, a significant part of the heat does not "fly into the chimney", and the temperature of the exhaust gases is practically equal to the atmospheric temperature.

The device is a simple condensing single-circuit gas boiler.

According to the current standards, both in Russia and in Europe, the efficiency of heating boilers is calculated according to the lowest specific heat of combustion, therefore, taking into account the additional heat extracted from the condensate leads to values of more than 100%. When calculated based on the gross calorific value, the efficiency of condensing gas boilers is 96-98%, depending on the model and type of installation: wall-mounted boilers usually have higher efficiency than floor-standing boilers (this applies to all gas boilers).

It can also be noted from the table that the average efficiency of solid fuel boilers also differs depending on the fuel used, this is due to the degree of fuel combustion, its heat transfer, combustion temperature and heat loss with physical heat of slags removed from the combustion chamber. Even the same solid fuel boiler can produce different efficiency when operating on different types of fuel.

Operating rules affecting the value of the boiler efficiency

In order for the heating equipment to always work properly, experts recommend adhering to the basic operating rules that affect the value of the boiler efficiency.

In this case, it is necessary to clearly follow the following points:

- Choose only the optimal blowing modes and the functioning of the hood.

- Control the intensity of combustion and the completeness of fuel combustion.

- Constantly monitor the amount of drift and failure.

- Assess the condition of surfaces that heat up when burning fuel.

- Clean equipment regularly.

How to increase the efficiency of a gas boiler

It is almost impossible to increase the efficiency of fuel combustion by interfering with the technical device of the boiler, the same layer of thermal insulation cannot be installed due to the banal non-provision of the place for it by the manufacturer. In addition, do it yourself is prohibited. Nevertheless, there are ways to increase the efficiency of a gas boiler, especially if it is an imperfect old model:

- Finished chimney economizer - replaces a certain section of the chimney and is designed to accumulate heat from the exhaust gases through the chimney (a kind of imitation of condensing boilers). However, it is necessary to accurately calculate the parameters of the economizer and the requirements for the chimney in order to maintain the required draft and prevent reverse draft, for example, in strong winds. Issue price - 1,700-2,500 rubles.

Sandwich mesh economizer for chimney pipes. - Homemade economizer - almost identical with the above-described finished products. We have already described how to make an effective economizer in one of the previous articles.

- Cleaning the boiler and flushing the heat exchanger - these are regular maintenance measures, meaningless for new boilers, but extremely effective for those in operation for at least several seasons. The fact is that during operation, scale and other salt deposits form inside the heat exchanger, the outer fins of the heat exchanger, burners and igniter are clogged. All this leads to an increase in gas consumption, a decrease in heat output, and, accordingly, a decrease in efficiency (often up to 20-30%).How and how often it is necessary to clean the gas boiler, we have also already disassembled earlier.

- Gas filter - it is installed in front of the shut-off valves of the gas main and is designed to clean gas from debris and impurities, sometimes found in the composition. This not only helps to reduce soot formation, but also, while improving the quality of the fuel, slightly reduces heat loss in case of underburning.

The rest of the methods consist in the correct start-up and adjustment work, which are carried out once, at the first start of the boiler, exclusively by specialists. With the correct initial setting, the efficiency guaranteed by the manufacturer is ensured. It is important to understand that it is impossible to increase this indicator by interfering with the technical device of the boiler itself, and even more so, it is not safe.

Instructions Boilers Energy saving technologies

The boiler efficiency will be higher if ...

To exclude as much as possible chemical underburning of the fuel, ensure the required excess air ratio inside the boiler (1.2-1.3 for solid fuel, 1.05-1.15 for gas), and for this:

- Install a draft limiter on the boiler chimney, which I have already written about above,

- Buy your boiler ONLY in a specialized organization, which, when starting up the boiler, MANDATORY, with the help of an expensive device - a gas analyzer, will adjust the required volume of air passing through the boiler. DEMAND to do it, pay money for it. Otherwise, you will spend extra money on fuel every day.

- Try to buy a boiler with an installed lambda probe, which is designed to maintain the desired balance of air and fuel in the boiler burner

How to calculate power

Before buying heating equipment for servicing a private house, it is necessary to calculate the power that would be enough to maintain the high-quality operation of the boiler. If you do not have sufficient experience and knowledge, seek the help of professionals, since mistakes at this stage will certainly affect the performance and durability of the equipment.

Note!

Problems arise not only in the event of a shortage of heating equipment, but also in the event of its excess. There are special formulas for calculating power. Using them, you can independently calculate which boiler is suitable for servicing the house.

When calculating the power of a gas boiler, the following parameters should be taken into account:

- the average temperature in the winter months in a given area;

Gas boiler operation and heat loss

- what materials the house is built from;

- what materials were used to insulate the house, and whether they were used at all;

- the area of the residential premises of the house.

You can use special formulas to calculate the power of heating equipment for a private house.

Note!

The power of a gas boiler also depends on whether hot water is required in the house.