Types of grates

Material

The temperature in the furnace is high enough, forcing the craftsmen to make gratings from special metals:

- The most durable is the cast iron grate for the stove.

- There are also steel parts, the most popular of which is antipyretic steel. Such grates do not lend themselves to oxidation and corrosion when burning a flame, and also do not deform. These devices can have different sizes and shapes, the abundance of which provides the possibility of choosing a grate even for a non-standard stove model.

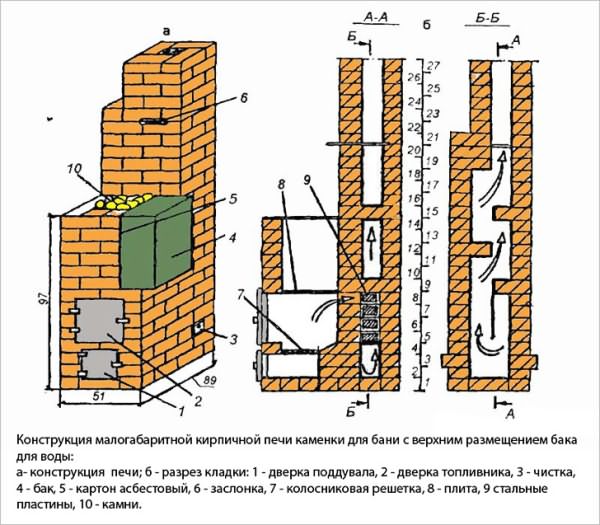

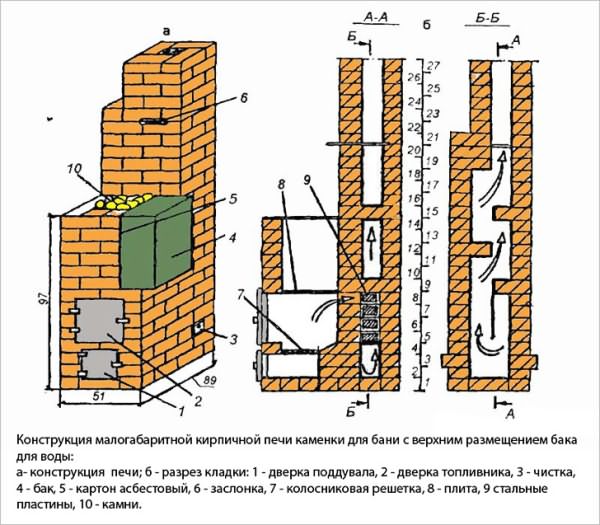

An example of a grate for a furnace

Solid and typesetting

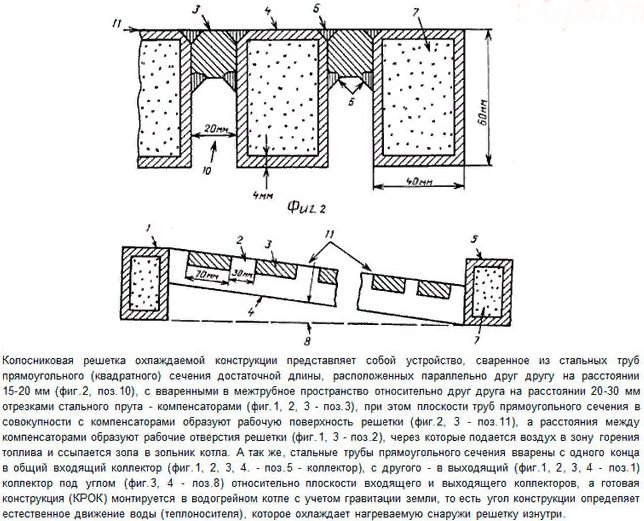

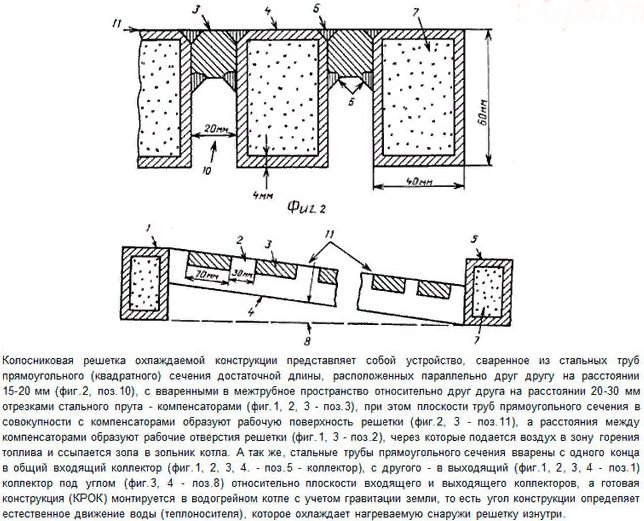

For convenient use, you can choose different designs of grate grates:

- Whole. have the form of monolithic lattices, they are not decomposed into smaller components. For most manufacturers, the dimensions of the grates for the furnace are standard, focused on the most popular models of furnaces. The choice of sizes of solid parts is large enough. Preference should be given to a particular product taking into account the fuel surface area.

- Inlaid grates. They have a collapsible shape, assembled independently. The number of their components depends on the required area of the device. This guarantees their versatility, because the oven grate can be made in any size, suitable for non-standard ovens.

Stationary

Fixed devices - grates that do not move.

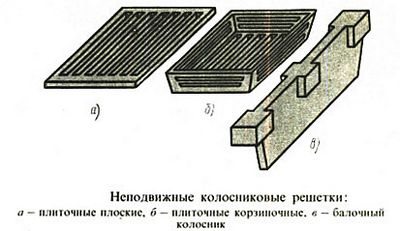

Subspecies of fixed grates:

- tiled flat, the most popular;

- basket, rarely used;

- beam.

Tiled - these are rectangular-shaped parts that are the most popular. They can be used for any model, they are versatile and easy to install. The stores offer a huge selection of grates of this particular type.

Basket grates are not very popular, because they are used for open ovens. In the old days, they were part of the ovens on which food was cooked. Now gas and electric stoves are used for this.

Beam grids visually resemble a construction beam. They are only collected by hand. Consumers like their versatility, the ability to install in any oven.

Movable

Subspecies of movable grates:

- full revolving;

- swinging;

- chain.

Movable furnace grates consist of several parts. These include sections and shaft. Due to the possibility of rotation, the process of cleaning from ash is simplified. Movable gratings are divided into full-revolving and swinging ones: the angle of inclination of the former is 180 degrees, the latter can rotate from 30 degrees. Another type of such lattices is chain. In its design, the elements are connected to each other by chains. The disadvantage of this type of grate is incomplete combustion of wood or coal.

Grizzly functions and design differences

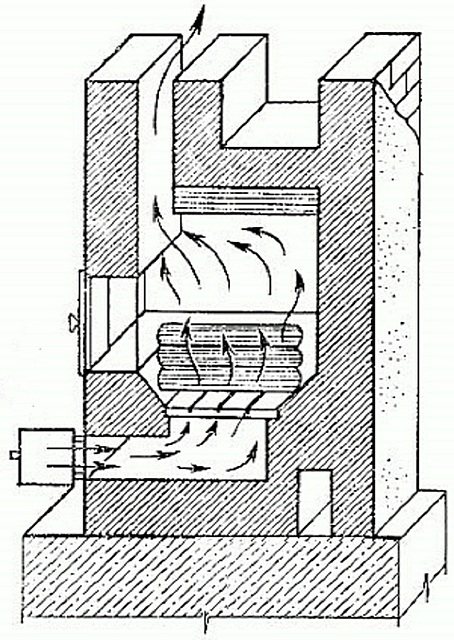

It doesn't take much skill to light the stove. It is much more difficult to keep fire in it. For normal combustion, it is necessary to provide an air flow. This cannot be done with the firebox door closed. But in order for the air, nevertheless, to enter the combustion chamber, an additional chamber is made - a blower - located under the firebox. These two chambers are separated by a grate that prevents the fuel from falling down.

The main functions of grate bars

Furnace grates are metal rods (most often cast iron) of various lengths, which allows you to choose them according to the dimensions of the firebox. The cast iron grate for the furnace has a wedge-shaped or trapezoidal cross-section.

Such elements are laid in the lattice with the wide side up.This facilitates the access of air from below to the hearth of combustion, and ash through the gaps between the grates freely falls into the blower.

The grate, being one of the most important elements of any furnace, performs the following functions:

- divides the combustion chamber into two parts - the firebox and the blower;

- fuel for preliminary drying can be placed in the firebox;

- evenly distributes the air flow from the blower;

- provides normal traction;

- in cooperation with the blower door, it allows you to regulate the flame in the combustion chamber.

Oven grate - functions

Design differences

Grates operate in high temperature zones and are subject to the oxidizing effects of oxygen. The material from which the grate structure is made must withstand these aggressive influences for a long time. The most suitable material for these purposes is cast iron, since only it can work in such conditions. It is from it that almost all the components of the grate are made.

Since the designs and dimensions of the furnaces can be different, the designs of the grates also differ from each other. There are such grate structures:

- solid;

- composite;

- fixed (tiled flat, basket, beam);

- movable (full-revolving, swinging, chain);

- refrigerated.

Grizzly structures

Dimensions (edit)

Another condition for choosing a grate for the furnace is its length and width. The sizes of grates for the furnace are different, they are due to the type of fuel:

- For light firewood or briquettes, gratings from 140x120 mm to 330x252 mm are sufficient.

- For coal, large parameters are needed: 300x300, 350x300, since this fuel emits a large amount of harmful substances during combustion.

Variety of grate sizes

Self-installation of the grate in the oven

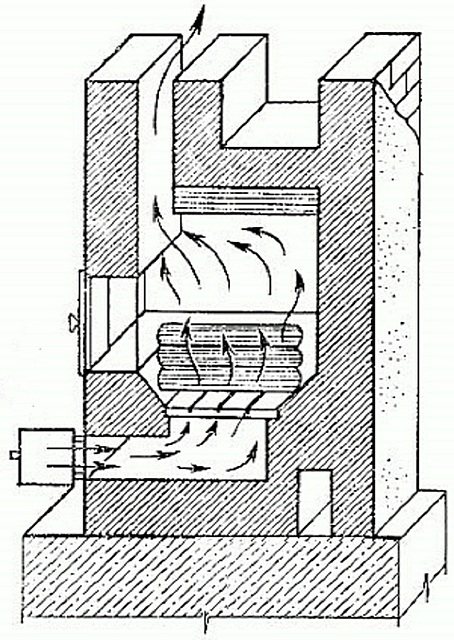

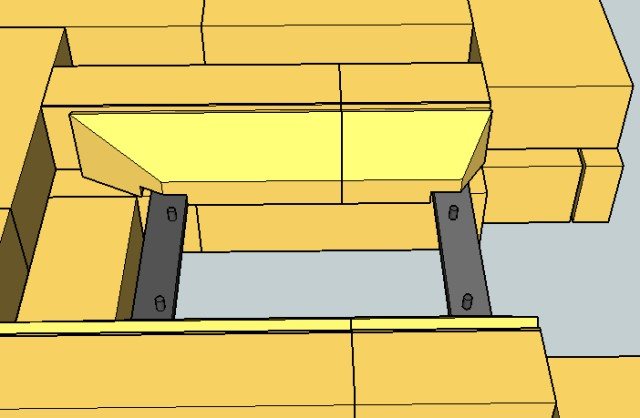

It is not so difficult to install grate bars on your own. Their location should be a brick thickness below the firebox door. This prevents burning fuel from falling out when the door is opened.

Further in the firebox, it is required to cut off the ledge, and install a grate in this place with the edges. It is imperative to maintain a temperature compensation gap of 0.5 centimeters on all sides. This gap is necessary so that the cast iron, expanding when heated, does not damage the masonry.

Installed grates in the oven

If a type-setting structure is installed, then the grate must be mounted with the wide side up. It is not recommended to close them tightly, so as not to fix them firmly. It is enough to fill the grooves with sand without cement. This will ensure both a good fit of the structure in place and unhindered expansion of the metal when heated.

Buying Tips

For high-quality combustion, not only the size of the grate is important, but also the weight of the fuel that it can withstand with one laying. The rods should not be deformed and worn out.

The grate must have a sufficient number of holes - at least 40% of the area of the part itself. If this figure is less, then there will not be enough oxygen to maintain the fire, and ash will remain on the grate and clog the stove.

If the gaps in the grate have a large area, then the remaining fuel will fall from the combustion chamber into the ash pan. Fuel consumption will become uneconomical.

Optimal lattice option

The main functions of the grate

The grate is a structural element of the furnace, most often made of high quality cast iron that can withstand high temperatures without compromising its integrity. It is installed at the bottom of the combustion chamber and serves as the basis for storing solid fuel. In furnaces of a classic layout, a stream of combustion air enters the fuel charge from below through the grate into the fuel charge.Ash, into which the fuel is converted during the combustion process, is poured into the ash pan through the gaps of the grate, freeing the combustion chamber for a new laying of firewood or coal. As it fills, the ash pan is cleared.

The principle of circulation of air flows through the ashtray (ash pan) and combustion chamber

In many ways, the efficiency of a heater or structure depends on the design of the grate. Its slots or holes (depending on the features of the model) must freely allow air flows regulated by the blower valve (door). Sometimes the special structure of the grille itself becomes a "regulator" of air blowing.

An important point is the correct installation of the grate in its seat, which is equipped for this in the lower part of the combustion chamber.

The grates are made not only of cast iron, but also of steel. But in heating households or appliances, the owners almost always give preference to cast iron.

What is needed for manufacturing?

It is possible to make a grate with your own hands. What to make a grate into an oven? It is better to use heat-resistant steel as a material, because it is impossible to work with cast iron at home. For the manufacture of the grate, you can use any materials that have heat-resistant characteristics. These can be fittings, angles, steel pipes or strips of metal.

To make grates you will need:

- metal from which the grill will be made,

- steel rods to create partitions;

- ruler, a tool for drawing marks;

- grinder to cut material;

- welding.

Which grate for the stove to choose and how to install it yourself

The design features of a modern furnace are constantly being modified and improved, new elements replace old ones. But a number of functional details remain unchanged attributes and it is simply unrealistic to do without them. These include grate bars for ovens.

This combustion element of a stove or fireplace, supporting firewood, coal and fuel briquettes, provides good traction. Ash falls through the holes, which allows you to free up space for a new fuel fill.

Cast iron grates of modern stoves can have different designs and are made of various materials, including a metal corner.

This element of the stove fittings ensures high-quality combustion and the maintenance of the flame at the time the stove is fired. When the first bookmark burns out, the residues fall into the ash pan, and the next layer goes directly to the grate, where better airflow is provided, which flows through the blower and the flame burns more intensely.

Thanks to the grates, wet fuel in the fireplace or stove dries out faster.

The design of this element with your own hands affects the efficiency of the furnace, and the materials used for manufacturing determine the service life.

It is correct to make the installation of the grate - to ensure the full performance of the assigned functions. Furnace casting determines how high-quality the heating of the home will be.

For the manufacture of grates, various materials and all kinds of designs can be used. In most cases, heat resistant steel or cast iron is used.

The furnace firebox can be of different sizes and shapes, which is why furnace casting manufacturers make all kinds of configurations. For a firebox with non-standard dimensions, you can also easily choose a suitable model.

note

Solid types include monolithic types without the possibility of disassembly. The choice of sizes is wide enough, so the area of the firebox is the main reference point. Several separate elements form the basis of typesetting models.

This is something like a constructor that you can assemble with your own hands and get the desired size of the lattice.

Currently, there are a large number of ovens of various designs. They may differ in how they work, in size and appearance.

Nevertheless, any stove always contains one required element - the grate. This device allows the resulting ash to pour out through the holes, leaving the fuel chamber in this way.

In this material, we will talk about how to properly install grates in the stove and how best to choose them.

Thanks to the furnace grates, a uniform and efficient combustion of solid fuel in the furnace is ensured. As it burns, the ash spills into the blower, and the top layer of fuel goes down below, where there is a fresh air supply for full combustion. Moreover, grate bars help to dry damp wood.

A grate for a fireplace or stove is usually made of heat-resistant steel or cast iron. Since this structural element is constantly subjected to thermal stress, a cast iron grate is still preferable - this is a stronger and more reliable material.

In different stoves, the furnaces may differ not only in size, but also in shape. In this regard, grate manufacturers produce a large assortment of products, so you can pick up grates for the firebox, even with a non-standard shape.

By structure, they are distinguished:

- Solid grates. In this case, a product is produced that cannot be disassembled into parts. They are produced in several standard sizes, so when selecting a product, you need to rely on the total area of the fuel chamber of the furnace.

- Type-setting grids are assembled from several parts. From such components, you can assemble a grate for a furnace of the desired shape and size.

If we talk about products made of heat-resistant steel, then there are pipe and chain varieties of grates.

As for cast iron grates, there are several types of them:

- Tiled. Such rectangular grates are widely used in solid fuel stoves and boilers, fireplaces. We can say that these are universal products. You just need to correctly select the size of the lattice.

- Basket. This type of grate was used in open hearths where food was prepared. Nowadays, they practically do not occur.

- Beam. Outwardly, such grates are like beams for construction. They are single or double typesetting parts, from which you can build a lattice of any size.

- Movable grates. The peculiarity of this design is that the lattice links can be moved in the horizontal plane, changing the gap between them. As a rule, such grates are used for long burning furnaces.

We select grate bars

Before installing the grates in the stove, you should decide on what kind of fuel you plan to heat it with.

If coal will be used, then a grate of 350 × 205 or 300 × 205 mm is needed, briquettes and firewood require grates with sizes from 140 × 120 mm to 330 × 252 mm.

Please note that the grate must be strong enough to support the maximum weight of one load of fuel. The strength characteristics should be checked at the point of sale.

Since all metals have the property of expanding under the influence of high temperatures, the grate should be laid with gaps on each side of at least 5 mm. To make the grates for the stove with your own hands as best as possible, it is worth cutting off a ledge in the fuel chamber - the edges of the grate will be laid on it.

If there is a lattice with triangular rods, it is laid down in triangles.

findings

So, before you install the grates in the oven, you should choose them correctly. Cast iron products are considered the best option - they are equally suitable for both brick and steel stoves.

During the selection process, pay attention to the size of the gaps between the rods and the area of the grate, as well as the type of fuel. Installing monolithic models is a little easier, but the type-setting ones can be selected individually according to the size of the firebox.

Do not forget about expansion gaps around the perimeter of the grille and do not overwrite it.

Provided that all the subtleties are observed, the installed grate will not need to be replaced for a long time.

It is quite possible to make a grate with your own hands in a home workshop. What is a stove grate, how best to make and install it - we will try to tell about all this in the article below.

The grate for the stove is part of a support platform in the form of a grate for storing solid fuel in the combustion chamber of the stove.

The lattice can be either solid, or it can be laid in a row of bars with gaps between them. The size of the grate depends on the size of the furnace.

We invite you to familiarize yourself with Quality sockets and switches

The material from which the grates for the furnace are made at the factory are cast iron and steel. Homemade structures are assembled from steel elements.

This important element of the furnace compartment of the furnace allows you to get the maximum effect from fuel combustion. The structure of modern furnaces is constantly changing and improving, and only the main structural element of the furnace remains unchanged. The combustion equipment retains its lattice configuration.

The site supports any type of solid fuel (firewood, coal and briquettes). Through the openings, air is sucked in from below, which creates an effective draft inside the combustion chamber.

note

Combustion products (ash) fall into the ash pan (blower), making room for the upper layer of fuel.

The grate promotes uniform combustion of the fuel, thereby maximizing the return of thermal energy from the placed fuel into the combustion chamber.

Types of grates

The material from which the grates for the furnace are made at the factory are cast iron and steel. Homemade structures are assembled from steel elements.

This combustion element of a stove or fireplace, supporting firewood, coal and fuel briquettes, provides good traction. Ash falls through the holes, which allows you to free up space for a new fuel fill.

Cast iron grates of modern stoves can have different designs and are made of various materials, including a metal corner.

Thanks to the grates, wet fuel in the fireplace or stove dries out faster.

The design of this element with your own hands affects the efficiency of the furnace, and the materials used for manufacturing determine the service life.

Correctly make the installation of the grate - to ensure the full performance of the assigned functions. Furnace casting determines how high-quality the heating of the home will be.

note

The fact is that grates are continuously exposed to fire and therefore it is better to choose cast iron. since it is distinguished by a large indicator of strength. There are two types of grate:

Solid types include monolithic types without the possibility of disassembly. The choice of sizes is wide enough, so the area of the firebox is the main reference point. Several separate elements form the basis of typesetting models. It's kind of like a constructor.

which you can assemble with your own hands and get the desired grid size.

Steel grates for a type-setting stove have the form of a belt conveyor and are called chain, and models with the possibility of cooling and made of pipes by hand are called pipe.

Cast iron grates can be of several types:

- tiled. Rectangular models used for solid fuel boilers, fireplaces and heating stoves. They are universal, the main thing is to determine the standard size;

- basket. Ideal for an open hearth.The main purpose is cooking, but today they are used extremely rarely, since the design is outdated in moral terms;

- beam. These models owe their name to the similarity with construction beams. They look like a type-setting structure and consist of double or single elements. The optimal solution if you need to assemble a non-standard grate;

- movable. Such grilles have a design feature. allowing you to change the width of the gaps, which is often not enough during installation. In most cases they are used in long burning ovens.

Tiled lattice

How to make grates for the oven with your own hands?

From reinforcement

It is not difficult to make a grate from fittings yourself. It is enough to choose the desired length of the product and cut the reinforcement with a grinder. It is necessary to determine the number of strips and take into account the ventilation gaps.

When the required amount of material has been prepared, you can start welding the grate with rods. Do-it-yourself grates for a furnace from fittings can be seen in the photo below:

Video instruction:

From the corner

It is even easier to make a grate for a furnace with your own hands from a corner than from fittings. To do this, it is enough to weld together two corners of the required dimensions: one side is equal to the width of the product, the second to the length. As a result, you will get a rectangular base of the future part. The lattice can be made from reinforcing rods or thick mesh.

Video instruction:

Furnace grate dimensions

The dimensions of the cast iron grates for the stove depend on the types of fuel. Possible sizes are shown in the table.

| Firewood | Coal |

| 330 * 252mm | 350 * 205mm |

| 300 * 252mm | 300 * 205mm |

| 250 * 252mm | |

| 250 * 180mm | |

| 140 * 180mm | |

| 120 * 140mm |

If it is necessary to install beam grids, remember that the length is 250, 330 and 470 mm.

How to install grate bars in the oven with your own hands?

It is not necessary to call the foreman to install the grate in the oven. You can do this yourself, spending very little time and effort on this process.

Installing a grate in a brick oven has its own characteristics:

- You need to understand that metal tends to expand. Therefore, you need to make gaps of at least half a centimeter along all edges of the product.

- The grate should be placed slightly lower (about one brick) from the firebox door. This will prevent heat from escaping from the oven.

Stage 1

Stage 2

Stage 3

- Do not place the grates too tightly in the oven. This can lead to deformation and cracks when the metal is heated.

- The gap between the grate and the stove is filled with sand. It is important not to use cement admixtures, because the part should not be tightly held.

Does it matter which side of the grate is placed in the oven? Yes, when the bars of the lattice are triangular or any other protruding shape, then the top should be directed downward.

Examples of installation in a brick oven:

Example 2

Example 3

Example 4

Example 5

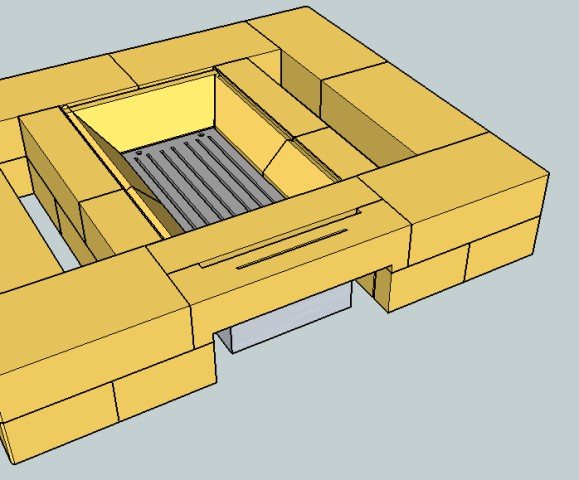

Ash pan (blower) for the oven

Any fuel, be it coal, peat or wood, does not burn without residue. Some of the combustion products in the form of smoke, soot and soot are removed through the chimney. The rest remains in the combustion chamber. These are ash and ash.

Photo: Ash pan (blown)

Purpose of the blower

For a stove to produce good heat, excellent draft is necessary. The clogging of the furnace with ash prevents this, the air does not flow to the fire. Especially a lot of ash is formed when burning firewood from soft tree species. Therefore, the design of the furnace has always been provided blew, in other words, ash pan... This is a small chamber with doors under the grate of the firebox. The ash pan is often equipped with a metal pallet. Ash from the firebox enters the ashtray through the grate. Air flows through the grate to the fire, thereby ensuring efficient fuel combustion. And then it comes out with smoke through the chimney.

Blower door

Most often, the blower is made with doors, although they may not be there. To increase the air flow, you need to open the door. You can reduce the intensity of the fire by closing the door. In the absence of doors, you can increase traction by pulling out the drawer. In blowers without doors to avoid spilling ash and ash outward, underneath should be inclined.

Photo: Ash pan design

Ash pan design

Ash pan of the furnace (a) and retractable ash pan bunker (b): 1 - under; 2 - lattice; 3 - door; 4 - ramp; 5 - bunker

Blower (ash pan) size

Just as there are no absolutely identical stoves or fireplaces, there cannot be a generally accepted uniform size of the blower. The basic rule is that the ash pan must be the same size as the grate. With a smaller size, most of the ash will remain on the grate and will not allow air to flow to the fire. If the ash pan for the furnace does not have doors, then it is necessary to install a drawer or tray. The size of such a device is determined as follows. The width of the tray should correspond to the distance from the wall to the wall of the blower. Length - exceed the firebox, because for good traction, you will have to extend the device. And the ash in this case will wake up, accumulating at the back wall. Most manufacturers of metal fireboxes have taken into account the presence of blowers in their products.

Photo: Material for the ash pan

Ash pan material

The close location of the ash pan to the fire dictates the requirements for the material for its manufacture. Metal devices withstand high heat well. The most optimal option is steel with a thickness of 0.8 mm. For ash pans with doors, a drawer is optional. The ash pan is laid out of the same brick as the oven itself. Refractory is preferred.

How to clean a stove blower

Although a drawer or tray in the ash pan is optional, it is most convenient for cleaning. It is enough just to remove it and pour the accumulated ash. If there is no such device, then cleaning will take a little longer. Wait for the ash to cool completely and start cleaning. You will need a brush, scoop, bucket. To cope with a more thorough cleaning of the firebox from dust, ash and ash, you can use a special vacuum cleaner for fireplaces.

Fireplace ash pan

Photo: Ash pan for the fireplace

Whether the fireplace should have a blower - opinions differ on this point. It is believed that since the original fireplaces were without blowers, then today there is no need for them. The ash can be simply swept off the surface. And to increase traction, purchase a special metal basket for firewood with legs. A small distance from the surface of the firebox will ensure good air flow. However, today there are designs for every taste. There are models of fireplaces in which the ash pan is located directly under the grate. Removal of incombustible residues is carried out after the hearth has completely cooled down. Owners of fireplaces with doors can choose a model equipped with a blower. Such devices will provide good fire, safety during combustion and at the same time excellent traction.

In order for the stove to please with high heat, even humming of the firebox, it is necessary to provide good draft in blower... Regularly keep it clean, remove the ash - and you will get an excellent work of the hearth.

Price policy

A quality product cannot have a low cost. High-quality cast iron parts that will last more than one year are expensive. Conversely, lightweight and cheap, made from a mixture of unknown materials, will quickly deteriorate.

Approximate prices for grates for the oven:

| The size | The cost |

| 800x200 mm | 1200-1600 rub. |

| 915x250 mm | 1100-3000 rub. |

| 260x540 mm | 400-500 rub. |

It is better to buy these products in specialized stores. They provide a wide selection of models in different materials and price ranges. The consultants will help you make the right choice based on your preferences, the nature of the fuel, the frequency of operation of the heater.

Output

When choosing a high-quality grate, one should take into account the design features of the stove. The choice of a specific design and lattice components depends on the nature of the fuel. A grate for a cast iron sauna stove will last longer than the same one made of steel or other metals.

Also of great importance is the weight of the fuel itself. Installation of grilles does not require any special knowledge. You can put the grates in the oven correctly on your own; it is enough to take into account only a few nuances. With the right choice of material and installation, they will serve you for a very long time.

What are the functions of grate bars for ovens

This element of the stove accessories allows you to achieve high-quality fuel combustion and maintain it while the stove is fired.

When one portion of firewood or coal burns out, the ash is poured, and the upper layer of fuel is shifted to the grate, where it is better blown by the air coming from the ash pan and burns more intensely. Thanks to the presence of grates, the task of drying wet fuel is simplified.

The efficiency of the furnace depends on the design of the elements, and durability depends on the material from which they are made. It is also important to correctly install the grill so that it fully performs its functions.

For the manufacture of furnace accessories, cast iron and heat-resistant steel are most often used. The grates are constantly exposed to the flame, therefore it is better to give preference to cast iron, because it is more durable.

Furnace furnaces vary in size, come in different shapes, so manufacturers make furnace casting of all possible configurations. You can also find a suitable model for non-standard fireboxes. The grates can be:

- Whole. Monolithic models that cannot be disassembled. There are various standard sizes, when choosing one should be guided by the area of the furnace.

- Typesetting. Consist of separate elements. This is a kind of "constructor" that you can assemble yourself and get a lattice of the desired size.

Steel grates are made chain (resemble belt conveyors) or pipe (cooled models made of pipes).

Cast iron are of several types:

- Tiled. These are rectangular models that are installed in solid fuel boilers, heating stoves, fireplaces. They are universal, the main thing is to choose the right size.

- Basket. A good option for open hearths intended for cooking, but since they are practically not used, the design is obsolete.

- Beam. They got their name because of the external resemblance to building beams. These are type-setting structures consisting of single or double elements. Well suited for the assembly of non-standard grates.

- Movable grates. They are called movable because of the design features that allow you to change the size of the gaps. Grids of this type are most often chosen for long burning ovens.

Movable grate design. Element number 1 - thrust, 2 - horizontal axis of rotation, 3 - lattice itself.

When choosing a specific model, consider the type of fuel you will be using. For example, for coal, a design of 350 or 30x205 mm is suitable, and for firewood and briquettes - from 140x120 mm to 330x252 mm.

The grate must be taken in such a way that the rods withstand the maximum possible weight of one portion of fuel. You can find out how much a particular model can withstand from the seller.

If in doubt, consult a specialist.

In order for the grill to be well cleaned of ash, the gaps should occupy at least 40% of the area of the entire structure. If there are fewer of them, the firebox will work less efficiently, because the amount of air supplied is not enough for intensive combustion. Gases can accumulate if ventilation is insufficient. If the area of the gaps is larger, then unburned fuel will be poured into the gaps along with the ash.

Metals expand when heated, so the grate should be installed with a minimum clearance of 5 mm on all sides. In the firebox, you need to cut off the ledge on which the lattice is laid with the edges. In a brick oven, the location is usually chosen one brick below the firebox door. This is to prevent burning coals from falling to the floor.

During installation, it is undesirable to embed the grates tightly. Different materials expand to varying degrees when heated, so too strong fixed fixation of a metal element can result in metal deformation or cracks in the masonry. Having laid the grating, the grooves are tightly filled with sand without cement.

Note! If the cross-section of the lattice rods is triangular, then it should be laid with triangles down.

Summing up

- The best material for grates is cast iron. It is reliable and durable, and can be installed in brick and even steel ovens.

- When choosing a grate, the weight of the fuel and the area of the clearances must be taken into account. Monolithic models are easier to install, and stacked models are well suited for assembling non-standard gratings.

- When installing, be sure to leave gaps for metal expansion and do not fill the grooves with cement.

If you take into account all these nuances, the new grate will last for decades, and you will not need to think about replacing it.