Installation of a ball valve on risers

Shut-off valves are used in almost any residential and industrial premises. The installation of a ball valve can be carried out in a car stove, on water pipes and other outlets, where it is necessary to control the flow of water.

Principle of operation

A ball valve is a shut-off valve where a metal or rubber ball acts as a shutter. It is connected to a lever or a special device that controls its position (reducer, pneumatic or electric drive). The ball has a hole, which must be the same size as the diameter of the connected pipe. When you turn and open the device, these holes coincide and water begins to flow. If you turn the lever in the other direction, the flow stops.

In apartments, houses and utility rooms, a lever mechanism is used, but to control the operation of the device on large-diameter outlets, it is necessary to use drives. The main advantage of this mechanism is that you can control hot and cold water with one handle.

Sometimes ball valves are even installed in the stove of a VAZ car to control the antifreeze fluid. But this is not the best way out - dust and dirt are clogged under the ball, which significantly reduces its service life.

Types of ball valves :

- Flanged. They are mounted on large-diameter communications. A distinctive feature is the presence of an additional sealing element near the locking ball, which ensures the maximum level of sealing. Therefore, they can be used for pumping gas and oil products, heaters and installed on heat converters;

Photo # 8212; flanged

- Fitting. The most common. They can be dismantled many times, the locking mechanism can be either static or smooth installation type;

Photo # 8212; choke design - Welded. It is installed only once, it is used in main water pipelines, in conditions of increased head pressure and if a well-free installation is needed.

According to the material of the case, there are polyethylene and metal (copper, stainless, steel). The former are necessary in special working conditions, for example, where the pressure exceeds 10 bar.

Installation

Correct installation of the ball valve can be easily done by hand. Consider several options for mounting the device.

Pipe mounting:

- First, you need to drain the water from the entire system. To do this, turn off the water supply and open the valves;

- Before starting work, you need to select a device. You can buy ball valves with a double-sided external or internal thread, models where on one side the connection is American, and on the other - a thread, etc. In addition, please note that the size of the valve opening must necessarily coincide with the diameter of the communication;

- At the installation site of the future water supply tee, the pipe must be cut and prepared.

Output

Connecting the washing machine to the water supply can be done in different ways, but in any case, you need to use a special tap. With its help, it is possible to easily turn off the water after stopping the wash, which is definitely recommended by the manufacturers, otherwise additional pressure is created on the valve of the appliance.

The valve is installed independently in any place suitable for this. The video in this article will provide an opportunity to find additional information on the above topic.

Did you like the article? Subscribe to our channel Yandex.Zen

Cold and hot water. Which side?

Depending on the type, a thread is cut on it or the outlet is simply cleaned of dirt and dust (when dismantling the old fittings);

When the winding is over, you need to additionally check the connection point and turn on the water supply. If water has flowed from the lower section of the tap, then it must be removed and the oil seal checked (some unscrupulous manufacturers sell devices without them at all). In some cases, you have to install it yourself or additionally seal it with flax rope or special fillers.

Installation tips choke ball valve:

- If the thread comes in very easily, then wind up some more sealing tape. With a sufficient amount of "fum", the fittings should be screwed in with little effort;

- The liquid seal is only used for devices with a diameter of less than 5 centimeters, for example, sink or sink outlets;

- The tape winding scheme is very simple - you need to wind it in the same direction as the thread is screwed in;

- Do not push hard when screwing on the tap - the tap may burst.

Installation of the flanged model is carried out in the same way, the only difference is in the larger diameter of the branch and the size of the valve. It is worth remembering that in flange models it is recommended to use additional rubber seals at the junction of the lock and the pipe.

How to install a welded faucet

On the one hand, this installation process is much easier than a threaded one - you do not need to cut the thread and process it with seals. Instructions on how to install an angle welded ball valve:

- The section on the pipe is measured where the installation will be made. A certain section is removed, the section is cleaned and degreased;

- The crane is installed and centered. For this, you can use both improvised means and special devices. For example, you can use metal reinforcement or a clamp with a wide bow. After the welding machine is warmed up;

- Depending on the material from which the pipe is made, additional couplings may be required. They are put on the pipe, a crane is installed in them and welding is performed;

- After finishing work, you cannot turn the tap and turn on the water for some time - it must first cool down. If dismantling is necessary, the pipe is simply cut, a crane is taken out of it, and another is welded or screwed in its place.

Photo # 8212; steel welded

This type of connection is useful for underground piping, under carpet or heating installations. The price of a welded ball valve is slightly higher than a choke valve, therefore, using it, the total estimate will be slightly less than when working with threaded connections.

Check out articles on similar topics:

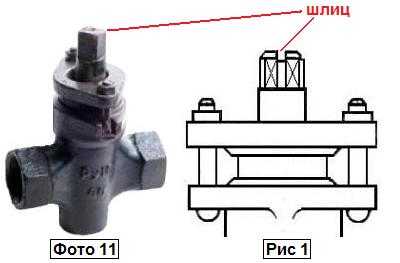

… Plug valve

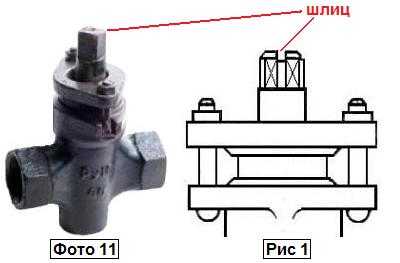

Someone else has plug valves on old various pipeline systems or gas lines. An especially relevant question is in what position the open or closed plug valve should be in the absence of any handle on it (Photo 11).So, usually a slot (risk) is made on top of the end of the stem (plug) during manufacturing, to visually determine the through hole in the plug (Fig. 1).

As in the case of ball valves, if the slot in the position across (perpendicular) to the plug valve is closed, the slot along (parallel) is open.

Similar articles:

- Mayevsky crane

Ball valve installation

In this article I will tell you how to properly install a ball valve on water supply and heating pipes, but first I will tell you a little about the pros and cons of ball valves. At the moment, such valves are the most common, popular, and very practical and convenient, their undoubted advantage over the old-style taps is that there is no need to change the gaskets, since they have a different device and principle of operation. There is a ball inside the tap, in one position it is open, and when turned 90 degrees, the water shuts off, but there are big disadvantages to ball valves: With poor water, the ball can become slagged, and if you do not turn it for a year, especially in hot water, then close it it becomes very difficult, and sometimes impossible, so you need to turn it at least once every 2 months in order to bring down salt deposits.

If rusty water comes from the tap, then when opening and closing, scale or sand can damage the surface of the ball, and then the tap will pickle in the closed position. On ball valves of average quality, with frequent opening and closing (most often found in hot water and heating), it starts to flow from under the oil seal, of course it can be tightened, but in many cases the nut that tightens the oil seal rotates with the lever and continues to drip, and some taps do not have an oil seal at all and if it leaks, you can only throw it away and install a new one. And one more minus, you cannot install a ball valve in a room where the temperature may be less than 0 degrees in winter, when the water freezes, it breaks.

How to install a ball valve on a pipe

When installing a ball valve on a pipe, you must:

1. If you are replacing the valve, then you need to remove the old one, clean the thread from flax, and try to screw on the valve. More than once I have met with the fact that when removing the old valve, 2-3 turns rot, in which case it is necessary to cut the thread. The valve must be screwed onto the pipe at least 4 turns!

2. If, when dismantling the old valve, the thread remains in good condition, but during installation the valve is screwed in less than 4 turns, be sure to drive the thread with a die!

3. Check, without flax, the tap turns on 4-5 turns, wind up flax. and twist 4-5 turns.

4. If you are installing a water supply system or heating, then first measure exactly where the ball valve will be installed, cut it off in the right place, cut the thread on the pipe, and wind it 4-5 turns.

And as usual, a few tips, if you have a centralized heating supply, and the system has high pressure, use Bugatti ball valves, they have proven themselves very well, do not install valves on which there is no oil seal, if it starts to leak, then you will not be able to fix it before replacing the tap.

Ball valves are with internal threads on both sides, internal - external, external - external, and internal on one side, and American on the other, so calculate and buy those that are needed for further connection of water supply or heating.

Watch the video, installation, installation of a ball valve, and how to thread a pipe.

What to do with a jammed ball valve

If ball valves are not rotated for years, then they tend to sour and seize. In such a situation, do not try to resolve the issue physically and do not force the butterfly with pliers or a gas wrench. It is made of a brittle alloy and is likely to break. Proceed like this:

- Unscrew the retaining nut and remove the butterfly handle from the stem.

- Most of these valves will have a nut under the handle that secures the plastic gland. Loosen it by turning the key half a turn. If there is no nut, go to the next step.

- Take an adjustable wrench or other device that allows you to securely grip the flats on the stem. Rotate it as far as possible without making much effort.

- When you feel resistance, turn the stem back until it stops and again forward, trying to turn it a few more degrees. Work carefully and without haste!

- Adjust the valve to rotate 90 ° in this way, then tighten the gland nut and refit the handle.

Adjustable wrench allows you to grasp the edges tightly

Advice. If you find WD-40 aerosol lubricant in your household, apply it to the stem and wait 5-10 minutes before rotating.

Be doubly careful when shutting off the batteries with sour taps during the heating season. If you rush too much and apply a lot of force, you will break off a metal rod or ball, and in the worst case, the valve body will burst. A jet of hot water may hit from the crack and burn you. While you go down to the basement and close the heating riser, the coolant will damage the interior of the room, and you can roughly guess how much it costs now to renovate the apartment.

If you are not sure of your actions, call the plumbers. For more information on how to close a jammed ball valve in order to disconnect the heating batteries, see the video:

Correct installation of ball valves. Tips.

Install, replace # 171; ball # 187; crane in this there is nothing complicated. Anyone can replace him. Ball valves got their name due to the fact that a ball is installed inside it that blocks the pipeline through which the working medium moves. Ball valves are simple and reliable to use, thanks to this they have gained popularity.

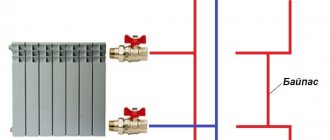

The main thing is to choose the right one for you. Their sizes are standard and are measured in inches. the design is simple. The body consists of two parts, connected by a thread, inside # 171; ball # 187; with a through hole, stem, oil seal, handle. The most popular, so to speak, at home are the sizes: 1/2 # 8242 ;, 3/4 # 8242 ;, 1 # 8242; there are more. Before buying, I advise you to find out the country of the manufacturer. It is advisable to buy Italian, Spanish cranes. They are of higher quality and stronger. Chinese, although visually they cannot be distinguished visually, but you can pick them up by weight, the Chinese will be much lighter than the European ones. You need to install the tap correctly. If it is not installed correctly and breaks down during operation, you can get a leak. As indicated above, the body consists of two parts, one of the sides is molded in one piece and the other part is its nut, which is screwed along the thread to one another. The one-piece cast part of the valve must be screwed to the pipeline that comes out of the riser. In this case, if the valve breaks in half under the influence of different conditions, you will have the opportunity to quickly shut it off because the ball itself inside will remain on the one-piece cast part of the valve. Otherwise, a ball will fly out and one nut will remain on the pipeline. Cranes are afraid of frost. If your taps are installed somewhere on the street. Let's say on a watering pipeline. For the winter, naturally, the water is drained and it is better to leave the tap in the open position. Since water can collect somewhere, the remains will not all go away and the tap will simply burst.

We recommend:

No comments yet!

21.07.2014

Shut-off valves on water pipes - an inattentive attitude to this thing can cost you a significant amount.

Just imagine: a tap on a cold water supply pipe breaks down. Obviously, there is a fountain in the apartment. And if you are on vacation, then the fountain quickly turns into a lake and all this flows to the neighbors below. And if they are also on vacation / at work or something? Another floor below. And so on.You can figure out the financial side of this case yourself.

The tap is where the leak is most likely to occur. The pipes are welded securely. If not, it will be noticeable immediately, but problems with the crane accumulate gradually. So let's try to figure out which of them is more reliable in operation.

Ball or valve?

For an apartment, only these two options are possible. Available at any plumbing store, there is an assortment for pipes of different diameters. We look at the pros and cons of each.

Valve

The main plus is maintainability. And this is the main disadvantage. Such a crane is a little more complicated both in the device and in operation. It needs to be twisted and unscrewed, often you don't want to bother with this, and besides, the gaskets and seals wear out regularly, the oil seal begins to leak. We changed the gasket - for the time being, everything is fine again.

The valve can be used as a shut-off and control valve. Ball only shut-off. This is an iron rule - the ball valve has only two positions: open and closed.

Ball

Easier in design and operation. They turned the flag - and it's done. There are compact flags (butterflies). They are convenient in that they do not take up extra space (the butterfly does not protrude beyond the dimensions of the pipe).

And in which direction do your taps open and close?

But it is inconvenient to open taps on large-diameter pipes with a butterfly. It is better to take here with a flag-handle.

Due to the simplicity of the design, the durability of the ball valve is higher. With the same (and sufficiently large) number of closing / opening cycles, the valve will flow much earlier. But! At home, you are unlikely to open them as often. This is not a kitchen faucet. And this is where the main problem of ball valves opens up.

The ball turns sour during operation. And then it is not so easy to block it. Therefore, it is impossible to leave the ball valve in a half-open state. The harder the water, the faster the mirror of the ball will "grow". As a preventive measure, you can periodically (every two to three months) open and close the tap, thus removing scale. The only question is not to be lazy.

Well, and most importantly, it is impossible to repair the ball valve. Complete replacement only. In contrast to the valve.

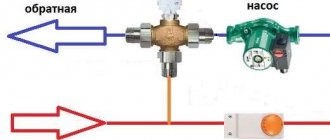

In what order is it necessary to open and close the cocks (valves) in the batteries?

The battery has two taps. They say that if you close them in the wrong order, there may be water hammer.

For the heat to enter, first of all, it is necessary to bleed the air from the radiator, therefore, first of all, we open the Mayevsky tap (drain) and free up space for further steam (water) intake.

As soon as the air is deflated, open the main tap (at the inlet) and wait for the batteries to warm up. Water hammer is a real phenomenon, but it happens very rarely in apartments, therefore, in order to avoid an accident, you must follow simple instructions.

- When starting the heating radiator, you must first bleed the air from the battery.

- Therefore, first we open the air valve, then the tap to open.

- After water flows from the battery through the air valve, this will mean that the air has been deflated.

- We open both taps for the whole, the system will start working (water circulate).

Comments (1)

comments powered by HyperComments

Igor Kulbeda

So that the ball does not turn sour every time you turn it when you check the meter readings.

Ball valve - This is a shut-off device for shutting off (cutting off) the supply of the working medium transported in the pipeline under pressure with a quarter-turn working stroke.

Correct installation and proper operation of the ball valve will extend its service life and ensure reliable and safe operation of pipelines.

Example of the construction of a brass ball valve STC.

1. Body - hot-pressed nickel-plated brass CW617N + Ni; 2.

Which way to turn the tap on the battery.

Shutter ball - chrome-plated hot-pressed brass CW617N + Cr; 3. Seat rings - Teflon (polytetrafluoroethylene) with the addition of carbon and silicon-based thermal additives P.T.F.E. + C + EM; 4. Stem - hot-pressed brass CW617N; 5. Stuffing box seal - Teflon (polytetrafluoroethylene) with the addition of carbon and silicon-based thermal additives P.T.F.E. + C + EM; 6. O-rings - EPDM rubber (ethylpropylene rubber); 7. Support washer - Teflon (polytetrafluoroethylene) with carbon and silicon-based thermal additives P.T.F.E. + C + EM; 8. Gland bush - hot-pressed brass CW617N; 9. Handle fastening nut - hot-pressed brass CW617N or galvanized (chrome-plated) steel; 10. Handle - galvanized steel with PVC coating Steel + Zn with PVC. Ball valve closes by turning the knob clockwise 90 degrees, Opens by turning 90 degrees counterclockwise. The parallel position of the lever to the axis of the valve indicates that it is open, and the perpendicular position of the handle to the axis of the valve indicates that it is closed.

Installation of a brass ball valve.

An employee with sufficient qualifications may be allowed to install (operate) the shut-off valves.Before installation valve to check its compliance with the documentation for the pipeline. Install the valves only after preliminary cleaning the internal parts of the pipeline. Prepare the valve for installation in the following way: - remove the plugs present on the valve and pipeline; - check the cleanliness of the internal and connecting surfaces of the valve and the pipeline; - remove the preservative grease from the valve (if any). the valve on the pipe, it should be held with a wrench by the octagon (hexagon) of the body from the side of the screwed-in pipe. From the opposite side, it is strictly forbidden to hold and screw the pipe or screw the valve onto the pipeline. The same procedure for dismantling. If this rule is not observed, the threaded connection holding both parts of the valve body may loosen or turn, which will lead to the loss of the valve tightness and will require replacement.

| WRONG | RIGHT |

During installation, it is allowed to use a tool corresponding to the dimensions of the pipe and valve, it is not allowed to use a pipe (gas) wrench. It is forbidden to lengthen the keys or use additional levers. The valve and the pipeline during installation must be coaxial, It is forbidden to install the valve with forced pulling on the pipe or pull the pipe to the valve.

The valve can be installed together with the pipe in any position convenient for the consumer, which in the future will be able to provide maximum ease of use and quick access to the valve. The threaded connection of the valve and the pipe must be sealed using winding or sealants used in hydraulic systems (FUM, flax fiber, sealant etc.). The most effective thread sealing with FUM tape, because PTFE ensures tightness of the connection (up to 10 MPa and T = 180 ° C), easy screwing on and easy dismantling, PTFE is highly resistant to most aggressive substances, excess FUM is easily squeezed out when tightening the thread. ... this can lead to damage to the valve body. Manufacturers recommend: the maximum tightening torque of the thread of the coupling brass valves DN 15 (DN 15) - no more than 10 Nm, DN 20 (DN 20) - no more than 15 Nm, DN 25 (DN 25) - no more than 20 Nm. The thread at the end of the pipe should not be longer than the thread in the valve, so that after tightening the threaded connection, the end of the pipe does not rest against the O-rings, which can damage the valve.

| WRONG | RIGHT |

The valve is not intended to be subjected to an external mechanical load. During the installation of pipelines, a pipe fastening structure must be provided that completely excludes the possibility of external mechanical impact on the ball valve, including axial, radial or torsional loads.

| WRONG | RIGHT |

Operation of a brass ball valve.

It must be remembered that the ball valve is designed to quickly shut off the flow inside the pipeline. The valve can be opened and closed only by the handle installed by the factory., using a tool or extending the handle is strictly prohibited.The design of the brass ball valve is not intended to regulate the flow of the pumped medium and the valve can only have two operating positions, i.e. it must be completely open or completely closed... In intermediate positions, due to the fast flow of the pumped medium, the O-rings may be deformed or damaged, which in the future will render the valve completely unusable and will require replacement. To carry out the necessary adjustments, we recommend installing a regulating device after the ball valve that corresponds to the characteristics of the pumped medium. It is not allowed to use the valve for media with contamination that can cause mechanical damage to the valve gaskets. Most manufacturers of brass ball valves prohibit their repair. Manufacturers recommend: - if the rotary handle is weakly attached to the stem, tighten the nut (screw) of the handle; - in case of leakage of the stuffing box packing of the stem, slightly tighten the stuffing box nut located under the handle of the valve. Other repairs to ball valves are prohibited by the manufacturers.

How to tell if a ball valve is open or closed?

A ball valve of an unidentified model is installed in front of the valve with milling of the neck stem, made in the form of a square for a wrench. Close the tap to shut off the system.

The task is complicated by the following factors: 1) there is no handle on the valve (in most cases, if the handle is parallel to the axis of the pipeline section on which the ball valve is installed, then the valve is in the open position, if the handle is perpendicular to the pipeline axis, then the valve is closed); 2) there is no milled line on the ball valve stem that allows you to determine the state of the ball plug; 3) there is no ball valve rotation limiter.

| If the ball valve had a restrictor, the following actions could be taken by personnel to accomplish this task before removing the control valve cover: - turn the valve clockwise, and then, if the ball valve was in the open state, then the ball plug will block the movement of the working medium and this will allow successful revision work, or the travel stop will not allow this operation to be carried out and the valve will be identified as closed; - turn the valve counterclockwise, and then, if the ball valve was open, it will be identified as open, or, if it was closed, the ball valve will open, after which the personnel will need to close it. |

From the point of view of quantum mechanics, the ball valve is in a state of uncertainty - it is open with a probability of 50% and closed with a probability of 50%. Before the cover of the control valve is removed, it will be in both states at once.

Written by Alexander Osipov to cheer up (2016)

We are all accustomed to the appearance of the radiator - these are sections and a faucet on the side. And every time adults and parents scold children when they touch him. It is quite a common sight, but not everyone knows why this "tap" is needed.

The crane is attached to the radiator for a reason. This armature has its own purpose and more than one.

How to turn off the water yourself?

So, for some reason, you needed to turn off the cold or hot water supply, or both.

For these purposes, shut-off valves (faucet, valve, gate valve) are provided. It is installed directly at the water supply inlet in an apartment, house, or other living space. But since the maintenance of the highway is completely and completely carried out by specialized organizations, in which there are enough locksmiths even without me, I will not grovel deeply in this matter, but I will only touch the area of the apartment and the valves installed in the basement of an apartment building that cut off the water supply to the risers. And what to do if they are not working properly.Let's say your plumbing equipment has a malfunction (leakage along the thread, does not hold the toilet tank, the hose to the mixer has burst or the mixer does not completely block the water, or it buzzes, etc.), before you do something, you must completely turn off the water supply to the system and only after to do the job.

I strongly advise against doing anything under pressure.

Except in cases of emergency.

bronze valve

First of all, we close the taps at the input, they should be installed in every apartment, if you have never paid attention to this and do not know if they exist, then look at the water pipes from the risers (risers are pipes passing through your floor from the bottom up), to the nearest water outlet on your comb (the comb is water pipes located horizontally across your apartment and supplying water to all devices). It is in this place that the taps should be installed, they are installed during the installation of the water supply system for emergency shutdown, if necessary.

Close them by rotating the "lamb" clockwise. After that, check on the mixer if the water is shut off. If yes, then feel free to do what you needed.

But it doesn't always go so smoothly.

Often, in old houses, and in new ones, it happens that the taps are not kept. The reason for this may be a cracked rubber gasket if a valve is installed, or "overgrown" inside with rust if a ball valve is installed. And if the valve is cast iron, then the stem itself is not possible to move from its place, also due to rust. There is also such a case that shut-off valves are not provided on the comb at all.

A little off topic, but I think this knowledge will not hurt, so I will dwell on this issue in more detail:

No matter what material the valve is made of, it consists of a body and an axle box valve.

cast iron valve

Most often, its malfunction lies in the absence of a gasket, or it is cracked, torn. But it happens that the "mirror" has scratches, or shells or pores there. "Mirror" is a surface located inside the body, against which a rubber gasket is pressed against clockwise rotation of the axle-box valve stem. So if there is no way to shut off the water supply on the comb, that is, he closed the taps, but it still flows from the mixer, or there are no taps at all, then it is necessary to shut off the water already in the basement, to your riser, there are also installed either valves or taps. You close them and revise yours on the comb.

You unscrew the valve on the axle box and change the gasket, or all of it, if it is not working. Details of this process can be found in the valve repair article (video tutorial).

And do not forget to inspect the "mirror" for damage.

In the absence of shut-off valves in the apartment, I strongly recommend installing.

Here you can read which cranes are reliable in operation. In apartment buildings it is problematic to get into the basement, for some time now only a locksmith serving ZhKO has access there, this is due to preventive measures against a terrorist attack, and homeless people so as not to climb. So, if the basement is closed, then you will have to contact the PRUE at the place of residence. Keep in mind that in order for them to turn off the water, you will have to pay a certain amount to the cashier, or you can negotiate directly with a locksmith. The water will be closed and opened at the agreed time.

If this option does not suit you and you have access to the basement, then read on.

In the basement, you can face the same problem - the water does not close. They blocked the fittings on the risers, but from the mixer, all the same pressure. I mean a strong pressure.

You need to make sure that these risers are yours.

Wiring in basements can be "tricky", and it is not always easy to establish what kind of water is supplied to your apartment.There is a very simple, but effective way, ask in the apartment to evenly tap on one of the risers and be guided by the sound in the basement. But here I will draw your attention: tapping only light so that the water supply does not clog, the pipes are abundantly covered with rust from the inside, with strong blows which, breaking off, can easily lead to clogging of the valve, or the mixer, or the toilet bowl, and these are additional "headaches". If the water leaks slightly from the faucet, and there are dumpers in the basement, you can also use a small trickle of water while working in the apartment, leave it to drain into the basement, this is absolutely harmless and is often used by the locksmiths themselves. But again, if only the trickle is not large. Everything, you can go up to the apartment and do the intended work.

Let's consider one more option:

You are sure that the risers are yours, and the water is not blocked. This means that the fittings on the risers are faulty. In this case, it is necessary to close the water supply valve to the house, after that, as soon as possible, revise the valves on the risers and open the water to the house. Then do your work in the apartment.

In that order.

That is, for the revision of the fittings on the risers, you must have everything prepared, only after that you close it at home. Otherwise, you cannot avoid troubles. This is due to the fact that in the absence of water, residents immediately call the PRUE and scandal, you can not even imagine how quickly this happens. Well, for the unauthorized shutdown of the water supply to an apartment building, I assure you, you will not be patted on the head. For this, rather serious sanctions are provided.

Okay, nothing scares you, and everything is at hand for revising the valves on the risers. We read further.

We close the central valve.

cast iron valve

When twisting its stem clockwise, you will understand that the water is closing by the subsiding noise in the pipe.

Now attention:

It happens very often that it seems to be twisted to the end, and the water in the pipe is noisy, tighten the steering wheel of the valve with a gas wrench. It also makes noise. Unscrew back and close again.

You may have to perform this action up to four to five times. This is due to the fact that there is a build-up of rust on the mirror of the valve. And if you open it several times, you close it, it will rip it off, and as a result the water will be closed. If this did not help, and there is a noise of water in the pipe, then the last option remains: tighten the stem, tap on it from above with the same gas wrench, open and close again. Everything. Now the water should be cut off, but if all the above actions did not help you, then one way is to submit an application to the PRUE to turn off the water. The locksmith will come and inspect, or they will replace the valve on the house. There is, of course, another option, but it is not for the amateur. Here it will be necessary to shut off the fittings either for several houses or for a quarter. But it's better not to get in here.

And the last very important point, ATTENTION:

I closed the water, did the job, turn on the water in two stages. You open the armature slightly, hear the noise of the filling system, wait for it to stop, then open it completely.

You do this to prevent clogging of the system. With a sharp opening, there is a high probability that the pipes inside will become clogged with torn off scale, and that the valve on the comb or the toilet bowl will clog up, this is "don't go to the grandmother."

I think I explained everything in detail, if something is not clear, you are welcome in the comments column.

I will finish with this question. And here you can watch a video of how I install the water supply system. After looking at it, and after reading my book "How to replace the water supply yourself?", It is easy to cope with this work. The book is free, download via the form at the very bottom of the page. To be sure of the benefits of this knowledge, and there was, so to speak, motivation for action - call the organization involved in the installation, ask about the cost of such work. I think the choice will become obvious.

Follow this link for a detailed article with a video: "How to wind up the thread tightly."

Want to know more about plumbing and related equipment? Below I post links to free courses corresponding to the name, click on the one of interest and enter your email address. After going through the easy registration procedure, download and study.

60 of the most incredible and non-standard questions in the construction of water supply and sewage systems The warmth of your home is in your hands - here, about various technologies of heating systems.

That's all for me, I recommend guests to subscribe to receive new articles, the form will open by scrolling down the page. Success in editing, sincerely Andrey.

Did you like the article? Click on the social network icon, I would be very grateful.

Share with friends online:

1

How to understand that the water is blocked? Help me please..

Therefore, when installing heating devices, a specialist will always tell you where it is better to install a tap on a battery, in which places and joints a frequent accumulation of air is possible.

Sectional crane

Buying such a crane will not take a lot of money. The pricing policy is very acceptable, prices for fittings vary from three hundred rubles to two thousand.

Of course, it all depends on the quality of the material used and on the firm. But it is worth noting that behind the beautiful name is a completely ordinary object, only it costs twice as much. Therefore, before buying, you should consult with a specialist or ask your neighbors.

Starting batteries after an outage - what is the risk?

The long-awaited start-up of hot water in radiators after a summer shutdown is a big event. Residents expect warmth in their apartments and houses.

But let's take a look at this process.

Radiators half spring, all summer and half autumn were inoperative. With the first start-up of water from a thermal power plant, the dirtiest, rusty water will flow through our batteries.

Of course, I don't want our radiators to get clogged from the inside. Imagine what would happen to the batteries if all this water remained inside: premature wear, rust, poor heat transfer. But the crane will come to the rescue.

How to turn on the tap on the batteries and do everything right?

The water is drained from the battery

At the first start of the water, it is necessary to slowly turn the plug and open the tap, it is advisable to substitute a bucket or basin under it, because dirty water will flow from the radiator. I don't want to ruin the floor or carpet. An example of water discharge can be seen in the photo.

In theory, it is necessary to drain the water for two days, then you will certainly keep the radiators intact. But, as a rule, everyone is waiting for the warmth and ignores this rule. Therefore, as an alternative, you can drain the water at least at night, and shut it off in the morning and enjoy the warmth and comfort in your apartment.

But don't forget about prevention. Bleed air once a month for the radiator to work properly.

Material on the topic of air and water release in batteries: https://kvarremontnik.ru/kak-spustit-vozdukh-iz-batarei/

Enjoy your winter evenings!