Choice of materials

In search of an answer to the question of how to insulate the floor, you will have to study several options for materials. Such qualities as durability, weight, moisture resistance and thermal conductivity deserve special attention. If the task is to carry out repair work with your own hands, then ease of use should also be taken into account.

Most often, for these purposes, they are used:

- expanded clay;

- Styrofoam;

- perlite;

- mineral wool;

- stone wool;

- technical plug.

Each of the presented heat insulators has both pros and cons. When choosing, it is worth considering the size of the cottage, the climatic zone, the time at which it is planned to live in this house, etc.

Mineral wool is the most popular insulation

The most common material for repair work in the field of floor insulation is mineral wool. It is made from various raw materials, which allows it to be classified into glass, stone and slag.

What are its advantages? First of all, it's easy to work with her. Cotton wool is easy to cut and fit. It has excellent performance properties: it is chemically neutral and is not afraid of exposure to high temperatures.

With its help, it is possible not only to improve the thermal insulation properties of a summer residence, but also to solve the issue of sound insulation.

When choosing mineral wool as a heater, it is necessary to take into account its ability to absorb moisture. In this case, it is impossible to do without laying a layer of material with vapor barrier properties.

The thickness of the mineral wool layer depends on many factors. This is both the purpose of the premises and the climatic zone. If it is planned to live in the dacha all year round, then the layer of such insulation should be about 20 cm.For living in the warm season, 4 cm is enough.

What material to choose

The choice of insulation is determined by several criteria:

- material capabilities of the owners of the dacha;

- the complexity of styling;

- durability;

- resistance to moisture and rodents.

The last point is especially important, because if the owners live in the dacha only periodically, dampness and mice are the main reason for the destruction of floors.

The range of heaters is wide, and along with modern ones, many summer residents willingly use the already familiar, time-tested materials. With a limited budget, you can pick up several acceptable options.

Expanded clay - lightweight porous granules perfectly retain heat, mice and insects do not start in them, the material does not emit harmful vapors. For effective thermal insulation, it is necessary to provide reliable protection against dampness and to fill in expanded clay with a thick layer - up to 30 cm.

How to easily identify high-quality expanded clay

Wood shavings and sawdust - cheap and environmentally friendly material that can be purchased at any woodworking enterprise. The shavings retain heat well, but are afraid of moisture, so they also need high-quality protection. In addition, insects and rodents can start in it.

Sawdust and shavings

Slag - an affordable and practical way of ground insulation. He also needs waterproofing, but he is durable, non-flammable and mice will not start in it.

Slag for floor insulation

Glass wool - affordable, perfectly retains heat and muffles sounds, is not damaged by insects or rodents.The disadvantages include the tendency to shrinkage and the need to use protective equipment during installation, since thin fibers are very fragile, easily penetrate the respiratory tract, irritate the skin.

Styrofoam - easy to install, moisture resistant. It has a long service life, but in the absence of mice, since these rodents are very actively destroying it.

Floor insulation with foam

The use of modern materials gives an incomparably better result: installation is carried out with minimal labor costs, the effectiveness of insulation increases significantly, you can forget about repeated repairs for at least 20 years. The only drawback is the high price, but financial investments are fully paid off in several years, thanks to significant savings on heating the home.

| Material | Basic properties |

Prices for Rockwool mineral wool

As a bulk insulation, many use expanded vermiculite - a granular material with a scaly structure. It is lighter than expanded clay and retains heat better, and serves as excellent sound insulation. Unlike EPS and mineral wool, vermiculite is completely environmentally friendly, but at the same time it is not affected by fungi, putrefactive bacteria, insects and mice do not live in it. Well, the disadvantages include only the high cost, which is why vermiculite is inferior in popularity to cotton wool insulation and polystyrene.

Isolation options

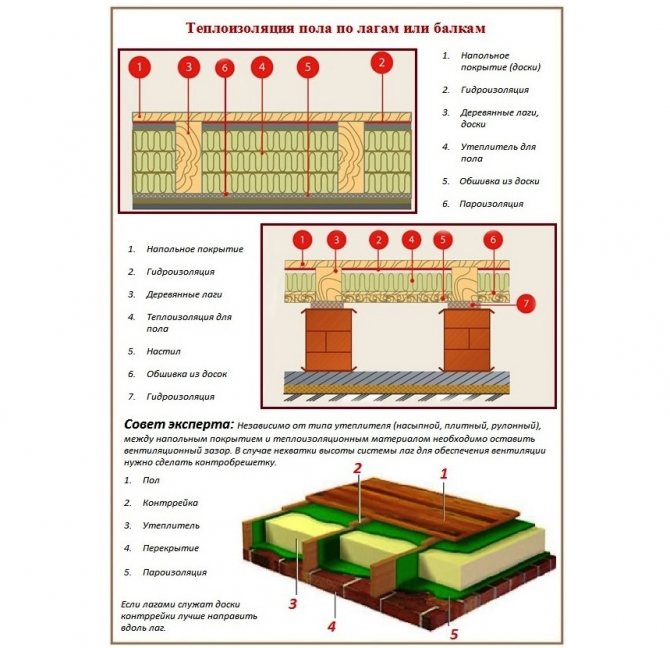

In a country house, floor insulation is most often done in one of two possible ways:

- by lags;

- on a concrete base.

The first method is applicable to both wood and concrete floors. It has one significant advantage: there is no load on the insulation, which allows you to choose any option as it.

When choosing the second method, serious pressure will be exerted on the material defined as insulation, which imposes a number of restrictions on it, it must be strong and dense.

Materials for floor insulation

The question of how to insulate the floor is not urgent today. A huge variety of heaters makes it possible to choose the one that will meet all the requirements of the construction of a wooden or concrete floor, as well as the financial capabilities of the owners of the dacha.

- Inexpensive expanded clay. For floor insulation on the ground - the best option. True, taking into account the climatic zone, its laying thickness can be significant, but not less than 10 cm.

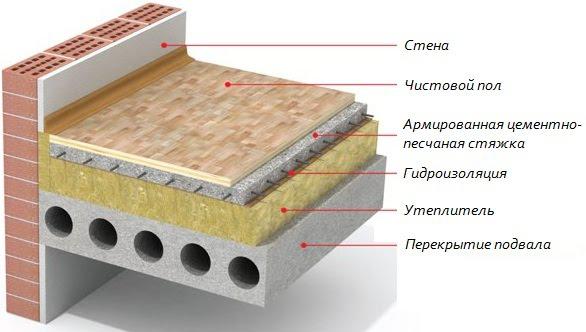

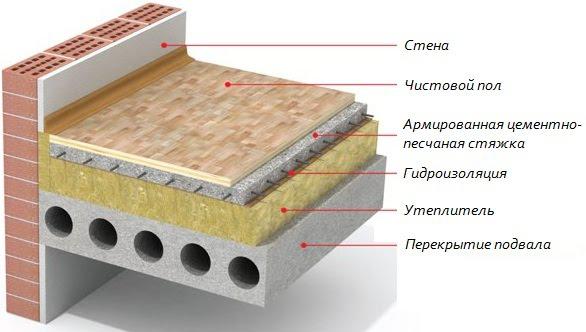

- It is better not to lay mineral mats under the concrete screed, as their strength is not the same. And they have high vapor and moisture permeability. Under the influence of moisture, mineral wool quickly loses its thermal insulation qualities. With the advent of waterproofing membranes on the market, problems with the use of mineral wool insulation began to be solved. Therefore, they can be used as floor insulation in log structures.

- Polyurethane foam is the most expensive option, but also the highest quality. It is better not to use it in structures on the ground, its surface is too uneven, against which the waterproofing film will tear. But between the lagged beams, it can be applied without problems.

- The optimal solution is polystyrene foam boards, especially with high density, the varieties of which include the well-known Penoplex. This insulation can be used in floors and on the ground, and on logs. In addition, Penoplex is not afraid of moisture and water, so it can be installed without protective membranes, which is economical.

The decision to insulate the floors in the country house on its own is justified not only from the standpoint of saving money and comfortable living in winter, but also from the standpoint of proving who is the man in the house.

Wood floor insulation technology

It is worth paying attention to the two-layer insulation system. In this case, the structure has the following layers:

- rough floor;

- insulation;

- finishing coating.

The main task of the subfloor is to perform the thermal insulation function. It can be made of rough planks attached to beams.This option can be called the most common and popular.

However, it also has a number of disadvantages. Over time, the prefabricated structure becomes unstable and loose. To eliminate such a problem, it is recommended to attach the cranial bar to the lags along the lower edge and lay the pieces of the board into the pockets formed. The insulation process consists of the following steps.

Surface preparation

The first step is to prepare the base. For this, the old coating is dismantled. The surface is cleaned of dirt and dust.

Leveling the floor

As practice shows, most summer cottages have uneven floors. They need to be aligned. This will facilitate further repairs.

To do this, you can make a concrete or cement-sand screed.

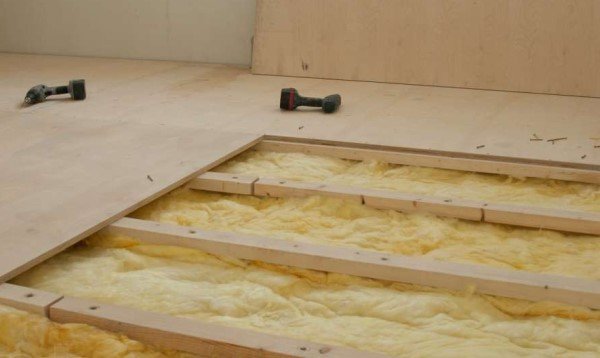

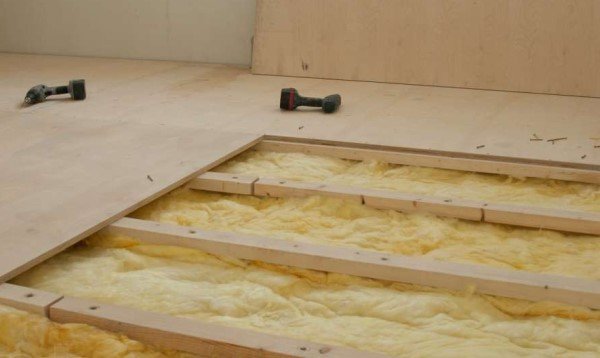

Installing lags

Lags are laid at a distance of 60-100 cm from each other.

In the case of mineral wool, it is recommended to maintain about 90 cm.

Waterproofing

The organization of waterproofing is carried out on both sides of the insulating layer.

If penoizol is used as insulation, this step should be omitted.

Insulation laying

Mineral wool is cut in layers, depending on the size of the grooves and placed between the logs. The width of the fragments should be slightly larger than the distance between the beams. This will allow the material to fill all cavities better.

If the room is high enough, then the insulation can be laid in two layers.

Laying the finished floor

This stage is final. Plasterboard, laminate, plywood, ordinary boards, etc. can be selected as cladding.

How and how to insulate the floor in the country

The main problem of country houses is moisture and rodents. Therefore, when insulating a country floor, it is necessary to take into account these features. Usually, when working with insulation, one of two options is chosen, either directly on the subfloor, or on top of already laid boards. Both methods are good in their own way and are easy to use. In general, if you do not know how to insulate the floor in the country with your own hands, then this article will provide you with a lot of answers.

How to insulate a rough floor

The subfloor is used more often than the second option, it is universal in terms of use on any basis, there will be no load on the insulation, so even loose and fragile materials are suitable.

We will need tools such as:

- Roulette.

- Screwdriver.

- A hammer.

- Building level.

- Hacksaw or jigsaw.

From the materials we take:

- insulation,

- glassine,

- primer for wood,

- construction scotch tape.

Preparing the base

Our article will allow you to find out the answer to the question of how to insulate the floor in the country without disassembling. But we'll talk about this later. In the same case, we perform the following actions.

- First, we assess the condition of the floor, remove the boards and inspect them for wear, if the boards are in order, then we clean them of dust and dirt. Do not forget to number the boards to make it easier to lay them back. It is also better to prime the boards, having previously cleaned and polished them. Next, dry them properly in the sun.

- Now we assess the condition of the foundation. If it is a cement screed, then simply sweep it up. For lags, a beam of 100x150 mm is suitable, or strong boards with a section of 100x50 mm. Keep an eye on the evenness of the wood, there should be no defects on it. First, we ground these logs properly, and lay roofing material on the base.

- The timber is laid at a distance of 60-80 cm, in exceptional cases 100 cm. We control the horizontal position of the installation with a level. The floors in the country house do without heavy loads, so the logs can not be fixed with dowels.

Competent installation of waterproofing.

Glassine is perfect in this capacity because of its cheapness and durability. Place it on top of the log and distribute it well. They are usually fixed with a construction stapler from the inside.Be sure to leave an overlap of 10-15 cm and fasten the seams with tape or mastic. We overlap it on the walls by about 15 cm.

You can, of course, do with simple polyethylene, but for rodents it will not be an obstacle, keep this in mind. And it is attached in the same way as glassine.

Warming process.

What is the best way to insulate the floor in the country? This question also requires logical reasoning. Even with inexpensive heaters in the country, with their correct use, you can get an effect no worse than their expensive counterparts.

We prepare the insulation, depending on the shape, cut the slabs 2 cm more than the distance between the logs, and cut the rolled insulation immediately during installation. First, we treat the sawdust with a fire retardant, then mix it with lime in a ratio of 10% lime by the volume of sawdust. This mixture will scare off mice, and the fire retardant will give the sawdust an anti-combustible effect. Now we dry the sawdust.

So, we place the selected insulation and level it between the lag. We try not to leave any gaps and gaps, because because of them, the entire thermal effect can be greatly underestimated. So the gaps between the slabs must be filled with foam. Just to avoid gaps and ruptures, the insulation is laid in 2 layers, when the upper layer overlaps the joints of the lower layer with solid plates. But even the second layer should be a couple of cm below the lag, this is the space for the necessary underground ventilation.

Now we stretch the vapor barrier film from above. You can use the same glassine or a special membrane here. We also lay it with an overlap, securing the joints with mastic or tape. You can't just fix it to the walls, and it should lie completely free, in order to avoid shifts, you can fix it with a stapler.

If, when laying the insulation, you did not manage to observe the ventilation gap, then after laying the vapor barrier, the slats should be nailed crosswise to the logs, the subfloor will already creep onto them.

Take note of the following information about insulation:

Min. cotton wool ceases to be a heater with an excess of moisture, so vapor barrier is its only protection. Otherwise, after a short period of time, you will have to change the layer of mineral wool again.

Various types of mineral wool in terms of density.

Types Density Heat Prev. Temper. Combustible. Mats 50-85 0.046 700С NG Light 20-40 0.036 400C NG slabs Soft 50-75 0.036 400 NG slabs Semi-rigid 75-125 0.0326 400 NG slabs Rigid 175-225 0.043 100 G1 slabs Cylinders 200 0.046 400 NG Loose cotton wool 30 0.05 600 NG

Polyfoam is easily gnawed by mice. If the dacha is not particularly residential, then a huge number of mice can breed under the floor, which will gnaw both the film and the foam, but they cannot get to the foam through the glassine.

Sawdust is mixed with dry lime to avoid settling and pressing, when you can not expect heat from them. If you add only 10% lime of the total volume to them, and add dry gypsum (5%) and an antiseptic solution (approx. 8%) to this, then the insulation will be what you need. The mortar will add moisture to the sawdust with gypsum, and the gypsum can easily set ahead of time, so the mass must be quickly positioned in the right place within a short time. Then we get, where necessary, a solid and durable mass with excellent heat-retaining characteristics. It will not rot and mold is not scary to her. Cement can be used instead of plaster.

We lay the floors

This is the final stage of the insulation process. Remember we numbered the boards? So, now is the time to evaluate this convenience, which will save you a lot of time. Now we lay them, tightly fitting them to each other and fix them with self-tapping screws. If gaps suddenly appear, we drive wedges into them or putty. Don't forget about horizontal measurements. At the end of the work, put the skirting boards back and cut off the excess film if they stick out.

In a new home, you can use chipboard or OSB instead of boards. We measure them in size and fasten them to the logs with self-tapping screws.Plates should be shifted slightly along the length to avoid gaps. Then the seams should be putty, cleaned, sanded and can be primed. Linoleum, laminate flooring, or something else can already be applied to this base.

We insulate wooden floors

If you are interested in the question of how to insulate the old floor in the country? Then we are ready to offer an answer to it too. If the floors of your house are not a concern, then insulation work can be carried out directly on top of them. Just be prepared that the ceiling height in the country will be reduced by 8-10 cm.

We will need:

- Electric jigsaw.

- Grinding attachment.

- Primer.

- Building level.

- Beam 50x50 cm.

- Wood putty.

- Vapor barrier film.

- Chipboard or other sheet material.

- Self-tapping screws.

- Insulation.

- Screwdriver.

- Construction scotch tape.

- The bars will be instead of lag, they need to be prescribed with an antiseptic liquid and dried properly.

- After removing the plinth, we clean the floors from dust. Next, we check their level for horizontalness.

- We grind the protrusions with a nozzle, and fill the cracks with putty.

- Next, apply the soil on the floor in two layers and let it dry.

- We lay the beam on the floor at a distance of 30 cm, we retreat 3 cm from the edges of the walls.We use a level when laying out and put wedges under the bars if necessary, then fix them to the floor with self-tapping screws.

- Now we fill the space with mineral wool insulation and polystyrene - the best options. Blow out the seams with foil.

- From above we cover everything with a vapor barrier membrane, straightening and fastening the seams with tape.

- We make the flooring sheets square to facilitate the task and from the second row we shift them by 20-25 cm when laying. To make the seams less noticeable, you need to fit the sheets as tightly as possible to each other.

- If it is planned to lay something else on this covering, then the sheets can be left unprocessed. But if you plan to leave everything like that, then get ready to first grind, then prime and wait for drying.

With the right approach to the technology of work, such homemade floors will last at least 10 years.

Compare floor insulation

Sawdust.

Cheap, lightweight, environmentally friendly material. But it burns and rots. Thermal conductivity comp. 0.090-0, 180 W \ mK.

Expanded clay.

Eco-friendly and durable, non-rotting and non-flammable. But fragile and heavy. Thermal conductivity comp. 0.148 W / mK.

Styrofoam.

Waterproof and lightweight, does not rot and is easy to work with. Thermal conductivity comp. 0.035-0.47 W \ mK.

Min. cotton wool.

Eco-friendly and non-flammable, easy to use and with low thermal conductivity. But when wet, it shrinks and loses the properties of a heater. Thermal conductivity comp. 0.039 W \ mK.

Summing up

We hope that with our recommendations, you will be successful in insulating the floor in the country with your own hands. In general, purchase all the necessary materials and do this work yourself.

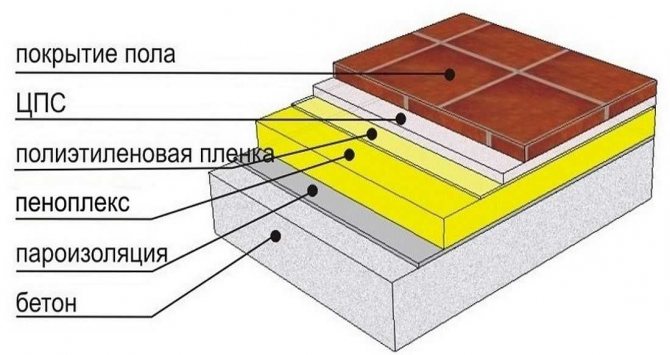

Concrete floor insulation technology

Insulation of a concrete floor deserves special attention, as it is usually very cold. For thermal protection, the lag technology discussed above can be applied.

Another option is floating floors. In this case, it is necessary to arrange the cement screed. It is recommended to assign the function of the insulation to such a material as extruded polystyrene foam, since it has a high compressive strength and better withstands mechanical stress.

As a result, the floor will consist of several layers: concrete base, insulation, screed and floor covering.

Expanded clay

Expanded clay is round granules of a porous structure. It is an inexpensive material, it is immune to chemicals, it is not afraid of rot, frost-resistant, heat-resistant, lightweight and has a long service life. Before insulating the wooden floor with it in the country, it is necessary to carry out a number of preparatory work. First you need to remove the old floor covering, including the logs. Then - lay the waterproofing and fill in expanded clay. To make the coating durable, expanded clay is poured with liquid cement.The optimal thickness of the expanded clay layer is considered to be 30 cm.

Modern methods of insulation of a concrete floor

When working with concrete floors, there are a number of additional ways to achieve the task at hand. This should include:

Coating the floor with heat-insulating paint

This method has many advantages. Anyone can independently carry out these repairs. The paint is suitable for both new and old buildings.

It is applied in several layers to the previously cleaned floor. Each layer should dry well, only after that you can move on to the next. As a rule, you can insulate the dacha in this way within a day.

Floor covering with warm linoleum, technical cork or carpet

Carpeting and linoleum cannot sufficiently solve the problem of insulation. However, such options are quite economical.

When choosing a technical plug, you will have to incur significant material costs, but this material is considered the safest for health and is characterized by excellent operational properties.

Covering with plywood sheets or moisture resistant fiberboard and chipboard

This option is referred to as budgetary methods. These materials can be laid both on logs and directly on the concrete floor. A more tangible effect can be achieved by laying them in two layers on the concrete pavement itself.

It should be remembered that the plywood sheets should not completely coincide with each other. Between them, you need to leave small joints of 1.5 mm, which will prevent unevenness of the finished floor, for which floor you can choose laminate, linoleum, carpet and other options.