Facade decor

Facade decor from expanded polystyrene is a budget alternative to any other stucco molding, be it concrete, fiber-reinforced concrete, or even more so, natural stone.

Facade products made of polystyrene, presented in our online store, can be made in any size, the price for decor of a different size must be requested additionally.

ATTENTION! The dimensions of the foam decor have a small size tolerance of ± 1-3 mm, since the foam material is soft and a slight error is inevitable in construction.

Cutting styrofoam according to your drawings of styrofoam decor in our production at prices as in the catalog of finished products.

Samples of stucco molding can be obtained free of charge, for this you need to order them by phone.

When buying stucco decor through the basket, choose self-pickup, delivery by any transport company, our managers calculate individually.

Our store of stucco molding offers to buy in Moscow various profiles from polystyrene of our own production.

Whether to make your home beautiful is up to the person himself. If yes, then the first step in solving this problem will be the design of the facade, which involves an integrated approach to design, which must take into account a lot of factors, such as:

- The environment where the house is located.

- Used wall material

- Existing coatings that cannot be replaced

This is the minimum that must be taken into account. Of course, there can be much more factors in each specific case.

Two boxes, similar in shape and size, with a design similar in style, look different.

Private house facade design, implies a complex finish that can be made from various materials.

A store that sells polystyrene stucco moldings exists in the production of facade decor in the city of Pushkino. We produce stucco moldings using two different technologies:

- Facade elements made of concrete according to drawings.

- Stucco molding from polystyrene, both according to the catalog for sale in the online store or in large wholesale, and under the order according to the drawings.

Shaped cutting of polystyrene is carried out on programmed machines. The term for the production of concrete stucco moldings is from 45 working days, while the production time for the same volume of foam decor is from 3 working days. Since the labor intensity of production is much lower, polystyrene stucco molding is much cheaper.

Private house facade design, implies a complex finish that can be made from various materials.

The price of stucco molding in our store is minimal, because we ourselves sell and produce it. In other places, the stucco moldings of our production will probably be sold at a higher price, despite the fact that we give good discounts to wholesale buyers.

The catalog contains more than 100 types of various profiles. In addition, we make cutting of polystyrene of any products according to your drawings or sketches.

If necessary, we can also offer solutions for the design of the facade.

You can buy front decor in our store by placing an order through the basket, delivery is carried out from 1 to 10 working days, depending on the volume of the order. Please negotiate the delivery time separately.

Styrofoam in the interior and on the facade

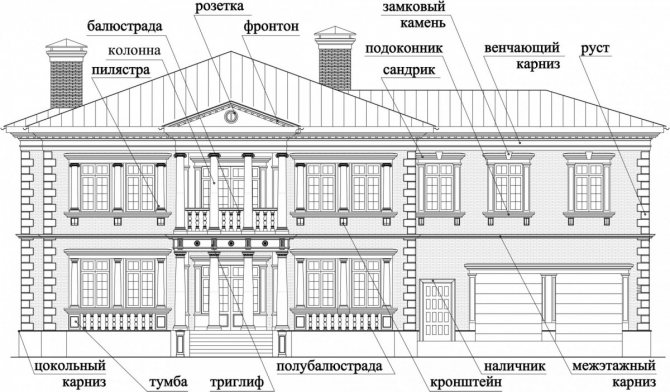

Buildings with facades decorated with styrofoam are exclusive and romantic.The upper part of the wall of the house, decorated with an entablature, adds mystery, the columns with a figured capital turn the house into a real classic structure, and the arched opening, framed by a decorative archivolt, completes the overall vivid impression.

For interior decoration, polystyrene stucco molding is used on the ceiling and walls. In the design of the ceiling, any modern solution is appropriate. The decoration around the chandelier, illuminated moldings-cornices looks attractive. The wall décor suggests a classic style.

So, decorating a house or apartment with polystyrene foam is quite affordable, inexpensive and practical. Working with him, you can discover the talents of a designer and be proud of your own achievements later.

https://youtube.com/watch?v=T_LkShpDoOc

Categories of goods

Categories of goods

What we produce

We have been manufacturing reinforced foam decor parts for 14 years. Over the years, our products have significantly changed the architectural style of various buildings throughout the country.

Among them will be your house, if you take advantage of the offer and buy decorative elements for the facade of the cottage (house) from us. The collection of the company is formed taking into account fashion trends, as well as market requirements. Today it includes:

- interfloor cornices, crowning, basement;

- door and window frames;

- columns;

- pilasters;

- rustic stones;

- castle stones;

- brackets;

- balusters;

- other elements, including details that allow you to create volumetric ornaments for the ceiling.

Ecowool

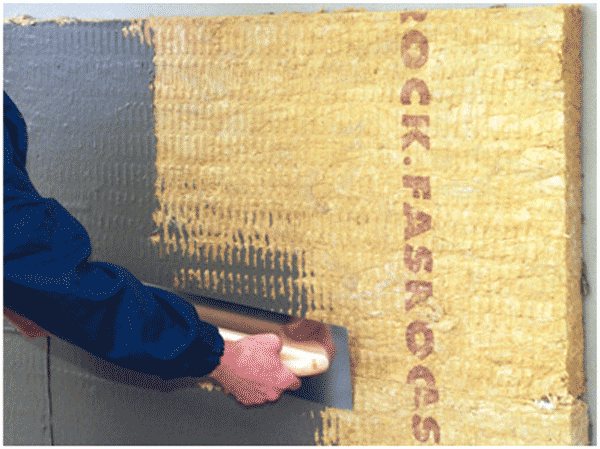

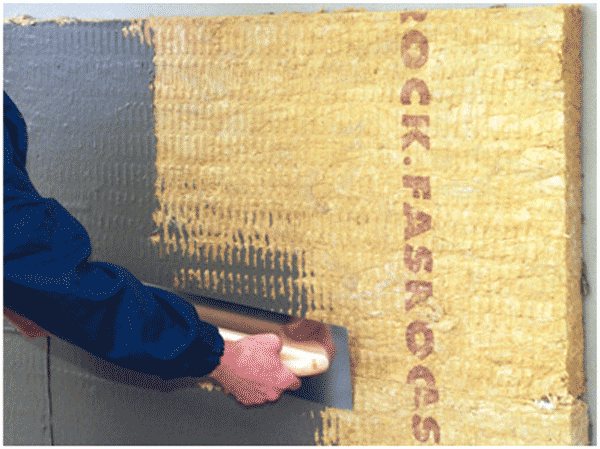

The name "ecowool" means a friable material consisting of cellulose with the addition of flame-retardant compounds. Filling the cavities with ecowool gives a continuous heat-insulating layer that penetrates into hard-to-reach cracks and corners. For facade insulation, both dry and wet-glue installation methods are used.

At the first, a box-like structure is mounted on the facade, into which the material is blown dry. In the second, an adhesive composition and a humidifier are mixed with the material, spraying the resulting mass on the surface using blowing machines, and after drying it is aligned along the guiding edging knife. A layer of ecowool of 5 cm in terms of thermal conductivity replaces one and a half brick laying. After the composition has hardened, the insulation can be veneered from the outside using various materials, including siding.

Despite the difficulties in applying ecowool on vertical surfaces, it has its own advantages: the possibility of using it on any curvilinear and complex shapes and minimal shrinkage during operation.

As you can see, there are many technologies for finishing the facade with the use of insulation, which makes it possible to take into account its initial characteristics and the conditions for the future operation of the building as much as possible. Competently selected materials and finishing technology contribute to the effective protection of the walls of the building from external influences and to optimize its internal microclimate.

We have a large selection of products made from lightweight and reliable materials

Each product is presented in several models, sizes, shapes and areas of application. The photos and descriptions placed on the product pages will help you to choose the necessary facing element.

The catalog of polystyrene parts includes products intended for exterior decoration of buildings as well as for creating the facade design of a building. Made of lightweight material, they can be used for cladding various types of buildings, making them more effective and memorable.

Architectural decorative plastic casing is also widely represented in our assortment; you can buy it to decorate any room.

Warming options

Installation of insulation panels for external walls depends on how flat the surface on which the slabs will be installed.The cladding of other parts of the house, in addition to the facade and sides of the building, has certain features.

Insulation of uneven walls

To align the walls, the frame method of laying the panels is used.

When installing panels on walls, it is necessary to take into account irregularities leading to deformation of the thermal panels. To avoid this, a frame installation method is used. The lathing is made of wood or metal, the second option is preferable. If wood is used, the bars are treated with an antiseptic.

The length of the steps of the frame lattice horizontally and vertically is selected in accordance with the dimensions of the wall plates, the location of the fastening holes should coincide with the centers of the bars or metal profiles. For the panels to fit well, the frame must create a flat plane. If there is a risk of heat and moisture retention in the space between the battens and the panels, it is filled with construction foam. If it is impossible to install the frame grille, the wall is leveled with cement. This method is less economical.

Fastening panel elements to the battens:

- Thermal panels are laid up from the bottom corner.

- If corner pieces are available, they are secured first. If not, the end parts of the slabs are sawn down for joining at an angle of 45 degrees.

- The installation of the main panels on the crate is carried out using self-tapping screws. Their length should exceed the thickness of the product by 4–5 cm.

- Each subsequent row is mounted with offset vertical seams to improve tightness. To save money, they take an extra piece from panel scraps. The front part of the plate for fitting to size is sawn with a grinder with a disc corresponding to the outer material, the insulation is easily cut with a knife.

Insulation of a flat facade

For even walls, installation with glue or dowels is possible

Plates can be installed without lathing. If the installation is carried out directly on a wall made of bricks or concrete blocks, the panels are attached to the supplied dowel nails. Their length should be 4–5 cm more than the thickness of the cladding. The locations for drilling holes in the slabs are usually already marked.

Begin laying from the bottom wall corners upwards. In general, the process is similar to installing slabs on a batten.

Before installation, the space between the wall surface and the slabs can be filled with polyurethane foam to provide additional heat-shielding properties. On the wall, you need to find the most protruding place and level the surface along it. But it takes a lot of time, effort and money. It is easier to install the frame and fix the plates to it, and then either foam the space inside, or leave a ventilated layer.

Cladding examples

It is possible to choose panels of any size and shape

Panels for the facade with insulation can be used to decorate not only walls, they have proven themselves perfectly when facing the basement, eaves, columns and architectural extensions.

For the base, it is preferable to choose a material that is additionally reinforced with pressed metal or plastic bushings. Such slabs differ in size - they are smaller than wall slabs.

If the eaves overhang, terrace or balcony ceiling, porch canopy with insulated panels are being hemmed, it is necessary to leave holes for ventilation. The easiest option is to create a gap between the panel and the wall or build in grates for aeration. For such work, be sure to choose panels with a moisture-resistant insulation.

Facing of square columns and flat-walled architectural forms is carried out according to the principle of facade decoration. But for rounded parts, you need to choose elements of the appropriate shape.

Benefits of styrofoam decor

Facade stucco molding is actively used in the architecture of many countries. It serves as a decoration for the outer walls and at the same time gives individuality to the facade. Today, various materials are used for its manufacture: from gypsum to natural stone.The greatest demand among them is for expanded polystyrene products, which is due to a number of advantages, including:

- Ease. The weight of such decor is 2.5 times lighter than that of glass fiber reinforced concrete and 5 times lighter than that of elements made of concrete and natural stone.

- Environmental friendliness. Ensuring the absence of harmful effects on human health and the environment.

- Resistant to high and low temperatures.

- Exact dimensions. This was achieved through the use of a special computer shaped cutting machine.

- Strength and durability.

Types of materials

The most popular and common heaters include:

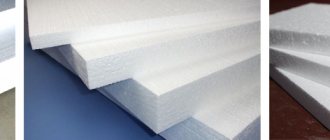

- Styrofoam (expanded polystyrene);

- Penoplex (extruded polystyrene foam);

- Mineral wool;

- Various siding and panels.

Types of popular heaters: polystyrene, mineral wool, panels, penoplex

Carrying out the insulation of the facade of a cottage or house, you can combine various facade insulation, as well as lay them with different thicknesses. For example, the layer of insulation on the south wall of a house may be thinner than the rest.

Thermal insulation of facades with foam

Polyfoam is the most traditional and well-known material with a very low specific gravity, moisture resistance and low thermal conductivity, since it consists of 90% air bubbles. Polyfoam as insulation has an advantage - low cost. However, the foam is easily damaged by rodents.

Styrofoam is cheap and easy to install, but easily damaged

Insulation of the facade with penoplex

Penoplex is the domestic name for extruded polystyrene foam. Like polystyrene, it is obtained from polystyrene by foaming, but using a slightly different technology.

Penoplex has a higher sound insulation

Polyfoam is produced by sintering individual granules, while in the case of foam, not individual granules are transformed, but a single liquid substance. Therefore, it has a solid, uniform and denser structure, consisting of the smallest closed cells.

Penoplex has a higher sound insulation, and foam - breathability, which allows the walls to "breathe".

Insulation of the facade with mineral wool

Mineral wool is characterized by excellent soundproofing and fire resistance

Mineral wool is divided into 3 types:

- fiberglass;

- stone or basalt;

- slag.

Glass and stone wool is used for thermal insulation of facades. It is distinguished by increased strength, moisture resistance, good resistance to mechanical stress, sound-absorbing properties, and also fire resistance (it can withstand temperatures up to 1000 ° C).

Insulation of the facade with panels

The panels will help not only to insulate, but also to refine the exterior of the building.

By their design, panels for insulating the facade of a house consist of a polystyrene base (foam) and clinker tiles with imitation of brickwork. Their overall dimensions may vary depending on the manufacturer.

In addition to brick, panels can imitate other types of finishes: stone, wood, etc.

Why choose us

Making styrofoam facade decor for your home is a hobbyhorse. We make standard solutions but, if necessary, make custom-made decor. Email us if you are refused elsewhere. Extensive work experience, qualified personnel. as well as the availability of modern high-performance equipment allows us to manufacture the most complex architectural elements.

If you are interested in any of our products, we will be happy to answer your questions. To contact our managers, you can call (+7 (495) 767-73-17)

Styrofoam decor for the facade

Manufacturing of facade stucco moldings according to any of your sizes and catalogs of any manufacturers - LEPNINAPLAST, PRESTIGE DECOR, EUROPLAST, REGENT DECOR

Height: 60

mm Width:

60

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 80

mm Width:

80

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 60

mm Thickness:

25

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 60

mm Thickness:

30

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 60

mm Thickness:

15

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 70

mm Thickness:

20

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 75

mm Thickness:

60

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 80

mm Thickness:

30

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 80

mm Thickness:

40

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 80

mm Thickness:

20

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 80

mm Thickness:

30

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 85

mm Thickness:

50

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 85

mm Thickness:

60

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 90

mm Thickness:

20

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 90

mm Thickness:

25

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 95

mm Thickness:

50

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 95

mm Thickness:

35

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 95

mm Thickness:

30

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 70

mm Thickness:

40

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height: 80

mm Thickness:

40

mm Length: 1200 mm Price per item made of reinforced polystyrene

Height

: 85 mm

Thickness

: 65 mm

Length

: 1200 mm

Price for a product made of reinforced polystyrene

Internal diameter

: 340 mm

Outside diameter

: 100 mm

Height

: 120 mm

Price for a product made of reinforced polystyrene

Internal diameter

: 400 mm

Outside diameter

: 120 mm

Height

: 120 mm

Price for a product made of reinforced polystyrene

Internal diameter

: 500 mm

Outside diameter

: 160 mm

Height

: 120 mm

Price for a product made of reinforced polystyrene

Since 2007, he has been successfully engaged in the manufacture and installation of facade elements made of lightweight stone, gypsum and certified expanded polystyrene covered with a special protective polymer coating, in any size provided by the customer. The unique protective layer that covers the products allows them to withstand significant temperature changes and does not allow moisture to pass through, as a result of which there is no expansion of the elements, the appearance of cracks, joints. The facade created by us will delight your eyes for many years! As a manufacturer, our company can guarantee the lowest prices with high quality products. We draw your attention to the fact that now on the market there are many one-day companies with a representative office in one region, and production in another, and offering very low prices for products. After payment of the advance payment, such would-be contractors disappear or use cheap material, poor-quality coating in the manufacture of products. The result is that you accept the work, and after six months you have to dismantle the products. We do not promise discounts from the lowest estimates of competitors, since in our work we use only high-quality materials and provide a guarantee for products and work performed!

Examples of our work:

1. Lightweight stone.

Material: white cement (grade 600), coating - marble chips. Color: white, tinting is possible at the manufacturing stage. The surface of the details of the facade stucco molding imitates the natural stone travertine of various types (color, texture). Concrete products imply the selection of joints as a decorative element, therefore, the length of each part must be calculated for symmetry. Due to this, the production and installation time increases.Due to the rather heavy weight of the products, there are special requirements for the strength of the mounting surface of the facade. Tinting can be carried out during manufacture, which makes it possible to refuse further painting. During operation, only the washing of the facade is required.

2. Made of gypsum treated with hydrophobic impregnation (moisture protection)

... For the manufacture of complex decorative items, high-strength gypsum of the G-16 brand (Samara) is used. Plaster molding is a classic option for making decors of any complexity.

3. Polystyrene foam with polymer coating

... Material: base PSB-25F, the coating is a mastic mixture based on a copolymer styrene-acrylic dispersion, fractionated marble filler and a complex of modifying additives. The curly cutting technology allows you to create various architectural elements from expanded polystyrene. The big advantage of this technology is the ability to fully implement the plan of the architect and designer, and the low weight of the structure will make it easy to install the finished product. The decorative elements are covered with strengthening and coloring agents, this will give them a finished look and durability, but at the same time they will be relatively inexpensive. Lightweight stucco molding is easy to install, does not load the facade, competent installation allows for the absence of joints between the elements. Covered with facade paint or facade varnish. During operation, only the renewal of the paintwork is required (every 10 years, depending on the quality of the paint or varnish).

Technology for installing foam on the facade

To carry out insulation, professionals advise to lay the foam on the facade with a continuous layer. As a mounting agent, frost-resistant facade glue is used without the presence of solvents in the composition. In addition, you will need disc dowels and polyurethane foam for the design of the seams.

The work is carried out according to the following algorithm:

Facade surface preparation. To do this, the old finishing layer is removed from it, the walls are leveled as much as possible, all existing cracks are necessarily filled. A horizontal stop is fixed at the bottom of the wall, which is a metal corner that does not allow the foam to slide off the wall. Such a shelf should be the same thickness as the insulation material. It is attached to dowels with a step of 30 cm. Surface treatment with a deep penetration primer and antiseptic components added to it. Preparation of the adhesive mass in accordance with the attached instructions and applying it to the facade foam. The layer is applied evenly around the entire perimeter of the slab, only in the middle is a point design possible. Pressing the foam sheet against the wall and holding in this position for about a minute. In this case, all surplus that protrudes beyond the edges are removed immediately. Advice! During application, the glue must be positioned so that 5 cm remains to the edge. This makes it possible not to remove excess during installation.

Pasting with plates using the same technology on the entire surface of the wall. All the resulting seams are sealed with polyurethane foam

After the foam has set, its excess is cut off in such a way that the clearance of the gaps is flush with the surface of the board. Important! It is best not to leave gaps more than 2 mm wide.

Another layer of Styrofoam is glued to the dried finish so as to cover the existing seams. After the final solidification of the glue, the foam is fixed with disc dowels.

Facade decor made of polystyrene foam with a polymer coating.

Domestic produces facade decor from expanded polystyrene with a 6 mm polymer concrete coating. The binder is gray cement or optionally white. This decor is a good alternative to expensive and heavy fiberglass concrete, as well as low-cost acrylic-coated foam.Our polymer concrete on expanded polystyrene is intended only with subsequent painting. The range of products goes far beyond our two catalogs, which are presented on the main page of the site.

Fiber is always included in our polymer coating. If the facade mesh protects the cornice from linear extensions and wind loads, then the fiber excludes microcracks along the entire surface of the cornice.

We do not have the cost of forms, the client pays only for the size of the products, the design of the product can be any. Important: cornices, window sills, window trims, pilasters, columns and other straight products are produced in 2-meter segments. The total cost of the products will depend on the density of the foam. For your information: the cost of the densest foam is three times higher than the price of the lightest foam. (This is where the low prices come from) This can positively or negatively affect the life of the decor.

The polymer coating starts with the correct façade mesh:

Painting mesh reinforcement: fiberglass meshes are for indoor and outdoor use. The net for the interior is often called a serpyanka, in photo No. 1. The next density is 70 grams, per 1 square meter of the grid, in photo No. 2 it is also a net for interior work. Decor manufacturers often use these nets in their products to reduce the cost of labor and reduce the cost. They are very convenient to work with, they are very soft (due to the very thin hairs of the fibers), and fit comfortably on any relief of the detail. BUT these nets are highly alkali-afraid and not alkali-resistant. These serpyanka are intended mainly for gypsum plasters where there is no alkali. In addition, meshes of this density are very weak to break. Serpyaka is designed to prevent drywall microcracks, but not facade loads. Breaking stress in rooms and on facades varies greatly. That is, in five years, thanks to the alkali in the cement, this mesh will simply “dissolve” in the cement layer, and the reinforcement will disappear along with it.

Reinforcement with a facade mesh: we use a front reinforcement mesh with a density of 120 or 160 grams, per 1 square meter, in photos No. 3 and 5. The threads are glued tightly and evenly, do not creep, there is no "looseness" in the mesh. These nets are produced by a European manufacturer.

It is interesting that No. 4, with a higher declared (on the label) density, looks less dense in comparison with No. 3. The impregnation of mesh No. 4 is minimal, the mesh itself feels loose - this is a Chinese manufacturer of nets. No. 5 is the same European manufacturer of nets. The purchase price of mesh No. 3 is 50% higher than the Chinese mesh No. 4. Tactilely, No. 3 feels denser than No. 4.

The next moment is an alkali-resistant protective impregnation. Without such impregnation, the meaning in the mesh is lost. Please note, some with low density fiberglass 70-90 grams per 1 sq. M. This means that the mesh will withstand only light loads, such as wall microvibration. (People sometimes have to buy the cheapest. Unscrupulous manufacturers take advantage of this by offering low-density facade meshes made according to TU (self-written quality requirements). After all, even some builders do not pay attention to the density figures. At first glance, the mesh is like a mesh. Its density is lower than the GOST mesh for facades, soon cracks will appear on such walls)

Next, we use fiber to increase the strength of the entire layer of cement pavement. We use other additives to increase the water resistance and frost resistance of decorative elements.

Types of facade panels

All types of facade insulated panels for exterior decoration of the house are distinguished by ease of installation and low heat loss. But each has its own technological advantages.

Thermal panels

Thermal panel - a layer of insulation at the bottom, facing material on top

They are used for insulation at the same time as facing work.A wide variety of modifications and shades allows you to choose the right building material for the beautification of office buildings and industries, shops and medical facilities, residential high-rise buildings and suburban buildings.

They produce products of different thicknesses - up to 8 cm. When choosing, they are guided by the climatic features of the region: thinner models are needed for the south, thicker for the middle lane, and the inhabitants of Siberia should prefer 8-centimeter versions.

The outer layer is represented by metal, polyurethane, clinker tiles. The porcelain stoneware-coated thermal insulation boards imitate masonry, giving the building a solid appearance. As an inner layer, foam or more expensive and high-quality polyurethane foam is used. But external thermo-facade panels for a house with such a heater have a significant drawback - low resistance to open flame.

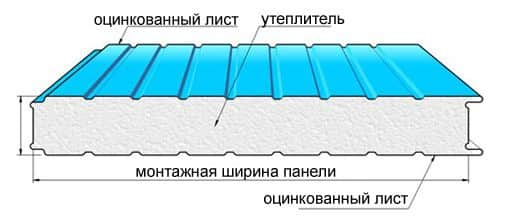

Sandwich panels

Sandwich panels are used in the construction of prefabricated structures

These are three-layer "pies", which consist of an insulating layer and cladding on both sides. From such panels, you can build new houses or insulate ready-made ones. For cladding layers, manufacturers use wood chips, less often metal. Usually, sandwich panels need additional finishing, as they do not look presentable. But you can find on sale slabs with a decorative coating that imitates the surface of wood or stone.

Warm sandwich panels for the outside walls of the house are characterized by lightness, durability, and increased energy efficiency. They are made by pressing internal insulation and sheathing.

When choosing, the emphasis should be on the quality of the warm layer:

- Mineral wool does not burn, is environmentally friendly, does not attract mice, rats and insects. Of the shortcomings, the most important is instability to moisture, therefore, it is required to monitor the tightness of the coating.

- Polystyrene is a durable building material with high heat-shielding properties that is not afraid of moisture. It is adversely affected by the sun's rays, but thanks to the outer skin, this flaw is leveled. The insulation does not differ in fire safety, when it burns, it emits harmful substances, rodents settle in it.

- Polyurethane foam is not afraid of moisture, even with direct contact with water. The material is lightweight, the panels are easy to transport and install on walls. Plus - the load on the foundation is reduced. The thermal conductivity of the building material is 1.5–2 times lower than that of other heaters.

- Polyisocyanurate (a type of polyurethane foam) self-extinguishes when ignited. It is increasingly used as the inner layer of sandwich panels. Building material does not grow moldy, is not susceptible to fungal infection. Among the disadvantages is the risk of damage by rodents.

Heat-insulating panels for plastering

Plaster panels do not have a decorative layer

Plaster panels for insulating the facade of the house are produced on the basis of foam sheets made of marble or quartz chips of half a centimeter fraction. Their thickness varies from 5 to 10 cm. The boards successfully resist the negative effects of external factors and are attached to the outer walls using a foam adhesive. An additional plus is the ability to create a visually seamless surface.

Why not buy acrylic-coated polystyrene foam?

Acrylic (mastic) coating is made from a water-based styrene-acrylic dispersion. This dispersion is also used for water-based interior wall and ceiling paints. That is, the dispersion is quite hygroscopic and not frost-resistant. The styrene-acrylic dispersion in a solidified form has significant drawbacks, one of which is that at subzero temperatures the binder loses its elasticity and is subject to glass transition. Do not confuse acrylic dispersion with acrylic plastic.

The next point - any material has thermal expansion, foam is no exception. Expanded polystyrene is 92% air, we know from physics - air is compressed in winter and expands in summer. The elastic acrylic coating does not have a rigid reinforcement in the form of mesh and fiber, therefore it grows and shrinks with the foam. Of course, this happens unevenly, so cracks appear at the seams.

Production of architectural and decorative elements for facade finishing at the best prices

Styrofoam decor - luxurious solutions for decorating the facade of any building!

Buy various decorative elements for the facade of the house from polystyrene offers. We always have in stock cornices, rustic materials, stucco moldings, all kinds of architectural elements made of reinforced extruded foam and other equally popular facade decor made of expanded polystyrene.

Use the form "ORDER CALCULATION"by specifying the dimensions and additional parameters of the decorative facade elements made of foam plastic you are interested in, or ORDER A CALL and our manager will contact you within a few minutes to clarify all the necessary details.

Installation of decor on the facade of the house

When carrying out such work, you must follow the algorithm of actions. First, you need to carry out preparatory work with the surface on which the decor will be attached. To do this, remove the remnants of old plaster from the surface, remove dust, dirt

Armed with facade plaster, it is important to eliminate all internal irregularities

Advice! If voids are identified, cement mortar can be used to level them.

Then, they designate the places where the decorative facade elements will be attached. If some elements of the product will protrude by 10-15 centimeters, you will have to strengthen the structure with dowels driven into the walls of the house in advance. Before starting work related to the design of a foam plastic facade, professionals recommend checking the evenness of the surface.

The next stage of the installation work will be to dilute the glue, apply it to the back of the decorative fragments

When attaching them to the wall, a little effort is required to improve the quality of adhesion of the adhesive to the surface to be formed.

Attention! Be careful when working with decorative fragments, as the product is fragile. The installation process is completed by sealing the fastener gaps with polyurethane foam or sealant. After it is completely dry, you can remove the remains with a spatula.

After it is completely dry, you can remove the remnants with a spatula.

The installation process is completed by sealing the fastener gaps with polyurethane foam or sealant. After it is completely dry, you can remove the remnants with a spatula.

Further, a high-quality priming of all decorative elements is carried out using a special solution. At the final stage, the polymer decor is painted with acrylic dyes according to the design project. To increase the service life of products, professionals recommend painting 2-3 times.

Applying additional protection to the facade decor is an obligatory stage of finishing work. This will protect the finished product from sudden temperature changes and high humidity.

APPLICATION OF FOAM FOR FACADE DECOR PRODUCTION

Every insignificant detail, every contour and element used to decorate buildings and structures fulfills its own, infinitely important function. They create a special image of the house, giving it personality and helping to express its owner.

For the manufacture of such parts, various materials are used, among which a special place is given to the production of facade decor from polystyrene (expanded polystyrene).This unique material is the ideal solution to create a wide variety of architectural forms and implement the most daring design solutions.

Polyfoam has firmly taken its place in the architectural and decorative design of facades, and every year it is increasingly crowding out traditional materials such as stone, marble, and gypsum, since it has a lot of undeniable advantages:

- a huge variety of shapes, ease and speed in processing and finishing;

- evenness of the surface without the presence of seams;

- low weight, which allows avoiding additional loads on the building structure;

- ease and convenience of installation, without the use of special tools;

- resistance to external influences - precipitation, wind, ultraviolet radiation and temperature extremes;

- environmental friendliness - it is absolutely safe and non-toxic;

- durability - thanks to special coatings, the foam is not susceptible to the formation of fungus and mold, insect damage, as well as rotting;

- fire safety - in case of fire, it has the ability to self-extinguish almost instantly;

- cost is the most inexpensive material used for architectural design.

If you do not know where to buy facade decorative elements and other foam products at low prices in Moscow, please contact.

Features of thermo-facade panels

Thermo-façade panel consists of a cladding layer, behind which insulation is hidden

Structurally, all types of thermo-facade slabs are identical: they consist of two or three layers of facing building material, which is hidden from the inside by insulation. The front side is usually decoratively trimmed. The greatest interest from home owners is used by panels designed for clinker tiles, brick, natural stone.

Advantages and disadvantages of using

Thermal façade panels keep heat in cold weather and cool in summer heat. The insulating effect of such a cladding implies significant energy savings. High thermal insulation properties allow you to recoup costs during three to four heating seasons.

Another advantage is the low weight of the facade thermal insulation panels. They do not significantly load the foundation. Also, lightweight elements are easier to mount: most of the products are fixed manually without the use of special equipment.

Thermal façade slabs have other advantages:

- long service life;

- mechanical strength;

- resistance to temperature extremes and exposure to sunlight;

- moisture resistance;

- immunity to mold and mildew;

- fire safety;

- environmental friendliness.

The surface of the wall must be thoroughly prepared before fixing the slabs.

Properties and characteristics

The facade panel can be selected according to three parameters - temperature range, length and width

Cladding panels have the following parameters:

- length - 100-125 cm;

- width - 42–46 cm;

- temperature range - from minus 50 to plus 60 degrees.

The thickness of the products depends on the number of layers and insulation. Wall panels for insulation are durable. According to the manufacturers, they will hold out without loss of useful qualities and original shade for more than fifty years.

Sophisticated finishing of facades with PRODUCTS from "TOP-PENOPLAST"

is engaged in the production of products from expanded polystyrene, which can be used to decorate both external surfaces of buildings (facade decor) and internal interiors (decoration elements).

The list of foam elements for external decoration of building facades manufactured by our company is very wide: classic facade columns, pilasters, brackets, platbands, cornices, arches of any configuration, rustic materials, stucco moldings, capitals, gables for windows, moldings, and many other foam products at very attractive prices.

For the manufacture of architectural elements of facade decor from foam plastic, our company uses high-density polystyrene foam, the so-called extruded or extruded foam. Thus, all the decorative finishing of your home made of expanded polystyrene will retain its original appearance for a long time.

We pay great attention to the choice of coating that gives the products additional strength and protection from mechanical stress. At the same time, the use of special materials, such as elastic plaster, allows them to remain sufficiently plastic and prevents the formation of cracks.

Separately, it is necessary to mention the painting of products and the application of decorative coatings, thanks to which, elements of the facade made of foam plastic, you can give the appearance of natural stone, wood or marble.

QUALITY FOAM PRODUCTS for FACADE FINISHING AT FAVORABLE PRICES

The cost of all our products is more than democratic, therefore, when ordering even the most complex parts from expanded polystyrene for a facade in a luxurious palace style, you can be sure that you will not face significant financial costs.

If you want to buy decorative foam for the facade or order expanded polystyrene products according to your own sketch, please contact us. The facade decor made of foam plastic from is an ideal solution that combines high quality and affordable cost of all products!