Technical characteristics of the gas boiler AGV 80

The main indicator of heating equipment is power. However, another parameter is encrypted in the name of the model - the volume of the tank, which is 80 liters.

Of the important technical characteristics, there are:

- The time for heating the water in the tank is 60-70 minutes.

- The temperature range of the liquid is 40-90 ° C.

- The efficiency is 80%, in modern modifications it is higher - up to 85%.

- Thermal power - 7 kW (and heating capacity - 5.7 kW). The heated area is small: even with minimal heat loss, it is 60 m². Therefore, the boiler is suitable for small country houses or city apartments that cannot be connected to central heating.

Gas consumption is small, however, given the low (compared to modern boilers) efficiency, such a characteristic is unimportant.

Despite the spacious tank, the model does not take up much space. With a height of 1560 mm and a diameter of 410 mm, it is easy to find a suitable area for the device. The total weight of the equipment is 85 kg.

New generation of AGV

The AGV manufacturer was in no hurry to discontinue production of its popular boilers due to the obvious advantages. However, technical progress also affected this equipment: during the modernization, significant changes appeared in their design:

- Unreliable glass thermometers have been replaced with sturdy Italian ones.

- The new systems are equipped with automation from the American company Honeywell.

- To turn on the device with a handle, a piezo lighter is used.

- New coating technology has improved the appearance of the boiler.

Boiler agv 80 impressive technical characteristics

Design features

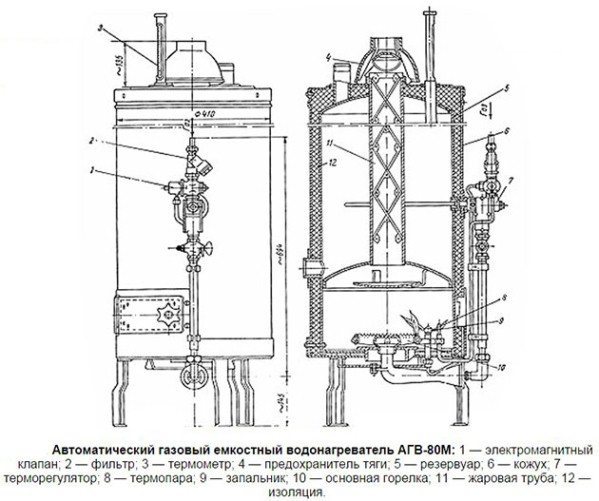

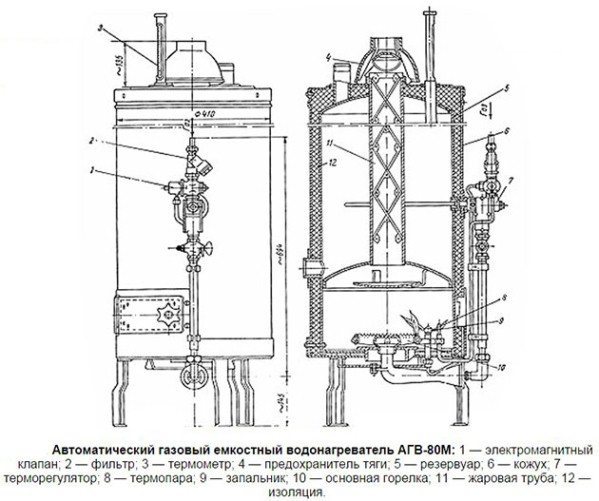

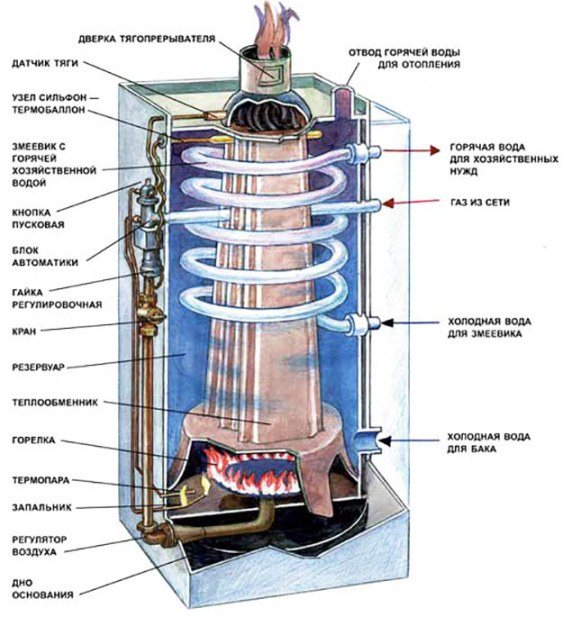

The main elements of the boiler are:

- galvanized tank with a volume of 80 liters, the walls of which are not subject to corrosion;

- heat exchanger - a flame tube equipped with a heat flow extension and passing through the center of the tank;

- the main burner, which ensures the operation of the coolant;

- devices for ensuring automatic safety (thermocouple, solenoid valve, igniter, draft sensor, thermostat);

- valve for gas supply to the burner.

The boiler is designed with thermal insulation of the galvanized tank. For these purposes, mineral wool is used.

The solenoid valve controls the flame. The part consists of a gas and an electromagnetic part, between which a membrane is placed. The thermocouple is a welded structure made of chromel and copel metal wires.

If the required temperature is maintained at the place of soldering of dissimilar conductors that are connected in series, then a closed circuit with a thermoelectric current is obtained. The work is based on the Seebeck effect: a thermocouple heated during gas combustion creates an electric current. The latter ensures the work of the protective automatic component.

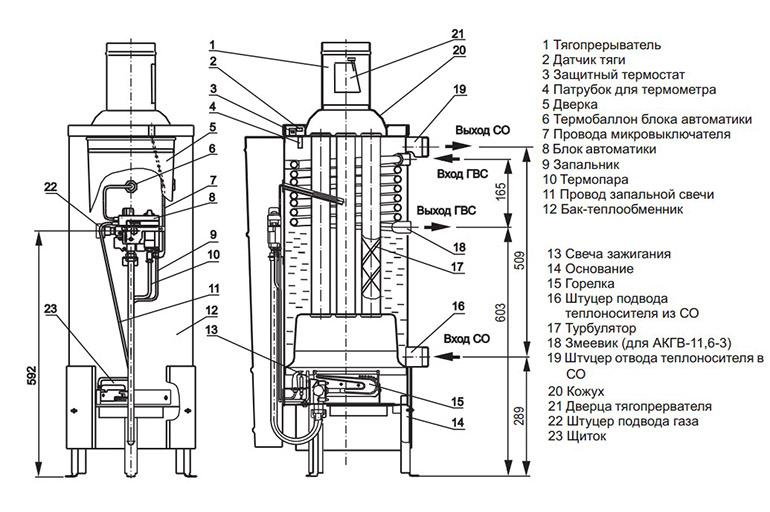

They also produce more complex modern modifications of boilers:

- AOGV - single-circuit models intended only for heating;

- AKGV - combined devices that allow you to additionally receive hot water.

Despite the fact that many details have been improved, both models practically do not differ in design from their predecessor.

AOGV uses a complex thermoregulation system to control temperature, which includes special sensors and valves. As soon as the indicator reaches a predetermined value, the automatic devices are triggered and the gas supply is stopped.

The system is powered by an electric current created by a thermocouple.The expensive versions of AOGV use thermostats that give a warning signal for the owner to adjust the temperature. The AKGV boiler is equipped with the same sensors for convenience and safety.

AGV design

The principle by which the most common model of those times functions - the AGV 80 gas boiler, is very similar in its simplicity to an ordinary kettle with water, put on a gas stove. A primitive round burner was installed under the mouth of one vertical steel pipe, ending on top of a chimney.

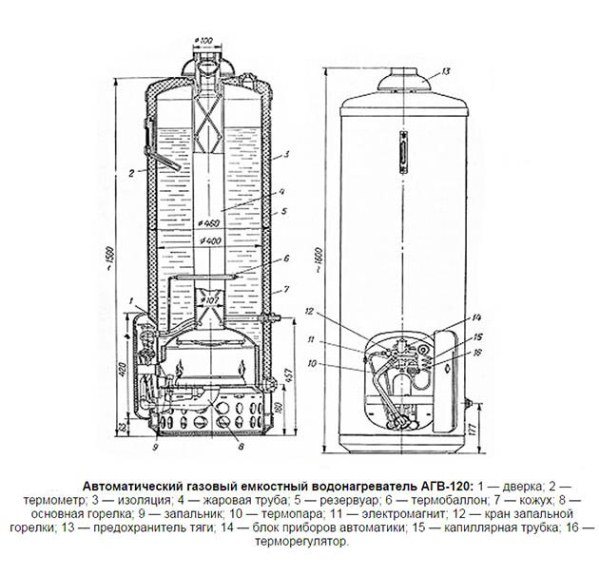

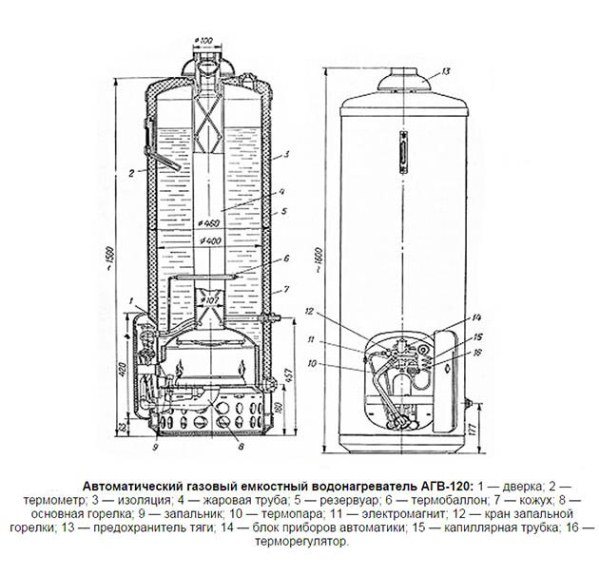

There were no copper or steel heat exchangers on the 80th model and the more powerful AGV 120, the only flame tube was immersed in a cylindrical water tank, as shown in the diagram:

To slow down the velocity of the flue gases, a turbulator was placed inside the pipe, due to which the efficiency of the installation increased slightly. As can be seen from the diagram, the apparatus was equipped with an automatic device that shut off the gas supply to the main burner when its pressure decreased or the water was heated to a certain temperature. More powerful boilers AGV 120 as a whole had the same design, this can be seen in the figure:

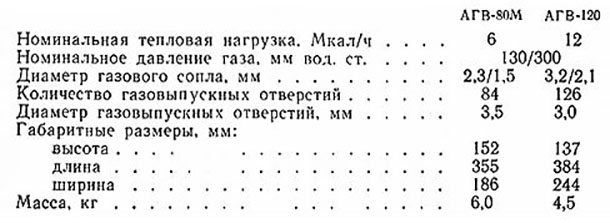

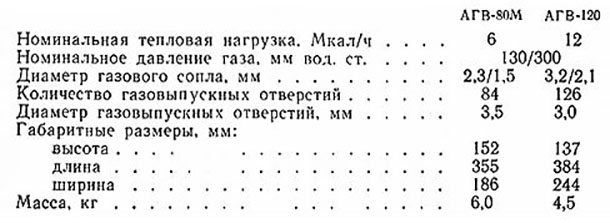

Here, the burner power and the unit's dimensions are larger, in addition, the temperature sensor here is not an ordinary brass tube with an Invar rod, but a thermocylinder. The kerosene expanding in it through the capillary tube influenced the gas valve mechanism, closing it if necessary. General technical characteristics of the AGV 80 and 120 boiler are shown in the table:

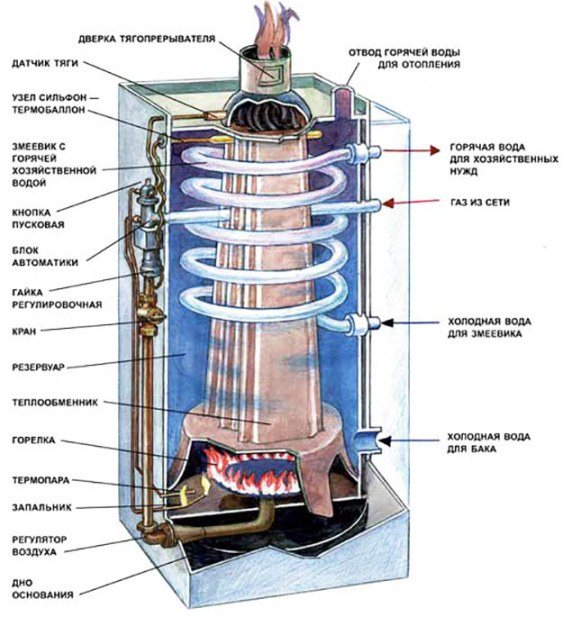

Modern boilers AGV (in decoding - automatic gas water heater), of course, have a more reliable and efficient design. The flame tube is now divided into several sections with turbulators in each, and a coil is installed in the water jacket of the device to prepare water for the needs of hot water supply. Details are clearly visible in the diagram:

The gas valve, the thermostat for the boiler and the entire set of automation are also modern. In budget modifications, Russian-made devices are installed, and in more expensive ones, Italian ones. They are designed to shut off the gas supply to the main burner if:

- the draft in the chimney will disappear, for which the corresponding sensor is responsible;

- there is a separation of the flame or spontaneous extinction of the burner;

- the gas pressure in the line has dropped.

Note. Also, the gas supply stops when the temperature of the heat carrier reaches the set value. In a word, in the updated AGV units for a private house, all systems function in the same way as in conventional gas boilers. The only difference is in the organization of heat exchange.

Principle of operation

The main element of the AGV design is a galvanized cylindrical tank. It is connected to the heating system of the house through pipes. Inside the tank there is a flame tube - a heat exchanger that heats up when the gas is burned.

In classic models, including AGV-80, a turbulator is placed in the tank, the operation of which increases the efficiency of the installation.

The heating system itself is a network that includes:

- ascending pipeline for hot water;

- radiators;

- expansion tank;

- return pipeline.

This provides a full cycle of equipment operation, which can be represented as the following algorithm:

- Heating of the coolant due to gas combustion.

- The rise of the liquid along the ascending pipeline to the radiators.

- Heat transfer.

- Reverse flow of water into the appliance, where the heating cycle is repeated again.

This system is called thermosyphon. It is based on natural circulation. Therefore, for full-fledged operation, additional nodes are not needed (for example, a circulation pump powered by electricity).

AGV is one of the non-volatile heating equipment models. Compensation for water losses in such devices comes from an expansion tank.

The AGV design allows you to install an external pump and provide forced circulation of the liquid. But then it is necessary that the house be able to connect it to a stably operating power grid, otherwise you will have to buy a UPS and a generator.

The system is based on the principles of natural draft. The air for the operation of the unit is taken from the room, and the combustion products are discharged through a pre-arranged chimney.

Advantages and disadvantages

Despite the apparent simplicity, AGV-80 boilers have such advantages as:

- Comparative ease of installation and ease of further management and maintenance. This concerns the safe regulation of the water temperature within a predetermined range.

- The tank is made of metal, corrosion resistant, strong and durable.

- Manufacturing of important units and parts using high-precision modern technologies. They are considered sensitive to the slightest changes in the parameters of the system.

- Energy independence. For the operation of the AGV, stable operation of the network, the cost of checking the sockets and wiring, and the adaptation of the system to increased load are not required.

- Virtually silent operation. There is no circulation pump and fan.

Installation of AGV means that the piping in the heating system can be made of any materials - cast iron, steel and metal-plastic, resistant to heating.

The operation of the unit does not depend on gas pressure drops in the network. Sophisticated protection allows you to turn off the system in time when the pressure drops.

Compared to models equipped with a circulation pump and a fan, AGV has a lower efficiency, there is no remote control.

There are technical features that lead to the destruction of the device. For example, if the temperature of the water in the system drops below + 50 ° C, condensation will begin to precipitate. Unlike modern models, in such boilers it is not used in any way, but it is able to extinguish the flame.

When combustion products are mixed with condensate, sulfuric and nitric acids are formed. The latter are harmful to human health and equipment, as they lead to corrosion.

When the temperature drops below 50 ° C, the water circulation in the system stops. If we are talking about a private house, in which no one lives in winter, the liquid must be drained and replaced with an “anti-freeze”.

Positive and negative sides

Previously, no one was too worried about gas consumption, and therefore the device satisfied everyone: manufacturers - with ease of manufacture, buyers - with cheapness. Now the device of water heaters has been brought in line with the modern requirements of regulatory documents on safety and energy saving, the efficiency of the units is 86-89%. The technical characteristics of the AOGV boilers manufactured by the Zhukovsky Machine-Building Plant are shown in the table:

Note. Models with a Russian automation unit belong to the Economy line, with an imported one - to the Universal and Comfort series. The letter "O" in the abbreviation means "heating", the letter "K" - combined, heating water for hot water supply.

Now let's objectively evaluate the positive aspects of heating with AGV. So, the currently offered autonomous gas water heaters have the following advantages:

low cost of equipment: this is the main advantage of these devices, their price is the most acceptable among all gas heaters;

- the simplest design: any gas boiler AOGV or AKGV is easy to operate and maintain;

- reliability;

- compactness;

- non-volatility: the device does not require electricity for its operation.

As usual, there are negative aspects. The durability of the unit is questionable, since it is not made of the best materials.Problems arise with the operation of Russian automatics on budgetary devices, and all, without exception, AOGV gas boilers inherited the disadvantage of their “ancestors” - the formation of condensate. This is even stated in the operating instructions: until the coolant warms up to a temperature of 25-30 ° C, condensate will drip onto the burner, flowing down from the walls of the tank.

Combined boilers AKGV create problems when heating water for hot water supply in the summer. According to the same instructions, the device goes into normal mode after 10 minutes. after opening a hot water tap, which is not very convenient for users.

Installation tips

Equipment installation rules are simple:

- Before starting work, carefully study the instructions for the unit.

- When installing AGV, organize a separate room for it, since this type of equipment takes air from the room.

- Provide good ventilation.

- Equip a chimney. It must be no less than the pipe diameter (minimum length - 5 m, horizontal section - up to 3 m).

- Clean the device through a special hatch. Since the chimney passes outside the house, debris and condensate are collected in it, causing the structure to fail.

- When installing the boiler, leave a free space in front of it within a radius of 1 m, the distance to the nearest wall is at least 2 m.

The walls and floor in the room where the AGV stands are finished with non-combustible materials. If it is not possible to perform such work, then a special screen made of basalt cardboard or sheet asbestos is used.

The connection of AGV to the gas supply system must be carried out by professionals. Basically, these are representatives of a company that has the appropriate license.

Criteria for choosing equipment for heating a private house

The main aspect when buying a unit is power. It is believed that for every 10 m² of the area there is 1 kW of energy. However, this calculation does not take into account heat loss. They depend on what materials the walls, ceiling and floors are made of in the house, from the region in which the building is located. All this, when carrying out complex calculations, is taken into account by specialists.

The power of the boiler in question is 7 kW. Taking into account the efficiency at the level of 85%, the indicator will only be enough for heating 60 m² - if the house is located in the southern region, and the walls and ceiling are insulated with modern materials. For the northern regions, the figure is up to 20% of additional capacity.

An important selection criterion is the functionality of the unit (only heating or that and hot water supply). It is generally accepted that the second option is less profitable, since it is more expensive, however, the first type of equipment (single-circuit apparatus), despite the savings, requires the installation of an additional boiler for liquid.

As for the automatic safety systems, even in advanced modifications they are quite simple. Electronic filling and many levers are not provided, but the security system is reliable and is not inferior to that of imported models.