Connecting the thermostat to the boiler is practically nothing complicated, therefore it does not require a call from a specialist. You just need to understand how the thermostat works, and connecting any thermostat to any gas boiler will no longer be a problem for you. And it doesn't matter what kind of boiler you have: Baxi, Bosch, Protherm, Ariston or another. The principle is the same everywhere. We will talk about this in our material.

Types of thermostats

Thermostats fall into two main categories: mechanical, which are simpler in design and cheaper, and electronic, which are more intuitive and functional.

Mechanical thermostats are controlled by a rotary wheel that controls the temperature and an on / off button. The error of such a thermostat is usually 1-1.5 degrees. The thermostat works with a special gas, the volume of which changes when the room temperature deviates from the set norm. When the temperature rises or falls, the mechanical thermostat opens or closes the contacts, thereby turning on or off the burner in the boiler.

Electric thermostats are a little more complex, but easy to use. Usually they have a display and several function buttons, with the help of which the temperature is regulated. At the same time, on many models, you can also set different temperature regimes for day and night, thereby creating a comfortable temperature for sleeping. This feature is also useful for offices after the end of the working day. This saves on gas costs.

The choice of one of the options depends entirely on your needs and the boiler model. Some manufacturers of gas equipment recommend using mechanical thermostats for their equipment, since they do not support high-tech electronic ones. Therefore, before buying a thermostat and connecting it to a boiler, it is imperative that you familiarize yourself with the technical characteristics of your boiler and its compatibility with various devices.

Selection Tips

- If you are on a budget, then get a simple, wired, electronic thermostat. Such devices are more technological, with better response, and the quality of their operation does not depend on contacts oxidizing in air, as in mechanical analogs.

- If you are concerned about saving energy resources, and with it your own funds, get a weekly programmer. This device will significantly reduce the temperature in the room, and, accordingly, the frequency of turning on the boiler plant during hours when all households are at work.

- If you have already made repairs, and there is no desire to chisel the walls for laying the cable, then purchase wireless air thermostats.

Basically, any room thermostat is like any wall mounted gas boiler. However, boiler manufacturers strongly recommend connecting air thermostats of only one brand. For example, according to the manufacturer, a room thermostat for a baxi gas boiler should only be of this brand. This is a marketing ploy to attract more buyers!

Remote thermostats and site selection

A significant advantage in favor of electronic models can be the presence of remote thermostats. In this case, the adjustment takes place using a separately removed panel, which can be placed in any place convenient for you.The selection of a location for a remote thermostat in any building should be guided by safety and comfort parameters. It is better to place the thermostat out of the reach of children; it is also worth considering the factors that can disable the device.

Currently, electronic thermostats with Wi-FI module are also produced. Data from thermostats can be transferred to your smartphone directly using special applications created by the developers. With these applications, you can adjust the temperature remotely. Such models will perfectly fit into the “smart home” system.

Principle of operation

Let's move on to an analysis of the principle of operation of a gas boiler directly, without a connected thermostat. Let's say your boiler is currently set to a temperature of 60 degrees Celsius. As soon as the burner flares up, the temperature begins to approach the preset value (in our case, 60 degrees). After reaching this temperature, the burner turns off, and the pump that cools the coolant in the heating system continues to work, and the water temperature drops.

It is also worth understanding what is happening in the boiler electronics at this time. While the boiler is heating up, a certain signal freely passes from point A to point B along a closed circuit. As soon as the temperature reaches the desired values, the circuit opens and the burner goes out. The network is opened by nothing more than a piece of wire, the so-called jumper. A relay thermostat, in its essence, is also such a jumper, only it does not work based on the water temperature, but taking into account the air temperature in the room.

Briefly about the principle of work

For a better understanding of the principle of operation of thermostats, we first explain the operation algorithm of the hot water heater in the basic configuration:

- The user ignites the boiler, using buttons or control knobs sets the desired temperature of the heating medium.

- Each device is equipped with an immersion or contact sensor that informs the control unit about the degree of water heating. When the temperature of the coolant reaches a predetermined threshold, the gas valve is triggered and cuts off the fuel supply to the main burner. The circulation pump continues to "drive" water through the system.

- After the coolant cools down to the lower temperature limit, the gas supply resumes, the burner ignites again and heats up the water.

Reference. In turbocharged wood-fired boilers, the automation turns off the blower fan. The flow of air into the furnace stops, the unit goes into smoldering mode.

Without an external temperature sensor, the heater “does not see” the air temperature in the premises and stupidly heats the water up to the specified limit. Result: in the transitional autumn-spring period, the so-called cycling is observed - frequent start / stop of the burner (once every 3-5 minutes), which reduces the resource of the unit as a whole.

Now about the main thing. The remote thermostat extends the intervals between turning on / off the gas boiler, since it is guided by the temperature of the air, which cools down more slowly. The device is switched on in the open circuit of the power supply of the gas valve (on TT-boilers - turbines) and the built-in pump.

Installing an automatic thermostat allows you to kill three birds with one stone:

- reduce energy consumption;

- make boiler control more convenient;

- extend the life of the heat source.

Important note. The listed items apply not only to gas heaters. Any heat generator equipped with an electronic or electrical control unit is connected to the thermostat - solid fuel, diesel, electric boiler, and so on.

When the room warms up to the specified temperature, the thermostat breaks the circuit, the burner and the built-in pump of the heat generator stop.The unit starts up after cooling the air by 1–2 degrees, which increases the downtime between shutdown and ignition to 15–20 minutes.

Let's note 2 significant nuances:

- When using a room regulator, the standard start / stop function based on the water temperature in the boiler jacket continues to operate. When the coolant in the boiler heats up to the set limit, the gas burner will turn off.

- If the burner is extinguished by the command of the internal temperature sensor, the standard circulation pump continues to work. When the remote thermostat is triggered, both devices stop - the burner and the pumping unit.

That is why it is important to correctly set up the connection between the boiler and the external thermostat.

Benefits

Thus, we completely disassembled the principle of operation of the heating system using an electronic or mechanical thermostat. This is a very convenient solution for several reasons:

- There is no need to manually adjust the water temperature to keep the room temperature comfortable.

- When using a wireless thermostat, there is also no need to set up the boiler directly, it is extremely convenient if the boiler is taken out in a separate room - the boiler room.

- It becomes possible to set different temperatures for day and night, this significantly saves gas at night.

Saving electricity and gas, a stable comfortable temperature, a minimum of time spent on adjusting heating equipment - all these are not whims, but well-founded requirements for a properly organized heating process.

Therefore, connecting a room thermostat to a gas boiler, to ensure all of the above conditions, becomes an obvious necessity. We will talk about the principle of operation of the thermostat and the types of the device. Let's look at the differences in the functionality of different models.

The article describes in detail the principles of connecting a temperature controller. The rules for installing different variants of the device are given. Following our recommendations, you will be able to carry out the installation yourself, without the help of heating technicians.

Benefits of using a thermostat in heating

Gas heating is already a blessing in itself and significantly increases the quality of life. But simplifying the management of gas heating equipment is an issue no less urgent.

Setting up and controlling the operation of a gas boiler can be carried out in two ways - manually or using a thermostat, which will automatically ensure a stable temperature regime.

Manual adjustment helps to set a certain temperature of the coolant in the system - when the temperature rises to the set values, the boiler turns off, when it drops, it turns on. As a result, the temperature in the house is maintained at a certain level.

But with a change in temperature outside, the set mode turns out to be incorrect and you have to manually reprogram the heating device. Such manipulations are carried out throughout the entire heating season, and this is inconvenient.

In addition, manual regulation means that the gas boiler operates in a constant on-off mode, with a working cycle period of about 10 minutes. This does not in the best way affect the duration of the boiler operation.

Even in a system with manual adjustment, regardless of the operation of the heating function, a constant circulation of the coolant is ensured with the help of pumping equipment, which means that excess electricity is consumed.

Automatic regulation, in contrast to manual control, turns off the circulation pump. The thermostat for the heating boiler maintains a stable temperature in the room by reacting to the temperature of the air in the room, and not the coolant in the heating circuit.

As a result, the microclimate in the house is significantly improved, the frequency of boiler starts is reduced, which means that its service life increases.

There are other advantages to using a thermostat:

- the device sets the optimal / economical temperature regime depending on the time of day;

- solves the problems of the gas boiler clock - frequent switching on and off;

- facilitates operation and increases the reliability of the heating system.

These are just some of the obvious advantages common to all types of thermostats. The advantages of individual models can be studied in more detail immediately before purchasing.

Types of room regulators

For automatic regulation of the boiler combustion according to the room air temperature, 2 types of thermostats are used:

- Mechanical. The circuit is broken and closed by a bimetallic plate, bending from heating. By changing the desired temperature, the user rotates the handle, which increases or decreases the gap between the plate and the second contact.

- Electronic (digital). Here, the role of a heat-sensitive element is played by a thermistor, which changes the resistance depending on temperature. The circuit, which includes the specified part, closes the relay contacts, focusing on the change in resistance and user settings.

Reference. Mechanical and electronic temperature sensors are used not only for the boiler. Thermostats are successfully used in other areas of the heating system, for example, to turn off the circulation pump of a separate radiator branch or for zone control of underfloor heating.

The mechanical device is connected to the heat generator via a cable. Most electronic models provide wireless connectivity. According to reviews, radio-controlled thermostats are gaining wide popularity due to their ease of installation and operation. How the wireless boiler thermostat works:

- The device consists of two units equipped with radio modules.

- The first block, which turns on the executive relay, is placed directly next to the heater and connected to the required connector. Power supply - from 220 volt household electrical system.

- The second unit with a display and control buttons is powered by batteries and installed in a convenient place in the home.

- A thermal sensor located inside the remote control reacts to the temperature of the air environment. At the right time, the radio module sends a signal to the first block to turn on / off the boiler. He opens the relay contacts, heating and circulation of the coolant stops or resumes.

Usually, electronic models are equipped with programmers that allow you to set the boiler operation schedule for a week. The room temperature can be changed several times during the day. Individual copies are programmed for 90 days and controlled via mobile communication, for example, via SMS or the Internet application of a smartphone.

Types of thermostats for gas boilers

Thermostats can be classified into three main types: mechanical, electronic, and electronic wireless.

Wired models cost less, but require cable laying - it is better to install a thermostat on a gas boiler before or during repair work in the house. Wireless models are more expensive, more functional, more convenient.

The choice of a thermostat for connection to a gas heating system is carried out taking into account the following basic criteria:

- functionality;

- accuracy of adjustment;

- the cost of the thermostat;

- ease of use and installation.

By functionality, they are distinguished:

- simple thermostats - help maintain the desired temperature in the house;

- wireless thermostats - they have a transmitter unit that is placed in another room for more accurate temperature control;

- programmable - allow you to set a stable temperature mode separately for day and night, program the heating system on days of the week, which significantly reduces fuel consumption;

- with hydrostat function - help to control the level of humidity in the room, reducing or increasing it according to the settings.

- With an additional floor sensor - the model is used, among other things, to regulate the temperature of the coolant in the "warm floor" system.

- With an additional water heating sensor - the device is used to regulate the temperature of the hot water supply and to control the heating system.

Separately, it is necessary to say about programmers - thermostats that are more complex in terms of functionality, which are installed, among other things, for controlling climate systems in so-called smart homes.

Programmers control the operation of not only heating and water heating equipment, but also air conditioners, pumps, and other devices. Some of them help to program an individual temperature regime for each day of the week with the ability to set from 1 to 6 fixed operating points.

What are thermostats for an electric boiler

What are they for and how they are used

Simple mechanical thermostat.

The temperature controller is a wired or wireless control panel that can be mounted on the wall in any convenient place.

There are both simple mechanical models, the functionality of which is smooth temperature control by degrees (especially important for electric boilers with mediocre 3 or 6-step power control), and automatic programmable models with an information display, which allow you to set more than 50 parameters of the boiler operation, program them change for the next day and even a week.

Automatic thermostats allow you to adjust the boiler operation once and up to a whole or even several heating seasons.

In general, room thermostats for electric boilers perform functions such as:

- measurement, control and maintenance of a certain comfortable temperature of the working environment;

- transmission of signals to the electric boiler from any place convenient for the owner in the house;

- protection against overheating or freezing of the heating system;

- programming the operating mode for the next day or week;

- remote control from the phone if there is a Wi-Fi or GSM module in the thermostat;

- remote notification (including via a smartphone) about malfunctions and emergencies in the operation of the heating system.

Existing types

The settings made on the thermostat have priority over the settings of the electric boiler itself. The principle of operation of the device depends on the type of temperature sensor used in it:

1. Mechanical thermostats

The simplest models, the principle of which is based on the operation of membrane and capillary temperature sensors. They use substances that significantly expand at the slightest increase in temperature, placed in a capsule. The expanding substance, upon reaching the maximum temperature threshold, exerts pressure on the relay membrane, as a result of which the contacts open, the thermostat signals a partial or complete decrease in the power of the electric boiler.

The main disadvantages of such thermostats are simple functionality, limited by turning a round rotary knob to set the desired temperature, and a high error - up to 3-4 ° C.

2. Electromechanical

They have a more complex design, based on which special metal plates are used as a temperature-sensitive element, producing a micro-discharge when heated to a certain temperature. The micro-discharge activates an electromagnetic relay that controls the mechanical valve.In general, electromechanical thermostats have + - the same functionality, but a much smaller error, their cost is 20-40% higher.

3. Electronic

The most modern and multifunctional devices equipped with electrical boards (automation), often with external sensors: both internal and external (outdoor). They are able to maintain or change the operating mode of the electric boiler without human intervention. Allow a minimum error of up to 0.5-0.7 degrees. We recommend paying attention to electronic thermostats in view of their functionality and economy.

Automation of modern models is able to maintain the most economical mode of operation of the electric boiler, constantly adjusting its operation in accordance with the temperature in the working room, which completely prevents unnecessary consumption of electricity. After all, reducing the temperature by 1 ° C is up to 5% savings.

How to choose an external temperature sensor and organize weather-dependent boiler control

General principles of connecting the thermostat

The method and diagrams of connecting the thermostat to the heating equipment itself can be found in the technical passport of the gas boiler. Modern equipment, regardless of the manufacturer, requires connection points for the thermostat. The connection is made using the terminals on the boiler or the thermostat cable included in the delivery.

When using a wireless thermostat, place the measuring unit only in a residential area. This can be the coldest room or the room where the largest number of people gather most often, the nursery.

It is impractical to install a thermostat unit in a kitchen, hall or in a boiler room, where the temperature regime is unstable.

Connection of various types and models of thermostats may have their own characteristics, installation is carried out in accordance with the manufacturer's instructions, which is attached to the device.

Recommendations include a comprehensive description of the regulator operation, connection method and diagrams. Next, we will tell you how to correctly connect the thermostat to a gas boiler and about the installation features of the most typical regulator models.

Mechanical thermostat connection

The mechanical-type thermostat is distinguished by its reliability and simplicity of design, low cost, and long-term operation.

At the same time, it supports only one temperature regime, which is set by changing the position of the knob at the temperature scale mark. Most thermostats operate in a temperature range of 10 to 30 ° C.

The mechanical thermostat has the simplest principle of operation and is triggered by opening and opening the circuit, which occurs using a bimetallic plate. The thermostat is connected to the boiler through the terminal box on the boiler control board.

Installation of an electronic thermostat

The design of the electronic thermostat assumes the presence of an electronic board that is responsible for controlling the device.

The potential serves as a control signal - a voltage is transmitted to the boiler input, which leads to the closing or opening of the contact. The thermostat must be supplied with a voltage of 220 or 24 volts.

An electronically controlled thermostat is used to organize the operation of complex climate systems. It will help in controlling not only an atmospheric or turbine gas boiler, but also a pump, air conditioner, and a servo drive in the heating system.

How to connect a wireless thermostat?

The wireless thermostat consists of two units, one of which is installed in the living space and acts as a transmitter. The second block is mounted near the heating boiler and connected to its valve or controller.

Data transmission from one block to another is carried out over a radio channel.To operate the device, the control unit is equipped with an LCD display and a small keyboard. To connect the thermostat, set the address of the sensor and install the unit at a point with a stable signal.

The main disadvantage of the wireless thermostat is the power supply of the external unit from the batteries, which have a limited resource and therefore require frequent replacement. To ensure trouble-free operation, the device is equipped with an alarm function that warns of the need to replace the battery.

How to connect a room thermostat to a gas boiler

To install the regulator, you do not need any professional skills or special tools, it is enough to understand the installation diagram, follow the instructions of the manufacturer of the gas boiler and regulator, observe safety precautions for working with electric current. Then the installation can be done independently without the help of a specialist.

Connection diagram

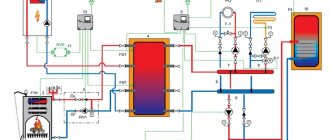

The diagram of a gas boiler should indicate whether it is possible to connect a thermostat to it

It is important to make sure that the installation of additional equipment is approved by the manufacturer and will not harm the heating system.

Incorrect installation can lead to damage to expensive equipment and loss of warranty.

In the case when the installation of the control unit will be carried out inside the boiler, they find a suitable place for it. An installation box can be used if required.

Important! When connecting the thermostat, it is strictly necessary to comply with the boiler manufacturer's requirements!

If you study the circuit of the main board of the gas boiler, you can see that it has two contacts connected by a jumper, where the electric current first leaves the board and then returns to it, controlling the switching on and off of the heating boiler. In many modern models, for ease of installation, this jumper is located on a separately brought out block, where the thermostat is simply connected.

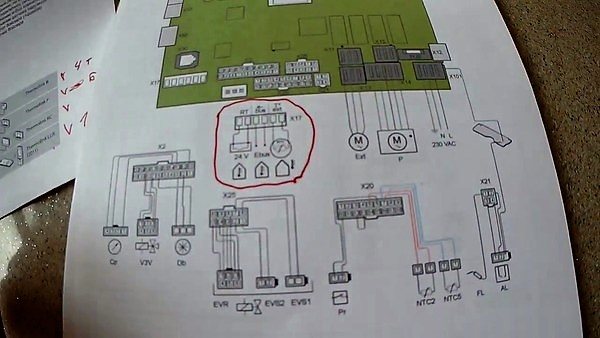

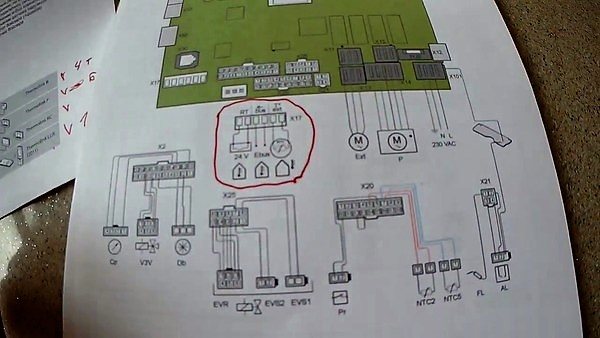

Photo 1. Printed circuit board of a gas boiler. The part that shows the possibility of connecting various thermostats is circled in red.

But on some types of heating equipment, the installation site will have to be looked for directly on the board. In this case, the screws that hold the jumper are unscrewed, removed, and the wires going to the thermostat are mounted on this place.

A correctly connected thermostat passes through itself an electric current going to the boiler from the network, thus controlling the switching on and off of the entire heating system. If the air in the room is heated more than that set on the regulator during its adjustment, then the device turns off the gas boiler, and when the temperature drops below the specified limit, then the heating turns on again and the air in the house heats up.

Materials and tools

No special tools are required to mount the thermostat to the gas boiler. Everything that is needed to install the device in the heating system is included in the delivery kit.

To install the regulator, you will need technical passports of the thermostat and the heating boiler to verify the electrical wiring diagrams, a household screwdriver, a tester for checking the presence of voltage in the network, a set of tools for mounting the device on the wall in a living room.

Choosing a place to install the thermostat

Before starting the installation work, choose a place for installing the thermostat

It is extremely important to choose the right room for the device, because it is precisely according to the temperature and humidity of the air in this room that the entire heating system in the house will be adjusted.

The thermostat must be installed in a residential area, and not in a technical one. Usually they choose the coldest room in the whole house, for example, a corner room. Installing the appliance in a boiler room or in a storeroom will lead to incorrect operation of the heating.Do not hang the regulator near heating batteries, household appliances that emit thermal noise: stoves, heaters. It is not recommended to place the regulator in a draft, near windows, or where it will be exposed to direct sunlight.

The thermostat must be easily accessible and visible in order to change the temperature settings or replace the batteries at any time.

Installation rules:

- Installation height is no more than one and a half meters above the floor level.

- Do not install on an external, cold wall of the house.

- The device must be freely accessible.

- Do not hang near stoves, air conditioners, windows.

- Do not expose the device to direct sunlight.

Efficient heating management is a vital part of the efficient operation of a boiler and home heating system. Proper use of controls will reduce the energy consumption of the unit, while creating a comfortable temperature in every room of the house, avoiding overheating of the premises

A thermostat (or programmer) controls the operation of the boiler depending on the temperature in the room.

Up to 20% of the volume of consumed energy carriers can be saved by using this kind of automation. And the prices for energy carriers are quite high and every normal person wants to reduce his expenses.

We consider the situation when the boiler is designed correctly, the necessary insulation of the premises is completed, and the heating system is functioning normally.

Conclusions and useful video on the topic

How is the thermostat connected to a gas boiler:

Room thermostats for regulating the heating system:

Self-assembly of the device should not cause absolutely any difficulties. But do not forget, when connecting the thermostat to a gas boiler, to study the instructions that come with the device and the technical documentation for the heating equipment.

Tell us about your own experience in choosing and connecting a thermostat to a gas boiler. Share useful information that may be useful to site visitors. Please leave comments in the block form below, ask questions, post photos on the topic of the article.

We make the connection of an IR heater through a thermostat by video

Hello everyone! In this short post, I will answer the most popular question that comes up after buying a room thermostat. This question sounds like this: "How to connect a room thermostat to a gas boiler ???". It often happens that the instructions for this useful gadget cannot answer this most important question. Then you have to use imagination, logic and common sense. Hope this post makes this task easier for you. Let's start the description, as usual, from simple to more complex.

Mechanical thermostat operation diagram.

A mechanical room thermostat is the simplest version of a room thermostat, in which a circuit is closed or opened using a bimetallic plate. Such a thermostat does not require power supply. The scheme by which it works is as follows:

As you can see from the diagram, there are two ways to connect such a thermostat;

- Through the NC terminal - connection for turning on air conditioners.

- Through the NO terminal - connection for gas and other boilers.

On the other side, it is necessary to connect the wires to the terminal box on the boiler control board. In this case, you must first remove the jumper and fix the ends of the wires with screws.

This connection scheme is the simplest and is used on mechanical and electronic programmable thermostats. In this article, I will introduce one more circuit.

Installing and connecting the device

The installation of a household regulator consists of two stages - fastening in a convenient place and connecting to a gas (solid fuel) boiler.In order for the thermostat to record the temperature without deviations, position the control element according to the recommendations:

- the minimum height from the floor is 1.5 m, the maximum is 1.7 m;

- no heating radiators, heaters or other household appliances that distort the thermal picture (including air conditioners) should be within 1 m of the device;

- exclude the impact of drafts, working ventilation;

- it is undesirable to place the sensor away from heated rooms.

Advice. For a private house with underfloor heating, it is worth buying a thermostat model equipped with an additional temperature sensor. The latter is placed under the floor surface and measures the temperature in the lower area of the room.

After fixing the device to the wall according to the manufacturer's instructions, lay the wire to the heat source in a hidden or open way (if available) How to connect the regulator to the boiler:

- Connect one end of the control cable to the terminals marked COM (common) and NO (normally open) of the thermostat. On the wireless version, these terminals are located in the relay box.

- In the operating instructions for the heat generator, find the connection diagram for the external thermostat, the marking and the location of the contacts.

- Remove or fold down the front panel of the gas heater, which covers access to the control board and connectors.

- Remove the jumper inserted between the terminals indicated in the passport. Do not throw away the part, you may need it later.

- Connect the wires from the regulator contacts to the freed terminals. It is not necessary to observe the polarity.

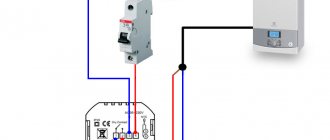

- When installing the wireless thermostat, run a three-wire 220 V power cable with a ground wire to the second relay unit.

Advice. If on the contacts of your device instead of the indicated marking there are numbers or incomprehensible letters, find the 2 necessary terminals using a tester (the circuit between them must be open). There are three contacts in total, the COM and NC pair are initially closed, as shown in the diagram above.

Details of installing a wireless thermostat are shown in the video:

Non-volatile floor standing boilers equipped with gas automatics 630 SIT, 710 MiniSIT, SABK, Orion and the like are incompatible with remote controls. The reason is the completely mechanical design of the gas valve and the absence of electrical circuits where a relay-breaker can be turned on.

Connection diagram of the regulator to the SIT 820 NOVA valve

The exception is gas heat generators equipped with "Kare" automatics and the latest generation of Italian valves EuroSIT - 820 NOVA. These blocks are provided with solenoid valves and special contacts for connecting external thermostats of two types - mechanical and digital.

A solenoid valve is used in the "Kare" automatics, where the thermostat is connected.

Connection diagram for electronic thermostats.

The electronic thermostat has an electronic circuit inside instead of a bimetallic plate. The supply voltage must be connected to this electronic circuit. It can be equal to 220 or 24 volts and is supplied through the wire.

Here, the control signal is potential (voltage), which is supplied to the terminal box of the boiler or a special hub. To make it clearer, look at the picture below:

It can be seen from the picture that not 2, but 3 wires go to the electronic thermostat:

- L is the supply voltage.

- N - neutral wire.

- I - output signal.

An unconnected port is used to enable "night" operation, in which the room temperature is reduced by 4 degrees without thermostat regulation.

Electronic thermostats are used to organize complex climate control systems in the house, such systems are popularly called "Smart Home". They can be used to control pumps and valve servos in heating systems. How it looks can be seen in the picture above.

How to choose a thermostat for an electric heating boiler

There are two ways to maintain the temperature of the coolant in a house heated with electricity:

in manual mode;

using automation.

Nowadays, most people give up manual control by choosing the second method. To use it, you must have a device that constantly measures the temperature and, depending on its value, turns off or turns on the heating.

For this purpose, devices are used that constantly perform the following functions:

control of the temperature of the working environment;

transmission and reception of signals through communication channels;

information processing and team formation for the executive power unit;

The block-by-block principle of the regulation system is shown in the figure.

Structurally, such devices can be performed:

1. mechanical autonomous devices of direct action;

2. electronic automatic installations.

Direct acting thermostats

They work on the principle of changing the geometric dimensions of a bimetallic plate, working fluid, gas or paraffin during heating and cooling.

Composite plates of two metals with different coefficients of linear thermal expansion are used in low-power devices on thermal relays of various designs. When heated, the bimetal bends and opens the contacts, turning off the power supply. After the plates have cooled down, the circuit returns to working condition.

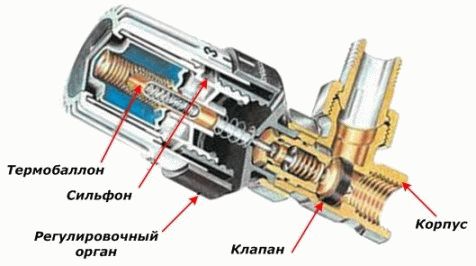

The design of the direct-acting thermostat includes:

spool with valve and stem;

bellows with a working thermal medium.

The entire device is installed in the hot water supply pipeline, senses its temperature. When heated, the working medium expands and acts on the valve, which moves, blocking the flow area of the line. When the coolant cools, the valve returns to its place.

Direct-acting thermostats measure the temperature of the water circulating through the heating system to regulate it. This method only indirectly maintains heat in the premises, does not take into account its true value.

Air electronic temperature sensors

To better maintain the microclimate in the premises, sensors that monitor the air temperature in the room help. It is customary to call them thermostats and add the word "air".

Thus, it turns out that the thermostat simply maintains the temperature of the coolant in a certain range, and the thermostat works more accurately, stabilizing the microclimate of the room. If the air in the room is additionally heated by some sources, for example, by the sun's rays through the glass of windows or from the heat of operating electrical appliances, the thermostat will not quickly sense these factors, and the thermostat will react quickly, saving energy and equipment resource.

Thermostats operate as part of electronic automatic devices, have a certain temperature stabilization range and, by their design, can transmit information to the logic and control unit:

2. using radio waves.

They all need power supply. The former are supplied with electricity using the power supplies of the circuit, while the latter are powered by built-in batteries or accumulators. To save their energy, intermittent mode is often used, when the air thermostat takes measurements for fractions of a second and transmits them to the logic block, and then turns off for a few minutes. The following measurements are repeated in a similar cycle.

Electric boiler control principle (click on the picture to enlarge):

Wireless thermostats typically operate on one of two frequency ranges officially designated for household appliances:

868 MHz (elite class);

433 MHz (economy class).

Which wire can be used to connect room thermostats?

Another important point in connecting a thermostat is the choice of wire.Usually, the cross-section and number of cores are indicated in the instructions for a specific product. In addition, one must remember the distance from the thermostat to the boiler or hub to which the thermostat is connected - if the output on the thermostat is potential, then the length of the wire can have a significant effect on the operation of the automation. This is due to the voltage drop on the wire. To reduce it, it is worth taking a wire of the largest possible cross-section.

Most often, a two-wire wire with a cross section of 0.5 or 0.75 "squares" is used to connect mechanical thermostats... For electronic ones, as I described above, it is important to consider the length of the wire. The longer the wire, the larger the cross-section should be (the usual cross-section does not exceed 1.5 "squares")... But the manufacturers do not advise exceeding the wire length of 100 meters, although this is not specified in the passports and product instructions.

Wireless thermostat connection diagram.

At the moment, wireless thermostats are widespread and have seriously pushed their wired counterparts. It is easier to work with them, there is no need to pull wires from the thermostat to the sensor throughout the house. It is enough just to set the address of the sensor and install it in a place with stable signal reception from the thermostat. As for the connection diagrams for such devices, there may be two of them:

Open circuit connection diagram.

The diagram is no different from the wiring diagram for a mechanical thermostat. The inclusion of a boiler, pump or servo drive occurs when a current appears in the circuit.

Potential (voltage) connection diagram.

In this diagram, when the circuit is connected, the thermostat transmits a voltage to the boiler input, which turns on the boiler, pump or servo drive.

Features of different installation schemes

The IR heater is connected as standard, like all electrical appliances. This can be a connection through an outlet or a separate line drawn from a separate one on the electrical panel. That is, there are two wires: neutral and phase.

The thermostat is installed in the network between the vending machine and the heater. Simple circuit for one or two heaters

:

The thermostat has four terminals: two input (phase and neutral) and two output (also "+" and "-").

If the heater is alone

:

- from two wires are laid, which are connected to the corresponding terminals of the thermostat;

- two wires are attached to the output terminals of the latter, taking into account the polarity - they are connected to the IR heater. This is a serial connection.

If there are two heaters

:

- From the thermostat, you need to remove four wires (two phases and two neutrals) and route the wiring to the heaters. This is the so-called parallel connection.

- Two wires need to be removed from the thermostat, lead them to one heater, and then to the second. This will daisy chain two heaters.

In some cases, it will be necessary to connect the phase directly (from the machine to the heater), and the neutral through the thermostat. The disadvantage of this method is that the thermostat does not work correctly. Complicated wiring diagram for multiple heaters

:

- the thermostat is connected to the machine on the electrical panel;

- output terminals are connected to a magnetic starter;

- the outgoing contacts of the starter are connected to the heater.

This type of connection is suitable for industrial heaters or multiple IR heaters. assumes automatic operation.

In conclusion, I would like to remind you that any powerful electrical devices, and even more so heating or heating ones, require increased attention to safety measures.

First of all, this concerns grounding. the heater must be equipped with conductors of sufficient thickness and low resistance. In fact, the protection is obliged to divert excess current of any unthinkable magnitude. Human life depends on it!

Connecting a thermostat is not an easy task.Even if you easily figured out all the intricacies of the process, you may not have enough skills in handling tools. Having assembled everything according to the diagrams yourself, you need to ask a specialist to check your work again.