Heat pump calculation example

We will select a heat pump for the heating system of a one-story house with a total area of 70 sq. m with a standard ceiling height (2.5 m), rational architecture and thermal insulation of the enclosing structures that meets the requirements of modern building codes. For heating the 1st quarter. m of such an object, according to generally accepted standards, it is necessary to spend 100 W of heat. Thus, to heat the whole house you will need:

Q = 70 x 100 = 7000 W = 7 kW of thermal energy.

We choose a heat pump of the "TeploDarom" brand (model L-024-WLC) with a thermal power of W = 7.7 kW. The compressor of the unit consumes N = 2.5 kW of electricity.

Reservoir calculation

The soil on the site allocated for the construction of the collector is clayey, the groundwater level is high (we take the calorific value p = 35 W / m).

The collector power is determined by the formula:

Qk = W - N = 7.7 - 2.5 = 5.2 kW.

Determine the length of the collector pipe:

L = 5200/35 = 148.5 m (approx).

Based on the fact that it is irrational to lay a circuit with a length of more than 100 m due to an excessively high hydraulic resistance, we accept the following: the heat pump manifold will consist of two circuits - 100 m and 50 m long.

The area of the site that will need to be allocated for the collector is determined by the formula:

S = L x A,

Where A is the step between adjacent sections of the contour. We accept: A = 0.8 m.

Then S = 150 x 0.8 = 120 sq. m.

"A heat pump is very expensive!"

Indeed, turnkey installation of a geothermal heating system in 2000-2010, cost about $ 30,000-40,000... There were three main factors behind such a high price:

- the cost of drilling at that time was 35-50 USD. for 1 meter. As a result, 60-70% of the total budget went to the device of the external collector. Now, thanks to the crisis, the cost of drilling has dropped to $ 15-17. for 1 meter.

- the price of heat pumps has now significantly decreased both due to the increased internal competition in the Belarusian market, which made the appetites of local players in this market “curb", and due to the worldwide reduction in the cost of equipment of this type.

- wider introduction of "horizontal" reservoirs, the installation of which is two times cheaper than "vertical" drilling, and at the same time is not inferior to "vertical" reservoirs in terms of efficiency.

As a result, today the average the cost of the "Turnkey" system device (with all equipment and works) decreased up to 9000-15000 USD At the same time, you do not need to develop and approve a project in the Ministry of Emergency Situations, the construction of "step-down" stations (during gasification), the installation of a chimney, compliance with fire regulations, etc.

Types of heat pump designs

There are the following varieties:

- ТН "air - air";

- ТН "air - water";

- TN "soil - water";

- TH "water - water".

The very first option is a conventional split system operating in heating mode. The evaporator is mounted outdoors, and a unit with a condenser is installed inside the house. The latter is blown by a fan, due to which a warm air mass is supplied to the room.

If such a system is equipped with a special heat exchanger with nozzles, the HP type "air-water" will be obtained. It is connected to a water heating system.

The HP evaporator of the "air-to-air" or "air-to-water" type can be placed not outdoors, but in the exhaust ventilation duct (it must be forced). In this case, the efficiency of the heat pump will be increased several times.

Heat pumps of the "water - water" and "soil - water" type use a so-called external heat exchanger or, as it is also called, a collector for heat extraction.

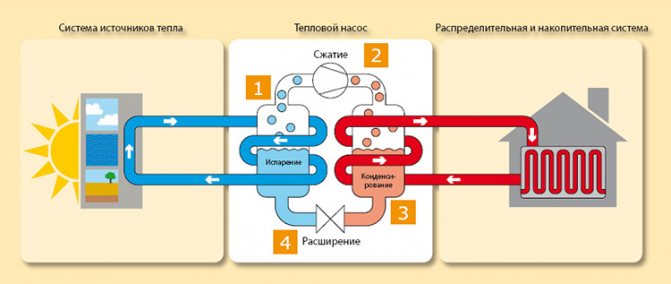

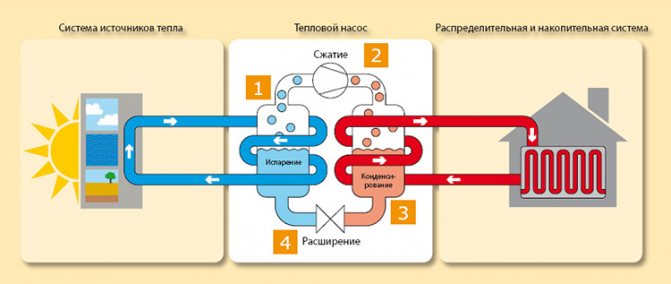

Schematic diagram of the heat pump

This is a long looped tube, usually plastic, through which a liquid medium circulates around the evaporator. Both types of heat pumps represent the same device: in one case, the collector is immersed at the bottom of a surface reservoir, and in the second - into the ground. The condenser of such a heat pump is located in a heat exchanger connected to the hot water heating system.

Connection of heat pumps according to the "water - water" scheme is much less laborious than "soil - water", since there is no need to carry out earthworks. At the bottom of the reservoir, the pipe is laid in the form of a spiral. Of course, for this scheme, only a reservoir is suitable that does not freeze to the bottom in winter.

Why a heat pump?

In addition to heating in the cold season, the pump allows you to switch to the process of air conditioning in the living room in the summer. To do this, the pump is transferred to the reverse mode of operation - the cooling function. To ensure the environmental cleanliness of not only their own homes, but also the atmosphere of the entire planet as a whole, the use of heat pumps as heating is very justified. In addition, the equipment boasts long term of work, cost savings, safety and the creation of a comfortable environment in the home.

All types of energy resources are becoming more expensive with each term, so zealous owners are ready to install expensive equipment that will pay off by working without the use of artificial fuel. The purchase of liquid, gaseous or solid fuels is not required for the efficient operation of the heat pump.

In private houses with a large area, the use of a heat pump in conjunction with a backup heating method allows you to recoup the investment costs in the sixth year of operation. At the same time, about 6 kW of heat is released per 1 kW of consumed electricity. The heat pump allows you to obtain a water temperature in the system up to 70 ° C.

In a house with an installed heat pump no need to use air conditioning, since in the summer period a coolant circulates along the circuit, which is cooled in the ground to a temperature of 6 ° C. It is cheaper in cost than using separate air cooling systems. To make the pump even more efficient, additional heating branches of the pool are connected to it, and in the summer, energy from solar panels is used.

Heat pump in action

Under the hard crust and mantle of the planet is a red-hot core. For many years to come, over the life of many generations of earthlings, the core will not change its temperature, and will warm up our common home from the inside. Depending on climatic conditions, at a depth of about 50-60 m, the temperature of the earth is within 10-14 ° C... Even in permafrost, the use of a heat pump is possible, only the depth of pipe laying will have to be increased.

How it works

The equipment is designed to collect low ambient temperatures at depth, convert it into high-temperature energy and transfer it to the home heating system. The planet constantly emits heat, which is used to heat the home. Heat is obtained from the surrounding air and water, which accumulate solar energy.

In fact, a heat pump is a unit that resembles the operation of refrigeration equipment. Only in the refrigerator is the evaporator located so that it discharges unnecessary heat, and in the heat pump it is in constant contact with the source natural heat:

- using vertical or oblique wells, interacts with the land mass located below the freezing point;

- the use of pipes at the depth of warm lakes and rivers allows you to collect the energy of non-freezing water flows;

- special devices collect the temperature of the warm air outside the dwelling.

The movement of the fuel carrier through the system is organized by a compressor. To increase the temperature collected at the depth of the earth, a system of narrowed funnels is used. Passing through them under pressure, the carrier contracts and increases the temperature. The condenser installed in the system gives off energy to heat the liquid in the heating system, which ultimately enters the radiators of the internal heating circuit of the house.

For use of the heat pump all year round the system supplied with two heat exchangers... The evaporator of one releases cooling energy, while the other acts as a heat supplier to heat the room. The source for collecting heat is the bowels of the earth, the bottom of non-freezing water bodies or air masses, from which long pipes borrow low-temperature energy.

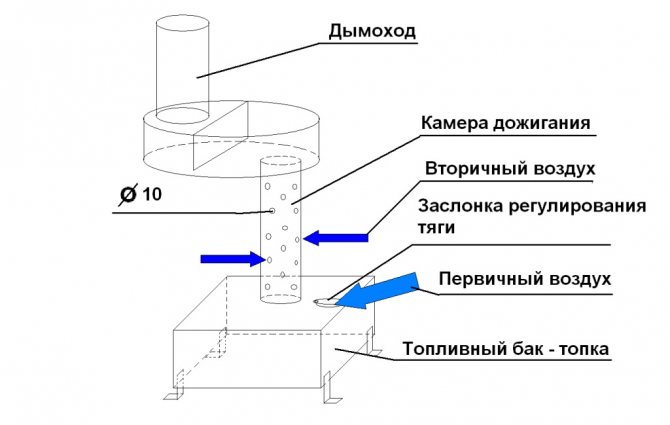

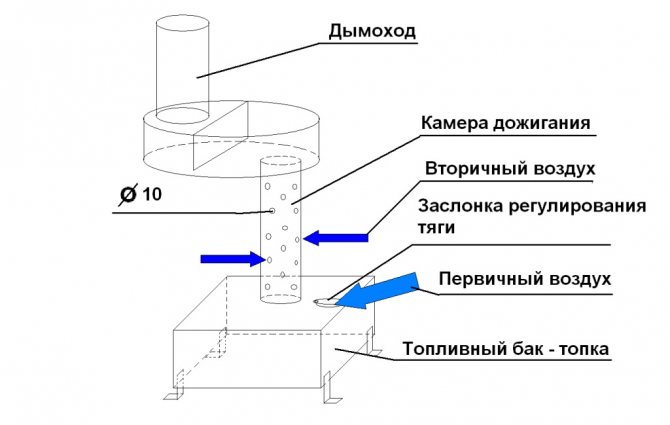

Structural diagram of a pump of a private house

- a system of pipes for external, sometimes remote collection, in which a heat carrier is constantly moving;

- working system of the collector, which includes a compressor, pipes, heat exchangers, valves and funnels of various actions;

- internal heating system of the house with pipes and radiators or air cooling system.

The operating period during which there will be no breakdowns of fuel equipment, manufacturers and installers of pumps are called 20 years. But such a statement is unlikely, since no one has canceled the laws of physics, and constantly rubbing and moving parts will fail earlier. The optimal period of work without repair and replacement of parts can be designate a figure at 10 years.

Making a heat generator with your own hands

List of parts and accessories for creating a heat generator:

- two pressure gauges are needed to measure the pressure at the inlet and outlet of the working chamber;

- thermometer for measuring the temperature of the inlet and outlet liquid;

- valve for removing air plugs from the heating system;

- inlet and outlet branch pipes with taps;

- thermometer sleeves.

Selection of a circulating pump

To do this, you need to decide on the required parameters of the device. The first is the pump's ability to handle high temperature fluids. If this condition is neglected, the pump will quickly fail.

Next, you need to select the working pressure that the pump can create.

For a heat generator, it is enough that a pressure of 4 atmospheres is reported when the liquid enters, you can raise this indicator to 12 atmospheres, which will increase the heating rate of the liquid.

The performance of the pump will not have a significant effect on the rate of heating, since during operation the liquid passes through the conditionally narrow diameter of the nozzle. Usually up to 3-5 cubic meters of water is transported per hour. The coefficient of conversion of electricity into thermal energy will have a much greater influence on the operation of the heat generator.

Manufacturing of a cavitation chamber

But in this case, the flow of water will be reduced, which will lead to its mixing with cold masses. The small opening of the nozzle also works to increase the number of air bubbles, which increases the noise effect of the operation and can lead to the fact that bubbles begin to form already in the pump chamber. This will shorten its service life. As practice has shown, the most acceptable diameter is 9–16 mm.

In shape and profile, nozzles are cylindrical, conical and rounded. It is impossible to say unequivocally which choice will be more effective, it all depends on the rest of the installation parameters. The main thing is that the vortex process arises already at the stage of the initial entry of the liquid into the nozzle.

Calculation of the horizontal heat pump collector

The efficiency of a horizontal collector depends on the temperature of the medium in which it is immersed, its thermal conductivity, as well as the area of contact with the pipe surface. The calculation method is rather complicated, therefore, in most cases, averaged data are used.

- 10 W - when buried in dry sandy or rocky soil;

- 20 W - in dry clay soil;

- 25 W - in wet clay soil;

- 35 W - in very damp clay soil.

Thus, to calculate the length of the collector (L), the required thermal power (Q) should be divided by the calorific value of the soil (p):

L = Q / p.

The values given can only be considered valid if the following conditions are met:

- The plot of land above the collector is not built-up, not shaded or planted with trees or bushes.

- The distance between adjacent turns of the spiral or sections of the "snake" is at least 0.7 m.

When calculating the collector, it should be borne in mind that the soil temperature after the first year of operation drops by several degrees.

How heat pumps work

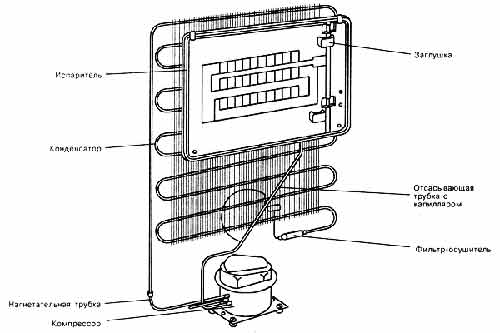

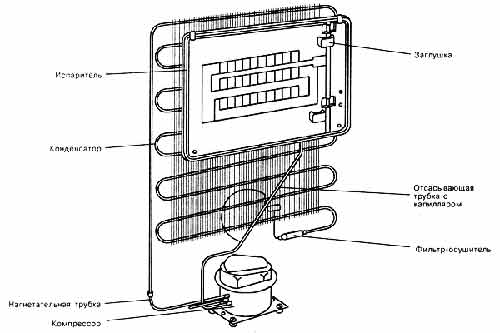

Any heat pump has a working medium called a refrigerant. Usually freon acts in this capacity, less often ammonia. The device itself consists of only three components:

- evaporator;

- compressor;

- capacitor.

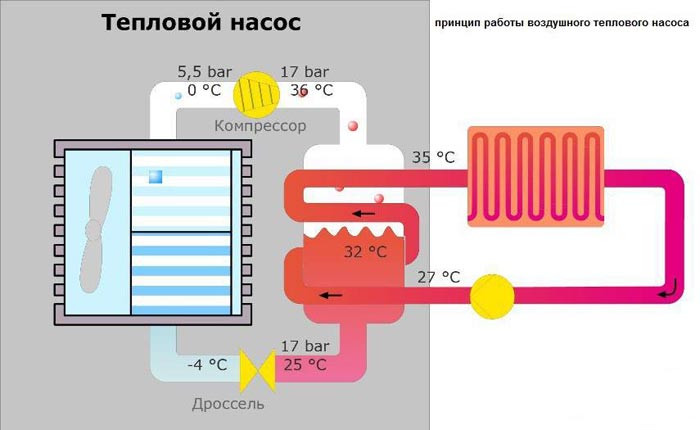

The evaporator and the condenser are two tanks that look like long curved tubes - coils. The condenser is connected at one end to the outlet of the compressor, and the evaporator to the inlet. The ends of the coils are joined and a pressure reducing valve is installed at the junction between them. The evaporator is in contact - directly or indirectly - with the source medium, and the condenser is in contact with the heating or DHW system.

How the heat pump works

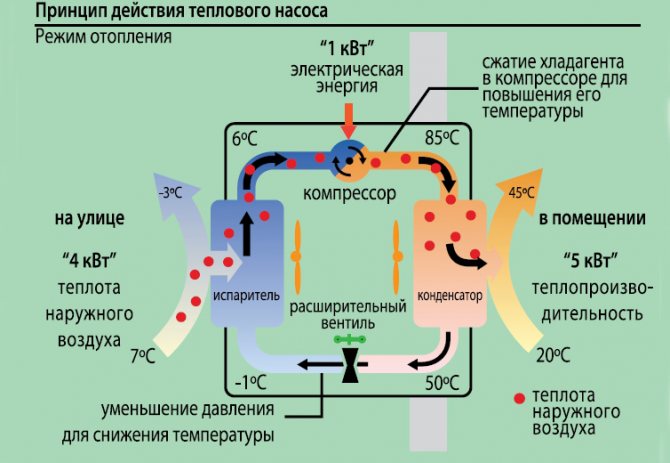

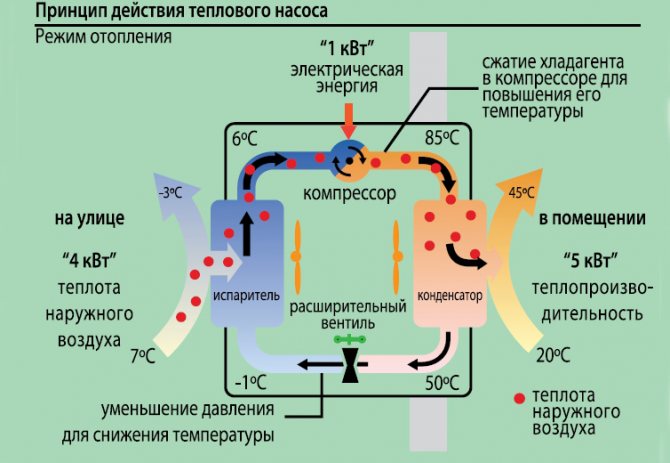

The HP operation is based on the interdependence of gas volume, pressure and temperature. Here's what happens inside the unit:

- Ammonia, freon or other refrigerant, moving along the evaporator, heats up from the source medium, for example, to a temperature of +5 degrees.

- After passing through the evaporator, the gas reaches the compressor, which pumps it to the condenser.

- The refrigerant discharged by the compressor is held in the condenser by the pressure reducing valve, so its pressure is higher here than in the evaporator. As you know, with increasing pressure, the temperature of any gas increases. This is exactly what happens with the refrigerant - it heats up to 60 - 70 degrees. Since the condenser is washed by the coolant circulating in the heating system, the latter also heats up.

- The refrigerant is discharged in small portions through the pressure reducing valve to the evaporator, where its pressure drops again. The gas expands and cools down, and since part of the internal energy was lost by it as a result of heat exchange at the previous stage, its temperature drops below the initial +5 degrees. Following the evaporator, it heats up again, then it is pumped into the condenser by the compressor - and so on in a circle. Scientifically, this process is called the Carnot cycle.

The main feature of heat pumps is that thermal energy is taken from the environment literally for nothing. True, for its extraction, it is necessary to spend a certain amount of electricity (for a compressor and a circulation pump / fan).

But the heat pump still remains very profitable: for each spent kW * h of electricity, it is possible to obtain from 3 to 5 kW * h of heat.

Sources of

- https://aquagroup.ru/articles/skvazhiny-dlya-teplovyh-nasosov.html

- https://VTeple.xyz/teplovoy-nasos-voda-voda-printsip-rabotyi/

- https://6sotok-dom.com/dom/otoplenie/raschet-moshhnosti-teplovogo-nasosa.html

- https://microklimat.pro/otopitelnoe-oborudovanie/otopitelnye-pribory/teplovoj-nasos-dlya-otopleniya-doma.html

- https://avtonomnoeteplo.ru/altenergiya/148-teplovye-nasosy-voda-voda.html

- https://avtonomnoeteplo.ru/altenergiya/290-burenie-skvazhin-dlya-teplovyh-nasosov.html

- https://kotel.guru/alternativnoe-otoplenie/teplogenerator-kavitacionnyy-dlya-otopleniya-pomescheniya.html

- https://skvajina.com/teplovoy-nasos/

- https://www.burovik.ru/burenie-skvazhin-teplovye-nasosy.html

Submission to the element of air: heat pumps "air-water"

Finland has long been one of the leading economies of the European Union in terms of the rate of introduction of heat pumps (HP) per capita. The Finnish Heat Pump Association (Suomen Lämpöpumppuyhdistys, SULPU) has published interesting heat pump sales statistics for 2020 (Fig. 1) in this Scandinavian country with its harsh climate.

The graph shows that for several years in a row the number of sales of geothermal equipment has been decreasing, while sales of air-to-water heat pumps have been growing every year.If we translate these data into figures, we get the following picture: sales of geothermal heat pumps since 2016 fell from 8491 to 7986 units, which amounted to -5.9%, and sales of air-water heat pumps since 2020 increased from 3709 to 4138 pcs., which amounted to +11.6%.

This dynamics is due to the increased stability of the air-to-water heat pump due to the development of science and technology, as well as more comfortable investments and simple installation compared to geothermal heat pumps.

The leading heating technology manufacturer in Finland -) - has also focused on developing efficient and sustainable air-to-water heat pump solutions for many years, and recently the successful launch of Tehowatti Air has been on the market.

It is a versatile package solution suitable for many types of properties: private, commercial and public. The starter package always includes an outdoor unit, that is, the air-to-water heat pump itself and an indoor module, which includes: an electric boiler and a water heater made of specialized acid-resistant ferritic stainless steel, all the necessary automation, fasteners and a safety group for the indoor and outdoor units ... Thus, any client and installer receives a ready-to-assemble "constructor" and in the shortest possible time solves the problem not only with heating and hot water supply, but also, at the request of the end client, even with air conditioning at home.

The model range includes various combinations of outdoor units of HP "air-water" - from budget to "advanced" solutions that give the end user maximum savings.

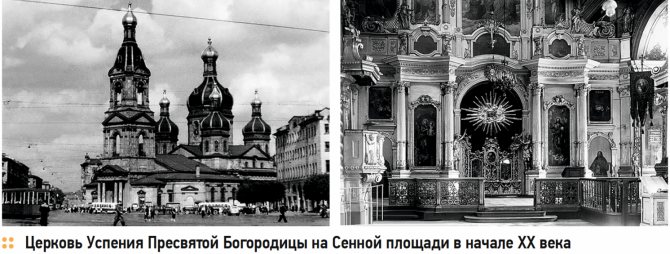

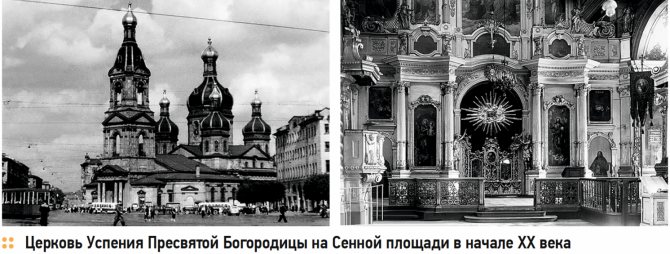

This option was also chosen by the parish of the Church of the Dormition of the Most Holy Theotokos (Savior on Sennaya) in 2020 during the reconstruction of the temple. The manufacturer JÄSPI and the distributor DOMAP jointly selected the optimal equipment package for solving this problem. The advantage of using Tehowatti Air lies not only in the fact that we offer a set of delivery that is convenient for installation, but also in the fact that this equipment can be easily integrated into the existing heating and hot water system.

A bit of history

The stone church was founded by the Archbishop of St. Petersburg and Shlisselburg Sylvester on July 20, 1753. The temple was built at the expense of a wealthy tax farmer Savva Yakovlev (Sobakin). Previously, Bartolomeo Rastrelli was considered the architect of the building, now Andrei Kvasov is recognized as the more likely author of the project.

The architecture of the temple was designed in a mixed style. The high gilded iconostasis was considered one of the best in St. Petersburg. Also notable were the painting of Greek writing and the silver throne weighing 6 pounds 38 pounds (about 113.8 kg).

In 2011, the active development of the project to restore the Church of the Assumption of the Blessed Virgin Mary on Sennaya Square began. In the same year, work began on the restoration of the temple. The builders were faced with the task of opening the asphalt and calculating the approximate location of the cathedral. It turned out that the old foundation was not destroyed. The architects were especially delighted with the holy of holies of the cathedral - the altar base. Not far from the altar plate, a sealed entrance to the crypt of the Savior was found - a buried entrance to the cellars of the church. Usually, priests and noble parishioners were buried in the crypt. Most likely, the Church of the Savior on Sennaya will be restored on the old foundation.

In 2014, the foundation of the church was recognized as a cultural heritage site by a special order. Now, any kind of work is prohibited at this place, except for the improvement of the territory and the restoration of the church building.

Onsite Tehowatti Air System

A JÄSPI Tehowatti Air air-to-water heat pump with an outdoor inverter unit Nordic 16 was installed at the site - this system was developed for efficient heating, cooling and hot water supply in both new and renovated facilities.When designing it, special attention was paid to ease of installation and ease of use. This system has been launched and is successfully operating for heating water underfloor heating and hot water supply in a public building. The outdoor unit of the air-to-water heat pump Nordic 16 effectively operates at outdoor temperatures down to –25 ° C, while being able to supply a heating medium heated to 63–65 ° C into the heating system.

Let's pay attention to details. As noted above, the internal tank of the JÄSPI Tehowatti Air system is made of acid-resistant ferritic stainless steel, which is used for particularly difficult conditions in the DHW system.

Also, the heat pump charging coil is made of comb stainless steel. This coil provides fast, energy efficient and accurate charging. Through the indoor unit, heat is distributed inside the room and for heating the domestic water.

If the heat pump does not receive from the street a sufficient amount of energy for the needs of the facility, then automatic heating and the necessary additional heat are provided with the help of the electric heating element of the internal block of the HP.

Finnish high quality Tehowatti Air components and materials provide long-term savings in the form of low energy consumption without frequent equipment maintenance. Both outdoor and indoor units operate with low noise levels.

JÄSPI Tehowatti Air air-to-water heat pump systems are designed and manufactured in Finland, have the best quality down to the smallest details, require virtually no maintenance and are highly reliable (solving a client's problem with an average service life of 20–25 years). When creating its equipment, JÄSPI ("Yaspi") uses a high level of knowledge in the field of heating and many years of experience in operating equipment in the harsh northern conditions.

Features of wells for heat pumps

The main element in the operation of the heating system when using this method is the well. Its drilling is carried out in order to install a special geothermal probe and a heat pump directly in it.

The organization of a heating system based on a heat pump is rational both for small private cottages and for whole farmlands. Regardless of the area that will need to be heated, an assessment of the geological section in the site should be carried out before drilling wells. Accurate data will help to correctly calculate the number of required wells.

The depth of the well should be selected in such a way that it can not only provide sufficient heat to the object under consideration, but also allow the selection of a heat pump with standard technical characteristics. To increase heat transfer, a special solution is poured into the cavity of the wells where the built-in circuit is located (as an alternative to the solution, clay can be used).

The main requirement for drilling wells for heat pumps is complete isolation of all, without exception, groundwater horizons. Otherwise, the ingress of water into the underlying horizons can be regarded as pollution. If the coolant gets into groundwater, it will have negative environmental consequences.

What is a heat pump?

The heat pump was invented 150 years ago by Lord Kelvin and named as a heat multiplier. It consists of a compressor, like a conventional refrigerator, and two heat exchangers. The principle of operation can be compared to that of a refrigerator. The latter has a grate in the back that heats up, inside the freezer, it cools down. If we take this freezer, give the tubes, put the freon tubes in the bath, then the water in the bath will be cooled, and the grate will be warming up from behind, and the refrigerator will pump heat from the bath and heat the room through the grate. The heat pump works the same way.

There are two pipes running into the ground here.Then they diverge and about 350 running meters of wells were drilled in this house. A y-shaped probe is inserted into each well. Liquid flows through this probe and is warmed by the warmth of the earth. A temperature of about -1 degrees comes out of the heat pump, and +5 degrees returns from the ground. This is a closed system with this circulation pump, it is pumped, and the heat is removed and transferred to the house. These two pipes heat the warm floor. An ordinary refrigerator, but with a more powerful compressor.

Homemade electronics in a Chinese store.

Prices for drilling wells for heat pumps

The cost of installing the first circuit of geothermal heating

| 1 | Drilling wells in soft rocks | 1 r.m. | 600 |

| 2 | Drilling wells in hard rocks (limestone) | 1 r.m. | 900 |

| 3 | Installation (lowering) of the geothermal probe) | 1 r.m. | 100 |

| 4 | Pressing and filling the outer contour | 1 r.m. | 50 |

| 5 | Borehole backfill to improve heat transfer (granite screening) | 1 r.m. | 50 |

Why did I choose a heat pump for my home heating and water supply system?

So, I bought a plot to build a house without gas. The prospect of gas supply is in 4 years. It was necessary to decide how to live up to this time.

The following options were considered:

- 1) gas tank 2) diesel fuel 3) pellets

The costs for all these types of heating are commensurate, so I decided to make a detailed calculation using the example of a gas tank. The considerations were as follows: 4 years on imported liquefied gas, then replacing the nozzle in the boiler, supplying the main gas and a minimum of costs for rework. The result is:

- for a house of 250 m2, the cost of a boiler, a gas tank is about 500,000 rubles

- the entire site needs to be dug

- availability of a convenient access for a refueller for the future

- maintenance of about 100,000 rubles per year:

- the house will have heating + hot water

- at a temperature of -150 ° C and below, the costs are 15-20,000 rubles per month).

Total:

- gas tank + boiler - 500,000 rubles

- operation for 4 years - 400,000 rubles

- supply of the main gas pipe to the site - 350,000 rubles

- replacement of the nozzle, boiler maintenance - 40,000 rubles

In total - 1 250 000 rubles and a lot of fuss around the issue of heating in the next 4 years! Personal time in terms of money is also a decent amount.

Therefore, my choice fell on a heat pump with commensurate costs for drilling 3 wells of 85 meters each and purchasing it with installation. The Buderus 14 kW heat pump has been in operation for 2 years. A year ago I installed a separate meter for it: 12,000 kWh per year !!! In terms of money: 2400 rubles per month! (The monthly payment for gas would be more) Heating, hot water and free air conditioning in the summer!

Air conditioning works by raising the coolant at a temperature of + 6-8 ° C from the wells, which is used to cool the premises through conventional fan coil units (a radiator with a fan and a temperature sensor).

Conventional air conditioners are also very energy-intensive - at least 3 kW per room. That is, 9-12 kW for the whole house! This difference must also be taken into account in the payback of the heat pump.

So the payback in 5-10 years is a myth for those who sit on the gas pipe, the rest are welcome to the club of “Green” energy consumers.

Air heat pump owners from the CIS

Alina Shuvalova, Dnipro (Dnipropetrovsk), Ukraine

They abandoned centralized heating and installed an air-to-air heat pump in the apartment (my husband's initiative). The savings are significant, due to the fact that everywhere there are plastic windows, the house is insulated, and from all sides the apartments are heated.

It so happened that we only heat up the apartment a little, and we ourselves can regulate the temperature. When we are at work, and the child is at school, the pump is turned off, it is on the timer and turns on when the son comes home (during this time the apartment does not have time to cool down).

Kashevich Alexey, Belarus

I bought an air-to-air heat pump for my house (before that it was heated with a stove). At first, everything went like clockwork, and when the cold came, traffic jams began to fly out constantly.I did not attach any importance to this, and when I began to knock out constantly, I called an electrician.

As it turned out, in the cold, it consumes too much electricity, and our network is not designed for this. There was a choice - either to return to the stove heating, or to sit in the cold. In general, the season turned out to be not particularly comfortable, I have not decided what to do next. It is too expensive to lay and connect a more powerful cable.

Installation nuances

When choosing a water-to-water heat pump, it is important to calculate the operating conditions. If the line is immersed in a body of water, you need to take into account its volume (for a closed lake, pond, etc.), and when installed in a river, the speed of the current

If incorrect calculations are made, the pipes will freeze over with ice and the efficiency of the heat pump will be zero.

What is a chiller and how does it work

When sampling groundwater, seasonal fluctuations must be taken into account. As you know, in spring and autumn, the amount of groundwater is higher than in winter and summer. Namely, the main operating time of the heat pump will be in the winter. To pump out and pump water, you need to use a conventional pump, which also consumes electricity. Its costs should be included in the total and only after that the efficiency and payback period of the heat pump should be considered.

a great option is to use artesian water. It comes out of deep layers by gravity, under pressure. But you will have to install additional equipment to compensate for it. Otherwise, the components of the heat pump may be damaged.

The only disadvantage of using an artesian well is the cost of drilling. The costs will not pay off soon due to the lack of a pump for lifting water from a conventional well and pumping it into the ground.

Heating heat generator operation technology

In the working body, the water must receive an increased speed and pressure, which is carried out using pipes of various diameters, tapering along the flow. In the center of the working chamber, several pressure flows are mixed, leading to the phenomenon of cavitation.

To control the speed characteristics of the water flow, braking devices are installed at the outlet and in the course of the working cavity.

The water moves to the nozzle at the opposite end of the chamber, from where it flows in the return direction for reuse using a circulating pump. Heating and heat generation occurs due to the movement and sharp expansion of the liquid at the exit from the narrow orifice of the nozzle.

Positive and negative properties of heat generators

Cavitation pumps are classified as simple devices. They convert the mechanical motor energy of water into thermal energy, which is spent on heating the room. Before building a cavitation unit with your own hands, it should be noted the pros and cons of such an installation. Positive characteristics include:

- efficient generation of heat energy;

- economical in operation due to the lack of fuel as such;

- an affordable option for purchasing and making it yourself.

Heat generators have disadvantages:

- noisy pump operation and cavitation phenomena;

- materials for production are not always easy to get;

- uses a decent capacity for a room of 60–80 m2;

- takes up a lot of usable room space.

Well drilling for heat pump system

It is better to entrust the well device to a professional installation organization. It is optimal for representatives of the company selling the heat pump to do this. So, you can take into account all the nuances of drilling and the location of the probes from the structure, and fulfill other requirements.

A specialized organization will assist in obtaining a permit for drilling a well for probes for a ground source heat pump. According to the legislation, the use of groundwater for economic purposes is prohibited. We are talking about the use for any purpose of waters located below the first aquifer.

As a rule, the procedure for drilling vertical systems should be coordinated with the state administration authorities. Lack of permits leads to penalties.

After receiving all the necessary documents, installation work begins, according to the following order:

- The drilling points and the location of the probes on the site are determined, taking into account the distance from the structure, landscape features, the presence of groundwater, etc. Maintain a minimum gap between the wells and the house of at least 3 m.

- Drilling equipment is being imported, as well as equipment necessary for landscape work. For vertical and horizontal installation, a drill and jackhammer is required. For drilling the soil at an angle, drilling rigs with a fan contour are used. The greatest application was received by the model operating on a caterpillar track. Probes are placed in the resulting wells and the gaps are filled with special solutions.

Drilling wells for heat pumps (with the exception of cluster wiring) is allowed at a distance of at least 3 m from the building. The maximum distance to the house should not exceed 100 m. The project is carried out on the basis of these standards.

What depth of the well should be

Depth is calculated based on several factors:

- The dependence of efficiency on the depth of the well - there is such a thing as an annual decrease in heat transfer. If the well has a great depth, and in some cases it is required to make a channel up to 150 m, every year there will be a decrease in the indicators of the received heat, over time the process will stabilize. Making a well of maximum depth is not the best solution. Usually, several vertical channels are made, distant from each other. The distance between the wells is 1-1.5 m.

- The calculation of the depth of drilling a well for probes is carried out taking into account the following: the total area of the adjacent territory, the presence of groundwater and artesian wells, the total heated area. So, for example, the depth of drilling wells with high groundwater is sharply reduced in comparison with the manufacture of wells in sandy soil.

The creation of geothermal wells is a complex technical process. All work, from the design documentation to the commissioning of the heat pump, must be performed exclusively by specialists.

To calculate the approximate cost of work, use online calculators. The programs help to calculate the volume of water in the well (affects the amount of required propylene glycol), its depth and perform other calculations.

How to fill the well

The choice of materials often rests entirely with the owners themselves.

The contractor may advise you to pay attention to the type of pipe and recommend the composition for filling the well, but the final decision will have to be made independently. What are the options?

- Pipes used for wells - use plastic and metal contours. Practice has shown that the second option is more acceptable. The service life of a metal pipe is at least 50-70 years, the walls of the metal have good thermal conductivity, which increases the efficiency of the collector. Plastic is easier to install, so construction organizations often offer just it.

- Material for filling gaps between pipe and ground. Well plugging is a mandatory rule to be performed. If the space between the pipe and the ground is not filled, shrinkage occurs over time, which can damage the integrity of the circuit. The gaps are filled with any building material with good thermal conductivity and elasticity, such as Betonit. Filling the well for the heat pump should not impede the normal circulation of heat from the ground to the collector. The work is done slowly so as not to leave voids.

Even if the drilling and positioning of the probes from the structure and from each other is done correctly, after a year additional work will be required due to the shrinkage of the collector.

Heat pumps: principle of operation and application

The second law of thermodynamics says: Heat can move spontaneously in only one direction, from a more heated body to a less heated one, and this process is irreversible. Therefore, all traditional heating systems are based on heating a certain heat carrier (most often water) to a temperature higher than required for comfort, and then bring this heat carrier into contact with the colder air of the room, and the heat itself, according to the 2nd the beginning of thermodynamics, will go to this air, heating it. And this is the paradigm of modern heating: if you want to warm a person - warm up the air in which he is! And to heat the coolant, you need to burn fuel, therefore, in all these forms of heating, the combustion process is involved with all the ensuing consequences (fire hazard, carbon dioxide emissions, a fuel storage tank or a not very aesthetic pipe near the wall of the house). But the reserves of fuel, although large, are not unlimited. And if this is a non-renewable consumable that should end up sometime, then it should not be surprising that the price for it is constantly growing and will continue to grow in the future. Now, if it was possible to use for the heating process some replenished source of heat, then the process of growth in value could be stopped (or slowed down) and, perhaps, got rid of the negative consequences of the combustion process. One of the first to think about this in 1849 was William Thompson, the English physicist who later became known as Lord Kelvin. Is it possible to obtain the necessary heat not by heating, but by transfer, taking it somewhere outside, and transferring it inside the room. The same 2nd law of thermodynamics says that you can start up heat in the opposite direction, transferring it from colder (for example, from outside air) to warmer (indoor air), but for this you need to spend energy (or, as physicists say, do work). How warm can cold air be? - you will say. Then answer one question: is -15⁰C warmer than -25⁰C? Correctly warmer! If you take energy from air at -15⁰С, then it will cool down, say, to -25 С. But how to take this energy and can it be used? In 1852, Lord Kelvin formulated the principles of operation of a heat engine that transfers heat from a source with a low temperature to a consumer with a higher temperature, calling this device a "heat multiplier", which is now known as a "heat pump". Such sources can be soil, water in reservoirs and wells, as well as the surrounding air. They all contain low-potential energy accumulated from the sun. You just need to learn how to take it and transform it into a higher-temperature form suitable for use. All these sources are renewable and completely environmentally friendly. We do not introduce any additional heat into the "Earth" system, but simply redistribute it, taking it in one place (outside) and transferring it to another (internal consumer). This is a completely new approach to creating a comfortable indoor climate. Outside, the temperature varies widely: from "very cold" to "very hot", and a person feels comfortable in a rather narrow temperature range of +20 .. + 25⁰С, and it is this temperature that he creates in his home. If the temperature in the house needs to be increased (heating in winter), you can take the missing heat from the street and transfer it into the house, and not create a source of increased temperature inside by burning fuel (traditional boilers)! And if the temperature in the house needs to be lowered (cooling in summer), the excess heat can be removed by transferring it from the room to the street. The latter is realized through all of us familiar air conditioners. So what do we have? For heating premises we use the same devices: boilers, stoves, etc., operating by burning fuel inside, and for cooling - others: air conditioners that transfer excess heat from the house to the street. And how tempting it would be to have one device for all occasions: universal climatic unitthat maintains a comfortable temperature in the home all year round, simply by transferring heat from outside to inside or back! Now we are going to show you that miracles are possible.

Let's go back to the heat pump. How does it work? It is based on the so-called reverse Carnot cycle, known to us from the school physics course, as well as the property of a substance during evaporation to absorb heat, and during condensation (transformation into a liquid) - to give it away... For a better understanding, let's turn to an analogy. We all have a refrigerator.

But have you ever wondered how it works? Its task, it would seem, is "to create cold": but is it so? In fact, the food inside the refrigerator is cooled by taking heat away from it. Let's say you brought chilled meat from the store at a temperature of + 1⁰C and threw it into the freezer. After a while, the meat froze, and its temperature became -18⁰С. We took from him as much as 19⁰C of heat, and where did this heat go? If you touched the back wall of the refrigerator (usually it is made in the form of a coiled coil tube), you would find that it is warm, and at times hot. This is the heat taken from the meat (those same 19⁰C), and transferred to the back wall. But in the process of cooling, the meat had intermediate temperatures of -5⁰С and -10⁰С, but the refrigerator still managed to take heat from it, cooling it more and more. This means that even from frozen meat with a temperature of -10⁰C, you can take heat by turning it into meat with a temperature of -18⁰C: this means that this heat was present there, but in a low-temperature form. And the refrigerator managed not only to take this low-temperature heat, but also to turn it into a high-temperature form. The heat from the back of the refrigerator can help keep you warm by leaning against it. In a sense, a cold piece of meat warmed us with the warmth it contained, although it’s hard to believe right away. We found out what the refrigerator did with a piece of meat: it took away the heat from it (inside) and transferred it to the back wall (outside). Now is the time to find out how he did it? Inside the refrigerator passes another coil, similar to the first one, and together they form a closed loop in which, with the help of a compressor, easily evaporated gas circulates - freon. Only it does not circulate freely. Before entering the refrigerator, the diameter of the coil tube sharply narrows, and then sharply expands after it. Freon, moving through the tube due to the operation of the compressor, "squeezing" through the narrow throat, enters the vacuum zone (lower pressure), because "Unexpectedly" falls into a greatly increased volume (pressure drop). Once in the low-pressure zone, freon begins to intensively evaporate (turn into a gaseous state), and, passing along the internal coil, absorb heat from its walls, and they, in turn, take heat from the surrounding air inside the refrigerator. Result: the air inside is cooled, and food is cooled from contact with it. So, as in the relay race, along the chain, the evaporating freon causes the outflow of heat from the products to the freon itself: the temperature of freon by the end of the "journey" along the inner coil rises by several degrees. The next portion of freon takes the next portion of heat inside. By adjusting the degree of vacuum, you can adjust the evaporation temperature of freon and, accordingly, the cooling temperature of the refrigerator. Further, the "heated" freon is sucked out by the compressor from the internal coil and enters the external coil, where it is compressed to a certain pressure, because at the other end of the external coil it is "prevented" by a narrow hole called Throttle or thermostatic (expansion) valve. As a result of the compression of freon gas, its temperature rises, say, up to +40 .. + 60⁰С, and passing through the external coil it gives off heat to the outside air, cools down and turns into a liquid state (condenses). Further, freon again finds itself in front of a narrow throat (choke), evaporates, taking away heat, and the process is repeated again. Therefore, the internal coil, where the freon evaporates, takes away heat, is called Evaporator, and the external coil, where freon, condensing, gives off the taken heat, is called Capacitor... The device described here takes heat in one place (inside) and transfers it to another place (outside). A characteristic feature of the device is that the closed circuit through which the freon circulates is divided into 2 zones: a low pressure (vacuum) zone, where freon is able to evaporate intensively, and a high pressure zone, where it condenses. The separator of these two zones is the throttling hole, and maintaining such different pressures in one closed loop becomes possible due to the operation of the compressor, which requires energy. (If the compressor were to stop, after a while the pressure in the evaporator and condenser would equalize and the transfer process would stop). Those. the device is able to transfer heat from colder to warmer, but only by spending a certain amount of energy. Those. simplified, taking the refrigerator and opening its door to the street, and turning the back wall inside the room, you can heat it. It is only necessary that fresh air of outside temperature always gets into the refrigerator, and that cooled from contact with the internal heat exchanger is removed. This can be easily realized by installing a fan at the inlet, which would drive new portions of air onto the coil. Then, the heat taken away from the outside air will be transferred inside the room, warming it. Those. refrigerator, open door to the outside, and there is a simple heat pump. The first series-produced air source heat pumps looked like this. They looked like window air conditioners. That is, it was a metal box inserted in the opening of the window, facing the evaporator outward, and the condenser inward. There was a fan in front of the evaporator, which drove fresh air streams through the coil heat exchangers, and cooled air came out from the other side of the box. The evaporator was separated from the Condenser by an insulating layer. There was also a fan on the inner coil, which drove the air of the room through its heat exchanger and blew out the already warmed air. With further improvement of the device, the outer part was separated from the inner part and began to look like a split air conditioner system. The two parts of the whole are interconnected by heat-insulated copper tubes in which freon circulates, and electrical cables for supplying power and control signals. Modern air heat pumps are a sophisticated device with intelligent electronic control that can operate autonomously, smoothly adjusting their performance depending on the external temperature, the set internal temperature and a number of modes. This allows you to get additional savings in consumed electricity.

The main classification of heat pumps (HP) is made according to a low-potential source from which energy is taken (air, soil, water) and to a consumer - a heat carrier, which exchanges heat with a condenser and is subsequently used in the heating system (air, water; instead of water, antifreeze is sometimes used ). Let's list the most common:

1. Air Heat Pumps (VTN). Most affordable category, especially air-to-air.

-TH air-air

-TH air-water

2. Ground Source Heat Pumps (GTN). The most expensive category, because expensive earthworks or drilling, hundreds of meters of pipe and a large volume of antifreeze are required.

-TH soil-water

3. Water Heat Pumps. Pipes with antifreeze are laid on the bottom of a reservoir (lake, pond, sea ...) or two artesian wells (fresh water is taken from one well, and cooled water is drained into the other). Expensiveness depends on which way of access with water - a heat source - is used. But not cheap anyway!

-TH water-water

Now - the most important thing: About Winning... Any of the listed heat pumps allows you to get more energy than was spent on its transfer (operation of the compressor, fans, electronics ...). The efficiency of the heat pump is estimated using the coefficient of performance COP (Coefficient Of Performance), which is equal to the ratio of the received thermal energy (in kW * h) to the consumed electrical energy. This dimensionless value shows how many times more heat energy is produced by the heat pump in relation to the consumed one. COP depends on the temperature difference between the Source (outdoor low-temperature heat) and the Consumer (temperature in the house +20 .. + 25⁰С) and usually ranges from 2 to 5.

This is our gain when using heat pumps: for 1 kW of consumed electricity, you can get from 1 kW to 4 kW of heat free of charge from the environment, which at the output gives from 2 to 5 kW of heat to the house.