Ecology of consumption. Homestead: The facing materials that adorn the ancient temples of our cities and the architecture of the Babylonians and Egyptians have too obvious advantages to send ancestral technology into oblivion.

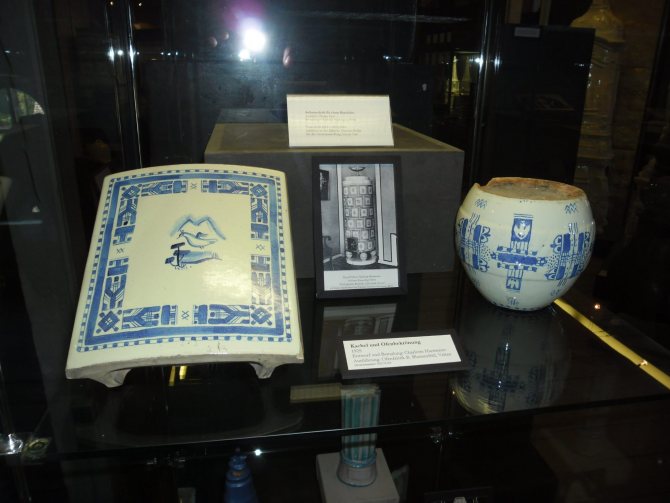

Tiles have been part of our culture for centuries. Gradually, this type of ceramics has lost its former popularity. But over the past 20-30 years, we have seen a growing interest in decorating stoves with tiled elements.

Tiled stove

For a while, the ceramic finishing culture succumbed to the pressure of Western technology and a huge variety of tiles. But the facing materials with which the ancient temples of our cities and the architecture of the Babylonians and Egyptians were decorated, have too obvious advantages to send the technology of the ancestors into oblivion.

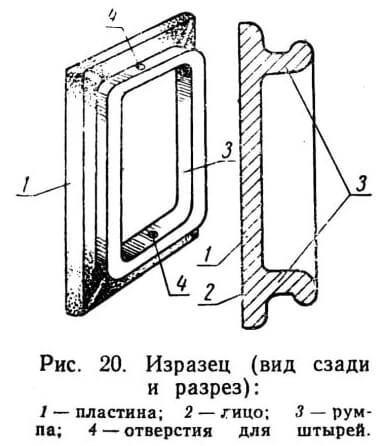

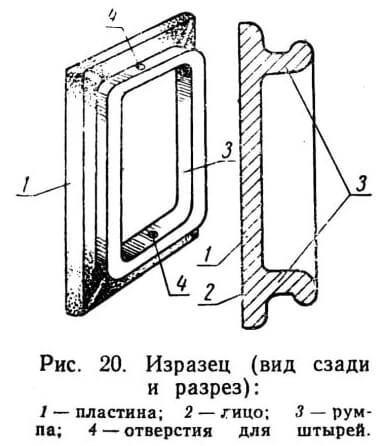

Tile construction

Tiles are ceramic tiles of an original design. The slabs can have different textures - smooth, rough, structural. But the essence of the products is the box format.

The tile consists of:

- front part;

- plates - the topmost layer;

- rumpy - the element that distinguishes this ceramics from all other types;

- holes for pins located in the tiller.

Tile construction

The volumetric shape, formed by the tiller, makes the cladding thermo-inert - the heat transfer of the furnace coating is felt for several days. Thanks to the boxes, a space is created between the tiles and the surface of the fireplace. We owe it to him for the accumulation of heat and such a prolonged release of heat to the room.

Holes in the tiller are needed for pins or wires that are embedded in brick joints - this makes the finish more durable and reliable. The classic cladding scheme involves the rejection of glue or other similar binders. For this reason, the heat transfer increases even more.

Despite the inertness of the heat carrier, the heat of the stove covered with tiles is very soft. While heating the room well, the stove is not capable of burning.

The main functional plus of such a tile is the heat transfer of the stove for several days.

Yuri V. Vodnev

Born in Smolensk on 10/12/1958. He has been engaged in stove business since 1986. Member of the Moscow Chamber of Crafts. Education is technical. Interests - design and construction of stoves with built-in room ventilation system.

Any finishing of the stove - plastering, lining of stoves with clinker brick tiles, ceramic glazed tiles, tiles makes sense not only as an improvement in appearance, but also of practical importance - increasing the heat capacity of the stove. In this article, I will talk about my personal experience with tiles and the problems I encountered.

Tile finishing is the most difficult and expensive option, but also the most durable, beautiful and hygienic - the glazed surface is easier to wipe and the likelihood of dust sticking on the surface is minimal. Modern materials and technologies make it possible to tile a ready-made working oven with tiles. Despite the fact that the classical fastening of the tiles is carried out simultaneously with the laying of the stove - a wire was knitted to the metal crutches inserted into the holes of the tile head and its ends were fixed between the rows of brickwork. It is very problematic to disassemble such a lining without disassembling the furnace. Modern methods also provide for tying the tiles to the wall of the stove, but already along a metal mesh attached to the masonry in various ways.Thus, reinforced tiles, with a properly selected adhesive composition, do not have the ability to come off when heated, which happens, for example, with thin-walled facing tiles.

Today there is a large selection of ceramic workshops engaged in the manufacture of tiles, each of them has its own long-term experience, its own compositions, secrets and manufacturing technologies, different artistic expressiveness and different costs, so it is not so easy for the customer to choose what is “necessary and sufficient”.

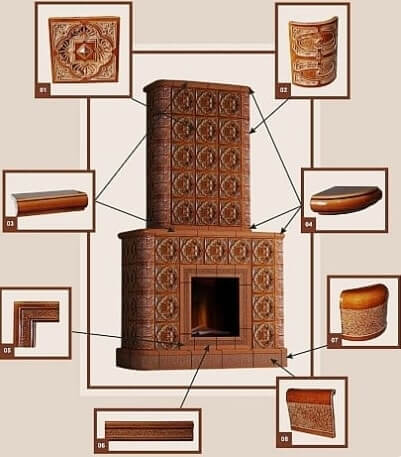

Types of tiles

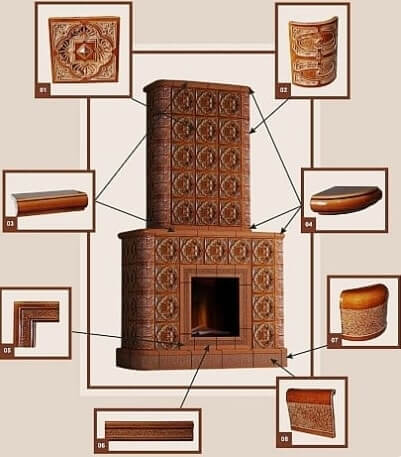

In terms of shape and purpose, tiled ceramics are divided into several main types. Among them:

- flat slabs - elements that cover the main area of the fireplace;

- corner - designed for decorating corners;

- basement and cornice - designed for finishing the lower and upper zones of the furnace, respectively;

- shaped - corner tiles, which are necessary for the decoration of corners of complex shapes.

Tiled tile options

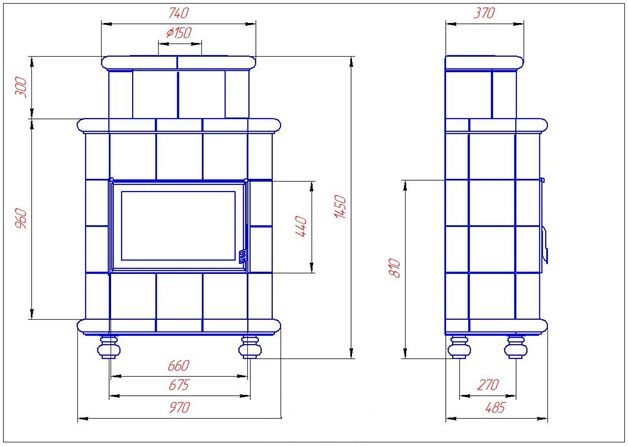

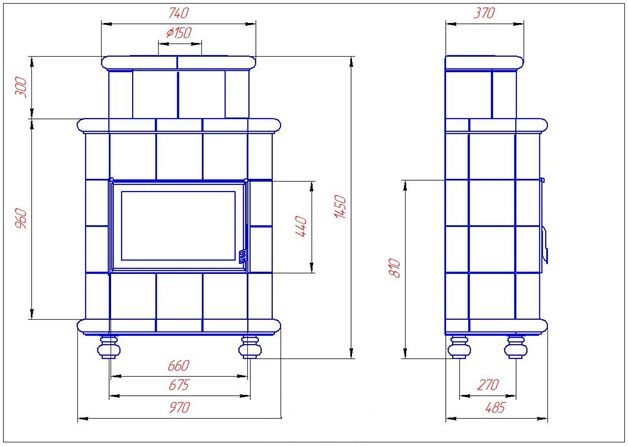

Drawing and scheme of laying tiled tiles

An accurate diagram is necessary in order to simplify installation and calculate the exact consumption of materials. With a detailed laying scheme at your disposal, it is easy to determine what configuration of tiles will be needed for finishing and what order of their installation. Taking into account the cost of a tile, this is an important aspect.

Note. Users recommend creating a safety stock for tiles. At least one piece of each type of tile should be available not only in case of unforeseen damage during laying, but also in case of damage during use.

You do not need to have the skills of an architect to create a tile drawing. It is enough to apply the dimensions of the stove and the location of the tiles.

Tiled stove drawing

Currently, 3D visualization of the project is popular.

Materials and tools

To work you need to prepare:

- tiled tiles for the stove - the main material;

- pins made of steel wire with a diameter of 5 mm. They are needed to connect the tiles to each other and the brickwork of the stove;

- soft wire;

- steel staples;

- clay for filling the grinder;

- filler: broken brick, river pebbles or gravel (for laying in a head);

Note. Refractory bricks are not suitable for filling the tampa, but only an ordinary stove brick. The fact is that the refractory brick expands under the influence of high temperature, which can lead to the splitting of the tile.

- plaster based grout.

Of the tools, there will be enough of those that each owner has: a building level, a plumb line, a square, a rasp, a spatula, a grinder.

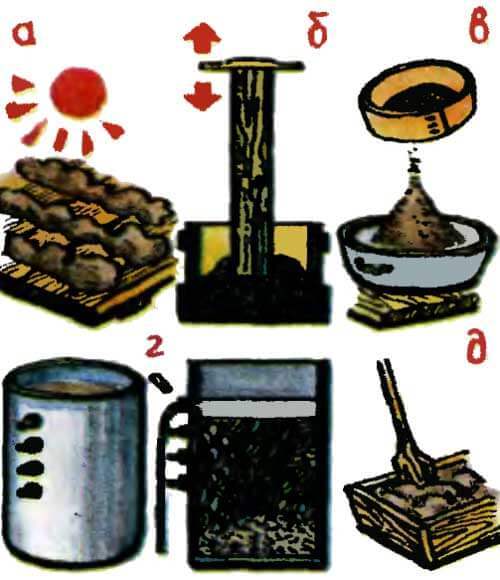

How are tiles made industrially?

The original veneering ceramic format emerged as a response to the need for good room heating and long-term retention of heat. Some modern furnace models are characterized by a noticeable temperature difference between the inner and outer zones of the furnace surface. Thanks to this, the usual ceramic tiles are quite enough for their facing. In other cases, it is much more expedient to use box-shaped plates.

In the past, rump ceramics were cast in wooden molds, after which the box was assembled and painted in a certain way. Today in the production of boards, both traditional technologies and modern developments are combined.

Stages of modern tile production:

- make a plaster mold; based on the estimated dimensions of the plates, the workpiece is cast; having assembled the base from several parts, it is covered with a special composition, after which the formwork is mounted and the model is poured with a plaster mixture; the form is brought to mind, cleaned and dried;

- prepare raw materials - clay; raw materials must be cleaned of impurities and made plastic; to give the required degree of viscosity, the clay is allowed to lie down, and then it is mixed for a long time and very efficiently - air is removed from the mixture;

- the ready-made raw material is filled in the form, carefully rolling it in the direction from the center to the periphery; after that, the clay is left to dry - the form absorbs moisture from the raw material; as a result, the clay mass shrinks and moves away from the walls of the mold without effort; at this stage, semi-finished products are removed from the molds and sent for drying to a special chamber, characterized by the required temperature and degree of humidity;

- future tiles are sent to the kiln for firing; here the tile gains strength, acquires color and the necessary coefficient of moisture resistance;

- the canvas of elements is decorated with clay or glaze, after which they are painted in a certain way;

- at the final stage, the slabs are fired again - this is necessary for the formation of a monolith of the base and glaze and for the formation of the final shade; sometimes, after the final firing, another layer of decorative composition is applied to the tile, for example, paint.

All this is curious, but many people have a natural question - is it possible to make high-quality tiles for stoves with their own hands? It is not easy, but the answer is yes - you can make your own ceramics, time-tested for centuries.

A little more about the advantages of tile cladding:

- Thick-walled tiles are distinguished by high performance: thermal resistance and heat capacity, thermal energy storage, strength and durability

- The beneficial effect of the return of radiant energy from tiles is comparable to the energy that a person receives from the sun's rays.

- Tiles are not afraid of water, their formulation and technology causes low water absorption. Tiles are used not only for stoves, but also for facade decors, and in damp rooms.

- Glazed surfaces do not retain the settling dust, as a result, the burnout of dust particles does not lead to the release of toxins into the air.

- Clean ecology both in terms of raw materials and production technologies and in further operation.

- The designs of the tiles themselves and their fastenings give unique properties: the cladding can withstand any temperatures on the surface of the furnaces, even fluctuations to thermal shocks, and retains the accumulated heat for a long time.

The structural strength of tiles, especially those with one-piece trowels, and the accuracy of installation using the correct technologies are the guarantee of the cladding service for decades without repairs, provided that it is handled carefully. The only thing that is required is periodic simple washing and cleaning, and protect the tiles from strong impacts.

How to make tiles yourself?

The process of making ceramics is divided into stages. You need to start with the preparation of raw materials.

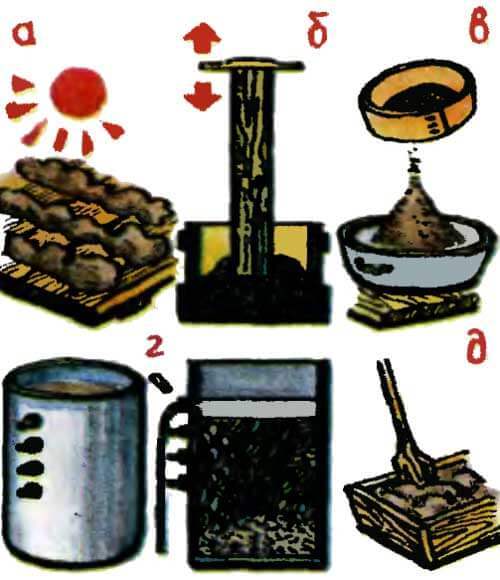

Clay harvesting

Clay is commercially available, but you can prepare it yourself. If you intend to work independently, then it is recommended to attend to stocks in the warm season. Clay lumps should be dried well in direct sunlight.

The dried clay is broken with a rammer and sieved, removing impurities. Crumbled raw materials are poured with water and mixed thoroughly. During this procedure, all the slag is on the surface - it is removed. The manipulation is repeated until the debris stops floating up.

Clay harvesting

For work, it is advisable to use a special container in which holes of different heights are made. The latter are initially sealed, but gradually opened as they rinse. Thanks to this, the liquid is drained - the liquid raw material remains in the container. The clay is moved into a wide, low basin and again dried in the sun. During the evaporation process, the source is constantly mixed. A doughy plastic material is considered ready.

It is important to achieve the purity and plasticity of the clay. This will allow you to work with comfort and not worry about the strength of the product.

Form making

Unrolling the workpiece

Facing materials can be made of any geometry.Based on the desired, prepare a form of plaster. Clay blank manufacturing scheme:

- roll out a cake from a piece of clay;

- cut out the required shape with a sharp tool and align the edges;

- sculpt a structural illustration and apply a patterned sketch using a stack; the contour of the workpiece is drawn up with clay rollers.

Next, a frame is made from the bars, into which the workpiece is placed. After that, gypsum is diluted in water - from a ratio of 7:10 (gypsum: water). The clay model is moistened and then poured with a plaster mixture.

Important! Plaster must be used immediately. It hardens very quickly and after a few minutes it loses its plasticity.

First, a model pattern is covered with a mixture, thinly. After that, the composition is filled in the frame to the very edge. It takes 15 minutes for the plaster to set. After a quarter of an hour, the frame is removed, and the mold is cleaned, washed and dried. At this stage, it can already be used to make tiles.

Shaping and firing tiles

Tile shaping

The plaster model is ready - it is filled with flexible material. Pressing clay into the structural surface of the mold, make sure that the raw material fills all the details. Next is the turn of the rump. The box is made of four rollers, which are placed on the workpiece. Remember about wire holes. After the semi-finished tile hardens slightly, it is removed from the base.

Clay is polished using any smooth element. The result should be a slight sheen on the surface. The decorative element is left for a while - it needs to dry.

Product molding process

The dried tiles are placed in a muffle furnace (heating device, which is characterized by the presence of protection from fuel and combustion products). There should be a small space between the tiles, otherwise the elements will be baked together. The firing temperature is about 900 degrees. The firing time is approximately 4 hours. After heat treatment, remove tiles from the oven only when they have completely cooled down.

Painting tiles

Tile painting

At this stage of production, the tiles are functional, but not effective enough. The minus is eliminated by painting. There are two options for decorating:

- cold method; oil paints are used - linseed tiles, dried during the day, decorated, dried and varnished again; re-firing is not necessary;

- painting with engobes (coated with liquid clay); requires a variety of clay and a second firing; There are two sub-variants of this method: the tiles are moistened in water, after which they are treated with a thin layer of light engobe; letting the tile dry a little, it is painted with heat-resistant gouache; if you refuse to enamel the tiles, crushed glass is added to engobe - for hardening; after painting, the parts are sent back to the oven;

- the tile is covered with creamy clay; it should be borne in mind that during heat treatment, painted tiled ceramics can change color.

Glazing process

Ready glazed tiles

Glaze is needed to enhance the effect and increase the strength of the tile. Enameling scheme:

- prepare a paste and mix it with crushed glass; the mixture should be creamy;

- tiles are dipped into the finished composition - either painted or without additional artistic processing;

- dry the ceramics;

- re-fired.

When heated, the paste with glass is sintered with the tiles and form one whole.

To simplify the production of tiles, gypsum putty can be used instead of clay, and the purchase of ready-made silicone ones can be preferred to the difficult process of making molds. In this case, firing is not necessary, and the casting procedure is noticeably easier. But with this approach, there is a departure from tradition.

Stove lined with thermo-inert ceramics

Tiles for fireplaces and stoves from the manufacturer

Tiles and tiled tiles are the nobility of natural material, limitless design variability, aesthetics and artistic value of hand-made products. Handcrafted tiles are expressive decor that can easily fit into the overall interior and exterior of the house. A wide selection of tiles in the catalog allows you to buy a ready-made version or make a unique set of tiles to order. Correctly selected tiles in the decoration are subordinate to the general idea and at the same time seasoned with a spicy note of individuality.

Behind the thin lines and external fragility of the tiled tiles, there is a standard of reliable and practical cladding. The unique material is used with equal success to decorate wood-burning fireplaces and stoves, false and electric stoves, bioportals, as well as for interior design and facade decor. The versatility of the material for interior and exterior decoration is due to its resistance to temperature extremes, excess moisture and mechanical stress. The beauty of shiny glazes and rich pigments retains its freshness and does not fade for many years.

It is thanks to the heat exchange and operational properties of ceramics that the first tiles acquired their significance. They were made by the masters of stove business. The very massive and unsightly tiles were used to decorate the hearths for purely practical purposes. Over time, such a fertile field for creativity became an object of interest for potters. Workshops, factories for the production of decorative tiles and shops for their sale were opened. At the cost of long efforts of the masters to improve the tiles, they have noticeably changed.

The evolution of the external appearance of finishing ceramics contributed to the increase in its artistic value. And step by step, tiles have become part of arts and crafts and architecture. Great artists and architects took to the work with clay to paint fireplaces and stoves, interiors of houses and public spaces, walls of buildings, stairs, squares and parks around the world with colored ceramic carpet. Terracotta and glazed tiles, etched and glazed, embossed and painted - an endless kaleidoscope of splendor from ceramics has played with patterns and colors for centuries, rotating under the influence of styles and fashion trends.

Tiles are timeless classics in the sphere of facing stoves and fireplaces. First, fire in its burning embrace transforms the clay mass into ceramics, and then ceramics encloses it in its delightful shackles of beauty. The sets of tiled tiles, which are made by real masters using hand molding and painting, as in ancient times, make the hearths inimitable.

Tiles for facade decoration and outdoor decor give the house individuality, style and character. Today it is not difficult to buy material for finishing the facade for every taste in a wide range of prices. But to make the exterior of the building unique and stand out from others is a special task. Tiles cope with such a mission to the fullest. A house with a tiled facade will certainly become a hallmark of the owner and will never get lost in the gray mass of faceless buildings. Facade cladding with tiled tiles, decorative inserts, majolica panels and friezes can also pursue advertising purposes. A representative office or a trade pavilion, a cafe or a hotel, a gallery or a theater will acquire a “sign” in ceramics, which will not only draw the closest attention to itself, but will also be engraved in memory for a long time.

Handmade tiles for interior decoration are able to decorate any surface. There is a place for tiles in any room - from the bathroom to the living room.Painted panels can become an expressive interior accent, a kitchen apron will allow you to create a creative culinary studio, wall and floor tiling - to decorate, organize or zone a space. Light and airy ornaments of tiled tiles for Provence and Mediterranean style, complex patterns for oriental flavor and ethnicity, contoured relief for classics, gold painting for lush Baroque, laconic geometry for minimalism - well-chosen tiles will support absolutely any style.

Several centuries ago, tiled decoration was available only to a narrow circle of nobility and wealthy people. In Moscow and throughout Russia, tiles are found in palaces and estates, estates and family estates. Today, exquisite ceramic decoration is still associated with chic and special status, but it can also become a property of your home. To do this, it is worth buying tiles or ready-made sets of tiled tiles for facing a stove or fireplace, sauna stove, barbecue, house facade, exterior decoration, interior decor. The cost of tiled tiles is not a price for a soulless product, but a payment for the works of ceramic artists, in which a love of ceramics is invested.

Read more