Why choose steam heating?

It must be admitted that steam heating systems cannot be classified as very popular. Such heating is rather rare. Let's take a closer look at its advantages and disadvantages.

The first, undoubtedly, include:

- Heating system efficiency. It is so high that a small number of radiators are enough to heat the premises, and in some cases you can do without them: there will be enough pipes.

- Low system inertia, due to which the heating circuit heats up very quickly. Literally a few minutes after starting the boiler, warmth begins to be felt in the rooms.

- There is practically no heat loss in the system, which makes it very economical in comparison with others.

- Possibility of rare use, since due to the small amount of water in the pipes, the system does not defrost. Alternatively, it can be installed in country houses, where they come from time to time.

The main advantage of steam heating is considered to be its efficiency. The initial costs for its arrangement are quite modest; in the process of operation, it requires relatively small investments.

However, even with so many advantages, the disadvantages of the system are very significant. They are primarily due to the fact that water vapor is used as a heat carrier, the temperature of which is very high.

Condensation of water vapor occurs inside a steam heating radiator. During this process, a large amount of thermal energy is released, which explains the high efficiency of the system.

Thanks to this, all elements of the system are heated to 100 ° C and even higher. It is clear that any accidental touching them will cause burns. Therefore, all radiators, pipes and other structural parts must be closed. Especially if there are children in the house.

The high temperature of radiators and pipes provokes active air circulation in the room, which is quite uncomfortable and sometimes dangerous, for example, in case of an allergic reaction to dust.

When using steam heating, the air in the rooms becomes too dry. It is overdried by hot pipes and radiators. This requires additional use of humidifiers.

Not all finishing materials used to decorate rooms heated in this way can withstand the proximity of hot radiators and pipes. Therefore, their choice is very limited.

The most acceptable option in this case is cement plaster painted with heat-resistant paint. Everything else is in question. Steam heating has another drawback that affects the comfort of those living in the house: the noise that steam passing through the pipes produces.

The more significant disadvantages include poor controllability of the system. The heat transfer of the structure is almost impossible to control, which leads to overheating of the premises.

Steam heating belongs to potentially hazardous systems, so the choice of equipment must be treated very responsibly. The pipes for the system must be made of metal only.

There are solutions. The first is the installation of automation, which will turn on the boiler when the premises cool. In this case, those living in the house will be quite uncomfortable from the constant fluctuations in temperature.

A more "sparing", but time-consuming method is the arrangement of several parallel branches that will need to be launched as needed.

The main disadvantage of steam heating, due to which it is little used, is its increased emergency danger. You need to understand that when a gust occurs from a pipe or radiator, hot steam will beat under pressure, which is extremely dangerous.

That is why such systems are now banned in apartment buildings and are less commonly used in production. In private houses, however, they can be arranged under the personal responsibility of the owner.

The main elements of the steam system

The steam system includes several required elements. Let's consider each of them in more detail.

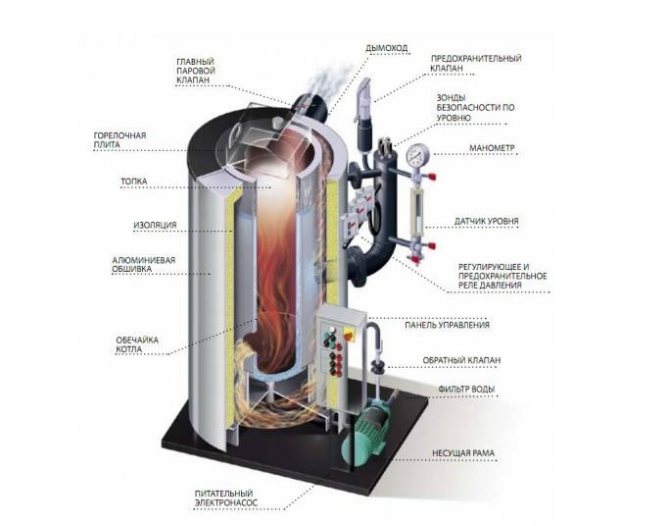

The steam boiler is the heart of the system

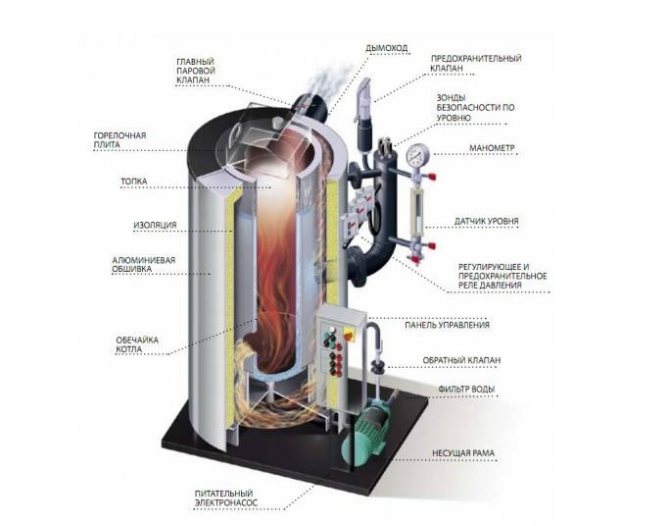

The main function of the heater is to convert water into steam, which subsequently enters the pipeline. The main structural elements of the device are manifolds, drum and pipelines.

In addition, there is a container with water, which is called a water space. A steam space is formed above it during the operation of the device. They are separated by the so-called evaporation mirror.

The figure schematically shows one of the varieties of a household steam boiler

Inside the steam space, additional equipment can be installed to separate the steam. The operation of the boiler is based on the principle of heat exchange of flue gases, water and steam.

There are two types of steam heating devices: fire-tube and water-tube. In the first case, heated gases move inside the pipeline laid inside the container with water.

They give off heat to the liquid, which reaches a boiling state. Water-tube varieties work a little differently. Here, water flows through pipes laid inside the flue gas chamber. It warms up and boils.

Water and steam inside the boiler can move either forcedly or naturally. In the first case, a pump is included in the design, in the second, the density difference between water and steam is used.

All types of steam boilers use approximately the same principle of converting water into steam:

- The prepared liquid is supplied to a reservoir located in the upper part of the boiler.

- From here, the water flows through pipes into the collector.

- The liquid from the collector rises into the upper drum, while passing through the heating zone.

- Steam is generated inside the water pipe as a result of heating, which rises upward.

- The steam, if necessary, is passed through a separator, where it is separated from the water. After which it enters the steam line.

A steam boiler can use a wide variety of fuels. Depending on this, certain changes are made to its design. They touch the combustion chamber. For solid fuel, a grate is set up, on which coal, firewood, etc. are placed.

For liquid and gaseous fuels, special burners are used. There are also practical combined options.

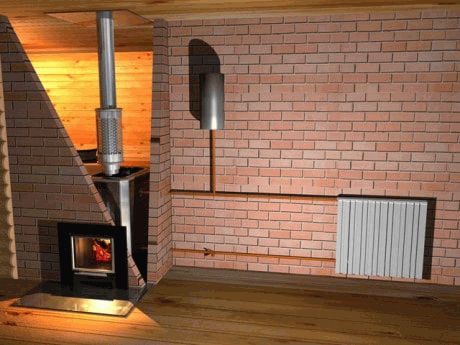

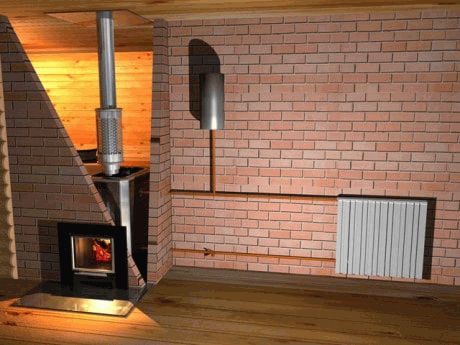

Among home craftsmen, the arrangement of steam heating using a stove is especially popular. The photo shows one of the possible options for reworking the furnace.

The power of the boiler is selected depending on the area to be heated.

This can be done based on the average values:

- 25 kW for buildings up to 200 sq. m;

- 30 kW for houses ranging from 200 to 300 sq. m;

- 35-60 kW for buildings from 300 to 600 sq. m.

If more accurate data is needed, they use the standard calculation method, where for every 10 sq. meters account for 1 kW of equipment power. Keep in mind that the formula is used for houses with a ceiling height of 2.7 m or less.

For higher buildings, you need to take more power. When choosing a boiler, special attention should be paid to its certification. Any steam heating system is potentially dangerous, therefore equipment testing is imperative.

Heating pipes and radiators

The coolant temperature in steam systems ranges from 100 to 130 ° C, which is much higher than in liquid systems, where it ranges from 70 to 90 ° C. Therefore, it is strongly discouraged to use similar equipment for arranging systems.

First of all, this applies to metal-plastic and polypropylene pipes. The maximum operating temperatures for these materials vary between 90-100 ° C, so their use is strictly prohibited.

Ideal for arranging a steam heating system copper pipes. They do not corrode, withstand high temperatures, but are very expensive

For main pipelines of steam systems, three types of pipes are usually used. The most inexpensive option is steel. They can easily withstand temperatures of 130 ° C, which is more than enough, and are quite durable.

However, the condensate formed inside the parts quickly destroys the pipes, since the steel is susceptible to corrosion, and the aggressive medium formed by the steam only enhances this disadvantage.

Another disadvantage of steel elements is the need for joining by welding, which takes a lot of time and effort. Galvanized steel pipes are much more resistant to corrosion. They also withstand high temperatures well.

To connect them, the threaded method is usually used, which greatly simplifies the process. The main disadvantage of galvanized pipes is their high cost.

Copper pipes are considered ideal. The material can withstand high temperatures, is sufficiently plastic and at the same time durable, does not corrode. Soldering is used to connect copper parts.

Copper piping is very durable and strong, but the cost is very high. Thus, the most acceptable option in terms of quality and price ratio is steel pipes with an anti-corrosion coating or galvanized.

The best choice for steam heating is cast iron radiators. They will be able to withstand the severe stress caused by the presence of hot steam inside the batteries.

Radiators for steam systems are selected on the basis of durability. It is important that they can withstand high temperatures and are corrosion resistant. Based on this, massive cast-iron batteries can be considered the best option, steel panel batteries are the worst.

Given the high efficiency of the system, in some cases, the use of ribbed steel pipes is quite acceptable.

Control and measuring equipment block

The steam heating system is characterized by an increased emergency hazard, therefore, the presence of control devices is mandatory. The pressure in the system is monitored, if necessary, it is normalized. For these purposes, a gearbox is usually used.

The device is equipped with a valve through which excess steam is removed from the system. For powerful installations, you may need not one, but several such valves.

Varieties of the heating system

In practice, you can find a fairly large number of variations in steam heating. By the number of pipes, one and two-pipe types of steam systems are distinguished. In the first case, steam moves continuously through the pipe.

In the first part of its journey, it gives off heat to the batteries and gradually turns into a liquid state. Then it moves like condensation. To avoid obstacles in the path of the coolant, the pipe diameter must be large enough.

It happens that the steam does not partially condense and breaks into the condensate pipeline. In order to exclude its penetration into the branch intended for the drainage of condensate, it is recommended to install condensate drains after each radiator or group of heating devices.

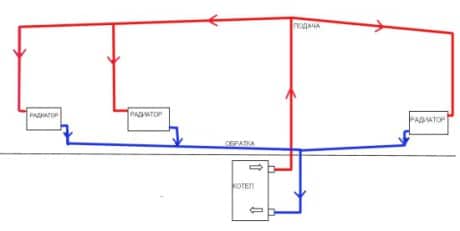

A significant disadvantage of the one-pipe system is the difference in the heating of the radiators. Those located closer to the boiler heat up more. Those further down are smaller.But this difference will be noticeable only in buildings that are large in area. In two-pipe systems, steam moves through one pipe, condensate leaves through the other. Thus, it is possible to make the temperature equal in all radiators.

But this significantly increases the consumption of pipes. Like water, steam heating can be single or double-circuit. In the first case, the system is used only for space heating, in the second - also for heating water for domestic needs. Heating wiring also differs.

Three options are practiced:

- With top wiring. The main steam line is laid above the heating devices, pipes are lowered from it to the radiators. Even lower, at the very floor, a condensate line is laid. The system is the most stable and easiest to implement.

- With bottom wiring. The line is located below the steam heating devices. As a result, steam moves along the same pipe, which should be slightly larger than the usual diameter, and condensate moves in the opposite direction. This provokes water hammer and depressurization of the structure.

- Mixed wiring. The steam pipe is mounted slightly above the level of the radiators. Everything else is the same as in a top-wired system, thus maintaining all its advantages. The main disadvantage is the high risk of injury due to easy access to the hot pipes.

When arranging a circuit with natural compulsion, it must be remembered that the steam line is mounted with a slight slope in the direction of steam movement, and the condensate line is for condensate.

The slope should be 0.01 - 0.005, i.e. for each linear meter of the horizontal branch, there should be 1.0 - 0.5 cm of the slope. The inclined position of the steam and condensate lines will eliminate the noise of steam passing through the pipes and ensure free drainage of condensate.

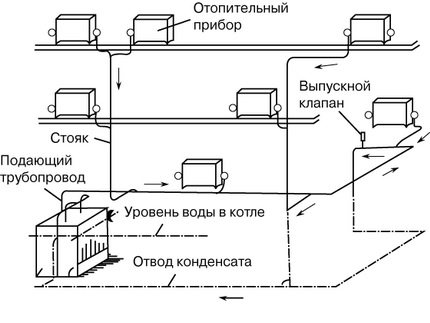

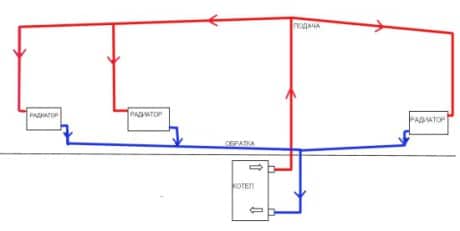

Steam heating systems are built according to a one-pipe and two-pipe scheme. Among the one-pipe, options with horizontal connection to heating devices prevail. In the case of constructing a circuit with vertical connection of devices, it is better to choose a two-pipe version

According to the level of internal pressure of the system, two main types are distinguished:

- Vacuum. It is assumed that the system is completely tight, inside which a special pump is installed to create a vacuum. As a result, steam condenses at lower temperatures, making the system relatively safe.

- Atmospheric. The pressure inside the circuit is several times higher than atmospheric pressure. In the event of an accident, this is extremely dangerous. In addition, radiators operating in such a system heat up to very high temperatures.

There are many options for arranging steam heating, so everyone can choose the best option for their home, taking into account all the features of the building.

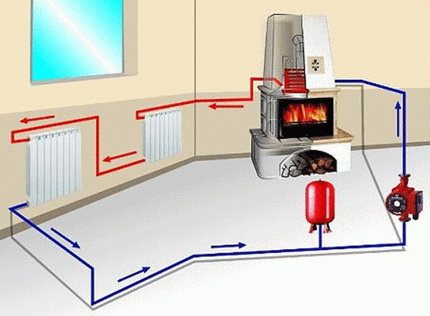

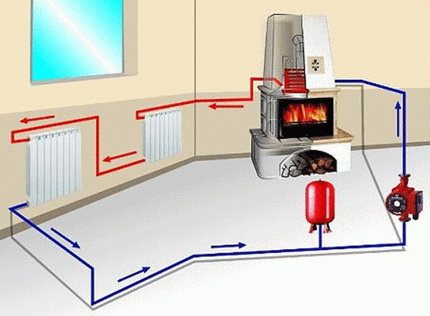

The figure shows a diagram of an open-loop steam heating system

Installation diagram of steam heating from a stove

- Natural and forced circulation system

A natural circulation system requires the heat exchanger to be positioned below the level of the radiators and all pipes at an angle. A forced system requires a pump to ensure smooth circulation of the heat exchanger.

Natural circulation circuit

There are also one- and two-pipe circuits.

- One-pipe scheme of steam heating of a private house

This circuit works on the principle of serial connection of radiators. The coolant moves along the pipe, passing from one battery to another. As a result, the first radiator turns out to be the hottest, and the last one is practically cooled down. Therefore, it is recommended to use such a scheme for rooms with a small area - from 40 to 80 m2.

One-pipe heating scheme

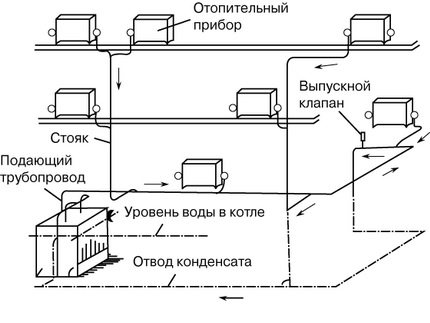

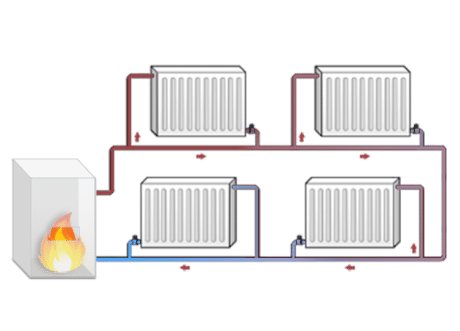

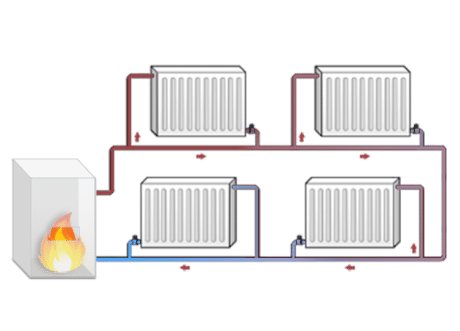

- Two-pipe scheme

This system is more suitable for houses with large areas, two-storey cottages. It differs in that the radiators in it are connected in parallel, using two pipes: inlet and outlet (condensing). In this scheme, the coolant is supplied to all radiators with the same temperature, since it does not have time to cool down.

Two-pipe heating scheme

How to equip a boiler room?

A steam boiler operating on any fuel must only be installed in a specially equipped room.

The standards developed for standard steam appliances with pressures up to 0.07 MPa, generating steam with a temperature of 120-130 ° C, provide for a number of requirements for such boiler rooms:

- the distance from the walls to the heater cannot be less than 100 cm;

- the height of the room must be at least 220 cm;

- the minimum level of fire resistance of doors - 30 minutes, walls - 75 minutes;

- the presence of high-quality ventilation;

- the presence of doors and windows facing the street.

It is best to equip the boiler room in a separate room, but partitioning of a suitable room is also allowed. Inside, it must be finished with non-combustible materials. Ceramic tiles are best suited for these purposes.

The walls in the boiler room should be finished with non-combustible materials, for example, ceramic tiles.

Steam heating in a private house with your own hands: diagram, instructions

A steam boiler operating on any fuel must only be installed in a specially equipped room. The standards developed for standard steam devices with a pressure of up to 0.07 MPa, generating steam with a temperature of 120-130 ° C, provide a number of requirements for such boiler rooms:

- the distance from the walls to the heater cannot be less than 100 cm;

- the height of the room must be at least 220 cm;

- the minimum level of fire resistance of doors - 30 minutes, walls - 75 minutes;

- the presence of high-quality ventilation;

- the presence of doors and windows facing the street.

It is best to equip the boiler room in a separate room, but partitioning of a suitable room is also allowed. Inside, it must be finished with non-combustible materials. Ceramic tiles are best suited for these purposes.

The walls in the boiler room should be finished with non-combustible materials, for example, ceramic tiles.

Steam heating is a very simple and economical way to heat your home. Many are attracted by its minimal heat loss, high efficiency and low operating costs. However, it must be remembered that steam heating is potentially dangerous, and an emergency situation in this case can lead to serious injury. Therefore, its calculation and arrangement should be taken seriously.

More and more people are convinced that an autonomous way of heating an apartment or house is more economical than a centralized one. Do-it-yourself steam heating is one of the difficult tasks, but quite doable if you have basic skills in working with a power tool. Even before installation work, it is necessary to make calculations and purchase the necessary components.

Essence of the question

Water heating

Some are confused and believe that in fact the correct name for such a system is water heating, and the prefix "steam" has remained from the past, when heating was carried out at the expense of industrial boiler houses that produced large volumes of steam. In fact, even today there are boilers that provide heating of premises by converting liquid into two states of aggregation. The strengths of this solution are:

- double heat transfer - by convection, as well as infrared radiation;

- minimum losses in the heat exchanger when transferring energy from the source;

- high reliability;

- there is no danger of defrosting the system during the cold season;

- the ability to use at any time of the year;

- long service life without failures.

Some of the disadvantages are:

- relatively high temperature of pipes and radiators;

- serious consequences in case of a breakthrough;

- some difficulties during installation;

- high susceptibility to corrosion.

The essence of functioning and high efficiency is that steam, passing through the main, condenses and settles, while a large amount of thermal energy is released. With the same fuel consumption, such a system will be much more efficient than a water system of a similar length.

Usually, in order to ensure the safety of users, certain restrictions apply in modern boilers. For example, the maximum temperature to which steam is heated is 130º C, and the highest point that the pressure reaches is 6 atmospheres.

All types of systems are divided into single-circuit and double-circuit. In the first variant, the entire boiler power is used to warm up the medium, which will take part in increasing the air temperature inside the room. In the second version, there is an additional heat exchanger in which running water is heated, which allows it to be used for domestic needs.

Different heating systems

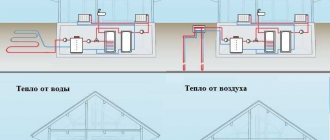

By the way of circulation of the carrier, as in the case of water systems, they are distinguished:

- Natural circulation or closed. In this case, after condensation, the water under the influence of gravity, by a natural current without a pump, returns to the boiler, where it is again converted into steam and used.

- Forced circulation or open circuit. In this case, water does not immediately flow back into the heater. At first, it is collected in a special tank, from which it is supplied with the help of a pump for further conversion into a gaseous state.

By the level of pressure inside, there are:

- Atmospheric. In them, the pressure value is several times higher than atmospheric pressure, which in case of an accident can cause serious injuries. In addition, in such a system, the emitters are heated to a high temperature, and the deposited dust burns up and an unpleasant odor is emitted.

- Vacuum. To implement this option, the entire line must be sealed. With the help of a special pump, a vacuum is created inside. The result is the conversion of water to a gaseous state at lower temperatures, which increases safety.

According to the method of pipe routing, there are:

- One-pipe. Steam moves continuously through one pipe. In the first half of the journey, it gives its energy to the radiators, gradually turning into a liquid state. In this case, the temperature of the radiators that are closer to the boiler will be higher than those that are at the end of the circuit. In this case, large diameter pipes will be needed so that no obstacles arise.

One-pipe heating system

- Two-pipe. Steam is supplied through one pipe, and condensate is returned through the other. In this case, the carrier reaches all devices, practically without losing temperature. This option will be relevant for large houses with several floors. If the premises are small, there is no point in it, this will only increase the total cost of the project.

Two-pipe heating system

Vacuum systems are still in the testing phase. When using them, the constant availability of electrical energy will be required, because the vacuum pump runs almost continuously.

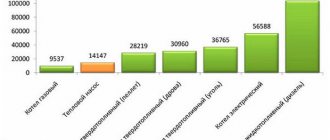

Boiler selection

Boiler selection

In order to choose the right heating device, the first step is to calculate the area that will be warmed up. To do this, you need to calculate the area of each individual room by multiplying the width by the length. After that, all the results must be added, the final figure will be the desired value. It is important to remember that this is true for a ceiling height of up to 3 m, if it is greater, then it is necessary to make an additional headroom.

- For a total area of up to 200-300 m2, a capacity of 25-30 kW is sufficient.

- For 400-600 m2 - 35-60 kW;

- 600-1200 m2 - 60-100 kW.

Read more: Do-it-yourself toilet cistern repair frequent breakdowns and repair methods

The next step is fuel selection. Steam boilers easily operate from the following sources:

- Liquid. This can be, for example, diesel fuel or waste oil. When using this option, it will be mandatory to place the unit in a separate room. This will help to avoid inhaling harmful fumes and their negative health effects.

- Solid - firewood, coal, peat and anything that can burn with the release of a large amount of heat.

- Gaseous. Usually it is natural or liquefied gas.

- Electrical.

In some cases, solid fuel solutions are significantly cheaper, but it is worth considering not only the cost of fuel, but also the time that will be spent on kindling. In this case, it can reach several hours, while it is necessary to constantly replenish the furnace in order to maintain the temperature at the proper level.

Some manufacturers combine different fuels. For example, they combine a furnace for loading solid fuel and provide a heating element. At the same time, the efficiency does not decrease, but it turns out to save on costs, and therefore on payment.

Choice of pipes

Types of pipes

When choosing, a lot will depend on the planned budget. What can be said unequivocally is that polypropylene pipes are by no means used for systems of this type. This is explained by their instability to high temperature conditions. You will need to choose from the following options:

- Steel tubes. For their installation, you will need a welding machine. They are resistant to high pressures and temperatures. Affordable price and prevalence are also on the positive side. The disadvantage is high susceptibility to corrosion.

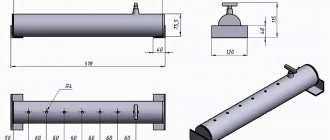

Longitudinal steel pipe

- Galvanized pipes. They include all the advantages of steel, plus the lack of corrosion instability is compensated for here. Joints are made with threaded connections, so no welding is required.

Galvanized pipes

- Copper. Are ideal. But they are much more expensive in cost, in addition, their installation will require special skills in soldering this material.

Copper pipes

During installation, pipes can be hidden in walls or floors. But it is important to take into account that the building material is resistant to thermal influences.

Additional nodes

Cast iron batteries

In addition to the boiler and pipes for the mainline, mandatory elements will be required, which cannot be dispensed with:

- Radiators. These can be cast iron batteries, steel products, or ribbed pipes. It is better to install them under windows. Thus, a heat plug is formed, which cuts off the cold air. This will also prevent the formation of condensation on the glass.

- Fitting. Various connecting elements: couplings, angles, bends, adapters that will be required when installing the pipeline.

- Reduction and cooling unit. Carries out the conversion of steam into a liquid state.

- Reducer. Designed to regulate the pressure in the system.

- Expansion tank. Better to use an open type element. If there is a desire to put a sealed tank, then it must be equipped with a pressure gauge and a pressure relief valve. If this is not done, then this can lead to its failure.

- Condensate collection tank.

- Circulation pump. For systems with forced fluid movement.

- Hydraulic shutter. It will be necessary when you need to drain the system to repair it or replace any components.

- Filter. It will be necessary to remove solids before water enters the boiler. This is necessary so that nothing degrades performance.

- Mayevsky's cranes.

An indirect heating boiler can be installed in the steam heating system. In this case, you will need a valve for three inputs. It connects to the thermostat and redirects the movement of the coolant.

Preparing to install the steam system

To make steam heating correctly, you need to start with the preparation of the project. Its development is a complex task, which is best solved by specialists. In the finished project, many points must be taken into account.

First of all, the calculation of thermal loads for each of the premises and for the building as a whole is carried out. The source of steam is selected, and the mechanism and degree of automation of the system is determined.

In addition, the steam consumption is necessarily determined, based on this, the equipment and the scheme of its use are selected. After the project is ready, you can start drawing up an installation plan.

To complete it, you will need a building plan, on which the locations of the equipment are applied. They usually start with a boiler. Its location is determined. If the system has natural circulation, the boiler must be below the level of the batteries.

In this case, it is usually lowered into the basement or into the basement, so the condensate can drain independently to the device. Then the layout of the entire heating system is applied to the plan of the house. Moreover, all the necessary equipment is noted.

Experts advise to perform this operation directly "on site", being in the room where the equipment will be located. This is the only way to notice and take into account all the protrusions and obstacles that will have to be skirted.

Before starting the installation, a plan diagram of the future system must be carried out, on which all equipment and radiator attachment points are marked

All transitions and corners must be marked on the diagram. After it is completed, you can proceed to calculating the amount of material required for its implementation. Once again, it is worth paying attention to the importance of choosing the right equipment.

The steam system is potentially hazardous, so you shouldn't skimp on materials and appliances. Everything must be of high quality and certified, otherwise serious problems cannot be avoided.

Steam heating installation technology

Work begins with the installation of a heating boiler. It is mounted in a pre-prepared room on a concrete base. In some cases, a separate small foundation is prepared for the equipment.

The device is installed on the base strictly horizontally, the correctness is checked by the building level. Any errors noticed are eliminated immediately.

The boiler placed on the base is connected to the flue gas system. The connection must be solid and completely sealed.

The next step is to hang the radiators. To do this, in the places indicated on the installation diagram, special hooks are driven into the wall, onto which the batteries are attached. If the use of finned tubes is supposed, then they are fixed.

Finned pipes can be used in steam heating systems instead of radiators. The high heat transfer parameters of the system will be significantly enhanced due to the increased area of the heat-conducting surface

The strength of the fixing of the heat emitters is checked. Next, you can start arranging the expansion tank. It is fixed at the highest point at a short distance from the heating boiler, it is best to keep this distance as minimal as possible.

You can now set up a group of control devices. They are installed at the outlet of the boiler. At a minimum, a pressure gauge and a relief valve should be located here.

All installed equipment is connected to each other by pipes. The connection method depends on the material from which they are made. In any case, the correctness and reliability of the connections should be carefully checked.

For open systems, a condensate collection tank is installed at the end of the line and a pump is installed. The branch pipe that goes from it to the heating device must have a smaller diameter than the rest of the pipes.

The steam boiler is connected to the heating circuit. In this case, all the necessary shut-off valves and filters must be installed, which will retain large particles of dirt that may be contained in the water.

If the equipment runs on gas, the fuel line is connected. In this case, it is forbidden to use flexible hoses - only rigid liners.

All connections are made exactly according to the standards in order to avoid an emergency situation later

Then you can carry out a test run. For this, water is poured into the circuit, after which the equipment is put into operation. At first at the minimum operating temperature, then it is gradually increased, while monitoring the correct operation and integrity of the system.

When the slightest shortcomings are revealed, the equipment is stopped and all malfunctions in its operation are eliminated.

Nuances when using steam heating from a stove

In brick ovens with a heat exchanger, more soot is generated in the chimney than usual and must be cleaned more often.

With a gravity system, the furnace will have to be built in the basement so that the condensate flows freely to the lowest point.

The installation of valves should not be neglected - they are essential for safety and prevention of accidents. Since the pump requires electricity, it must be borne in mind that in the event of a disconnection from the mains, it will be impossible to stop the operation of the furnace.

Heating in a wooden house

Steam heating in a wooden house is installed according to the same principle as in a brick one. It is only necessary to observe fire safety measures - to protect wooden surfaces from overheating.