Expansion tank calculation

To begin with, let's clarify the information a little: open-type expansion tanks (atmospheric) can also be installed on systems with forced circulation, this is the choice of the homeowner. We drew attention to this, since it is unlikely that it will be possible to make a closed-type membrane tank at home, but an open one is no problem.

But first you need to understand what dimensions it will have, and for this to carry out the appropriate calculation. Without going into the jungle of formulas, we will apply the old proven method of determining the capacity of the tank. Knowing that when heated from 20 ºС to 80 ºС water adds approximately 4-5% in volume, let's calculate the amount of water in the system. In this case, one should take into account:

- the volume of the boiler tank - according to the manufacturer's technical documentation;

- capacity of radiators - according to the product passport;

- the amount of coolant in the pipes.

The calculation of the volume of water in the pipes is quite simple. The lengths of all lines and connections are measured with a distribution by diameter. Then the cross-sectional area of each pipe diameter is calculated and multiplied by its length. All the results are added up and the total amount of water is obtained, to which the volume of the coolant in the boiler and batteries is added.

Taking 5% of the total and adding another 5% of the stock, we determine that open-type expansion tanks should contain a tenth of what is in the system. Well, knowing the volume, it is easy to determine the size of the container.

Expansion tanks in various heating systems

In any building, be it administrative or residential, the heating system can be represented by one of the following options: centralized, autonomous open / closed type.

Let us consider in more detail the design features of the expansion tank for the most common systems, as well as the functions it performs.

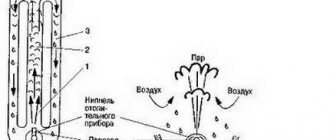

Centralized system... The expansion tank is a sealed container, at the top of which there is a valve designed to release excess air.

Attention. The Mayevsky crane should not be used due to its small bore, which can lead to an unnecessarily long bleeding of air from the heating system.

The tank is installed at the highest point of the upper spill of the heating system. During its operation, the air tends exactly there, displaced by a heat source moving downward. The system is launched in the basement by opening the circuit valves and bleeding air from the tank.

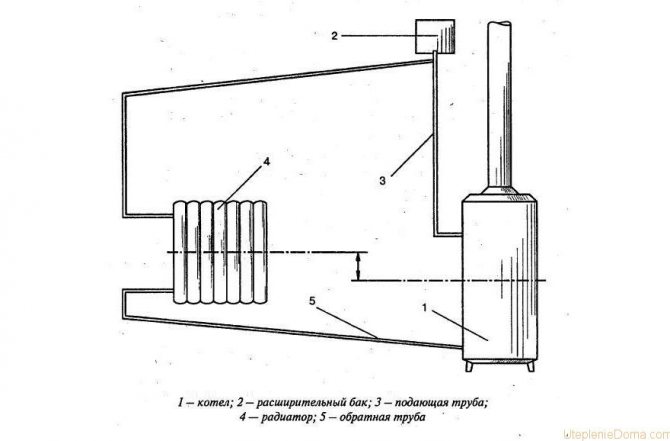

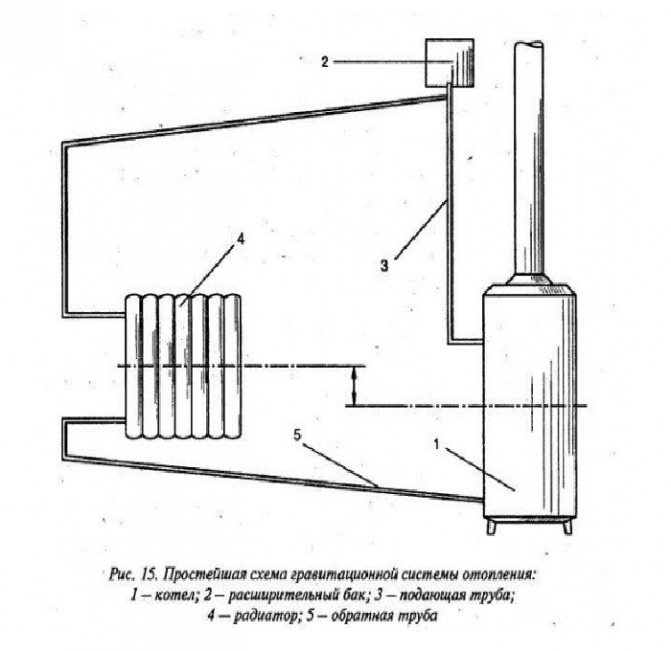

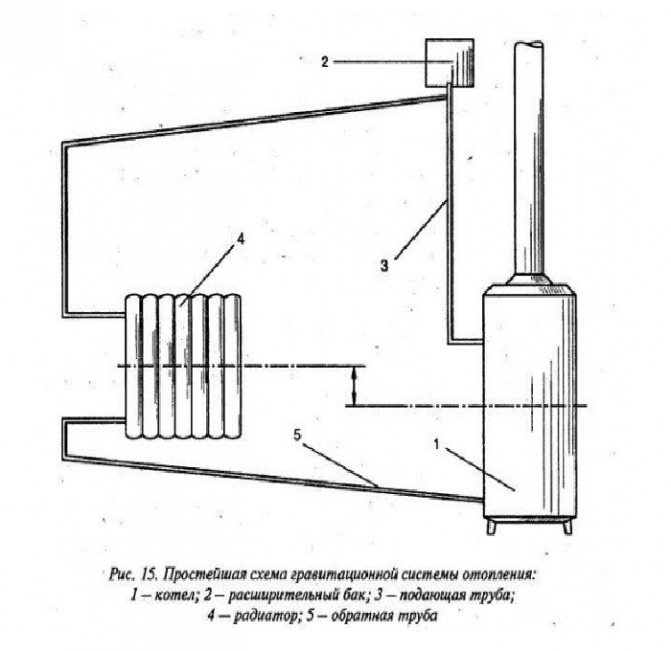

Open-type autonomous system. In this system, everything is arranged quite simply. The expansion tank is a non-hermetic design, closed with a lid to prevent dust, etc. from getting inside. The movement of the coolant through an open heating system is possible due to convection. In this case, the heat source comes into contact with air directly in the expansion tank, which, in turn, performs 2 functions: compensates for the expansion of the coolant and at the same time is the highest point of the circuit into which the vented air enters.

Tank design

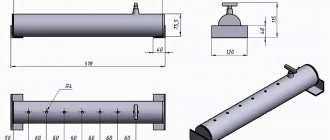

The shape of the tank can be either round or rectangular, it doesn't really matter. It's just a little easier to make a rectangular tank. At the same time, with large volumes of liquid, a square tank will require reinforcement of the walls, which makes the entire structure heavier. But she must be taken to the attic. A round vessel can be made from a pipe, but it is more difficult to attach a lid to it, and its capacity will be less.It's up to you to choose.

Note. Often, homeowners, in order not to mess around for a long time, make an open-type expansion tank out of all kinds of plastic containers - buckets, cut off cans, and so on. But we need a solid metal tank, so we will not talk about canisters.

In general, the tank is a metal container with an open top, closed by a lid. Nozzles for connecting the heating system and the overflow hose are cut into the body of the product. There is also a more advanced design, where there are 4 nozzles, the functions of each of them are indicated in the diagram:

There is a supply and return branch connected to the return line so that the water does not stagnate, as well as a minimum level control pipe. The latter function is very convenient to use, you do not need to climb into the attic to make sure there is water. True, with this option, the installation becomes more complicated, you will have to lay additional pipes through the floors with your own hands.

Many homeowners get by with two pipes - for the coolant and the overflow. When water is added to the system, the tap is opened and the hose taken out into the street is monitored. The make-up valve is closed when water runs out of the hose, but then the tank is full to the brim and when heated, the coolant flows out of it for a long time through the overflow.

There is another design of a homemade container, although it can hardly be called open. The inner space of the tank is not in contact with the atmosphere and is only half filled with water. The rest is occupied by air, which plays the role of a damper when the coolant expands. This heating tank has a pipe for replenishing water, draining and connecting to the piping network. The design is shown in the figure:

It is not worth making and using such a container, and here's why. When the system is operating, excess pressure will appear inside it, since there is no outlet for air, only an emergency valve. This means that under pressure, active diffusion of oxygen into the coolant will begin, which manufacturers of polymer pipes are constantly struggling with. Oxygenated water primarily destroys the steel parts of the boiler.

What it is

The expansion tank, in essence, is a tank included in the heating circuit, partially filled with air. Everything is just utterly impossible. However, the practical implementation can be quite different in different heating schemes.

Let's remember where you can find expansion tanks.

Central heating

The expansion tank for heating is installed at the top of the supply ring in the attic of houses with an overhead filling.

What is it and why is there a tank there?

- From the elevator unit, the supply pipeline of the house heating rises to the attic of the house and surrounds it around the perimeter. The return piping forms the same ring in the basement.

- The coolant gives off heat to the heating devices, going down the risers from top to bottom.

- All air, accordingly, is forced into the upper filling and, even with a minimal slope of the filling, is collected at its upper point. Which, in fact, is the expansion tank.

When starting the heating system, it is enough to open both house valves and after a while bleed the air from the expansion tank.

Curious: to simplify the start-up, the vent from the expansion tank in the attic is often removed to the basement. The front of water under a pressure of 4 atmospheres with a small diameter of the pipe will perfectly displace the air down.

Heating system

Both the type and the main function of the tank depend on the type of heating system.

Open system

As a rule, a system with natural circulation is made open. The name only means that the water in the system is constantly in contact with atmospheric air. The point of contact is precisely the expansion tank.

Its function in this case is twofold:

- When the temperature of the water in the heating circuit changes, the tank holds its increased volume. Thermal expansion, remember? All liquids slightly increase in volume when heated.

- There, in the tank with a properly designed heating system, air is displaced from the radiators and wiring. For this, the entire contour is laid with a slight slope along the entire length.

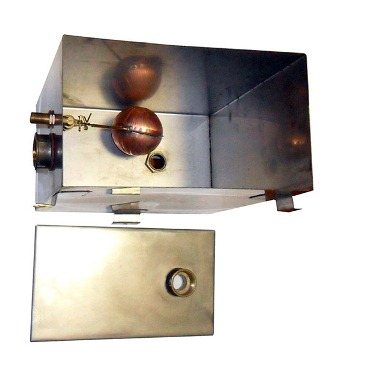

The photo shows an expansion tank for an open system.

Closed system

Finally, in an autonomous closed-type system, the expansion tank fully corresponds to its name - it compensates for the expansion of the coolant during heating. Otherwise, at the moment when the pressure of the increased water volume exceeds the tensile strength of the pipe, the heating system will become open in the most unpleasant way for the owners.

In all three described schemes, expansion tanks are quite different devices.

Which ones?

- A tank in a top-fill central heating system is a free-form sealed container with a relief valve or tap at the top of the structure. Mayevsky's taps for radiators are inapplicable in this case: the total volume of air for the house is too large to bleed off through a compact tap in a reasonable time.

- The expansion tank of an open-type heating system is an ordinary tank open on top. A lid is usually present, but its main function is not to provide a seal, but to keep out debris. In addition, water has to be periodically added to the tank to compensate for the inevitable evaporation.

- In modern closed systems, membrane expansion tanks are used, in which the volumes for air and for the coolant are separated by an elastic partition. Why is this needed? To prevent the air from saturating the coolant with oxygen, accelerating the corrosion of pipes and radiators.

Diaphragm tank diagram. As you can see, there is nothing complicated about this device.

Important: in addition to the expansion tank, a safety valve is usually installed in the system to relieve excess pressure. It provides additional insurance against exceeding the working pressure. It is also a good idea to mount a pressure gauge next to the reservoir.

Manufacturing and installation

To make the expansion tank of the heating system yourself, you need to have sheet metal, cut pipes of different diameters and a couple of corners in case you need to strengthen the wall or fix the container in place. From tools and devices you will need:

- welding machine;

- angle grinder;

- drill;

- a set of locksmith tools;

- tape measure, square.

Note. You can often hear advice that it is better to weld the container from stainless steel. Practical advice, it is relevant when the system is assembled from polymer or stainless steel pipes. If everything is made of metal, then there is nothing to worry about, you can cook from simple "black" steel.

Any home craftsman with welding skills knows how to weld a box. Then pipes are cut into the open expansion tank and sealed hermetically. The cover is made loose so that air can freely pass inside. When everything is ready, it remains only to check the welds for permeability and install the container in place, as shown in the diagram:

In order not to heat the attic space in vain, after installation, the tank body must be well insulated; for this purpose, mats or mineral wool slabs are suitable. Alternatively, you can glue the body with foam sheets. Some more skilled craftsmen automate the replenishment of the tank using a "toilet" float kit, but this is not a very reliable option. Recall how often the toilet hums in your house and you will understand what it is about.

The purpose of the expansion tank

In fact, pipelines and heating devices change the internal volume filled with the coolant insignificantly when the temperature changes. As a heat carrier in heating systems, water is often used, which, when heated to a temperature 90-95 ° C can increase volume by 2.5-2.8%.

Attention! Excess liquid volume is directed into a special container, which is located above all in the heating system.

Another problem that is solved when installing an expansion tank is that the presence of such a capacity allows you to fill the system with a coolant.

In order for the fluid flow to circulate through pipelines and heating devices, the condition of flow continuity (Daniel Bernoulli wrote about him in the middle of the 18th century).

Continuous flow - lack of places where there is no water. The presence of voids will create a condition under which the existing gas bubbles will not allow the fluid to move.

A similar phenomenon is observed in the initial period of the heating season, air lockswhich are removed by filling the system with water. Excess liquid is located on top in a special container.

Reference! Natural circulation inside an enclosed space is possible only if there is a certain hydrostatic head (Нst). The higher the Нst value, the more intense the circulation of the coolant.

With a decrease in the temperature of the coolant there is a decrease in volume... Part of the water from the expansion tank is returned to the heating system.

Heating systems perform with natural and forced circulation coolant.

Expansion tanks are used in traditional heating designs. open type.

In cases where the coolant is prompted to move with the help of special circulation pumps, expansion devices are more often used. closed type.

Open type

The open-type expansion tank is a conventional metal box connected to the pipe from the heating main. It is posted in the highest available location buildings (houses).

During the heating season, the presence of water in the tank is regularly inspected. If necessary, add liquid to the expansion tank.

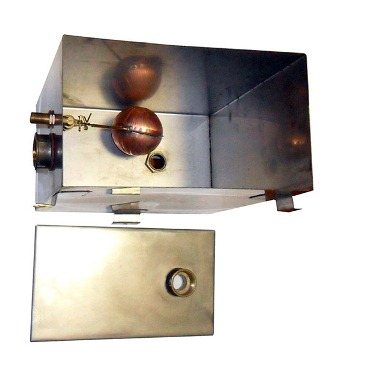

Some experts establish float system level control in the expansion tank. When the level drops, the float drops, which leads to the opening of the feed valve.

Water is topped up independently to the desired level. Automatic systems are installed only where there is a water supply system in which a pressure exceeding hydrostatic value Нst.

Pros of an open system:

- Extremely simple device, easy to make do it yourself.

- Can to function for yearswithout causing any complaints from users.

Disadvantages of an open system:

- Corrosion damages expansion tank primarily.

- Need to be monitored regularly presence of liquid and top up if necessary... Often in private houses, when installing a heating system, the tanks for expanding the coolant are remembered last. I place it near the ceiling, which creates inconvenience when refilling. Forced to use flat bottlesto add water.

- It is necessary to lay additional pipe, which will only heat the space near the ceiling.

Important! The heating medium tends to evaporate. It needs to be refilled periodically so that the inside of the heating system does not form air locks.

We make an open expansion tank for heating with our own hands

An open-type expansion tank can be made by hand.Not so long ago, when not many knew about the installation of individual heating, there was no question of an expansion tank - it was attached at the last moment from what came to hand. A large diameter flowerpot or any suitable container was used as a tank. Today, an expansion tank can be purchased at a store or you can make an open-type expansion tank with your own hands. It's much easier than making a closed tank.

What you need:

- marker;

- ruler;

- Metal sheet;

- Bulgarian;

- basalt wool;

- welding machine;

- gloves and other protective equipment.

How to make a tank:

It is better to make a stainless steel tank, then the tank will last for many years. If there is no such material, then use any metal.

- We make the markup: the dimensions of the tank depend on the length of the heating system circuit. If this is the standard, then you need to cut out 5 squares measuring 30 by 30 or 30 by 40 cm. These are the walls for the tank and the bottom.

- The workpieces must be assembled, placed at a right angle and welded with a welding machine.

- The structure is ready, you need to drill a hole in the bottom of the tank to insert the pipe. Through it, water from the system must flow into the tank. The branch pipe must be connected to the heating system (looped).

- It is advisable to insulate the expansion tank, because often the highest point of the circuit falls on an unheated room in the house (this is an attic). Therefore, it is necessary that the expansion tank be insulated so that the water in it does not freeze. Any insulation can be used, for example, basalt wool. It is resistant to even the highest temperatures.

- You need to be prepared for the fact that in an open tank (open circuit), the water reaches the boiling stage. Therefore, when choosing a heater, consider these nuances.

Expansion tank for heating with your own hands. Photo

Making an expansion tank with your own hands: photo

You should start work by creating drawing or sketch future product. At the same time, materials and tools for the manufacture of an expansion tank available from a home craftsman are evaluated.

Photo 1. This is a diagram of an open expansion tank with a float water level control system.

The volume of the tank for the heating system of a separate house or apartment

Only during operation will it be noticeable how the coolant evaporates quickly. It will require frequent filling. It seems to many that a small volume is needed. There are recommendations that it is enough for the expansion tank to have capacity for 5-7 liters. Of course, such a volume is easier to find or manufacture.

When the boiler operating mode changes (even in winter there are thaws, when the heating medium is heated to the temperature of the entire 40-45 ° C). From the expansion tank, water can completely escape into the system.

Reference! In practice, it has been proven that the minimum necessary to have this container with a volume not less than 10% from the total volume of the entire system.

It is not difficult to calculate the volume of the expansion tank. The length of the pipelines is determined, as well as the number of sections in all batteries. For example, for a house with an area about 100 sq.m. the volume of the heating system is 120-140 liters. Then the expansion tank should be not less than 12-14 liters. You can use a little more to add water less often.

Direct manufacturing

When a home craftsman starts work, he has the following options:

- you are using a ready-made container, such as a large saucepan, milk flask or can for 12-15 liters or more;

Photo 2. An expansion tank can be made from various containers, including a similar aluminum flask.

- available available sheet metal and welding machine.

How to properly make from a plastic canister

It's easier with ready-made containers. You need to have an electric drill with a set of drills. The process boils down to drilling a hole into which a pipe can be passed with a diameter of 21-27 mm.

- Find a drill so large diameter it can be difficult at home.Therefore, a circle is marked, and then holes are drilled along the contour.

- File with a file lintels and make the hole look acceptable.

- Use wide washers, rubber washers and nuts with the required pipe thread.

- Assemble the future design and set higher, preferably in the attic.

- To prevent intense evaporation cover with lids.

- To avoid freezing in winter they are additionally insulated... Use out-of-use warm clothes or various insulation materials, for example, "Ursa".

This method of manufacturing an expansion tank is the least expensive.

Important! If there is a milk flask available 40 l, then it is most convenient to use it to create an expansion tank for a heating system. The cover does not close tightly during operation, the rubber gasket is removed.

Manufacturing from sheet material

Certain requirements are imposed on the source material. The thickness of the sheets should be not less than 4 mm. If a thinner sheet is used, the service life may be limited to only a few seasons.

Stainless steel or plastic container

The expansion tank can be easily built with your own hands. To do this, it is enough just to make a container that has the required volume. Often the tank is made of stainless steel sheet with a thickness of 2-4 mm. You can also use ready-made plastic containers. Before starting work, you need to prepare the necessary tools and materials.

Sheet layout

At the initial stage, the prepared sheet of metal is marked. Preliminarily, a diagram of the future tank is made on paper. This will minimize waste. When cutting, it should be borne in mind that the grinder's disc will take a few millimeters. Thoroughly clean all edges after cutting.

Cutting blanks

A grinder is used for cutting metal. At this stage, you will need to prepare five or six blanks. The exact number of parts depends on the availability of the cover. If the tank is large, the lid can be split in two. One part is tightly attached to the body, and the other is installed on the curtain.

Welding works

During joining, the workpieces are set at right angles. In this case, welding can be carried out using different technologies. It all depends on the thickness of the metal. For workpieces made of 2 mm steel, gas welding is used. But, here the connection of steel with a thickness of 4 mm is carried out using electric welding.

A hole is made in the bottom of the body (bottom), to which a branch pipe of the required diameter is welded. A pipe for supplying a coolant will be connected to it in the future. The branch pipe is also connected to the common communication circuit.

Welding is carried out in different ways

Thermal insulation

As already noted, the tank is installed on top of the system. It is often installed in the attic. The peculiarity of such a room is that it is not heated. Therefore, the temperature in it is low, and sometimes completely negative. This increases the risk of water freezing in the tank. As a result, the system will not work and may be damaged.

To eliminate the occurrence of such a problem, experts recommend carrying out thermal insulation work in advance. It is recommended to use special materials such as basalt wool to insulate the system. It resists well the high temperature that is created when the container is heated.

Adding oil

In the tank body, in addition to the main one, other holes are made with nozzles that perform certain functions. So, it is necessary to equip an additional element through which the coolant will be added to the tank. Another hole serves as an emergency drain for excess water or oil. The other end of the pipe is connected to a sewer or a separate tank.

Since the tank is not airtight, water will evaporate during the heating of the house.In addition, air can enter the system through the cover. This is fraught with overheating of the pipes and disruption of the normal circulation of the coolant. To prevent this, experts recommend adding a little oil to the tank. It will cover the surface of the water with a thin film that protects the system from air.

Volume calculation

When calculating the volume of the unit, there are many factors to consider. The size of the tank is 5% of the amount of heating medium in the system. At the same time, 2% for evaporation and 1% for the reserve are summed up, which will prevent overflow of water over the edges. If a different heating medium is used in the system, then the value will be slightly different. It all depends on the coefficient of thermal expansion.

To determine the volume of the system, you need to add up the volume of the pipes, the battery and the boiler itself. A more simplified scheme can also be used. According to it, a boiler with a power of 1 kW is installed in systems with a volume of 15 liters.

Summary

The expansion tank is the most important device in the heating system, which ensures operability during the entire heating period. The simplest tanks can be made home craftsmen on their own. In case of difficulty, it would be better to contact to specialists.

At the weekend, I redid the heating, took out the expansion tank to the attic. The old one was made of a plastic canister into which a special brass adapter was screwed so that the pipe could be connected, I do not know what it is called correctly, to screw the brass adapter into the canister I had to cut such a hole (see photo below), at first the heating was imperfect and a few since my system boiled, so the canister from under the primer led a little, this is clearly noticeable, but nevertheless, for two winters, the canister faithfully served as an expansion tank.

This canister hung in an unfinished room and embarrassed me, I had long wanted to take it to the attic, and suddenly I came up with a way to make a hole in the canister and attach a brass fitting without cutting a huge hole for the hand to insert it from the inside. We take a canister from under the primer, I took it for 10 liters, my heating will be enough with a margin:

We make a hole in the right place, I made it just above the bottom, so that if suddenly some kind of debris gets into the heating system and just settles to the bottom. The hole is easily made with a clerical knife, I periodically check whether the fitting fits, cut off the excess.

Now in the canister there are two holes, one regular and the second made by me, we push into both a piece of wire, and the fitting slides along it directly to the hole made

I push the fitting into the hole, put on a rubber gasket

I put on the nut and tighten, the expansion tank is ready

My tank with heating is connected with a piece of rubber hoses with clamps, but you can solder an American woman to a plastic pipe and connect it more thoroughly, but as my two-year experience has shown, it is already quite reliable.

Do-it-yourself expansion tank from a canister

A reliable and durable structure is obtained from metal, but not everyone knows how to work with this material, so we suggest that you read the step-by-step instructions and find out how to make a tank from a canister:

- Immediately we draw the attention of the reader that the plastic canister will not last long, maximum - 2 winters. Therefore, this option, although fast, is not durable. In any case, the moment will come when you have to replace the old tank with a new one.

- The canister will need a volume of 10 liters, there is no need to cut a huge hole, and in the lower part, closer to the bottom to the right, we cut out a neat hole. This can be easily done with an ordinary construction knife. Check if the fitting fits well into the finished hole, if not, then you need to cut off the excess plastic a little more.

- There are 2 holes in the canister - the first is factory-made, the second we made at the bottom. In both holes you need to insert a wire and a fitting so that it slides along the wire directly into the lower hole.

- The fitting must be inserted and the rubberized gasket must be installed, then the nut and the thread must be tightened well.

- You can connect such an expansion tank to the heating system using a piece of rubber hose (put clamps) or take a piece of plastic pipe and make the structure solid.

Expansion tank with your own hands. Photo: