Correct selection

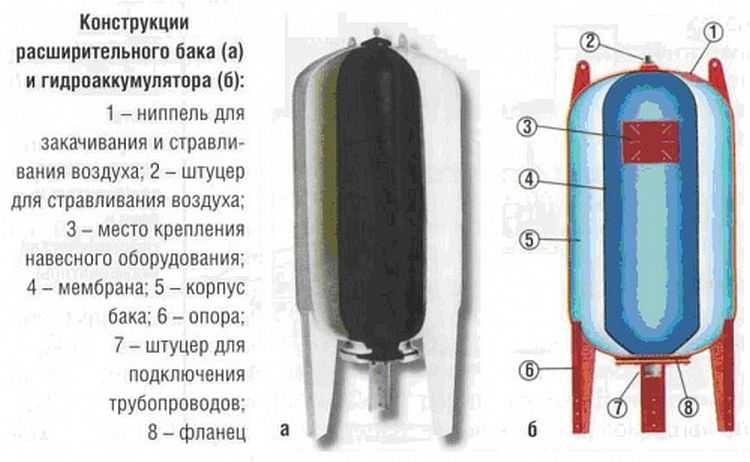

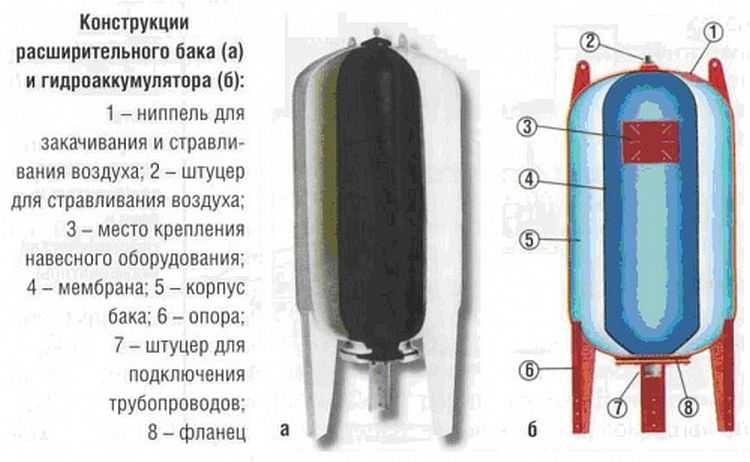

An interesting nuance: the name of this equipment does not depend on its design, but on the field of application. When it comes to water supply, the tank is called a hydraulic accumulator. And a tank built into a heating system with the same design characteristics will be called a membrane or expansion tank.

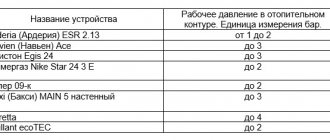

However, it is important to take into account the information provided by the manufacturer. Each product has its own operating temperature and pressure:

- up to 4 atmospheres and up to 120 degrees Celsius - for heating;

- up to 12 atmospheres and up to 80 degrees - for water supply.

In terms of volume, not the cheapest tank is selected, but the one corresponding to the parameters of the system.

A number of devices are used to normalize the pressure in the heating system. But the most important of them is either a hydraulic accumulator. Its design makes it possible to automatically stabilize the pressure of the coolant when the temperature changes.

Appointment

The accumulator is installed only for closed-type heating systems. They are characterized by high water pressure, which occurs as a result of its heating. Therefore, if the permissible indicator is exceeded, a compensation system is required. For this, the accumulator is intended.

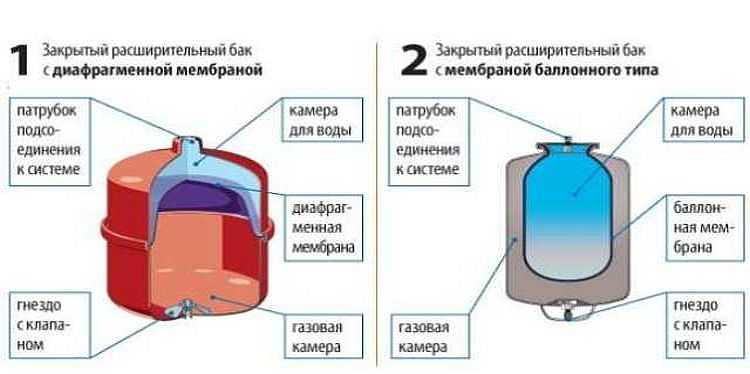

It is a steel structure that is internally divided into two chambers. One of them is designed to be filled with water from the heating system, and the second serves as an air expansion joint. To set the optimal pressure in the air chamber, a valve is provided in the accumulator. With its help, the degree of air injection is changed, thereby adapting the device to the parameters of a specific heating system.

The chambers are separated by an elastic membrane or a rubber balloon. When the temperature of the water in the pipes rises above the critical one, a pressure jump occurs. The liquid expands and begins to press against the walls of the separating membrane. It, in turn, under the action of this force, increases the filling volume of the water chamber. This leads to the normalization of pressure within the entire system.

Connection rules, diagram

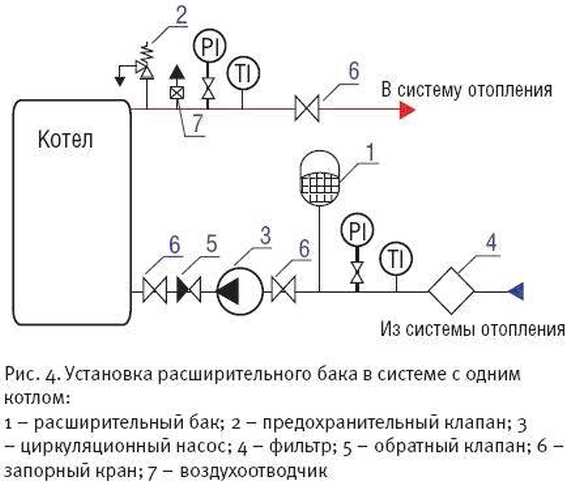

When installing the accumulator, certain rules should be followed. First of all, it is necessary to select a section in the heating main where it will be installed. Experts recommend installing the expansion tank in a chilled water return pipe. But at the same time, it must be installed before the pumping equipment. The general installation scheme is as follows.

As you can see, a safety valve is installed to protect the line from the differential pressure of the liquid at the outlet of the heating equipment. It performs the same functions as a hydraulic accumulator, but is designed for higher pressure surges. An expansion tank is necessary to normalize the operation of heating at small pressure drops.

Before starting installation, consider the following features:

- Choice of installation site. The main requirement for it is free access to the device. This applies in particular to the air chamber control valve.

- There should be no other shut-off or control valves in the area between the expansion vessel and the expansion tank. It can make significant changes in hydraulic resistance.

- The temperature in the room where the accumulator is installed should not be lower than 0 ° C.

- Its surface should not be exposed to mechanical stress or external influences.

- The actuation of the pressure reducer to release air from the chambers must be set according to the parameters of the heating system.

Guided by these rules, you can independently install an expansion tank. But at the same time, you should follow the connection rules, use products made of high-quality material and calculate the optimal volume of the tank.

For the calculation, you need to know the total volume of the heating system, the optimal and maximum pressure in it, as well as the expansion coefficient of the water. Formula for calculating the size of a membrane-type accumulator:

- e - coefficient of expansion of water - 0.04318;

- C is the total volume of the heating system;

- Pi is the initial pressure;

- Pf is the maximum pressure.

Let's consider an example of calculation for heating with a total volume of 500 liters, an optimal pressure of 1.5 bar, and a maximum of 3 bar.

This technique will allow you to correctly select and connect an expansion tank for a closed-type heating system.

How to choose a hydraulic accumulator for heating

Accumulators differ in type, they can be closed and open. Open is rarely used due to the demand for maintenance and some other shortcomings during operation. Closed type accumulators are installed in similar systems. Such a tank is an oval, round iron cylinder with a chamber (rubber) inside.

Expansion tank

With a small amount of water in the heating system, a tank with a membrane vessel inside is taken. The larger the tank volume, the higher the cost. The price also depends directly on the brand and design features. For small houses, a relatively small accumulator is needed.

Before buying an expansion tank, it is worth calculating the required volume for it. When installing, after the pump for water supply, it is impossible to install a hydraulic accumulator, otherwise sharp pressure drops may occur.

How to choose the volume of a water supply accumulator

The more often there is a change in the phases of operation and downtime of circulation pumps in the water supply system, the higher the energy consumption and wear of units and parts in the equipment of the hydraulic system. Therefore, it is advisable to choose a hydraulic accumulator in order to reduce the number of starts of the pump motor. The main criterion in this choice is to determine the optimal volume of the hydraulic tank. In this case, you can use both general (approximate) recommendations, as well as very specific and accurate calculation methods.

To save energy and extend its service life, the pump should be started no more than 30 times per hour. For an approximate calculation of the volume, you will have to take into account several more parameters:

- Pump capacity (QH). An average household pump has a capacity of about 2-3 m3 / h (2000-3000 l / h);

- The useful volume of the accumulator (VEF). This is the amount of liquid (water) that can be removed from the hydraulic tank within min. and max. relay actuation pressures. In life, it makes up about 40% of the total capacity.

To ensure this condition, you need to choose a GA with a total volume of at least:

V_min = Q_H / (30 ∙ V_EF) = (2000… 3000) / (30 ∙ 0.4) = 170… 250 l

If the volume of water in the accumulator is used as a reserve, for example, in the absence of electricity, a tank with a capacity of 24 liters or more is sufficient for a family of 1-2 people. For three consumers, tanks from 50 liters are recommended, and for four or more - from 100 liters.

It would seem that the larger the volume of the tank, the better. But do not forget that the supply of water is just an additional bonus and the desire to increase it may have disadvantages:

- Such a hydraulic tank takes up a lot of space, which means that you will have to have a large room for its placement.

- With a large volume and low consumption, the water in the tank may stagnate.

- It is not a fact that the minimum number of starts of the electric motor will extend the life of the pump.

Principle of operation

H2_2

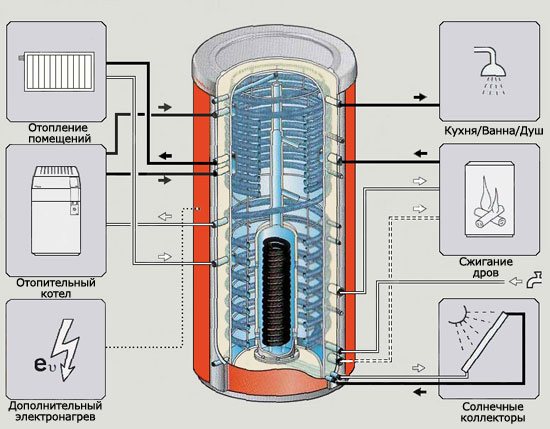

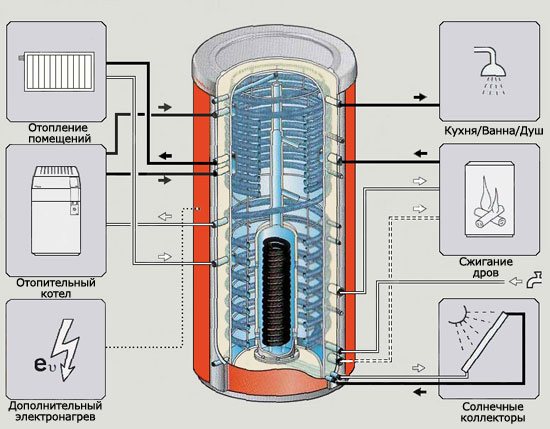

The storage tank begins to accumulate excess heat in the upper part of the tank after the room is fully heated. As it cools, the accumulator gradually releases heat into the heating system.

The capacity of the accumulator depends on how many times a solid fuel boiler will be loaded during the day.

The operation of the storage tank is based on the use of high heat capacity of water, which, when cooled by 1 ° C, releases several times more heat to heat 1 m2 of the room.

To calculate the volume of the storage tank, the ratio is used - 25 - 30 liters of capacity per 1 kW of power of a solid fuel boiler.

For example, for a 20 kW boiler, the volume of the tank will be from 500 to 600 liters.

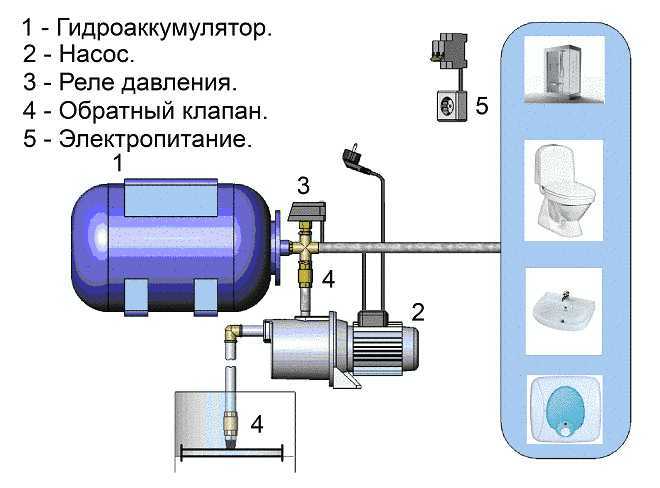

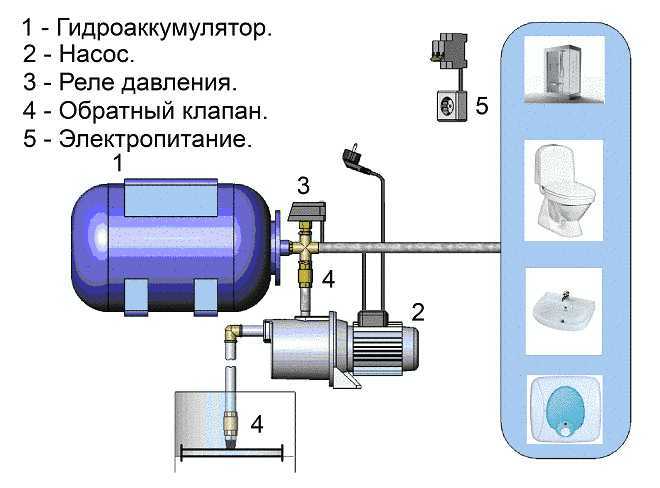

Connecting a hydraulic tank a minimum of complications

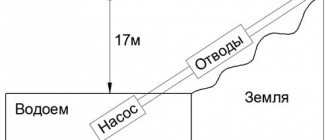

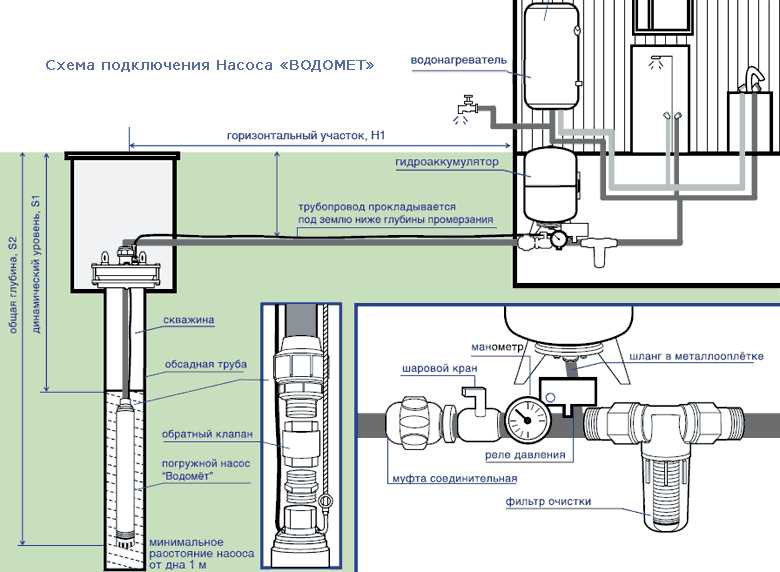

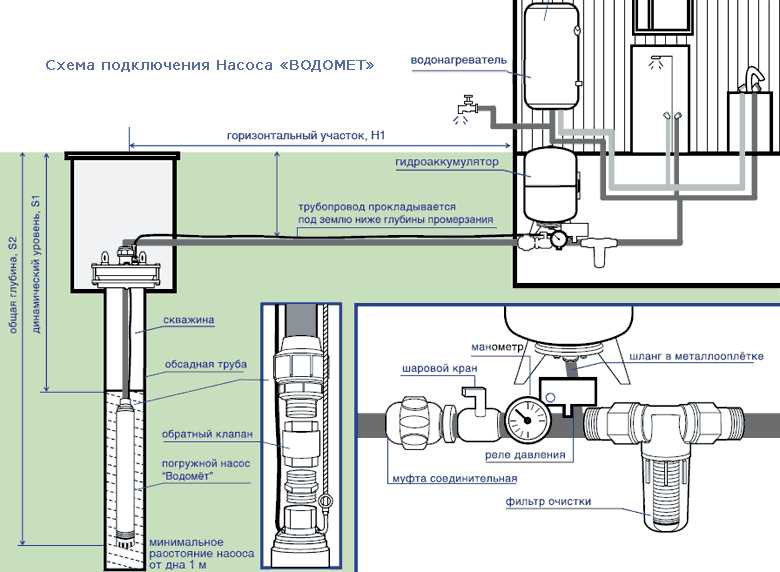

Self-installation of the accumulator in the water supply system does not cause any serious problems. If the device is connected to networks with surface-type pumping equipment, the procedure will be as follows:

- Measure the pressure inside the accumulator. Its value should be 0.2–1 bar less than the pressure of the pump start switch.

- Prepare a fitting for connecting a relay, hydraulic tank, pressure gauge and pump in one circuit. Nuance. Take the fitting with five outlets. An "extra" input is required to connect the water pipe.

- Buy a relay for pressure correction, as well as a fluoroplastic material-seal (FUM-tape) or tow with.

- Connect the fitting to the tank by means of a flange (it must have a through-valve) or a rigid hose.

- Fasten in turn all parts of the system. The last connection is made to the pipe that leads to the pumping device.

The installed tank should be checked for leaks. If there are any, it is necessary to additionally seal the joints of the individual elements of the device with FUM tape or a suitable sealant.

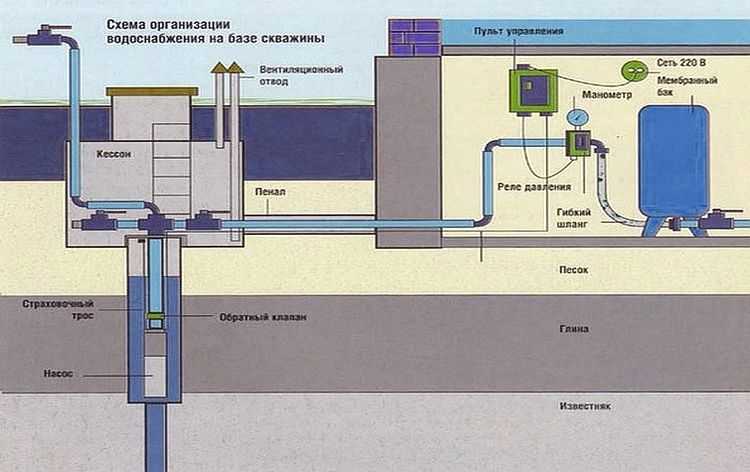

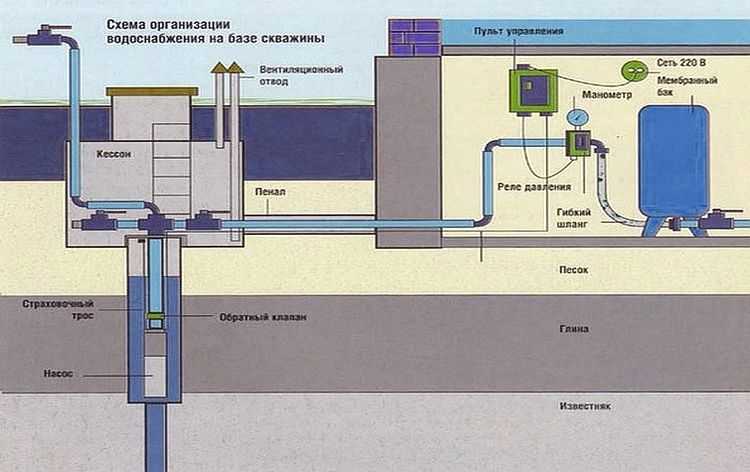

When using a hydraulic tank in systems with a submersible pump, it must be taken into account that the latter is installed directly at the place from where water enters the residential building (in a well, well). Such a scheme is potentially insecure. There is a high likelihood of water "rolling back" back to the source. How can I avoid this? Quite simply - by installing a special check valve. It is placed directly on the pump in front of the water pipe. The procedure for connecting the hydraulic tank will be similar to the one described above. But with one change. First you need to install a check valve. And only after that, connect all the elements of the hydraulic accumulator to the water supply network.

Choose and install a hydraulic tank in your home so that you never know problems with an autonomous water supply system!

Hydraulic accumulator - expansion membrane tank suitable for operation with potable water in water supply systems.

What then can fail there, is there any point in overpaying for the brand and are all accumulators really the same?

In this article, we will look at how some accumulators can differ from others, and most importantly, we will figure it out what factors affect their cost

.

How the hydraulic accumulator works simple and reliable design

The well-functioning plumbing system of a private dwelling is a merit of its owner. People who have come across the installation and operation of autonomous water supply networks imagine how difficult it is to avoid disruptions in the supply of water in such complexes.Sometimes just one pressure surge is enough for expensive equipment connected to the water supply (for example, a water heater, dishwashing machine) to fail. There is only one solution to this problem - the installation of a hydraulic accumulator. It maintains a given pressure in the system, creates a certain amount of water and eliminates the risk of damage to household electrical equipment.

The need to install such a device is obvious.

The hydroaccumulator device is quite simple. It is made in the form of a metal reservoir, inside which a rubber (rubber) membrane is installed. The latter is visually similar to a pear. The diaphragm is fixed to the body of the hydraulic tank by means of a special flange with a pipe. Water accumulates in the pear under pressure. The space between the battery housing and the membrane is filled with compressed air (if we are talking about household devices) or an inert gas composition (industrial hydraulic tanks). At the same time, the pressure in the system is maintained at a level of 1.5–3 bar. Air can be pumped into the hydraulic accumulator at home using a conventional car or even bicycle pump.

The considered devices are usually divided into three types:

- 1. For cold water supply systems. The device supplies water and accumulates it, protects the pumping equipment from early wear caused by frequent switching on and off of the system, protects electrical equipment in the house from water hammer.

- 2. For hot water. Such a hydraulic accumulator for water supply systems can operate without problems in high-temperature environments.

- 3. Expansion tanks. They are designed for closed hot water heating systems.

The device and the principle of operation of all these devices are identical. We will describe how such equipment functions below.

Expansion tank installation

Let's consider how to install an expansion tank in a cold water supply system.

Step 1. Water filters are connected to the water pump coming from the well.

Filter connection

Step 2. A tee, adapters, a ball valve, a "five-outlet" are installed for the future connection of a pressure gauge, a hydraulic accumulator and a dry-running relay.

Next, you need to install a tee, adapters, a ball valve, a "five-outlet" for the future connection of a pressure gauge, a hydraulic accumulator and a dry-running relay

Step 3. The expansion tank is fixed on the wall using a special mount and connected to the system using a flexible lead to the "five-outlet".

System connection

Step 4. The pressure gauge is installed on the "five-outlet".

Installing a pressure gauge

Step 5. The dry-running relay is connected.

Dry-running relay connection

Video - Connecting the Dzhileks hydroaccumulator

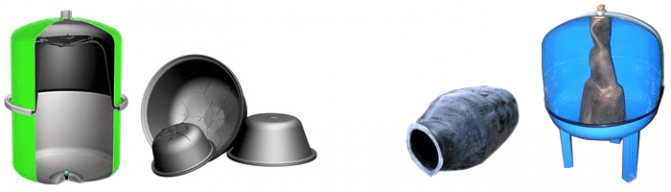

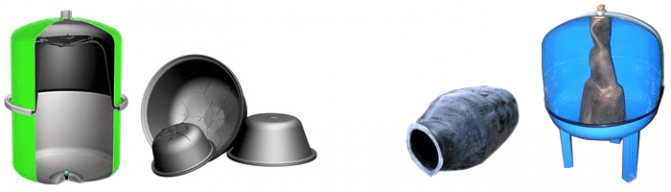

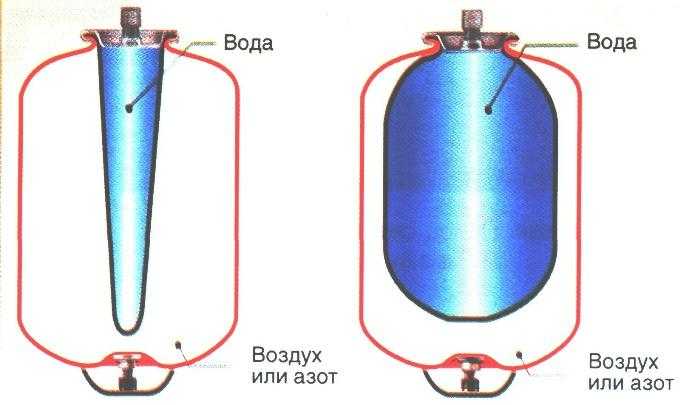

Balloon or membrane

Hydraulic accumulators are divided into two main types - membrane and balloon. The principle of operation of both types is similar - the elastic rubber film expands or contracts under the influence of pressure from the water and compressed air. The main difference is that in the membrane tank, the water coming from the well comes into contact with the metal walls of the tank, which can potentially lead to corrosion. In a tank with a rubber cylinder, water is in contact only with the cylinder itself, without touching the metal walls. The absence of conditions for the development of corrosion prolongs the life of the bladder accumulator.

An additional convenience lies in the fact that the balloon, unlike the membrane, is a replaceable part. The replacement will not cause any difficulties - even a non-specialist can do it. As a result, maintenance of a hydraulic accumulator with a cylinder will be cheaper. Taking into account the above factors of practicality and reliability, bladder accumulators are the best solution for individual water supply.

An important factor when choosing a hydraulic accumulator is the cost of spare parts

Please note that some manufacturers may unreasonably exaggerate the price of components. For example, a rubber cylinder can cost half or even more of the cost of the entire accumulator.

Heat storage installation

Improving the work of heating with additional devices with their own hands will make it necessary to carry out the following work:

Make a detailed diagram

When developing a drawing, it is necessary to take into account where the heating accumulator is located, the insulating layer, the height of the accumulator tank, the presence of drainage for water disposal - factors to reduce heat loss; Build a manifold-distributor into the system, making sure that the various systems are connected correctly; Having connected the parts of the pipeline, check the tightness of the connections; Connect the storage tank; Connect the circulation pump; After completing the assembly work with your own hands, conduct a test control of the tightness and correctness of the connections .. In order to prevent the pump from turning on every time a tap is opened in the house, a hydraulic accumulator is installed in the system

It contains a certain volume of water, sufficient for a small consumption. This allows you to practically get rid of short-term pump starts. The installation of a hydraulic accumulator is not difficult, but a certain number of devices will be required - at least - a pressure switch, and it is also desirable to have a pressure gauge and an air vent

In order to prevent the pump from turning on every time a tap is opened in the house, a hydraulic accumulator is installed in the system. It contains a certain volume of water, sufficient for a small consumption. This allows you to practically get rid of short-term pump starts. The installation of a hydraulic accumulator is not difficult, but a certain number of devices will be required - at least - a pressure switch, and it is also desirable to have a pressure gauge and an air vent.

Homemade heat accumulator

With minimal knowledge of physics and mechanics, you can assemble a hydroaccumulator with your own hands:

- External ready-made container of the required volume;

- Internal pipeline, less in height of the main tank by 5 - 7 cm;

- An internal container with holes for nozzles is welded.

Important! The accumulating capacity is mounted by hand already indoors; for a large area of the house, a large-volume battery is required. It is impossible to enter it into standard doors.

Optimum pressure in the accumulator

The air pressure in the hydraulic tank in the absence of water is one of the main operating parameters. This parameter is different for each accumulator and is indicated in its technical passport. Small fluctuations from the nominal value are allowed, but significant excess or decrease in pressure should be avoided, as the service life of the rubber cylinder (diaphragm) is reduced. For the water supply system to work, the pump activation pressure must be at least 0.5 bar higher than the operating air pressure in the accumulator.

The nominal pressure can be influenced by the number of storeys in the building. For example, if the accumulator will be located in the basement of a two-story building, then the minimum pressure in the water supply system should be 2 bar. 1 bar of pressure is needed to raise water to a height of 10 m, another 1 bar - to create the required water pressure in the tap at the consumer. In our case, 10 m is the average height difference between the basement and the second floor. Taking into account the pressure of 0.5 bar generated by the borehole pump, the working pressure in the accumulator should be equal to 1.5 bar.

The values of the pressure on and off the borehole pump can be set programmatically in the automatic control unit. A pressure switch serves as a sensor. Correctly set pressure values will reduce the frequency of pump activation and maintain the required pressure in the water supply system.Effective operation of the accumulator occurs when the difference between the pressure on and off the pump is from 1.5 to 4.5 bar.

What is a hydraulic accumulator for?

There are several types of accumulators that are used to operate heating or water supply systems. So for heating, an expansion tank is taken, which easily tolerates the high temperature of the water. This is what distinguishes it from a hydraulic accumulator for water supply. When water boils, he takes it into the tank.

Useful article: Why do you need a hydraulic accumulator for water supply systems

A hydraulic accumulator for heating in case of a breakthrough in the system or a drop in temperature near the water replenishes its missing volume in pipes and radiators. It also allows you to drive the accumulated air in the pipes.

The heating system is a ring with water circulating in it. When heated in the system, the water increases in volume, and the capacity of the circuit does not change. The hydraulic accumulator for the heating system takes excess water into itself. This allows the pressure to be equalized and the water does not boil. If this happens, the connections between the pipes and the body of the heat exchanger and other elements of the body may leak.

Functions, purpose, types

Installation site - in a pit or in a house

In the water supply system of a private house without a hydraulic accumulator, the pump turns on whenever there is a water flow somewhere. These frequent inclusions lead to wear and tear on the equipment. And not only the pump, but the entire system as a whole. After all, every time there is an abrupt increase in pressure, and this is a water hammer. To reduce the amount of pump activation and smooth out water hammer, a hydraulic accumulator is used. The same device is called an expansion or membrane tank, a hydraulic tank.

Appointment

One of the functions of hydraulic accumulators is to smooth out water hammer, we have found out. But there are others:

It is not surprising that in most private water supply systems this device is present - there are many advantages from its use.

Views

The accumulator is a sheet metal tank divided into two parts by an elastic membrane. The membrane is of two types - a diaphragm and a balloon (pear). The diaphragm is fastened across the tank, the balloon in the form of a pear is fixed at the inlet around the inlet pipe.

By purpose, they are of three types:

- for cold water;

- for hot water;

- for heating systems.

Heating tanks are painted red, water tanks are blue. Expansion tanks for heating are usually smaller and cheaper. This is due to the material of the membrane - for water supply, it must be neutral, because the water in the pipeline is potable.

According to the type of location, accumulators are horizontal and vertical. The vertical ones are equipped with legs, some models have plates for hanging on the wall. It is the upward-stretched models that are more often used when independently creating water supply systems for a private house - they take up less space. The connection of this type of accumulator is standard - through a 1-inch outlet.

Horizontal models are usually equipped with pumping stations with surface-type pumps. Then the pump is placed on top of the container. It turns out compactly.

Principle of operation

Radial diaphragms (in the form of a plate) are mainly used in gyro-accumulators for heating systems. For water supply, a rubber bulb is mainly installed inside. How does such a system work? While there is only air inside, the pressure inside the standard is that which is set at the factory (1.5 atm) or which you set yourself. The pump turns on, starts pumping water into the tank, the pear begins to increase in size. The water gradually fills an increasing volume, more and more compressing the air that is between the tank wall and the membrane.When a certain pressure is reached (usually for one-story houses it is 2.8 - 3 atm), the pump is turned off, the pressure in the system stabilizes. When you open a tap or another flow of water, it comes from the accumulator. It flows until the pressure in the tank drops below a certain mark (usually about 1.6-1.8 atm). Then the pump turns on, the cycle repeats again.

If the flow rate is large and constant - you type a bathroom, for example, - the pump pumps water in transit, without pumping it into the tank. The tank starts to fill up after all the taps are closed.

The water pressure switch is responsible for turning the pump on and off at a certain pressure. In most hydraulic accumulator piping schemes, this device is present - such a system works in optimal mode. We will consider the connection of the accumulator a little lower, but for now let's talk about the tank itself and its parameters.

Large tanks

The internal structure of accumulators with a volume of 100 liters and above is slightly different. The pear differs - it is attached to the body both above and below. With such a structure, it becomes possible to fight the air that is present in the water. For this, there is an outlet in the upper part, into which a valve for automatic air release can be connected.

What is a hydraulic accumulator

A hydraulic tank (or hydraulic accumulator) is a water tank with a rubber elastic membrane (resembling a pear) inside the tank and having a sealed connection to the metal tank body. This connection is made using a threaded flange for connecting the device to the water supply. The cavity between the membrane and the metal body of the hydraulic tank is filled with compressed air, usually the pressure is 1.5-2 bar. Hydraulic accumulators are used to maintain constant pressure and create a water reserve in domestic or industrial conditions. It is this unit that, when the pump is off, provides the required pressure in the system.

Fig. 1.

Hydroaccumulator device 1 - metal case; 2 - rubber membrane; 3 - flange with valve (allows air to pass through); 4 - nipple for pumping air into free space; 5 - cavity for compressed air; 6 - supports; 7 - platform for the pump. More information about the device of the hydraulic tank in the video: Back to the content

Role in the heating system

The main tasks of the accumulator:

- accumulation of "surplus" of the coolant in itself during its expansion;

- air removal;

- replenishment of the volume in case of possible leaks or a drop in the water level (antifreeze).

There are two types of tanks - open and closed. The second option is used in most modern heating systems. This is a completely sealed hydraulic accumulator with a membrane or a pear (it is used in large containers).

Hydraulic accumulators are installed only for heating with a circulation pump, since this system is characterized by a high working pressure.

Features of the

The hydraulic tank is called a hydraulic accumulator or diaphragm tank. It is used to maintain a stable pressure level in the water supply system. Also, the product protects the pump from wear, the drainage system itself from water hammer. Due to the hydraulic tank, you can use water even in the absence of voltage.

The advantages of vertical hydraulic tanks:

- Protection of the pump against early wear.

- Maintaining a stable pressure in the water supply system.

- Protection against water hammer that may form during the launch of the alluvial equipment. Water hammer can damage the pipeline.

- Maintaining water supplies in the system.

Vertical accumulators have disadvantages, which are complex installation. It will take some effort and some skill to install.

Hydraulic accumulator for heating systems: device, installation and principle of operation

The quality of the heating system of a private house largely depends on the stability of the water supply. Even during normal operation of communication networks, pressure drops can be observed. Usually, such failures occur without consequences and imperceptibly for the user, but the risk of damage to equipment and pipelines is always there, and at high loads it may well turn into an accident. A hydraulic accumulator for heating systems, which acts as a buffer pressure regulator, will help insure against troubles of this kind.

The principle of functioning of the hydraulic tank how everything happens

When the pumping equipment is turned on, water begins to flow into the membrane. The volume of the pear increases. This leads to the fact that the air in the accumulator body (outside the membrane) is compressed and forms some pressure. When the set value of the last is reached, the electric pump is switched off by the command of the control relay. Compressed air presses on the water in the pear and pushes it through the water supply. The consumer opens the tap. Water begins to flow through it, coming from the hydraulic tank at a given pressure.

After a while, there is less water in the membrane. Because of this, the pressure value also decreases. When it becomes minimum, the relay is activated again, the pump starts automatically. Then everything goes according to the scheme already described above. The pumping equipment starts up the more often, the smaller the volume of the hydraulic tank is used. The optimum capacity of the hydraulic accumulator for domestic use is 100 liters. In this case, the relay operates in 60 minutes no more than 5-15 times. With such indicators, the wear of the hydraulic equipment will be minimal.

It is important to understand that more frequent pump starts lead to premature wear of the diaphragm and other battery elements.

Water entering household hydraulic tanks most often rises from wells or specially equipped wells. Such a liquid is characterized by increased oxygen saturation. It can accumulate in the pear, standing out during the functioning of the domestic plumbing. Oxygen must be removed from the system periodically. For these purposes, in many models of accumulators, a special valve is mounted on the body (in its upper part). If necessary, it independently releases excess oxygen.

Active operation of the hydraulic tank often causes a decrease in the value of air pressure. No equipment is insured against such natural wear and tear. Experts recommend to completely empty the accumulator every 10-12 months and check the pressure indicator. This simple procedure will guarantee the comfortable use of the plumbing in a private home.

Accumulator volume

Do not buy a hydraulic accumulator, focusing on what your friends or neighbors in the country have installed. Perhaps this model will be ineffective for you. The volume of the accumulator (like all other equipment!) Should be selected only on the basis of the results of the hydraulic calculation. The number of models on the market is quite large.

Is there an optimal hydraulic tank volume? As we have already said, only a hydraulic calculation can accurately indicate a specific model of hydraulic equipment that is optimal for your conditions. But the number of typical volumes for various models of hydraulic tanks is not so large. That is, if, according to the results of the calculation, you need a tank with a volume of 51.5 liters, then you will not be able to find such a tank on sale. You will be advised to purchase a 60 liter hydraulic tank. Extra liters of volume will not harm, and even allow you to slightly increase the water supply and reduce the number of pump starts.

The experience of engineers who select and install water lifting equipment tells us the following:

- in the water supply system for three consumers with a borehole pump capacity of 2 m3 / h, a hydraulic accumulator with a volume of 25 liters can be installed.

- in a system with 4-8 consumers and a pump capacity of 3.0-3.5 m3 / h, a 60-liter hydraulic tank is optimal.

- if the number of consumers is more than 10 and the pump capacity is 5 m3 / h, then the optimal volume of the tank will be 100 liters.

Is there a difference between vertical and horizontal accumulators

The tanks described in the article are mounted according to two schemes: vertically and horizontally. The specific type of accumulator should be selected based on how compact it will fit into the area that will be allocated for its installation. In addition, in vertical and horizontal devices, the air from the membrane is removed in different ways.

It is important. In vertical devices, the accumulated oxygen is released by means of a safety valve (we have already mentioned it)

But in horizontal, it is necessary to additionally install a special pipeline to remove air. Structurally, the additional line consists of a ball valve, a drain and a nipple (it is called an outlet).

Pay attention to the following nuances:

- Vertical accumulators with a volume of less than 100 liters are never equipped with a safety valve. Bleeding air in such devices is carried out by completely emptying them.

- It is more reasonable to connect horizontal hydraulic tanks to external pumps, vertical ones to submersible ones, installed inside a specially designated room for them.

Any hydraulic tank must be able to bleed air. If you do not free the equipment from the accumulated oxygen in it, air locks will very quickly appear in the water supply system. They will prevent you from effectively operating your domestic water system.

Equipment device

At the heart of any accumulator, a tank is provided for the temporary water content, which determines the second name of this equipment - an expansion tank. The reservoir is divided into two parts, one for liquid and the other for air. These chambers are separated by an elastic membrane that can change position depending on the current pressure in the system and water filling. Also, the device of a hydraulic accumulator for heating systems is not complete without an air (pneumatic) valve, which takes air masses from the tank. Tanks of small capacity are complemented by separate regulators in the form of ball valves and tees, which also allow air to be removed from the pipeline. In sets with accumulators, manufacturers supply the necessary fittings for connection, installation and piping with other plumbing and heating equipment.

The parameters of the housing and the configuration of the location of the communication pipes will determine the conditions for installing the expansion tank. Vertical and horizontal designs have fundamental differences. In the first case, the tank has a modest size, which allows it to be located in a tight space. Although the optimization of the dimensions does not even apply to the cameras themselves, but to the external equipment with the body and branch communications. For example, the nipple is located at the bottom, which facilitates the process of extracting excess air. A vertical accumulator for heating systems is often used as an addition to circuits connected to submersible pumps.

In horizontal designs, a separate excess air discharge system is provided, which is provided by an outlet nipple with a drain pipe and a ball valve. With a lateral air outlet, an additional section of the pipeline has to be installed, which hides space, but the basis of the structure is not much larger than the vertical tanks in size.In addition, the possibility of installing a hydraulic accumulator under the pump in some cases turns out to be more profitable, if not the only possible one.

Connecting the accumulator to the system

Typically, the water supply system of a private house consists of:

In this scheme, a pressure gauge may still be present - for operational pressure control, but this device is not necessary. It can be connected periodically to carry out test measurements.

With or without 5-way union

If the pump is of the surface type, the accumulator is usually placed near it. In this case, a check valve is installed on the suction pipeline, and all other devices are installed in one bundle. They are usually connected using a five-way union.

It has leads with different diameters, just for the device used for piping the accumulator. Therefore, the system is most often assembled on its basis. But this element is not at all necessary and you can connect everything using ordinary fittings and pieces of pipes, but this is a more laborious task, besides there will be more connections.

How to connect a hydraulic accumulator to a well - a diagram without a five-way choke

With one inch outlet, the fitting is screwed onto the tank - the fitting is located at the bottom. A pressure switch and a pressure gauge are connected to the 1/4 '' outlets. The pipe from the pump and wiring to consumers are connected to the remaining free inch outputs. That's all the connection of the gyroaccumulator to the pump. If you are assembling a water supply circuit with a surface pump, you can use a flexible hose in a metal winding (with inch fittings) - it is easier to work with it.

A clear diagram of the pump and accumulator connection - use hoses or pipes where necessary

As usual, there are several options, you can choose. Connect the accumulator to the submersible pump in the same way. The whole difference is where the pump is installed and where to supply power, but this has nothing to do with installing a hydraulic accumulator. It is placed in the place where the pipes from the pump go. Connection - one to one (see diagram).

How to install two hydraulic tanks on one pump

When operating the system, sometimes the owners come to the conclusion that the available volume of the accumulator is not enough for them. In this case, you can install a second (third, fourth, etc.) hydraulic tank of any volume in parallel.

There is no need to reconfigure the system, the relay will monitor the pressure in the tank on which it is installed, and the viability of such a system is much higher. After all, if the first accumulator is damaged, the second will work. There is one more positive point - two tanks of 50 liters each cost less than one per 100. The point is in a more complex technology for the production of large-sized containers. So it is also more cost effective.

How to connect a second accumulator to the system? Screw a tee onto the input of the first one, connect the input from the pump (five-way fitting) to one free output, and the second container to the remaining free output. Everything. You can test the circuit.

To avoid depressurization of joints and heating equipment, a hydraulic accumulator or expansion tank is mounted in the system. This unit provides constant pressure - when expanding, water goes into it and does not harm the system.

How to connect?

The tank has two technical openings: a branch pipe for connection to the system and an opening on the opposite side, equipped with a valve for relieving excess pressure in the gas (air) chamber.

At the initial stage of installation, it is necessary to choose the right installation location. It is recommended to cut the accumulator into the water return pipe between the last battery and the heating boiler. Moreover, the closer the tank is to the boiler, the better it is for the stable operation of the system - there will be no sudden pressure drops.

A check valve and a pressure gauge must be installed in front of the tank to monitor the pressure indicators. The valve has the same task as a hydraulic accumulator. This unit compensates for pressure surges, but it is designed for heavy loads.

It is important that free access to the tank is provided - in some cases, the owners will have to independently adjust the air chamber valve.

It is forbidden to place shut-off valves on the section of the line between the accumulator and the circulation pump! The armature will violate the parameters of the hydraulic resistance.