Foam selection by area of use

If you need professional fire-resistant foam, then you should pay attention to RUSH FIRESTOP FLEX 65. It is suitable for structures that are subject to increased fire resistance requirements during operation.

You can use SOUDAFOAM FR to seal voids. This foam can be used for:

- protection of window blocks;

- between floors and ceilings;

- to fill the voids.

This composition is universal, because it can be used where fire resistance is required. With SOUDAFOAM FR CLICK & FIX foam, you can provide not only fire protection, but also form a layer that will differ in sound and heat insulation capabilities. NULLifire FF 197 has excellent adhesion properties, which is a one-component product that can be used in tandem with most building surfaces.

Types and types

The composition of the mounting fire-resistant foam used for fire insulation is the majority of manufacturing companies:

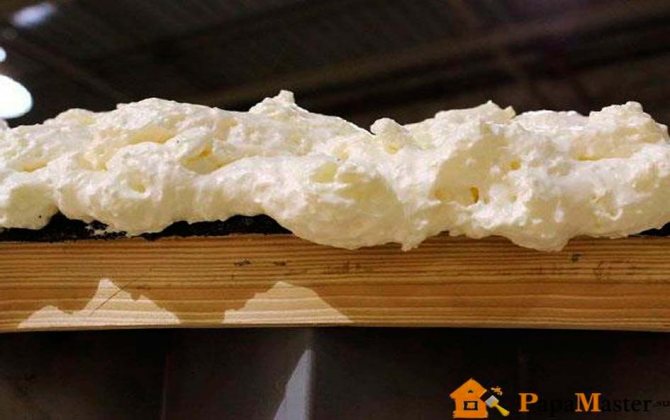

- Polyurethane sealant, immediately ready for use, multiplying in volume after leaving the cylinder (bottle), into which it was pumped at the factory.

- To impart fire resistance, special chemical and mineral substances - fire retardants - have been added to it, the list of names of which is not disclosed by manufacturers for reasons of commercial secrecy.

- The process of polymerization of fire-resistant foam occurs due to internal chemical reactions, as well as under the influence of water from the surrounding air.

Therefore, presenting the types, types of fire-resistant foam, we basically have to talk about various varieties of this commercial fire-fighting product presented on the Russian market, and those rather meager technical characteristics presented as advertising by manufacturers:

- One-component fire-resistant foam Profflex FireStop Despite the foreign name, these products are manufactured in Russia according to German developments. Its main parameters are: fire resistance - EI 240, high performance - up to 65 liters of foam, low secondary expansion and fast curing. The volume of the bottle is 850 ml, weight is 1020 g.

- Proffelex FireBlok 65 foam, which has similar characteristics, is packaged in 800 ml bottles, weighing 900 g.

- Fire-resistant polyurethane foam "OGNEZA" is also of Russian production. Fire resistance - EI The volume of the obtained foam - up to 45 liters. Balloon weight - 929 g. Operating temperature - from - 40 to + 80 ℃.

- Professional foam DBS 9802-NBS B Packed in 700 ml cylinders. Its fire resistance is low - EI 60.

- Fire-fighting foam BARTON'S Stop Fire of domestic production, in cylinders of 880 ml. Fire resistance - EI

- NULLifire FF 197 in 750 ml bottles from the Netherlands has an EI 60 resistance.

- TYTAN Professional B1 with fire resistance EI 240, foam volume up to 42 l from 750 ml bottle.

- FOME FLEX FIRE BLOK Pistol Foam is made in Switzerland. Depending on the layer of solidified mass that has filled the cavity, a seam in a building structure can have a fire resistance of up to EI.

Professional fire-resistant foam SOUDAFOAM FR GUN made in Belgium has a high fire resistance rate - up to EI 360 (under certain conditions), which makes it a kind of record holder in this type of fire-fighting products. By the way, almost all imported products have a unified volume of 750 ml cylinders for use with an assembly gun.

Fire resistance classes

Fireproof construction products must be used in all premises that will be used by humans. The polyurethane foam has several fire resistance classes.

- IN 1 - a composition that has the highest physical and fire-extinguishing characteristics: the substance does not support combustion at all, spontaneously extinguishes after the termination of contact with fire, for a long period of time retains its properties when exposed to flame.The products are recommended for use in buildings with a large crowd of people.

- IN 2 - a material that has average flammability. Foam can release toxins when it melts, but stops burning as soon as the fire is removed from it. It can be used for rooms with an average level of traffic.

- IN 3 - a composition that is rarely used for construction work due to its flammability.

Another indicator that is assigned to products is the fire resistance coefficient. This indicator is marked as follows - EI, where the letters are followed by numerical values inherent in one or another polyurethane foam. There are the following products.

- EI 30 - a composition that retains its properties for 30 minutes. It is allowed for use inside buildings, where the fastest possible evacuation in case of fire is possible. The number of people in the building can range from 15 to 300 people.

- EI 90... Based on the data obtained during the testing of such a material, it follows that when heated to 1000 C, foam shows stability and does not lose its qualities for about 90 minutes.

- EI 120, 150 - types of polyurethane products that have the highest level of protection during a fire. The area of use of such a sealant is quite extensive. The group of premises where the use of foam is recommended includes buildings with a high level of fire hazard. With the help of such compositions, cable penetrations are sealed, the products are used for arranging furnaces, chimneys, and repairing cracks.

Manufacturers

When buying fire retardant foam, it is best to choose well-known brands from major manufacturers. Among the most popular are:

- Macroflex. Among the wide range of building mixtures of this company is the fire-resistant foam Makroflex FR77. This sealant can withstand open fire and heat up to 1300 gr. The material does not shrink, does not emit smoke when heated. Compatible with cement, glass, plastic, metal, brick substrates.

Recommended for sealing cracks in stove and fireplace structures, sealing refractory panels in chimneys, fixing parts in boilers, ovens, stoves, braziers. Packaging - 300 ml cylinders for construction equipment.

- Soudal Fire Silicone B1 FR. Fire resistant silicone based foam. Has a fire resistance up to 4 hours. Suitable for sealing joints in wall panels, ceilings, window and door frames, indoors and outdoors. Possesses high adhesion to brick, stone, concrete, metal, ceramics. Has the highest class of fire resistance B1. Sold as 310 ml cartridges.

- OGNEZA-GT - fire-resistant foam based on acrylic can withstand heating up to 1200˚С for two hours. It is used for installation and sealing of electrical wiring, joints of firewalls, air ducts, windows and doors. On contact with fire, the mass expands, which prevents the spread of smoke. It is used for work on bases made of metal, plastic, brick, cement. Packaging - 310 ml bottle with dispenser.

- Penosil Premium Fire Rated Foam is a heat-resistant assembly foam for processing chimneys of stoves and fireplaces, sealing joints, voids of structures with an increased fire resistance class, insulation of electrical wiring, doors, windows. Withstands heating for three hours up to 1000˚С. Full curing occurs within 24 hours. The dense structure prevents the mass from flowing down vertical surfaces. Does not support combustion and self-extinguishes without a source of fire. Available in 750 ml cans with an applicator.

- Mastertex B1 PRO. Fire-resistant polyurethane all-season compound. Has resistance to burning up to 180 min. The structure of the material is finely porous, which contributes to an even distribution. Secondary expansion is not more than 70%, which allows you to control the application in hard-to-reach places. Packaging 750 ml. equipped with a dispenser.

Features of sealants for the steam room

Despite the huge offer of all kinds of sealing compounds, it is not so easy to choose a sealant for a wooden bath. Many of the products on the construction market are not suitable for a bath room, because do not meet the requirements for similar compositions.

General requirements for sealants for a bath

Criteria for choosing a sealant for a steam room:

- Ecological cleanliness and safety, the presence of natural ingredients in the composition. The product should be odorless and emit harmful substances. This is a particularly important condition for indoor sealing. At the extremely high temperatures that are present in the bath, volatile chemical compounds are released into the atmosphere and can cause serious poisoning.

- Water vapor permeability. It is necessary that the natural circulation of air is maintained in the bath, since in its absence the room will dry out poorly, which threatens the formation of mold.

- Moisture resistance. The sealant must repel moisture and protect the joints from water ingress.

- Must be heat-resistant and resistant to large temperature fluctuations.

- High elasticity. The sealant must have a stretch capability of at least 25% of its original length.

- UV resistant. This property is important for all types of sealants used outside the home.

What sealants can be used in the bath

The following products are best suited for sealing the steam room:

- Butyl rubber tape. It has good adhesion and ease of use. However, its price is quite high, and in addition, under the influence of high temperature, the material can deform.

- Thiokol sealants in the form of a paste or putty, consisting of several components and requiring dilution. To apply the composition correctly, you need to have certain skills, and mixing the ingredients is also difficult.

- Acrylic sealants. Most meet the requirements for sealants for steam rooms and saunas. They are made on the basis of an acrylic dispersion, safe for health. They are distinguished by high elasticity, do not interfere with the air exchange of wood, and withstand high temperatures well.

What materials are undesirable to use in the steam room

It is not recommended to use silicone and polyurethane compounds for sealing the bath. Such sealants have insufficient adhesion to the wood. In addition, many of them contain substances that cannot be used indoors, especially in those where there is a sharp temperature drop.

Types of fire-resistant polyurethane foam

- Main application - all foams are divided into two classes regarding resistance to negative temperatures. There is a fireproofing winter polyurethane foam - it can be applied even if it is -5 -10 ° C indoors or outdoors. For maximum adhesion of the conventional compound, the temperature should not be lower than + 5 ° C.

- Fire resistance - according to GOST, for most rooms with a high concentration of visitors, it is necessary to use class B1 fire-fighting polyurethane foam. Additionally, depending on the technical characteristics of the building, you should choose a sealant with the required fire resistance index, EI marking.

- The number of active ingredients. Fireproof sealant can be of two types.

- One-component formulations solidify under the influence of moisture. It is recommended to wet the surface to be filled before applying one-component foam for better adhesion.

- Two-component foam does not harden due to external factors, but due to the chemical composition containing the required reagent. It is the two-component composition that is designed to work in winter, at negative temperatures.

- EI 30 - the application is limited to rooms with a concentration of visitors from 15 to 300 people, subject to the possibility of quick evacuation.The foam retains its properties for 30 minutes.

- EI 60, EI 90 - the test of foam with a fire resistance coefficient of EI 90 shows that for 90 minutes, when heated to 1000 degrees, it can withstand the heat load while maintaining all the basic parameters. Depending on the technical characteristics of the premises, it can be used in buildings with a high concentration of visitors, shopping centers, etc. This figure is slightly lower for a sealant with an EI 60 - which is equal to 60 minutes.

- EI 120, EI 150 - maximum protection during fire. Scope of application - premises with high flammability, creation of fire belts and dividing partitions, sealing of cable passages, etc.

Views

In addition to the fire resistance class, assembly compounds differ in the permissible operating temperature. Depending on the optimum spray temperature, fire resistant foam can be:

- Summer. The permissible application temperature is from +35 to + 10˚С. Such a heat-resistant mixture is used for external work in warm weather or in heated rooms.

- All-season. The use of such material can be carried out in conditions of subzero temperatures, up to -15˚С.

The lower the temperature, the less volume the substance gains. The optimal range of application is from +10 to + 25˚С.

By the number of components:

- One-piece. Ready-to-use fire-resistant foams that set when exposed to atmospheric moisture.

- Two-piece. They consist of a polymer base and activators. The curing reaction occurs when two components are mixed, which are isolated from each other until application. Such high-temperature foam is used at subzero temperatures, its shelf life is much longer.

By scope of work:

- Household. It is used for self-isolation and small-scale local repairs.

- Professional fire resistant foam. It is used in industrial capital construction of residential, public, industrial structures and buildings.

What it is

Providing fire safety is the main task that is put before the builders during the construction of structures. Fire-resistant construction products everywhere displace materials that melt easily and release toxic substances during thermal exposure. Fire-fighting polyurethane foam has a specific feature that distinguishes it from conventional products - the composition is resistant to exposure to open fire.

Foam has a specific classification with respect to its flammability level, which depends on the manufacturer, brand and modification. Refractory foam is a relatively new material on the construction market. Products do not run down when applied to vertical substrates. In addition, the composition fills the cavities qualitatively.

Among the features of the material, it is worth highlighting a good level of adhesion to bricks, metal substrates, wood, various polymers, glass and cement. The product is essentially a one-component or two-component sealant based on polyurethane. The composition is implemented already completely ready for use. Immediately after application of the foam, the components of the product polymerize upon contact with moisture in the air.

Among the main components of the polyurethane foam there are substances that provide products with unique characteristics in terms of heat resistance, as well as impermeability to smoke and gas.

It is necessary to highlight the main technical characteristics of the composition.

- The products are resistant to moisture, as well as the development of mold and mildew on the substrate.

- The foam is resistant to temperature fluctuations in the range from +1000 C to -60 C. The available additives enable the material not to lose its strength and elasticity.

- Based on the type of product, the time interval varies during which the product retains its resistance to elevated temperatures and does not ignite.

- Self-extinguishing flammability is inherent in foam. Upon contact with a fire source, the substance does not drain from the base, and during the termination of contact with fire, the material itself extinguishes.

- The products have sound insulating qualities - the limit for most compositions is about 41 dB.

The disadvantages of fire-resistant polyurethane foam include its sensitivity to ultraviolet radiation. Therefore it is necessary to provide the product with an appropriate level of protection.

Foam composition

Fire retardant building components are in most cases a one-piece polyurethane foam mixture. It is already ready for application and is able to provide sound absorption, thermal and smoke insulation.

In order for fire-resistant foam to actively withstand thermal stress, its composition includes:

- Fire retardants. It is these substances that provide protection against the effects of fire on building mixtures.

- Activators. These substances provide foaming of the refractory mass, and its ability to increase in volume after leaving the tube. During application, the active gas expands, pushes the mixture out of the container, and the foam fills all the available space.

- Polymerizers. Provide curing of the foamed mass in a short time. Provides shape retention and adhesion to various surfaces. Polymer additives affect the consumption and viscosity of the substance.

- Stabilizers. Provides uniform dispersion of the flame retardant and the insulating properties of the foam after curing. They are at rest in the tube. For activation, shaking and contact with the atmosphere is required.

- Dyes. For visual marking, heat-resistant foam has a pink or red tint.

Professional sealing services for wooden houses

offers its services for the insulation of houses from a bar and logs located in Moscow, the Moscow region and adjacent regions.

We are official dealers of manufacturers producing premium sealants Remmers, Ramsauer, Oliva and others. Thanks to this, our customers can order sealing with branded products on favorable terms.

In our company, the main focus is on the quality of the services provided. We carry out a triple quality control of the work performed. Masters undergo regular training and professional development.

To contact us, go to the "Contacts" page, there you will find our coordinates and the application form.

Calculate the cost of painting and insulating your home right now

To date, the scope of application of classic fire-resistant foam has increased significantly, from now on it is used not only in the construction of window and door openings or when sealing cracks, but also as a "bridge" in places where a high temperature is expected, and this may even be a chimney. Often these are stoves or chimneys, where the temperature regime, as a rule, is constantly on the verge and as insulation, using modern means and components is much more efficient and safer. In principle, there are no common characteristics between the varieties, as such, but there are significant differences in the level of fire resistance, which we will get to know a little later. In addition, we will study the features of choosing a refractory foam for a chimney.

Selection features

When choosing components for construction, one should proceed from the practice of focusing not on cost, but on the specific characteristics of the product itself. In addition, pay attention to the type of chimney itself, for example, products suitable for brick shafts will not be successful for metal or combined channels.To choose a polyurethane foam, you need to distinguish between the following product features:

- Resistant to moisture and mold and other side effects.

- Ability to withstand significant temperature fluctuations, in the range from -60 to +150 degrees.

- If we take the sealant as a basis for comparison, then the refractory foam has significantly higher qualities of reliability and strength.

- Properties imply delayed combustion.

- Self-extinguishing. That is, the material was used in such a classification that, when hit by direct fire, it will not drain off with burning drops, but, on the contrary, will gradually fade out.

- But, do not forget that foams, and even of such characteristics as we are considering today, are quite demanding on the sun's rays, keep in mind when processing in open space.

Selection rules

First of all, you need to clearly understand for what purposes these products will be used, because for reliable fixing of a door or window block, the fire resistance indicator EI 60 will be sufficient, and for sealing the seams in the ceiling at the point where it intersects the chimney of a sauna stove, fireplace or heating unit on gas or liquid fuel, wood or coal requirements will increase immediately. Then it will be quite appropriate to purchase foam with fire resistance EI 240.

It is not difficult to choose the required type of foam, of which there is a lot in the domestic market. Replacing combustible types of polyurethane foam with it during the construction of a residential building, summer cottage, garage, workshop on their site, the owners eliminate materials that, when burned, emit toxic flue gases, increase the overall fire resistance of their property.

When choosing such a material for use, the main attention should be paid to the premises, their places and areas where there is either constant or periodic heating of building structures, finishing materials from local heat sources.

What is the best foam to choose, a choice in terms of cost?

Heat-resistant characteristics partly affect the cost, as a rule, if we take the average cost on the market, then one bottle will cost 400 rubles. subject to standard volume. Purchase orientation should be directed to the number of minutes of curing, as well as the characteristics of the level of fire resistance. But, remember that the price may well overcome the mark of 500 - 600 rubles. After all, this is partially influenced by the manufacturer and his brand. It is possible to use heat-resistant polyurethane foam and cheaper, as a rule, now there are few who are engaged in fakes, with this price range it is not cost-effective.

The choice of foam for fire resistance

When choosing a polyurethane foam, focus on the so-called coefficient, it indicates the level of fire resistance. On the tube itself, you can find not only the basic methods for application, but also the characteristics, but also the level of fire resistance. EI marking, so:

- A value of 30 means there is a restriction on indoor use where there are 16 to 299 people. This is subject to a possible evacuation. In this case, the properties are retained for 30 minutes.

- 60 and 90 means that when heated to 1000 degrees, the properties are preserved, and it is able to withstand the load. It is allowed to use in shopping centers and large stores.

- 120 and 150 are the maximum levels, they are best used to create "belts of fire" for chimneys and boilers. Chimney seams can also be done using this category.

Application

As already mentioned, mounting fire-resistant foam is used in rooms where there are constant or intermittent sources of fire or intense heating. Most often, the material is used for the installation of structures and communications:

- installation of window and door blocks;

- device of sockets and switches;

- fixing heating systems;

- for insulation of heat pipes and chimneys of stoves, fireplaces;

- when insulating internal structures (nodes of walls and roofs, ceilings);

- when carrying out roofing works with all types of roofs.

Fire-resistant polyurethane foam for chimneys has a corresponding note on the purpose, its fire resistance class is the largest. For facades, openings and other structures, you can use EI 60 and EI 90 foam sealant, for a private house you can take EI 30.

Foam selection by area of use

Heat-resistant foam should also be divided according to the scope of application, distinguishing several main factors that were listed in the subparagraph above. So, keep in mind when working in these areas and refer to the classification above.

- For filling joints in fire barriers.

- For reliable sealing of window and door blocks, including protection against fire and smoke.

- Sealing gaps in chimneys.

- As an adhesive base for insulation and insulation.

- For thermal insulation in chimneys, ventilation and air conditioning systems.

A few words about the application technique

The fire-resistant assembly compound is applied in the same way as a conventional polyurethane compound.

- For convenience and economical consumption, the foam cylinder is inserted into the assembly gun.

- Cut off the tip of the dispenser with a blade at an angle of 45˚. The higher the cut, the thicker the seam will be.

- The solution should be applied to a clean, dry surface.

- The gun is tilted at an angle of 90 ° to the plane of application.

- The slots and gaps are filled by no more than 2/3 of the volume.

- After complete curing, the excess foam is cut off with a blade.

- When working in cold weather, the foam itself must have a temperature of at least 15˚С.

Contaminated areas are cleaned with a dry, clean cloth, without waiting for drying. Do not use water to wash off.

We recommend watching the video instruction:

Chimney crack sealing - fire resistant foam

Not everyone got houses that were built according to their own projects, taking into account all the fire safety rules in the heating system. Many houses have been inherited or bought, already built, where they have to remodel and monitor the chimney system.

Why a chimney system, but if the chimney is offset and when installing several stoves, mainly the chimneys from them converge into one central pipe. At the same time, part of the horizontal pipes, from the outlet of the stove chimney to the central chimney, which is popularly nicknamed the "boar", undergoes the greatest temperature changes, humidity and subsidence of structures - therefore, it often cracks.

Cracks can be quite decent up to one and a half centimeters, which creates a danger of fire in the attic floor. In some regions, such chimneys are prohibited by firefighters, but in Belarus they are available, especially in village houses.

It is extremely difficult to close a crack if the chimney, due to temperature changes and due to its incorrect installation, constantly shifts during the heating season and summer, is extremely difficult, since fragile refractory materials are used: clay, putties, plasters.

Scope of application and characteristics of fire-resistant assembly foam

At the same time, the use of elastic materials based on rubber, bitumen is difficult, since they do not withstand high temperatures and can ignite.

It is in this case that construction, fire-resistant polyurethane foam is most suitable, which, due to its elasticity, can seal moving cracks, compensating for the displacement of the horizontal chimney structure.

Produced heat-resistant polyurethane foams do not belong to the category of completely non-combustible, so it can be used only away from the firebox. So, for example, in the upper masonry of the chimney, namely, where it goes into a horizontal position. The appearance of an open fire there is excluded, but if this happens, then this phenomenon will be short-lived.

I would like to say right away that all foam, although it is considered fire-resistant, but according to various classifications, to the most non-combustible class EN 13501-2: 205 - the fire resistance of the material reaches 240 minutes, you are unlikely to find foam.

The refractory class will be indicated on the cylinder: B1 - fire-resistant or B2 - combustible but capable of extinguishing.

Other articles on this topic:

blog comments powered by

Performance characteristics

It is important to understand that fire resistance does not mean complete impossibility of ignition. The sealant resists fire for a certain time, but will ignite with prolonged exposure. The term of resistance is different for all manufacturers, which affects the operational characteristics of the compositions.

Additional properties:

- In the high-temperature range from -60 to +100 degrees, the useful properties of the polyurethane foam are fully preserved.

- Absolutely inert to moisture, mildew and mildew, which will not adhere to the hardened sealant.

- Has increased strength characteristics relative to conventional foam.

- When heated, it does not melt, does not drip, has pronounced self-extinguishing properties.

The only drawback is the inability to withstand sunlight, since ultraviolet rays destroy the sealant and its properties. To protect the insulation, the foam is treated with cement mortar or putty, in some cases painted.

Fire-resistant foam is presented on the market in several types, which differ in component composition, operational properties and time of resistance to an open flame. Fire-resistant polyurethane foam is classified depending on the purpose and description of the properties and characteristics of fire resistance. Manufacturers produce sealants according to their own technologies, adding various components to the formulations in unequal proportions, therefore, fire-resistant sealants have unequal properties:

- Seasonal - all-season and winter.

- The composition is one-component and two-component.

- According to the area of use, the sealant can be household and professional construction.

It is necessary to follow the manufacturer's recommendations for the application of assembly joints, to work with a sealant in the specified temperature range. A variety of composition is chosen depending on the purpose of using insulation for passages of various cross-country areas. They take into account the category of fire hazard of buildings, equipment, communication channels.

Refractory polyurethane foam, question.

AlexKa

03-10-2017 14:31

Yesterday in the construction store I saw this very foam. The question arose, can anyone come across or did, whether it is possible with this very foam to foam the space around the pipe together with the exit of the latter from the roof. For there are cracks through which it blows. The foam is likely to touch the pipe. The outlet pipe is ordinary, not a sandwich. Thank you in advance for your consultation. I ask you not to send it to Google. Was. I did not find a clear answer to the question. As usual there is a lot of garbage and water ...

Abar

03-10-2017 14:45

I have this foam, only in the attic, where the pipe comes out of the ceiling, but the foam comes into contact with the pipe. The pipe is a sandwich. At the exit from the roof there is a master flash, a special rubber band.

AlexKa

03-10-2017 15:07

The elastic is worth it. Set on fire resistant sealant. A tree has been selected with a margin around the pipe. The metal remained. Somewhere from the joints and siphon. But the pipe coming out of the roof is ordinary. Next is a sandwich. When I was collecting one knee was missing, I put it temporarily

.

Abar

03-10-2017 16:01

It is not very clear, it is possible in more detail. Foam is possible if there is no hot iron there.

AlexKa

03-10-2017 16:45

Actually here. It was made clumsy because it was temporary because it was planned to block the roof and bring out a sandwich through the roof. Plans have changed and remained as it is. There are gaps in the roofing sheet on the sides of the pipe. It blows from there. If it's just that the wind is not particularly senior, but when the stove is heated, it happens that it draws in the smoke. Well, with a downpour, it sometimes leaks, but rarely. So I wanted to foam everything around the pipe. Today I will heat and feel the pipe. Is it getting very hot. The sandwich, of course, doesn't get hot ...

Abar

03-10-2017 16:49

If the temperature is not high, you can pour silicone, but the foam, will it hold water?

AlexKa

03-10-2017 16:52

Masterflash is set on a temperature-resistant sealant. There is no problem. Slots on the sides, one decent.Zadolbaeshsya pour sealant. Yes, and do not be lucky to crawl with a pistol.

Abar

03-10-2017 17:12

I also had a problem with the flush, water flowed under it and flowed straight along the pipe to the stove. As a result, another sheet of metal was placed on top of the ridge overlapping the flush, and the entire flush was removed and placed entirely on silicone. I had to do it naturally from the roof, there was no other way. In your case, you can plant it on a refractory sealant. You will not get bogged down there, you just have to climb onto the roof and not everyone can do that. If you fill it with foam from the inside, then the water may leak over time. It may stop blowing, although I do not really understand, well, it blows and blows, you do not seem to have an attic? Or is it not the attic in the photo?

AlexKa

03-10-2017 17:24

In the photo there is an attic. Under it is an attic. What is blowing in general is FSU, but when a strong wind draws smoke from the chimney into the gap. And through the cracks pulls into the room. The house is old, frame. Outside, the flash is planted on a sealant and attracted by roofing screws. Despite the fact that the iron is not smooth, nothing flows under the flush. The pipe is also coated with sealant. Of course, all this was done outside. The roofing sheets are short, the roof is made up of them. Here in the area of the pipe there are cracks in the roof itself. Self-tapping screws attracted but not much sense. There is generally some kind of wild iron sandwich hedged up ... In general, it is difficult to explain on the fingers. A competent pipe is necessary.

Refractory foams for ovens

Dismantle. Disassemble the roof. Cut a smoother hole. The roof, in this place, should be re-covered. Drive a sheet with an oval under the ridge. Through it, put a pipe and a new masterflash on the sealant, plus the masterflush can also be pulled on top with a clamp. But it is troublesome and, kmk, unreasonably laborious. Well, it's not a problem to climb on the lynch.

Abar

03-10-2017 17: 48quote:

Here in the area of the pipe there are cracks in the roof itself.

So are the gaps in the roof or between the pipe and the roof? I still do not understand where is it blowing? If, as you say, the sandwich is sealed and sits tightly on the sealant with self-tapping screws, it is smeared on the pipe with a refractory gemstone, then where does the smoke go? Can't you just deliver a sandwich? Doesn't this solve the problem?

AlexKa

03-10-2017 18:07