Thermal insulation of pipes: an important need

High-quality and inexpensive insulation of pipeline systems is required everywhere, from small country houses to large industrial enterprises, shopping malls, etc.

If you initially include thermal insulation in the project and carry it out at the first stages of construction, then you can save significant funds on the repair and operation of trunk networks.

If we talk about the requirements for insulating materials for pipes, then they depend on the specific types of lines, as well as the conditions of their operation. In general, the main task of thermal insulation is to protect the insulated surfaces for the longest time possible.

Often, thermal insulation materials made of mineral fibers meet all these requirements - their characteristics are simply ideal for various types of pipelines.

Indoor piping insulation

It should be noted that in the case of using mineral wool insulation for water supply networks, air conditioning and refrigeration equipment, it is possible to effectively protect structures from freezing, corrosion, and condensation.

In addition, high-quality materials will help reduce heat loss in the lines and significantly extend the period of trouble-free operation.

Main characteristics and features

Modern mineral wool insulation is a fibrous material that is obtained by melting mountain silicates, slags, and their mixtures. Depending on the type of raw material used, insulating mineral wool can be either stone or slag.

In the first case, such rocks as basalt, limestone and diabase are used, while in the second - slag and metal production wastes.

Heat insulators made in the form of cylinders

Due to the processing of raw materials under high pressure and with a special temperature regime, it is possible to give mineral wool unique characteristics, in particular, in terms of its level of heat and sound insulation, as well as resistance to the negative effects of many factors, the material simply has no equal.

And in terms of cost, mineral wool is in a fairly affordable range - its price is much lower than that of polymer analogues.

Mineral wool cylinders - comfortable and practical thermal insulation

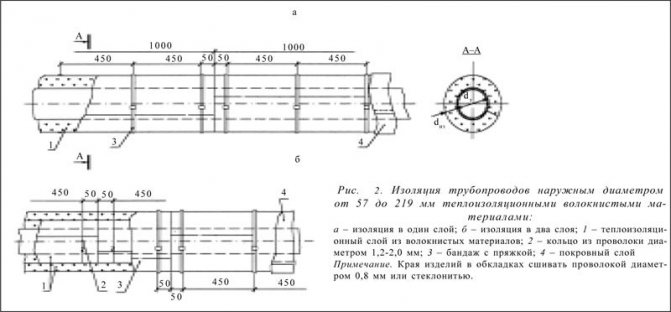

High-quality and modern heat-insulating stitched mineral wool mats are actively used for insulating pipes of various diameters and lengths. But at the same time, it should be noted that special cylinders made on the basis of mineral wool are more actively used.

These are products of a cylindrical shape, often made of basalt using a special winding technology.

An example of the use of basalt fiber insulation for insulation of external pipelines

Due to the use of cylinders and half-cylinders, the technology of thermal insulation of pipelines with mineral wool becomes extremely simple, it comes down to performing just a few basic steps.

Due to the large selection that the domestic market of heaters offers today, you can choose the best option for each type of pipe, providing them with the best conditions for operation for a long time.

Advice. Cylindrical mineral wool insulation should be chosen directly under the outer diameter of the pipe. In this case, it will be possible to achieve maximum insulation values, to exclude the formation of condensation and corrosion under the layer of cotton wool.

As a rule, in most cases, all mineral wool mats and cylinders are additionally covered with a layer of aluminum foil, fiberglass, and fiberglass mesh - this helps to protect them from damage, fire and other negative factors.

Due to the special packaging in which the products are sold, it is very convenient to store and transport them.

Photo of material with additional coating of aluminum foil

Installation of diaphragms

Before installation, you need to make sure that the diaphragm is supplied complete and its passport data and markings correspond to the specified ones, then the diaphragm parts are put back in the package and in this form are delivered to the installation site. Here the diaphragm is finally unpacked and wiped with a dry, clean cloth. Special care must be taken when handling the diaphragm disc to avoid damaging the sharp edge of the diaphragm bore on the side of the cylindrical bore. This is important to remember because nicks or scratches on this surface cannot be removed, even with files or sandpaper. After wiping the diaphragm, the sharpness of the leading edge of the disk is checked by examining it in diffused daylight or artificial lighting at an angle of 45 ° to the horizon. For diaphragms with an opening not exceeding 125 mm, the light beam incident on the edge should not be reflected. With a larger aperture, reflection of the beam is possible, but not due to the bluntness of the edge, visible to the naked eye.

The restriction devices should be mounted in pre-installed flanges only after cleaning and purging the process pipelines (preferably before pressure testing).

The installation of the restriction devices must be carried out so that in working order the markings on their bodies are accessible for inspection. If this requirement is impracticable, a plate is attached to the orifice device, onto which the data placed on the body of the orifice device is applied.

In fig. 20 shows the installation of diaphragms on vertical and horizontal pipelines when measuring the flow of steam and liquid; in fig. 21 - installation of a chamber diaphragm and a high-pressure nozzle.

Fig. 20. Installation of chamber diaphragms a - on a vertical pipeline for measuring the steam flow; b - on a horizontal pipeline for measuring steam flow; c - on a vertical pipeline for measuring the flow rate of a liquid with a temperature of up to 100 ° C; 1 - aperture disk; 2 - camera; 3 - gasket; 4 - flange; 5 - shut-off valve; b - condensation vessel; 7 - impulse pipe

Fig. 21. Installation of restricting devices of high pressure of a chamber diaphragm on a vertical pipeline when measuring the steam flow rate (a); high pressure nozzles on the horizontal pipeline (b) 1 - diaphragm disk; 2 - gasket; 3 - flange; 4 - condensing main engine; 5 - pipe of the connecting line; c - shut-off valve; 7 - nozzle

Currently, the most common is the installation of a diaphragm in the flanges of the installed pipeline. Installing a diaphragm using this method requires a preliminary expansion of the flanges using a simple device - a spacer sleeve (Fig. 22, a). Three couplings are installed between the flanges welded to the pipeline (Fig. 22, 6) and the flanges are evenly expanded to a size sufficient to enter the assembled diaphragm and gaskets. After checking the correct installation, studs are inserted into the mounting holes in the flanges free from the couplings. After installing the nuts, the couplings are removed and the fastening of the diaphragm is completed. It should be remembered that the diameter of the inner hole of the gasket should be 2-3 mm larger than the inner diameter of the pipeline. This will prevent the gasket from getting inside the pipeline while tightening the studs. The nozzles are mounted in the same way.

Fig. 22.Spacer sleeve (a), spacer of flanges using three couplings (b) 1 - thrust threadless cone; 2 - clutch housing; 3 - threaded cone; 4 - flange; 5 - coupling

Benefits of using mineral wool cylinders

A thermal insulation cord made of mineral wool or a full-fledged cylinder made of a unique material is the best option for insulating pipelines of various types.

The use of just such a form of heat insulator has a lot of advantages and benefits, among which are:

- Low level of thermal conductivity. Inside the layer of a cylinder made of mineral wool, a large volume of air is contained, which (due to the thin and flexible fibers of the material) remains stationary, does not allow heat to pass through;

- Resistant to fire and high temperatures. The instruction for the mineral wool cylinders says that they are non-combustible, do not melt and do not lose their shape even under the influence of extremely high temperature conditions (from -150C to + 750C);

- Long term of trouble-free operation. The use of basalt rocks as a raw material, as well as slag, extends the service life of mineral wool-based heaters by almost decades. On average, even the most inexpensive heat insulator can last 50-60 years without losing its performance;

Variety of choice of shapes and sizes of insulation materials

- Durability and reliability. Mineral wool can withstand even the highest loads and pressures with ease. Cotton wool has closely intertwined fibers, and therefore its density and strength are significantly increased;

- Hydrophobicity. The insulation has increased resistance to moisture due to protective layers of foil and fiberglass, due to this, it is not afraid of direct ingress of water. If necessary, you can additionally process materials with special hydrophobizing compounds;

Advice. If the pipeline is supposed to be used in conditions of high humidity, then it is best to subject the mineral wool to additional processing. Thus, it will be possible to extend the life of the highway, significantly reduce the cost of maintenance and repair.

- Availability. The price of mineral wool heat insulators is in an affordable range, which allows them to be used for insulating even long pipelines;

- Ease of use. Everyone can insulate even large volumes of pipelines with their own hands. The process of thermal insulation is quite simple, it requires the use of only available materials;

Mineral wool half-cylinders

- Environmental friendliness. Cylinders and half-cylinders made from natural raw materials are absolutely safe for human health and the environment. As a result, mineral wool materials can be used to insulate any pipes.

The effectiveness and benefits of using mineral wool heaters for pipes

Thermal insulation materials made of mineral wool, made in the form of cylinders, allow to achieve high efficiency, to provide the best operating conditions for the lines:

- Heat losses in straight sections of pipelines when using mineral wool will be reduced by almost 3.6 times. Unlike other materials, it loses only 8% of heat, which is very important, especially for hot water supply systems;

- Reducing the time spent on thermal insulation. It is no longer necessary to wrap pipes with fiberglass and mineral wool mats - the cylinders have an inner diameter similar to the dimensions of the line;

Easy cutting of the material with a knife during assembly

- Protective coatings will help to exclude damage to the cylinders from the insulation, to maintain the level of thermal insulation for a long time. At the same time, the thickness of the insulating layer is not lost throughout the entire service life.

Advice.The use of a construction knife will help to simplify the process of covering pipes with mineral wool insulation in the form of cylinders and half-cylinders. Cutting materials with such a tool is much easier, and the dimensional accuracy can be observed.

Thermal insulation materials made on the basis of mineral wool in the form of cylinders are an excellent option for pipes of all types, sizes and lengths.

It should be noted that the domestic market is filled with offers from various manufacturers, you can choose the right type of insulation specifically for a specific pipeline with a specific diameter, length and types of transported material.

The use of special coatings for additional protection of heat-insulating materials from the negative effects of mechanical damage and other factors

Finishing of ventilation ducts with stitched mats

- Mineral wool stitched mineral wool mats MP-100 GOST 21880-2011 with a density of 75, 100 and 125 kg / m³ are produced in several standard sizes - 50 and 100 mm thick. The flexibility of the material determines its suitability for finishing round and box ducts of different diameters.

- Insulation is mounted end-to-end - the surface of the material lined with fiberglass and metal mesh allows you to take advantage of the advantages of adhesive installation. Joints and interfaces are sealed with metallized mounting tapes.

- An aluminum shell is offered as a protective coating, in a residential interior - panel plasterboard or other material with similar characteristics.

Another option for effective external insulation is lamellar mats. The construction of the material consists of narrow strips of rigid compact insulation glued to a foil base. Lamellar insulation combines the compactness of rigid insulation with the assembly advantages of wired mats.

The lamellar coating is also characterized by high resistance to deformation loads and minimal operational shrinkage.

Output

Mineral wool is a heater with unique characteristics, the best option if it is necessary to protect pipelines of various categories from the negative effects of temperature changes, the negative effects of various factors, ranging from chemicals to mechanical damage.

Due to its convenient shape and affordable cost, it is possible to choose the most optimal heat insulators for each specific case, ensuring the performance of a wide range of works without wasting time and money.

In the video presented in this article, you will find additional information on this topic. The process itself is very simple, accessible to everyone, even those who are not prepared for construction work.

Instruments for quality control of pipeline insulation coatings

The quality of pipeline insulation can be monitored both during installation and during operation. If the coating is chosen and applied correctly, has the required properties, then it will serve as a reliable protection for the structure. Poor-quality insulation is not only the cause of losses, but also an additional item of expenses, because you will have to spend a lot of money on maintenance and electrochemical protection of the pipeline. Insulation quality control devices, in a wide range presented on the official website, will allow you to detect existing problems and eliminate them in a timely manner.

Thermal insulation of gas ducts and rectangular air ducts

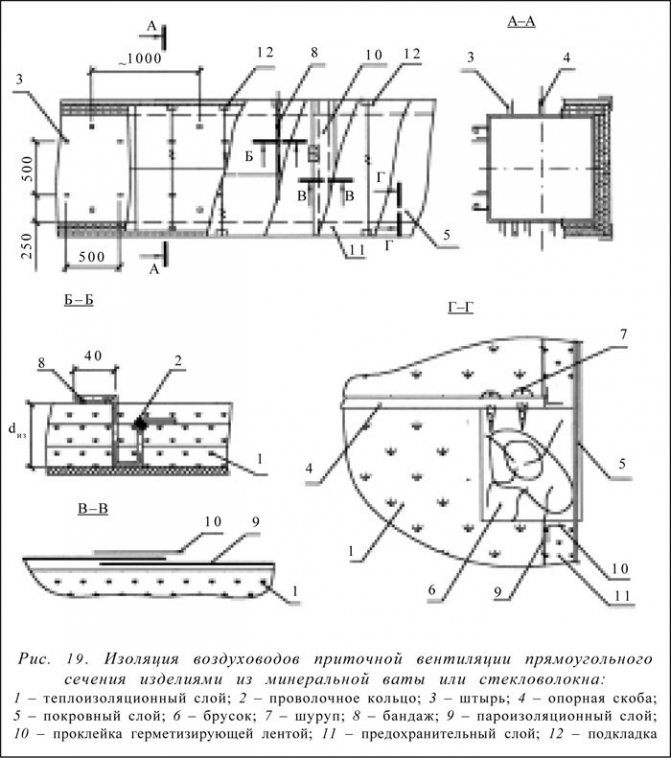

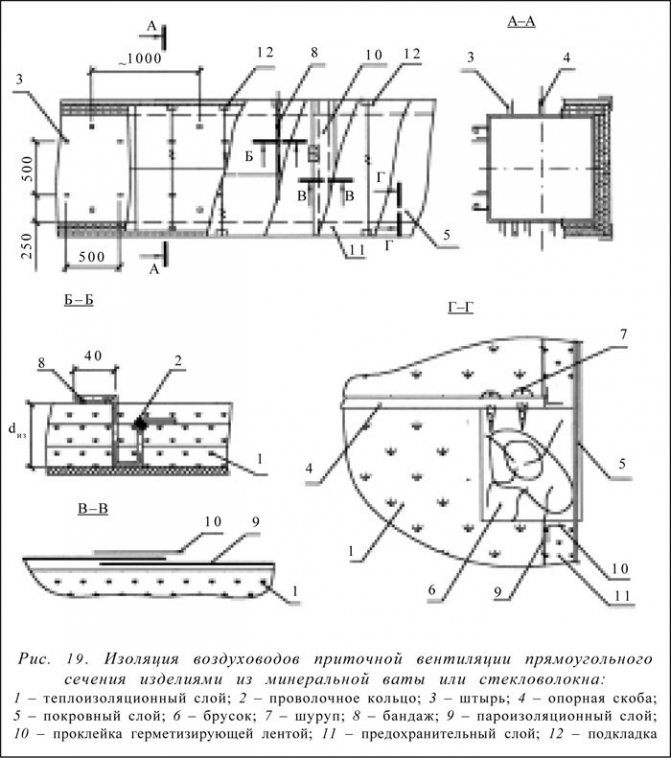

It is recommended to use heat-insulating plates for thermal insulation of rectangular gas ducts. Fastening of the heat-insulating layer can be carried out using pins (welded, plug-in) and bandages (or wire rings) (Fig. 18 and 19).

At the corners of the thermal insulation of rectangular gas ducts, metal linings made of the coating material are installed under the bandages or wire rings replacing them.As a rule, gas ducts have significant ribbing. If the height of the stiffeners is greater than the thickness of the thermal insulation, then they should be insulated. The insulation design depends on the configuration of the ribs. Pins, pins, staples and other fastening elements for thermal insulation and coating can be welded to the ribs. When insulating air ducts of supply ventilation, the heat-insulating layer of plates can be fastened with pins, wire rings and strings or glued with bituminous mastics. Wooden bars or structural fiberglass elements, which are attached to metal brackets, can be used as supporting elements under the coating. Instead of metal brackets, a frame made of wooden bars can be used, installed on the surface of the duct. In this case, the metal cover layer is attached to the frame with screws. A vapor barrier is installed along the thermal insulation layer. The joints of the vapor barrier layer are also recommended to be placed on the bars (elements) of the frame. When used as a heat-insulating layer of plates or mats coated with foil on one side, the joints of heat-insulating products must be glued with aluminum tapes with a sticky layer. These tapes can also be used as bandages to secure the thermal insulation layer of foil-coated slabs and mats. If the welding of the pins to the duct is not allowed, then a wire frame structure can be used, as in pipe insulation. Metal bands made of 2x30 or 3x30 mm tape with pins welded to them can be used. Such bands are installed on the surface of the duct and fastened together with bolts and nuts. When insulating the supply ventilation ducts, a vapor barrier layer is installed. To prevent damage to the vapor barrier layer made of polyethylene film or aluminum foil when using a metal coating with fastening with screws, it is recommended to install a protective layer with a thickness of 15-20 mm made of fibrous materials (Fig. 20).

Can be used canvas stitched or needle-punched fiberglass or other materials that have a small thickness. Other constructive solutions can be used, for example, fastening the cover with strips.

Thermal insulation of steel vertical cylindrical tanks

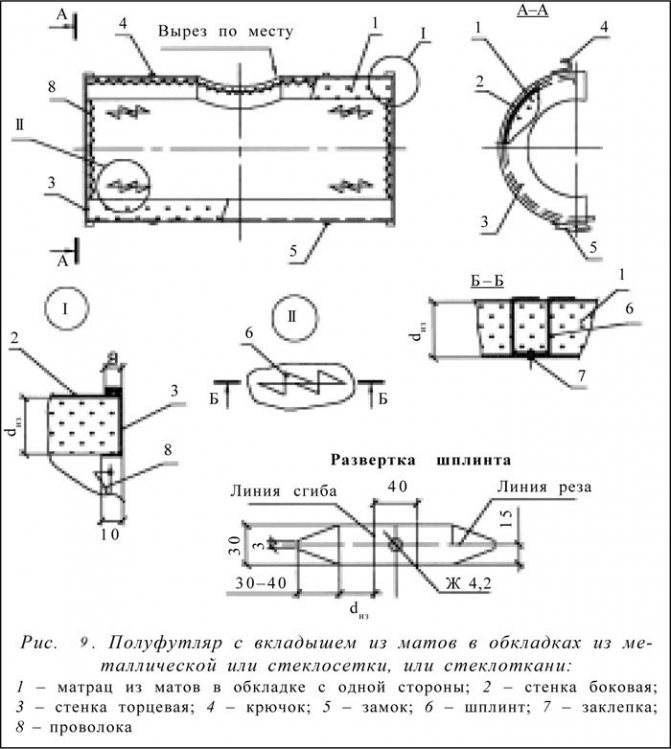

For thermal insulation of tanks for storing oil and oil products, it is recommended to use thermal insulation boards made of mineral and glass wool. Plates are attached to the tank wall with pins welded with a pitch of 600x600 or 400x400 mm. For fastening the metal cover, support structures of vertically positioned steel corners or strips can be provided. The protective cover is fastened with screws. The protective coating elements can be combined into paintings. A timber frame can also be provided. In this case, the covering layer is fastened with screws to the frame made of wooden blocks vertically and with screws horizontally (Fig. 20). The installation pitch of the supporting structures is determined by the dimensions of the protective coating elements and thermal insulation plates. Additional fastening of the plates can be provided by bandaging along the pins with wire (in the form of rings or crosswise). Support shelves should be provided along the height of the tank to prevent the thermal insulation layer from slipping. In the place of installation of the support shelves, expansion joints in the cover layer are also provided. Mats in wire mesh linings can also be used to insulate tanks. The spacing of the pins welding is 500x500 mm. If bandages are welded to the surface of the tank with a pitch of 3 m, then a construction of hinged mattresses made of mats with a heat-insulating layer of mats stitched in linings on both sides of glass cloth or glass mesh can be used (Fig. 21).

Hanging mattresses should be provided with hooks for attaching to bandages (fig. 22).

The mattresses are suspended from bandages and are attracted to the surface of the tank by rings made of wire with a diameter of 2 mm. The pitch of the rings should be taken 500 mm along the length of the mattress (along the height of the tank). It is recommended to sew mattress joints with a wire with a diameter of 0.8 mm.In this case, the roof of the tank should be insulated with mats, which are placed between the steel angle rails welded to the roof. Instead of a corner, strings of wire with a diameter of 5 mm can be provided, while the mats are attached to the strings with a wire with a diameter of 2 mm, and the cover layer - with clamps. When insulating cold water tanks, the insulation structure made of fibrous materials should have a vapor barrier made of polyethylene film, aluminum foil or foil-clad materials. When using materials with a closed-cell structure (foam glass, foamed rubber), the vapor barrier layer is not installed.

14.05.2010

Back to section