AGV-boiler is a simple, but rather reliable and efficient heating device. The units have been produced since Soviet times, the products were called the Zhukovsky Machine-Building Plant. However, gradually all domestic autonomous gas apparatuses began to be called such an abbreviation.

Construction and principle of operation of AGV boilers

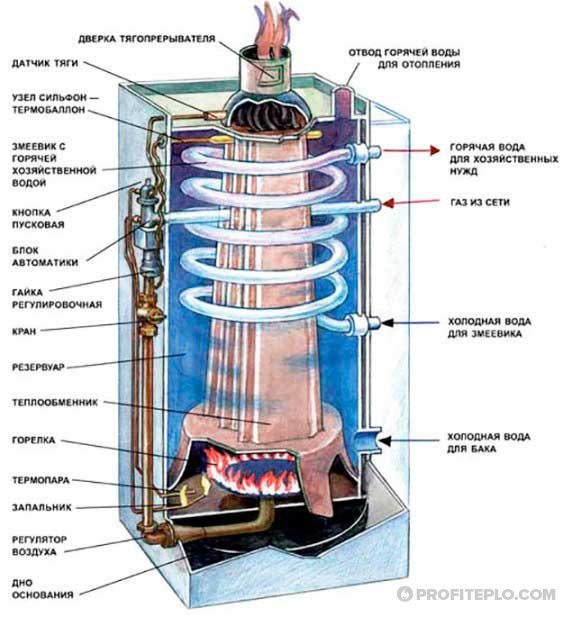

The unit is a non-volatile device. The equipment is characterized by a simple design, which includes:

- a tank made of galvanized steel (devices are marked according to the volume of the tank);

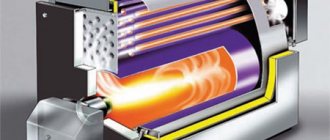

- heat exchanger;

- burner;

- igniter;

- automation.

All AGV are floor standing boilers. The device is a tank filled with water, inside which a fire tube passes. When a gas is burned, heat is transferred to the liquid through the latter. The resulting products are removed outside the room through a chimney connected to this device.

Water heats up and increases in volume - it becomes a coolant, which, in accordance with the laws of physics, rises through a specially provided distribution pipeline. From there, the liquid enters the radiators and transfers heat to them, which is used to heat the room. When the water cools down, it returns to the boiler through the return line. The cycle repeats again.

The AGV does not have a circulation pump and a turbofan. The nodes are independent of the availability of electricity. The circulation of water occurs exclusively by gravity, due to the difference in height between the heating tank and the radiators. Moreover, a closed cycle has been created.

Principle of operation

The water in the boiler circulates in a natural way - according to the thermosiphon principle. Heating takes place from a flame tube, through which hot gases from the lower burner pass.

The main blocking element of the gas line is a thermocouple-actuated solenoid valve. To light the burner, you must press the start button on it and bring an open flame to the igniter tube. A heated thermocouple generates a current that triggers the solenoid valve. After that, the gas supply valve to the burner is manually opened, the boiler is ignited.

The principle of operation of the AOGV boiler

To control the heating temperature, there is a sleeve in the top cover of the boiler, where a thermometer is installed. It is maintained at the same level using an automatic thermostat, which is based on the change in the length of a metal rod (brass) when heated. To work in a given temperature range, its lever rotates by only 14 °, which is a passive protection against unskilled actions.

If you want to raise the upper heat limit, first unscrew the locking screw on the thermostat control lever and turn it counterclockwise, then reattach and turn in the opposite direction. The design does not impede actions that may cause the water in the boiler to boil. Therefore, it will be better if they are carried out by a specialist. If you do not have one, read the technical description of the AOGV boilers and the rules for their operation by clicking on this link.

Advantages and disadvantages

The advantages of boilers include:

- low cost of equipment in comparison with other foreign and domestic counterparts;

- simplicity of design, which increases the reliability of the apparatus;

- non-volatility - such boilers can be installed even where it is not possible to provide a stable supply of electricity;

- compactness.

However, AGVs are not without their drawbacks.For their manufacture, not the most durable materials are used. Although galvanized steel resists corrosion, its performance characteristics are inferior to modern alloys.

Even the improved AGV models inherited the disadvantage of their predecessors. This is indicated in the operating instructions - until the water warms up to a temperature of +30 ºC, condensation may drip onto the burner.

What is the difference between AGV and AOGV

The autonomous heating gas water heater is a 1-circuit independent boiler. The main difference from AGV is that the device is considered more reliable and safer to use. The unit is equipped with advanced automation.

A separate room is required for the installation of AGV, since combustion air is taken directly from the room. Good sound insulation is required as a loud bang is heard when the appliance is turned on. AOGV eliminated this drawback.

When the water reaches the maximum temperature, the burner is switched to the minimum flame mode, but does not turn off completely. A separate room for AOGV is also not required, since a chimney with a size of 140 mm is laid through the wall, air is taken from outside. It is only important to install a special waste container under the pipe for waste that accidentally falls into the channel.

How AGV works

The design of the apparatus is quite simple. It looks like a samovar. This is a container in which a vertical pipe is located, and water is poured into the space between the walls of the pipe and the walls of the container itself. She will play the role of a coolant.

The gas burned in the boiler furnace passes through the pipe, giving it its heat. Accordingly, the pipe gives off heat to the water placed in the tank, after which, according to the laws of physics, it begins to move up the heating riser.

Modern AGVs are equipped with an automatic device that is responsible for the gas supply to the burner and controls this supply. The control process is also simple.

Gas heating

A temperature sensor is installed in the vessel of the apparatus, which monitors the temperature of the coolant. When the required value is reached, which is set, adjusting the operating mode of the heating system, the damper is automatically triggered. It shuts off the gas to the burner. But at the same time, a small wick remains on fire. The coolant temperature has dropped - the sensor is again triggered, and the gas supply is turned on, which is ignited from the wick.

The automation of this boiler works very efficiently. After all, gas is a capricious type of fuel, so it must be handled delicately. In the event that the flame of the wick has gone out, the gas pressure in the pipeline has dropped, or the chimney is clogged, the AGV automatics will not turn it on under any pretext.

Modern heating AGV

Compared to Soviet models, the manufactured devices have become convenient and functional. They are equipped with automation that makes the operation of the boilers comfortable for the user.

In modern models, there is a thermal sensor required to control the set temperature. A chimney draft control component is often installed. The functioning of the automation is carried out due to the electric current generated by the thermocouple. The latter produces it due to heating. This ensures the activity of the electromagnet, which makes it possible to control the gas valve. This also increases the reliability of the operation.

To choose the right model, take into account the characteristics of the equipment.

Modern AGVs are switched on with the help of a piezo ignition, which is more convenient than before. The automatics are mainly American, and the thermometers are Italian. New coating technologies have contributed to the attractive finish of the case.

User's manual

The main thing to remember is that such boilers do not have a built-in circulation pump. Good natural traction is required.This is possible only if ventilation is established in the room where the AGV is installed, and the chimney is arranged according to all the rules.

The installation features are as follows:

- duct height is at least 5 m with a total length of horizontal sections up to 3 m;

- the diameter of the pipe corresponds to the size of the outlet of the apparatus;

- do not connect equipment to exhaust ventilation ducts;

- a small hatch is arranged under the vertical part of the chimney to clean the system from condensate;

- when installing AGV, you need to make sure that there is a free passage in front of the device at least 1 m.

The recommended distance from the unit to the nearest wall is 2 m or more, this is the only way to ensure fire safety. The finishing of the vertical surface must be made of non-combustible material. If the owner doubts its properties, it is better to install a screen made of sheet asbestos.

Installation of AGV necessarily implies the connection of equipment to gas networks. You cannot do this on your own, you need to contact the specialists of a company that has a license to carry out the work.

As for the operating rules, the equipment is launched in the following sequence:

- First you need to check if the heater tank is filled with water.

- Then they look at the presence of draft in the chimney. This can be done using a thin paper flag. If there is no thrust, it will remain stationary. This is important as there is a risk of poisoning from unburned fuel.

- Open the valve mounted on the gas pipeline.

- The burner is ignited (with a match or a piezo ignition handle - depending on what type is provided on the model). Then only the igniter is turned on. After that, you can open the tap in front of the main burner. It should be powered by an igniter. It is recommended that you read the instructions first.

- After turning on the AGV, check the presence of draft in the chimney again.

- Close the firebox door.

If the igniter goes out, then you can re-ignite it only after a few minutes. When the water heater is running, it should be on constantly.

The AGV is also switched off sequentially. First you need to close the gas taps. They are installed in front of the main burner and the appliance. In the AGV-120 model, the pilot valves are closed separately and in front of the boiler.

The units do not need special care. The main thing is to provide protection against mechanical damage and liquid ingress, if the device is installed so that splashes from a shower cabin or a water tap reach it.

The operation of the device should be monitored. The flame has a bluish tint and the length of the tongues is 30-40 mm. If it starts to smoke, you need to slightly open the windows for oxygen to enter the system. When the smell of gas is felt in the air, specialists are immediately called in. Before the arrival of the emergency team, close the tap in front of the equipment and ventilate the room. At the same time, turn off electrical appliances and lighting to avoid sparking anywhere.

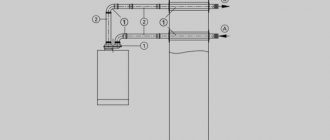

Option for mounting AGV in a private house

A room is allocated for the unit in the lower part of the building. The ascending section of the pipeline needs insulation. The reverse part should not be insulated.

Installation instructions for convectors, radiators, heating panels provide for their installation at the maximum height from the boiler. To mix the air layer, radiators or other devices are installed under windows.

The AGV boiler should be installed in a separate room (AGV 80 boiler)

The pipeline for the return of the network is laid at the floor level of the rooms. If it is laid over the door frames, it can contribute to the "airing" of the system.

Two-inch pipes in a home network do not have a very aesthetic appearance, but when trying to replace them with pipes of a different diameter, it must be borne in mind that when the pipe diameter decreases, the hydrodynamic resistance increases, weakening the water pressure in the system and the boiler efficiency.

Connection diagram of the AGV boiler

During installation, the pipeline is installed with a slope of 1 cm for each meter of its length. This technique prevents air locks in the system, improves water circulation and allows water to be drained from the system.

Note! Gas service specialists must connect the AGV boiler, they also register it.

Precautions:

- If the water temperature in the system drops to +50 degrees, abundant condensation appears, which can even extinguish the burner.

- Condensate, when mixed with combustion products, releases nitric and sulfuric acids, causing corrosion of equipment.

- With a decrease in the temperature of the coolant in the system to +50 degrees, its circulation in the system stops completely.

- If the boiler is not used in winter, the water from the system must be drained, however, this option significantly increases corrosion.

- You can use hot water without heating the entire system; for this, use a tap that cuts off the circulation in the heating system. And if you connect the direct and return lines, the turnover is preserved.

Foreign autonomous gas water heaters

Non-volatile boilers are popular. Imported units differ from AGV in a wide variety of models. However, more often these are floor heating devices. Wall-mounted options are rare.

But there is a variety, like parapet non-volatile boilers. They can be installed on the floor or hung on the wall (but not higher than the level of the windowsill). There are models that are mounted on a vertical surface.

Imported non-volatile devices also differ in the materials from which the heat exchanger is made. For example, stainless steel, cast iron or copper. The latter is considered expensive, but also the most reliable and durable option. Copper is not used for the production of AGV.

Equipment of the Slovak brand Protherm is popular. The models are named after animals. The Protherm Medved 20 TLO boiler is considered practical and powerful. The device is equipped with a heavy cast iron heat exchanger.

The unit has a higher efficiency compared to AGV - about 90%. This model is suitable for heating a house up to 200 m² (excluding heat loss), although the power is 18 kW.

From foreign devices, the Baxi boiler is popular. SLIM EF 1.22. The device is characterized by a high power of 22 kW, but the efficiency is lower than that of other imported units - 88%.

Criterias of choice

When buying boilers for a private house, several aspects are taken into account:

- The area of the heated room.

- Possible heat loss (depending on what materials the walls of the building are made of, floors and ceilings, windows and doors are made).

- Equipment power (the required indicator is calculated on the basis of 1 kW for every 10 m² of the area). But if the house is located in a region with harsh winters or is built from materials with high heat loss, the resulting figure is increased by 25%.

- Functional features of the boiler.

AGV are produced in different capacities, but the standard indicator is enough for heating a house up to 120 m². For buildings large in area, foreign autonomous boilers are bought. Additionally, improved AOGV or AKGV devices are considered as an alternative solution.

The latter is a complex water heater. These are double-circuit boilers that operate independently of the mains. The units provide heating and hot water supply.

However, experts believe that it is impractical to install such equipment in houses with an area of 200 m² and more, since it is impossible to create a stable natural draft. You will have to buy an additional circular pump, and to it - a UPS and a generator to ensure operation. Such disadvantages negate the advantages that the autonomy of the boilers gives.

Review of 2020 models of gas boilers of the Zhukovsky plant

Catalog / Gas boilers and their spare parts / Gas boilers AOGV and AKGV JSC "Zhukovsky MZ"

Review of 2020 models of gas boilers of the Zhukovsky Machine-Building Plant. Date of publication 01/27/2019 Gas boilers ZhMZ can be structurally divided into three main series. We must immediately give a decryption of the name "AOGV". This is a gas hot water heating apparatus. The word "hot water" in this case means heating the heating medium of the heating system. When the name of the boiler AOGV took on life, the only type of coolant in the system was water. In most cases, it remains, although there are options when an anti-freeze liquid is used instead of water. There is also the name "AKGV boilers". This abbreviation means - combined hot water heating apparatus. The letter "K" and the very concept of combined means that the boiler is a failure of a combination of a hot water boiler for heating and a built-in small-sized heat exchanger for preparing hot water. The preparation of hot water for domestic needs does not require the use of any additional capacities. The boiler remains the boiler. This is simply a design feature of the boiler. Which, if desired, can be by us, and not used, but there is this possibility in AKGV boilers. There is no such possibility in AOGV boilers. AOGV boilers are intended only for heating the house. The very name of the AOGV boiler has settled down so tightly in the mind and describes this type of boiler so accurately that we all immediately understand perfectly what it is about. Now, when, with the name of the boiler, we will more or less understand these three main types of AOGV that the plant produces today. The first type is AOGV Economy Here we see the remains of the AOGV-17.4 Economy and AKGV-17.4 Economy models. Variants of other models are already almost completely absent and may not be produced... The word Economy means equipping the boiler with a domestic-made gas valve. It is easy to operate, easy to repair. It is a little awkward or scary in appearance, but it performs its functions regularly. Both the block and the boiler are fully provided with spare parts. Nevertheless, the plant does not focus on such equipment. Although, the situation may change. Go to this section. The second type is AOGV Comfort (N) H - means new. Gas boilers AOGV Comfort New are equipped with Mertik Maxitroll gas valves. The main models of this series are AOGV-11.6 AOGV-17.4 AOGV-23.2 and AOGV-29.1. By the way, the boiler with a capacity of 29.1 kW is also equipped with a standard Mertik gas valve. This was due to the fact that this gas valve provides the throughput necessary for a boiler of such power in terms of the amount of gas consumed by it. By the way, this is the only model of this power from all the (H) series. AKGV options also exist. The plant canceled the large convex doors in this design and replaced them with a narrow casing, onto which the thermometer was brought out and hid all the rest of the equipment under it. All control knobs are brought out from above. Go to this section. The third type is AOGV Universal (N) Gas boilers AOGV Universal Novelty are equipped with a Eurosit 630 gas valve. The main models of this series are AOGV-11.6 AOGV-17.4 and AOGV-23.2. There is no boiler with a capacity of 29.1 kW in this line, because Eourosit 630 cannot provide the required gas supply for a 29.1 kW boiler and an 820 Nova valve must be installed here. And they are not yet at the plant. Variants of AKGV in this series are also present. The plant, in this version, also canceled the large convex doors and replaced them with a narrow casing, onto which the thermometer was brought out and hid all the rest of the equipment under it. The control handles of the block are brought out from above. Go to this section. The fourth type is AOGV BEETLE Beetle boilers are designed as follows. The cylindrical heat exchanger is housed in a square casing where all controls, a thermometer and handles are displayed. The boiler has three types of ciphers, which imply execution.It is just a BEETLE, as well as a BEETLE (01) and a BEETLE (02). What is the difference? The main difference between the Beetle and all the series shown above is the presence of a square casing. Due to this design, free access to the heat exchanger is very limited, and we need to control the presence of a flame on the igniter when the boiler is fired up. To facilitate this operation, the boiler is equipped with a pilot flame indicator. This is a window that simply changes color when there is a flame on the igniter. Next, we will describe all three options for ZhUK boilers based on the body, the flame indicator and the type of gas valve. Boilers series BUG. Square casing. Equipped with Flame indicator. Mertik Maxitroll gas valve. The lineup starts from AOGV ZhUK - 11.6 to AOGV ZhUK - 29.1. AKGV options are the same. Go to this section. Boilers series BEETLE (01). Square casing. Without indicator. Mertik Maxitroll gas valve. The lineup starts with AOGV ZhUK (01) - 11.6 for AOGV ZhUK (02) - 29.1. And the same AKGV. Go to this section. Boilers series BEETLE (02). Square casing. Without indicator. Gas valve Eurosit 630. The lineup starts from AOGV ZhUK (02) - 11.6 to AOGV ZhUK (02) - 23.2. And the same AKGV. Go to this section. It is worth noting that all dimensions of all modern AOGV (N) heat exchangers manufactured by the plant, as well as ZhUK boilers of all three versions along the axes and diameters of the connection pipes fully correspond to previously produced boilers and do not require any intervention in the piping if it becomes necessary to replace the old boiler with a new one. ... If the difference is only in the length of the heating supply pipe of boilers of the ZhUK series. It is higher than the existing standard heating “supply” pipe by several threads. And this is the only difference. Another important point. We have said before, and will say again, that all steel welded boilers work for a long time and stably only at an operating pressure of no more than 1.5 atm. All connection options with make-up from the water supply and the use of closed expansion tanks without specific knowledge and equipment will end up with a current heat exchanger. Therefore, we strongly recommend using open tanks or correctly selecting and regulating closed ones, with the mandatory installation of a 1.5 bar safety valve.

- Gas boiler AKGV-29-3 "ZhUK" (01) Comfort JSC "Zhukovsky Machine Building Plant" (Russia)