Implemented standard solutions (main heating system + backup):

• with a gas boiler;

• with a gas boiler and with a backup electric boiler;

• with wood / coal boiler;

• with a wood / coal boiler and with a backup electric boiler;

• with a gas boiler and with a reserve solid fuel boiler.

Building a system solely on an electric boiler is economically impractical. Especially if the private house is large enough (from 100 sq.m. and more). Utility bills may be too high. If gas is not available, we recommend installing a solid fuel boiler and an electric one as a backup.

Simple solutions for uninterruptible power supply

Ideally, any uninterruptible power supply system should require no more attention and fuss from the owner of the house than any household appliance. In this case, human actions should be limited to the "on / off" operation, and ideally the system should work automatically, without the intervention of the owner.

If we are talking about the need to provide power only to the heating system - a standard gas boiler with a control system and a circular pump, then the solution on the fuel generator will be more than utopian, after all. the heating system consumes only 300-500 watts. In addition, operation of the generator at idle speed or at low load (less than 20% of the nominal for a gas generator and less than 40% for a diesel) is not recommended, as this leads to excessive consumption of fuel and "winding" of the motor resource.

It is easier to power such a load from a battery backup system, which is similar to the computer UPS (UPS) commonly used in offices. The system itself consists of a battery pack (battery), an inverter and a control controller. The batteries in them are akin to ordinary batteries, exactly the same that are found in almost all the devices around us: a cell phone, a laptop, a watch - only of the appropriate size.

The inverter is the core of an uninterruptible power supply system. It converts direct current from batteries (12, 24 or 48 volts) into alternating current with the required parameters 220V / 50Hz. At the moment of a power outage, the system almost instantly switches to battery operation. The rechargeable batteries are recharged when the power supply to the external network is restored from the charger as part of the inverter.

The controller monitors the charge and discharge of the batteries and the voltage in the external network. If voltage fails, the controller instructs the system to switch to battery power. Most inverters can withstand short-term overloads, which allows them to be used to start electric motors or compressors (borehole or circular pump, refrigerator, etc.). Unlike a generator, for an inverter system, in principle, there is no problem of noise and exhaust gases, the need for fuel and constant monitoring. The whole system works in the "plug and forget" mode.

There are ready-made industrial UPSs, where the inverter board and the battery are located in the same case, an example of which are the above office uninterruptible power supplies for computer equipment. Such devices require a minimum of space and provide 5-20 minutes of computer (or other equipment) operation. The use of an office-class UPS is not recommended for the needs of boiler or refrigeration equipment, since they do not have compatible electrical parameters.Therefore, for household, and especially for refrigeration and boiler equipment, there are more serious devices, which are a separate inverter and a set of batteries. This option allows you to more flexibly form a backup power system without unnecessary overpayment.

If you thoughtfully approach the choice of an inverter, then you can choose a model with a higher power for several types of equipment at once (lighting + boiler equipment + borehole pump) or for the whole house. With this approach, the set of batteries can be expanded at your discretion. For example, one battery with a capacity of 100 A * h has an energy reserve of 1.2 kW * h, respectively, two such batteries will provide a reserve of 2.4 kW * h.

Inverter-battery systems are also advantageous in that, in addition to the above redundancy, they can also solve other problems. Accounting and statistics of electricity consumption, adding battery energy to the power of the external network, the possibility of using alternative energy sources - this is an incomplete list of the capabilities of such systems. Which is the best option? Whether paid fuel or a modern, economical and environmentally friendly battery-powered system, every homeowner makes his own choice.

Why is the battery cheaper than the generator?

1 liter of gasoline costs almost 30 rubles today. For example, let's take a simple cheap generator with a capacity of 0.8 kW and an operating time on a tank of 6 hours. A simple calculation gives 4.8 kW of electricity for 78 rubles. And 1 kW from the external power grid costs less than 2 rubles. To charge the battery after the power supply is restored, it will take almost 5.0 kW for 10 rubles. Here's a direct savings - more than 7 times in this example. This simple calculation already shows that the battery will ultimately be a more economical solution than a generator.

A step towards autonomy

Of course, when outages last for days, and power is needed constantly and in large quantities, most likely you cannot do without a generator. In most cases, modern technology makes it possible to use different energy sources to recharge batteries, making the UPS system more stable and efficient. Alternative energy sources (wind generators, solar panels) occupy a special niche here. So as long as the sun is shining or the wind is blowing, their energy replaces the network kilowatts and the owner does not pay for external energy.

The use of alternative energy sources in conjunction with an inverter-battery UPS system allows you to create even fully autonomous objects in which all household electrical equipment is powered by batteries, and charging is provided by solar panels and / or a wind generator. At the same time, solar panels can be called the most environmentally friendly and most durable of the existing power sources. Their price at the moment has become so affordable that everyone can really purchase a solar panel today. Therefore, complete independence of the house from external power supply is a reality that is achievable already today.

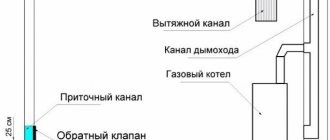

Heating system with gas boiler:

The most common solution in home heating is to use gas boiler

... Since this equipment is the most profitable to operate.

Parapet gas boilers Danko are single-circuit boilers and boilers with the function of heating water for domestic needs. Due to the fact that these are chimneyless boilers, they can be used in houses and apartments where it is not possible to connect to a chimney. gas boilers (https://danko.pp.ua/) of this series are designed to heat a room up to 140 sq.m. The boilers are equipped with modern Honeywell and SIT gas automatics with piezoelectric ignition and microflame burners.

System calculation.

The boiler is selected at the rate of 100 W per 1 m² of a residential building plus 2 KW for hot water supply, excluding the costs of ventilation and the pool.This technique for determining the power of the boiler is approximate with an accuracy of 5%. But it allows you to determine the approximate prices for equipment.

For a more accurate determination of the boiler output, a heat calculation performed by a heating specialist is required based on the design, location and required internal temperature of the building.

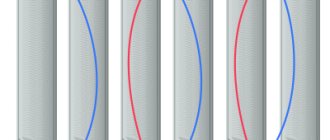

The heated water enters the distribution manifold and further into the radiators located in the immediate vicinity of windows and outer walls. Knowing the area of the room, it is easy to determine the heat output of the radiators.

In rooms where heated floors are installed, radiators are not required to be installed, only in cases of redundancy and exclusion of condensation on the windows. Depending on the boiler, hot water can be produced by the boiler or heated in the boiler. Usually, a 200 liter boiler or hot water heated by a boiler is enough for 1 family. For an accurate calculation, you need to know how many people will live in the house and how many plumbing equipment is installed.

See also the section - Gas heating at home.

UPS models

PN-1000 energy is a powerful backup power source. Thanks to the built-in stabilizer, the device provides the rated output voltage when the mains voltage changes within 120-275 volts. The waveform in the form of a smooth sine wave is perfect for supplying reactive inductive loads, such as the electric motor of a heating system pump. The PN-1000 energy together with the Delta DTM 12100L 100A / h accumulator provides uninterrupted power supply for the 150W heating pump for 8 hours. The device has a built-in line noise filter, information display and RS-232 interface.

This and other voltage stabilizers for the heating system from the Energia company can be found on the website of the official representative of the Energiya.ru company.

The compact emergency power supply Teplokom 222/500 is intended for use in heating gas systems. This simple device with a single-phase relay-type regulator allows operation with a load not exceeding 230 W.

The universal stabilizer Skat ST 1515 provides a voltage of 220 V with network fluctuations from 145 to 260 V and a frequency of 50 Hz ± 1%. If the voltage exceeds the specified parameters, the load will be disconnected automatically.

Summing up

Based on the operational requirements for electric motors of pumps for heating systems, the UPS must provide the following parameters:

- The voltage form is a smooth sinusoid;

- Power reserve - not less than 20%;

- Automatic load disconnection;

- Minimum switching time to reserve.

In addition, the device must operate in a certain temperature range, have a device for indicating modes and physical quantities.

Read with this:

How to choose a three-phase voltage regulator?

Thyristor and triac voltage stabilizers: what is the difference?

Types and circuits of voltage stabilizers

Which voltage regulator is better: the main types and their features

Did you like the article? Share with your friends on social networks!

With a gas boiler with a backup electric boiler:

To eliminate problems with heating in cases of accidents on the gas distribution system, an electric boiler is installed as a backup heat source.

The electric boiler is selected based on the electricity limits allocated for the building. To accurately determine the power of the backup electric boiler, a calculation is required based on the expected duration of the accident and the temperature maintained in the building.

To install an electric boiler in a heating system with a gas boiler, additional equipment will be required to eliminate hydraulic problems.

Read more about electric boilers in the section: Electric heating.

Reserve boiler in steam to gas boiler

In the case when in frosts the gas analysis in the gas pipeline increases, the final households at the end of the "pipe" may be left practically without gas. Some models of gas boilers will not be able to start and work at minimum pressure in the gas line. Accidents can also occur on the gas main for various reasons - from the illiterate carrying out of earthworks to the facts of willful insertion into the gas main.

In this case, as well as in the event of a failure of the gas equipment, for a period sufficient for the departure of the emergency team, you will need a backup boiler in steam to the gas boiler.

What options are there? Any solid fuel or diesel boiler will be able to support your heating system while an accident on the highway is eliminated or gas equipment is repaired.

If you have the opportunity to be at home at the time of an accident, you can choose wood or coal boilers. If you need to leave at this moment, choose fully automatic diesel or pellet boilers.

The model in this case does not matter, what matters is the reliability of the backup boiler. For this reason, it is not worth backing up gas heating with electric boilers or convectors. Because electricity is an even less reliable form of energy for heating than mains gas.

Heating system with wood / coal boiler:

The most common solution in the absence of gas is to use a solid fuel boiler.

For a house with an area of 100 square meters, the minimum tank capacity is 250 liters. For a more accurate calculation, you need to know the parameters of the wood boiler and the duration of the fuel burning.

An electric heating element can be installed in the storage tank, which will maintain the temperature at a time when the solid fuel boiler is not in use. If there is an electric boiler, then it can be used instead of a ten.

See section: Heating with solid fuel

With a gas boiler with a reserve solid fuel boiler:

To eliminate problems with heating in cases of accidents on the gas distribution system, a solid fuel boiler is installed as a backup heat source, which is selected, just like a gas one.

To accurately determine the capacity of a solid fuel reserve boiler, a calculation is required based on the expected duration of the accident and the temperature maintained in the building. To install the boiler in a heating system with a gas boiler, additional equipment will be required to eliminate problems with hydraulics, overheating and long-term heat retention.

You can ask questions to our specialists by phone numbers listed in the Contacts section.

We install heating in private houses and cottages. We carry out design, selection and supply of equipment, installation. We guarantee high quality and reliability of systems.

Terkont Group of Companies Copying without reference to https://terkont.ru/ is prohibited

Reserve boiler, which one to choose, how to connect ...

One single boiler will not provide the required heating reliability. It must be backed up by a device operating on a different energy carrier. Only this can be the basis for heating a private house. Which boilers should be back-up, and how best to include them in the general scheme….

Than we drown

There are no exact statistics on the use of a particular type of fuel in private houses, but heating installers know a rough picture. Boilers in popularity are distributed as follows, starting with the one that is most common:

- gas;

- solid fuel (firewood, coal);

- electric;

- pellet;

- liquefied gas;

- diesel fuel.

Where did the great popularity of the electric boiler come from ?, because electricity is the most expensive type of fuel. It turns out that this boiler is not only the most comfortable to operate, but also ...

What should be the reserve boiler

- In many cases it is desirable that the reserve boiler can be started automatically. For example, it starts when the coolant in the heating system has cooled down to the set value.

- The second requirement is the reliability of an emergency start after an arbitrarily long downtime (usually years ...) The reserve boiler must be switched on at any time, also preferably in automatic mode, i.e. without the presence of a person nearby.

Which boilers are poorly suited for the role of backup

- The pellet boiler can be called capricious in terms of reliability, after a while the pellets are caked, there can be no question of any confident emergency start ...

- Liquid fuel boilers also have low reliability, they will not start automatically more often, especially if there is a significant downtime ...

- With gas boilers, the story is the same, after a significant downtime in the pipeline, the concentration of pure gas drops, it takes time for the air-gas mixture to come out. Those. the launch is not automatic, but only by repeated starts in the presence of a person ...

- Solid fuel boilers, especially those not equipped with an electrical part, have the greatest reliability, but for their kindling and control, the presence of a person is needed ...

What they put

An electric boiler can now be found often because it is best suited for the role of a backup. It can start automatically after an arbitrarily long downtime, with an almost 100% guarantee, as long as there is electricity.

It is now installed everywhere, next to the gas one as a backup in newly built houses or when carrying out capital repairs of heating.

It is not uncommon to find it as a reserve or auxiliary (cheap night electricity rate, timer operation) next to any other types of boilers - residents value comfort and reliability.

Even for a two-phase supply, 4 kW of dedicated power will often suit users to prevent the system from freezing for some time (before troubleshooting the main boiler) in the coldest frost.

Normal boiler redundancy

Nowadays, a gas boiler is almost always installed as the main one, where it is only possible to connect to a pipe. And an electrical device is chosen as a reserve for it, since the reliability of the power supply is now quite high. Therefore, the recommended redundancy scheme for new buildings:

- gas main, electric standby.

The second popular option occurs in connection with the development of the gas network. Where, before connecting to the gas main, a solid fuel boiler was operated (the most common option), after connecting the gas, it remains as a backup. It turns out a reliable proven scheme, but without automation, designed for permanent residence:

- main gas, reserve - solid fuel.

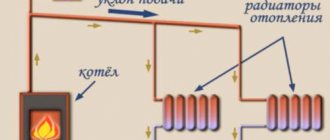

Redundancy scheme with manual start

Let's consider how you can connect two boilers - the main and the backup one into one heating circuit.

When the reserve is switched on manually, the circuit looks like this. Gas and electric (solid fuel) boilers are switched on in parallel through valves on the supply and return.

If it is necessary to turn on the reserve, then the necessary valves are opened and closed manually, then the boiler is started manually.

It is not uncommon for boilers to be equipped with built-in expansion tanks, but they are usually too small for systems in private houses. In order not to put an additional one in the circuit, use the tank of the second boiler. To do this, do not close the return valve on this unit, i.e.leave its hydraulics connected to the general circuit.

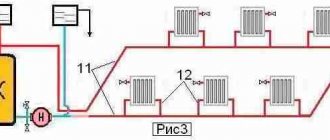

Switching on the second boiler with automation

When the reserve boiler is automatically turned on (without the presence of a person), the scheme is the same, but with the installation of check valves. The taps become open, since there will be no one to open them when turned on.

Check valves prevent parasitic circulation through the idle boiler. They are installed in front of the boilers, (it does not matter at the supply or return), but always according to the "meeting each other" scheme. Then the shutdown of one boiler and the inclusion of another can occur in automatic mode.

Diagram with low loss header

In homes where there are many heating circuits, a low loss header (hydraulic arrow) or a primary ring circuit is usually used.

In houses with a solid fuel main boiler, a buffer storage tank (heat accumulator) can be used.

These devices make it possible to coordinate the simultaneous operation of two boilers (in some cases). Those. the reserve one can also perform the role of an auxiliary one. This is how it is implemented with the buffer capacity (example).

But these are special cases, and it is definitely better to entrust the installation of complex circuits with hydraulic separators to specialists.

Do I need to automate the switching on of the reserve

Sometimes automation of turning on the backup heat generator is indispensable, for example, when the owners are away for a long time, and the supply voltage is not too reliable. The shutdown of the main unit must be accompanied by the start of the auxiliary unit, so as not to freeze the system ...

But in most cases it is harmful to do automation. As a rule, the boiler will be under the supervision of someone all the time, even if the neighbors are looking after the house. You also need to take into account that gas boilers are very reliable. According to statistics, one refusal to work over the years of trouble-free operation ...

At the same time, automation introduces some challenges. The rise in the cost of the system itself, and the rise in the cost of its operation, the check valve creates hydraulic resistance, which is overcome by the pump. This "trifle" becomes "not a trifle" for the entire period of operation. There is some pushing of the coolant through the check valve along the boiler circuit, it is necessary to clean and replace the valves, forced maintenance of the second unit due to the flow of liquid and the presence of pressure all this time ....

Is it worth it to create automation so that, perhaps once every few years, the reserve boiler turns on automatically? At the same time, users will stand side by side and observe ...

More options for combining boilers

Nowadays, the most suitable for redundancy is a highly reliable electric boiler. Therefore, even in the absence of sufficient allocated power for its full-fledged operation, it will prove to be an important assistant for small houses and summer cottages. Moreover, it goes well with any kind of other boilers.

But it should be borne in mind that next to the units, which often stop working abnormally, it is better to create a scheme for automated start-up. The owners are often tired of being on duty at capricious boilers, and they gladly rely on the automatic start of an expensive electrical unit.

The capricious ones include

- Pellet boiler - many mechanisms, periodic maintenance, pellet caking ...

- Diesel fuel - common clogging due to fuel quality, poor cleaning of containers ...

- Solid fuel with automation elements - the so-called "long" burning and the like - why you should not choose a long-burning boiler