The most important part of any building is the foundation. The quality and durability of the entire structure depends on its strength and reliability. Therefore, all work on its construction must be performed in accordance with all building codes.

But often there are operational problems associated with groundwater flowing close to the surface, or heavy precipitation. In this regard, there is a need for waterproofing the foundation and other reinforced concrete structures buried in the ground.

To solve this problem, there are many options in today's waterproofing market. It is the undisputed leader in this area in Russia. Its products are of high quality, using advanced technologies to solve both simple and complex and non-standard problems. In addition, the range of the company is truly extensive.

All waterproofing materials can be divided into two large groups according to the type of products manufactured and the method of application:

- roll materials,

- coating and sprayed.

Despite the differences, they all perform the same function - protecting concrete, steel and reinforced concrete structures from the harmful effects of moisture. Let's take a closer look at each of the groups, their properties and scope.

Roll waterproofing

Roll materials for waterproofing are varied. They differ in price, service life, purpose, technical characteristics and method of application. In order to understand all this diversity, it is necessary to navigate in the labeling and the specifics of the products.

All waterproofing rolls have a similar structure. In the middle there is a base, which is covered on both sides with bitumen or bitumen-polymer layers. Various materials can be used as the basis for rolled waterproofing products, on which technical characteristics and durability depend.

So, as a basis can be used:

- cardboard,

- polyester fiber (marking - "E"),

- fiberglass ("X"),

- fiberglass ("T").

Cardboard, as a base, is used in the cheapest material - roofing felt. The service life of such a product is the shortest and is only 5-7 years. Polyester fiber, fiberglass and fiberglass are used in both budget and expensive ones and last much longer (from 5 to 50 years or more).

The processing of the upper surface of the material is also important. It can be covered:

- fine-grained dressing - sand ("M"),

- coarse-grained dressing - stone chips ("K"),

- polymer film ("P").

The lower (inner) surface of the roll waterproofing can be covered with:

- polymer film ("P"),

- fine-grained dressing ("M"),

- special ventilation ducts forming a "breathing" layer ("B"),

- Adhesive layer for cold mounting ("K").

Let us now consider in more detail the assortment of rolled products "Technonikol":

- Bikrost Is insulation based on fiberglass or fiberglass. It is a budget option, and the minimum service life of such a material is 5-10 years.

- Bipole is also a budget option. It is based on polyester fiber.

- Linocrom - a product of the same price category and is produced both on the basis of fiberglass and fiberglass, and on polyester fiber. Like the Bipole, the service life is 5 to 15 years.

- Uniflex - This is a more expensive option for waterproofing.It is used for all types of structures and has a protective coating of granite chips, while it has higher performance, and the service life can be up to 25 years.

- Technoelast - this is the most durable material presented - the service life is more than 30 years. In this line, there are roll materials for both exterior and interior decoration. It includes:

- EPP- used on soils with seasonal ground movements and high groundwater levels.

- Alpha - additionally reinforced with a layer of foil and used to prevent the possible release of radioactive radon gas.

- Barrier and Barrier Light. The second of them is used for interior decoration of basements. On its outer part there is a special coating for subsequent finishing.

- Bridge. It has high strength values and is used to insulate the base of the foundation.

Vertical waterproofing of the base of the house

Diagram of vertical waterproofing of the foundation.

For this, a wide variety of materials can be used that can be combined. The cheapest is considered to be bituminous waterproofing of the foundation. This requires bitumen, sold in bars. A large container is filled with 70% of bitumen resin and 30% of waste oil. Chan needs to be warmed up by making a fire under it. After the bitumen has melted, it can be applied to the pre-leveled surface. With a brush or roller, bitumen is applied to the surface of the base, starting from its sole and ending 15-20 cm before the surface of the soil. Bitumen must be applied in several layers, bringing the total thickness to 3-5 cm. To prevent the bitumen from solidifying in the container, it must be hot all the time.

Bitumen fills the pores in concrete, protecting it from moisture penetration. The service life of such waterproofing is 5 years, after which the coating begins to crack and collapse, letting water into the concrete. To extend the life of the waterproofing, bitumen-polymer compositions are used that do not have the disadvantages of conventional bitumen.

Coated and sprayed waterproofing

Bituminous mastics and varnishes are an alternative to roll materials. In addition, they can be used in conjunction with roll-on waterproofing to increase water resistance.

They are of two types:

- hot application (require preheating to 180-200 degrees Celsius)

- cold application (do not require heating before use).

Their main advantages are ease of application and high adhesion. The most popular are the following compositions:

- №21. Differs in increased resistance to water and durability. This is a cold-applied mastic. It is applied in two times.

- No. 22 ("Vishera"). It is used as a basis for subsequent cold gluing of roll waterproofing.

- No. 24 - cold applied mastic. TRequires preliminary priming of the surface for lower consumption. It is applied in one layer.

- No. 25 is a bituminous varnish. Perfect for subsequent surface painting.

- № 27. Alternative to No. 22.

- No. 31 - water-based, fast-drying emulsion mastic. It contains artificial rubber and mineral fillers. It is mainly used indoors, as it does not emit any substances during application (only water evaporates).

- No. 33 ("Liquid rubber") - alternative No. 31. Contains latex and polymer additives.

- No. 41 ("Eureka"). This is a budget hot-apply option. It can be used even in winter.

- MBI is an oil-based, non-hardening, hot-applied bitumen mastic. Used for insulating metal structures.

- MBK-G - hot applied mastic. Differs in low price and fast curing.

- AquaMast - bituminous mastic for waterproofing foundations and gluing rolls.

In addition, on porous and rough surfaces, primers are often used as a primer before the subsequent application of mastic or roll materials. Primers are presented, mainly compositions No. 01, No. 03, No. 04. They dissolve in water for deeper penetration and filling of all pores and microcracks. However, they are quick-drying and can be applied by spraying.

Foundation horizontal waterproofing device

This design protects the foundation from moisture capillary penetration into the walls. One line is laid on top of the foundation in the place where the wall will be, and the second line is installed under the basement ceiling. It is recommended to make additional waterproofing, it is located at least 30 cm from the ground level. If there is a solid area around the foundation and rainwater is sprayed high, then at a level of 50 cm or higher from the ground level.

Materials and tools:

- bitumen-polymer-cement film;

- self-adhesive film;

- bitumen-polymer, bituminous mastics;

- polymer-cement and polymer solutions;

- bitumen-polymer-cement solutions;

- technical fabric, fiberglass mesh;

- spatula, trowel, paint trowel.

Cost of materials

We give the approximate cost of roll waterproofing:

| Material name | Cost of one roll |

| Bikrost | From 800 to 1000 rubles |

| Bipole | From 800 to 1100 rubles |

| Linocrom | From 650 to 1000 rubles |

| Uniflex | From 1100 to 1600 rubles |

| Technoelast | From 1200 to 3500 rubles |

Approximate prices for coating and sprayed waterproofing are as follows (large packages are taken as a basis, but there is also the possibility of purchasing packages with a smaller volume, except for No. 33):

| Material name | Weight of packing | Packing cost |

| № 01 – № 04 | 20 Kg | From 1250 - 1600 rubles |

| № 21 | 20 Kg | From 2500 rubles |

| № 22 | 20 Kg | From 2000 rubles |

| № 24 | 20 Kg | From 1600 rubles |

| № 25 | 20 Kg | From 1700 rubles |

| № 27 | 22 kg | From 1600 rubles |

| № 31 | 20 Kg | From 1700 rubles |

| № 33 | 200 Kg | From 31,200 rubles |

| № 41 | 30 Kg | From 1600 rubles |

| MBI | 16 Kg | From 450 rubles |

| MBK-G | 30 Kg | From 350 rubles |

| AquaMast | 18 Kg | From 1200 rubles |

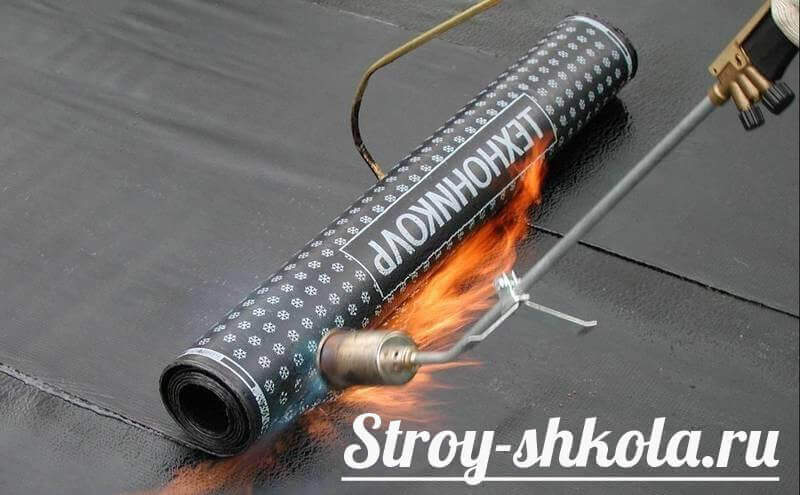

Methods for laying glued waterproofing

If the foundation of a house is constantly exposed to capillary or groundwater, this often happens when it is located below their level, then TechnoNIKOL gluing waterproofing, presented on the market by several types of materials designed for hot and cold installation, is highly effective. It is fusing or gluing sheet materials (roll or in the form of plates) on a prepared surface by heating or using special adhesive mastics.

- First, a bitumen-based mastic is applied to the foundation prepared for processing, to which a waterproofing sheet is carefully and tightly glued.

- If the rolled material of the TechnoNIKOL of the deposited type is selected, then a gas burner is required for operation, with which the material is heated.

- You can also choose the third type of waterproofing - self-adhesive, which is laid by applying it to the surface and strong pressure.

Blitz Tips

- Many options for waterproofing buried concrete structures make it possible to choose the necessary protection foundation for almost any part of Russia, depending on the temperature regime.

- You should also take into account the depth of groundwater. when choosing waterproofing materials.

- With high concentration and shallow groundwater, the best protection option foundation is the combined use of roll materials and coating mixtures.

- If necessary, for better protection of the house from moisture, waterproofing should be applied from the bottom, from the outside, from the inside of the foundation. Also, one should not neglect the insulation of walls from the foundation (especially when using porous materials when erecting walls - foam concrete, aerated concrete, expanded clay concrete, and so on).

- Application of waterproofing foundation will significantly increase its service life.

Features of the device

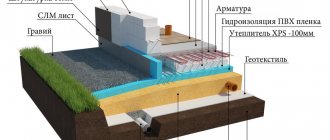

Usually, foundation waterproofing is done in conjunction with its insulation

Usually, foundation waterproofing is done in conjunction with its insulation. Each base unit of a house should be designed taking into account the following factors:

- the degree of soil saturation with moisture;

- the mark of the location of groundwater at the construction site;

- the tendency of the soil to heave in winter;

- types and depth of the foundation of the house foundation;

- soil composition, etc.

When designing various nodes of the base, it is especially important to pay attention to the indicator of the level of standing of groundwater. If in the summer period groundwater is less than one meter from the foundation of the house, then during a flood it will rise by 1-1.5 m and reach the building structures.

It is also very important to carefully study the unit for waterproofing the reinforced concrete foundation of the house during construction on waterproof soils - loams and clays. The thing is that in such a rock there may be a permeable layer that will be sufficiently saturated with moisture to exert lateral pressure on the base of the house. If, under such conditions, the foundation unit is designed in such a way that backfilling of the foundation pit is performed with non-heaving rock (sand), then such soil will be constantly saturated with moisture.

Since the foundation of the house is systematically affected by surface and ground waters, waterproofing with various materials is performed to prevent the negative effects of moisture.

Types of waterproofing for strip foundations

Important: correct waterproofing of the foundation will not only protect the base structure, but also prevent capillary moisture from penetrating from the foundation into the basement and walls of the house. If you look at the knot in the picture below, then you can understand that all these structures are connected together.

From here it becomes clear that the base waterproofing technology implies several measures at once:

- To protect against surface moisture, a protective layer at least 1 m wide, called a blind area, is made along the soil surface along the perimeter of the building. This is an asphalt concrete pavement that will not allow surface moisture to penetrate into the soil adjacent to the base.

- Vertical waterproofing of the foundation is carried out on the lateral surfaces. It protects structures from moisture coming from the adjacent soil layers.

- Horizontal waterproofing of the foundation is done at the border of the base with the upper structures of the house.

- If the groundwater on the site is located very high in combination with an underlying layer of clay water-resistant rock, then the waterproofing technology provides for measures to drain water from the foundation structures. To do this, the project includes the arrangement of the drainage system.