Waterproofing technology

To begin with, you will have to determine a complex of waterproofing works, taking into account a number of conditions:

- soil heterogeneity;

- groundwater level at the site;

- operating conditions of the future building.

If the groundwater level is more than a meter below the fundamental base, a horizontal waterproofing layer of roofing material, coupled with a vertical coating, will be sufficient. And if the groundwater is closer than a meter from the foot of the foundation, but does not reach the basement, you will have to expand the scope of work:

- perform horizontal waterproofing in 2 layers, smearing the space between the layers with mastic;

- equip vertical insulation not only with a coating, but additionally also with a pasting method.

If the budget is enough, all surfaces of the foundation and basement should also be treated with penetrating waterproofing compounds.

In extreme cases, when the groundwater level is above the foundation or heavy precipitation is typical for a particular area, it will be necessary to arrange a drainage system as a plus to waterproofing measures.

Is it worth spending money on waterproofing?

The process of creating a moisture protection for the substrate

Modern cement compositions already contain waterproofing salts and polymers, but their quantities are often insufficient to completely protect the concrete from destruction. In addition, such formulations are too expensive and not every developer is able to buy and use them. It is much cheaper to use the same roofing material, which will temporarily protect the foundation from moisture, or to make protection with special polymer mastics based on bitumen.

The use of one or another type of protective waterproofing is influenced by many factors, for example:

- Soil structure and type.

- Groundwater level.

- Seasonal vertical displacements of water horizons.

- The depth of the foundation.

- Base type, material of execution, quality of reinforcement.

- The type and size of the building, etc.

In dry areas, where precipitation is minimal and the groundwater is deep, waterproofing will be a waste of money, because the volume of capillary water in the soil will not be enough to destroy the concrete.

At the same time, waterproofing serves to increase the durability of the base, protects it from aggressive water environments, especially groundwater saturated with strong mineral acids. Therefore, it is necessary to do waterproofing in any case, regardless of the structure of the soil and the climate in the region.

Vertical waterproofing

The task number 1 of waterproofing such an arrangement is to protect the foundation from water penetrating from the sides of the house. These are melt water, rain and ground water, when the level of the latter rises.

Depending on the moisture content of the soil, vertical insulation can be:

- painting;

- pasting;

- or combined.

How to equip?

Vertical waterproofing is performed only after the completely rebuilt foundation and plinth are dry. Arrangement of such waterproofing is a uniform coating (resinous, bituminous) of all fundamental planes that are in contact with the ground. Moreover, such planes should be:

- clean;

- dry;

- smooth.

Even the seams of the masonry should be smoothed so that there are no irregularities.

Bituminous paint or mastic is applied in 2 compulsory layers. First one (and then it dries), then (after the first is completely dry) - the second. The bitumen dries completely for at least 4 hours.At the same time, it is better to use bituminous mastic for the second layer hot. And the layers of waterproofing should be homogeneous in composition.

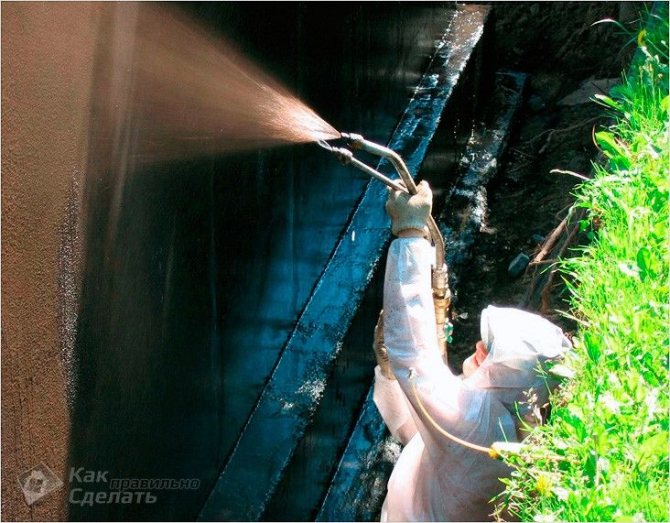

Cold bitumen mastic is applied with a brush or paint roller, smearing the entire foundation in the most thorough way. And in order to apply hot bitumen, you first need to warm it up to a liquid state in a special metal container. And only then the hot composition is distributed over a flat and clean surface.

For the arrangement of vertical waterproofing, instead of bitumen or mastic, you can also use special PVC compounds. And in addition to them, pieces of roofing material, iso- or technoelast can become.

Polyurethane mastic from "Khimtrast"

has developed its own polyurethane mastic, which can be used not only for waterproofing foundations, but also for roofs, swimming pools, tanks, basements, terraces, balconies, tunnels, as well as under screeds and tiles, for repairing old bituminous insulation.

When working with polyurethane mastic, observe safety precautions, work in a gas mask or protective mask, in special clothing that will cover all parts of your body.

After work, rinse all brushes with acetone, and store the mastic in a tightly closed container so that polymerization does not occur.

Experts are always ready to tell you which polymer is best for your purposes. Our warehouses can be found in Novosibirsk, Irkutsk, Yekaterinburg, Krasnoyarsk, Voronezh, Yaroslavl, Nizhny Novgorod, Moscow, St. Petersburg, Samara and Ufa.

A distinctive feature of the tape-type foundation lies in its very name. It is a closed chain - "tape" (reinforced concrete strip, laid under the load-bearing walls). Thanks to the use of strip foundations, the resistance to soil heaving forces is increased, while the risk of skewing or subsidence of the building is minimized.

Strip foundation - photo of a freshly poured structure

It is such a foundation that is built on dry or heaving soils. Moreover, the greater the weight of the future structure, the deeper the foundation is laid (sometimes even up to 3 m, depending on the depth of soil freezing and the level of underground waters).

These and other characteristics are regulated by GOST 13580-85 and SNiP 2.02.01.83.

GOST 13580-85. REINFORCED CONCRETE PLATES OF TAPE FOUNDATIONS. Technical conditions. Download file

SNiP 2.02.01-83. FOUNDATIONS OF BUILDINGS AND STRUCTURES. Download file

During construction, special attention is paid to waterproofing, since the strength, quality and durability of the structure will depend on it. In the absence of protection, groundwater and precipitation can significantly harm concrete, and the consequences can be the most dire - from permanent dampness to subsidence and cracking of walls. For this reason, do-it-yourself waterproofing of the strip foundation is one of the most critical stages.

Waterproofed foundation - photo

Below is the average depth of soil freezing in different regions. If your region is not in the table, then you need to focus on the one that is closer than others.

Regardless of the chosen isolation method (we will talk about them a little later), a number of technical requirements must be adhered to in the work.

- It is imperative to take into account the level of groundwater, because the type of insulation depends on it.

- It is also necessary to take into account the conditions for the future operation of the facility (if, for example, a warehouse is being built, then the requirements for waterproofing will be more stringent).

- It is also necessary to remember about the possibility of flooding during large floods or atmospheric precipitation (in particular, this applies to loose soil).

- The force of "swelling" of the soil during frosts also plays an important role (during defrosting / freezing, the structure and volume of water change, which can lead not only to the rise of the soil, but also to the destruction of the foundation).

Horizontal waterproofing

This method of protecting the foundation of a private house is considered the easiest to implement, and therefore the most used.

The main tasks of horizontal waterproofing are:

- Resistance to groundwater if a protective layer is laid under the base of the foundation.

- Protection against wet capillary action, when the waterproofing is laid in the transitions of the foundation walls into the load-bearing walls of the structure itself (private residential building).

This method of waterproofing is used in the construction of almost any structure, regardless of what features the soil has on the site, and what is the total amount of rainwater.

Traditionally, horizontal waterproofing is called a layer created from pieces of roll materials stacked on top of each other several times.

Stages of work

To perform high-quality horizontal waterproofing, you should adhere to the following algorithm of actions:

First you need to prepare the foundation. For this, all surfaces to be treated are cleaned and leveled (if necessary). Then they are thoroughly dried.- This is followed by the application of primers, which provide additional protection of the foundation and the maximum possible adhesion of the main waterproofing material to the base.

- At the next stage, the actual application of the waterproofing composition takes place. Most often, roll materials are used that are overlapped. If necessary, the waterproofing sheets or pieces are heated.

- Further, the surfaces are additionally treated with coating materials. And in order for them to provide the proper level of protection, they must be allowed to dry thoroughly. This will take 7 days, at least. Therefore, if the construction time is "burning", it is better not to use this method of waterproofing.

Foundation repair technology using penetrating waterproofing

This technology is used to eliminate leaks with a strong hydrostatic head, it is based on the property of the mixture to quickly form a waterproof concrete plug in the place of foundation damage.

- A crack or damaged seam must be expanded, deepened, and given the shape of a cone expanding inward.

- A solution of a thick pasty consistency is prepared so that a plug can be made from it in the shape of a hole in concrete. All work must be carried out very quickly: mixing - no more than 2 minutes, sealing a crack or hole - 3 minutes.

- Insert the resulting plug into the gully and press firmly with your hands or an improvised object for 1-2 minutes. During this time, the solution sets and active crystallization begins.

- The surface of the repaired gulch is leveled with a mortar for joints and seams, and then treated with a liquid solution for penetrating waterproofing.

There are also means used in the construction of a concrete monolithic foundation: they are introduced into the finished concrete in the form of an aqueous solution in the calculated amount. Concrete with such additives is resistant to moisture, mechanically strong, inert towards aggressive liquids.

All work on the application of penetrating waterproofing must be carried out in durable rubber gloves, glasses, avoiding the contact of solutions and pastes on the skin. For the repair of the foundations of old buildings made of brick, concrete, natural stone, injection penetrating insulation is also used.

The plinth protects the walls of the building from the penetration of ground moisture into them and, as a result, their destruction. But what will the base itself protect? Surely this is done correctly. finishing the basement of the house

, which only in the second place performs decorative functions, and in the first place - a protective role. It is this issue that we will deal with in the current article, in which, together with the site stroisovety.org, we will deal in detail with how to properly veneer the basement of a building so that it is completely protected from aggressive environmental influences and, moreover, has an attractive appearance.

Wrapping waterproofing

Instead of bitumen for arranging horizontal waterproofing of the foundation, today they increasingly use a unique innovative material - Technonikol sheets. And as a result, the waterproofing is laid in a layer 5 cm thick and consists of multi-layer moisture-proof membranes.

Such membrane sheets are self-adhesive polymer-cement films on a bitumen basis that perfectly protect any brick and reinforced concrete structures, including the foundations of private residential buildings.

It is very easy to apply these membranes to the surface. It is necessary to heat the sheets over a gas burner (very carefully), and then press firmly against the base being processed. Then level the surface with a roller, expelling the trapped air.

Such material perfectly bridges cracks and fights moisture. However, so far the use of bituminous membranes has not been able to achieve 100% protection of the foundation, as is the case in cases of using bituminous waterproofing. In addition, the new material is not able to reliably close the fine pores of the base.

In addition to bitumen and Technonikol sheets, other materials can be used to waterproof the foundation. The choice is varied today. And each material has its own characteristics, differs in capabilities, pros and cons, as well as in cost.

Coating waterproofing

This type of waterproofing can act as the main protective composition or an auxiliary one when it comes to the foundation. The coating layer is 3-4 mm thick and is applied directly to the surface of the foundation after cleaning, leveling and drying. As for the tools used, you can coat the surfaces:

- polymer solutions;

- bitumen-polymer mastics (cold or hot);

Depending on the composition of a particular preparation, such a waterproofing can be either elastic or rigid. And it is applied and leveled:

- spatula;

- spray;

- or using paint floats.

Plaster waterproofing

This type of waterproofing involves the application of protective compounds (solutions) by plastering the surface. As a result, a covering seamless layer up to 22 mm thick should be formed.

Most often, for the design of plaster waterproofing, a mineral-cement composition is used, to which special substances are added that increase the moisture resistance of the finished layer.

The following are actively used as such additives:

- polymer concrete;

- asphalt mastics;

- hydro-concrete, etc.

Plaster insulation reliably protects the foundation of buildings and structures from capillary wet absorption. However, cracks in the process can appear before the waterproofing protection is formed. Therefore, it is required to draw up it in an extremely hot way and always in several layers.

Having arranged high-quality waterproofing around the entire perimeter of the foundation of the house (that is, both vertical and horizontal), it will be necessary to bury the pit with oily clay, which, in turn, is also an additional natural waterproofing.

Waterproofing of basements, foundations. Protection against water leaks.

Like any natural element, water can be a friend of a person, and it can cause him a lot of trouble. Every year, the owners of country houses are faced with the appearance of water in the basement, which not only destroys or spoils the property in it, but also destroys the foundation.

You need to know the enemy by sight

In most cases, flooding is associated with so-called groundwater, which is divided into three main categories: groundwater, upper water and groundwater. The water in the soil is temporary and permanent. The first is formed from atmospheric precipitation, melted snow and irrigation water. Permanent water is widespread in swampy and silty soils with a close occurrence of groundwater from the surface of the earth.

The upper water always has a limited area of distribution and is temporary; it disappears during dry periods and reappears during a significant amount of precipitation. As a rule, it is found in sandy loamy soils. Groundwater is widespread in nature almost everywhere. They are usually free-flowing in nature and are directly related to atmospheric pressure. Therefore, the depth of their occurrence, temperature and other parameters are subject to systematic fluctuations - daily, monthly, as well as within one or several years. Don't forget about precipitation.

If you want to protect the basement - think about the roof

No one wants to live with a leaking roof, so its surface is always waterproof, and precipitation is forced to drain onto the area around the house. Then they are absorbed into the soil, closer to the walls of the foundation, and, penetrating inside, contribute to its destruction. Of the precipitation, 90-95% flows from the roofs of buildings, platforms and paved paths, waterlogging the soil of the site. To prevent this, you need a carefully thought-out vertical leveling of the surface and a well-executed drainage system.

Behold at the root

In order to avoid flooding a building, before starting construction, it is necessary to determine the features of the site on which it will be erected - its relief, saturation with groundwater. And only after that it will be decided whether there will be a basement in the house and how it will be - shallow or deep, which waterproofing means are best used.

If you thought about the need for waterproofing only when you dived in a flooded basement for canned vegetables, then in order to take effective measures, it is important to identify the cause of the "flood" as accurately as possible.

In both cases, special hydrogeological surveys are required. They will help determine how to protect your home from such troubles.

Classification is the basis of all sciences

Modern technologies offer a variety of ways to protect the basement of a country house from the effects of water. Waterproofing can be horizontal, involving the creation of drainage systems that drain water from the building, and vertical, which directly protects the foundation and walls.

There are two large subspecies of vertical waterproofing - anti-pressure and anti-capillary. The first seeks to prevent the foundation and walls from touching water, the second one prevents moisture from penetrating into the material from which they are built. The main types of anti-pressure waterproofing are coating, pasting, painting waterproofing, as well as cold-applied mastics, which are more technologically advanced to use.

We smear with bitumen

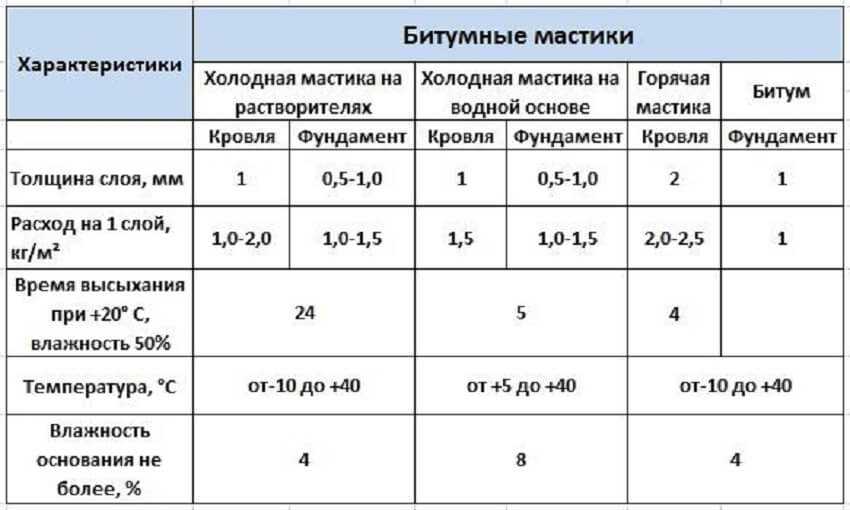

For coating, hot mastics are used, made from bitumen and filler, or pure bitumen, or cold mastics. When choosing this or that material, you need to pay attention to the type of soil.

In dry soils, the outer surfaces of the basement walls are recommended to be leveled with cement mortar and covered twice with hot bitumen or cold mastic. Thus, it will be possible to protect the building under construction from the penetration of soil moisture. In an already built house, such a measure will also be effective, but the costs will increase, since it will be necessary to provide access to the surface of the outer walls. Wet soils are usually heavy, they are represented by loams and clays, which have a high moisture capacity and are very reluctant to part with "their" moisture. In this case, it is recommended to plaster the outer surfaces of the basement walls with a cement-lime mortar, and after drying, cover it twice with hot bitumen. Cold mastic can be applied directly to the cleaned foundation without prior plastering.In very wet soils, various additives, sealing mortars and concrete are introduced into the cement slurry, or special grades of cement such as Hydro-S, Hydro-VS or similar are used. There are many waterproofing materials on the market today, which are used to treat the surface of waterproofing plaster to enhance waterproofing.

How can you paste over the foundation

The glued waterproofing is performed on a leveled, clean and dry base. The cement base is covered with a cold primer, then rolled waterproofing material is glued to it. For this purpose, gluing materials made on the basis of polymerized bitumen and applied hot are used. Their service life is 25-35 years.

The most widely used pasting materials include glass-insulated cold-glued (service life - 15-20 years). More reliable glass-elast and rubitex based on polymerized bitumen. They are hot glued and have a service life of 20-25 and 25-35 years, respectively.

When gluing, each previous panel overlaps by at least 100 mm in the longitudinal joints and 150 mm in the transverse ones. The joints are staggered. On vertical, inclined and vaulted surfaces, roll materials are glued from bottom to top. In addition, it is possible to perform glued insulation using the cold method, using the same “cold” mastic, which is much more technologically advanced.

Crystalline protection

Anti-capillary waterproofing materials have a different principle of operation. They "impregnate" the concrete wall, making it moisture-proof thanks to a chemically active additive. Of the materials with deep penetrating action, one can name Aquatron-6, Hydrotex, OSMOSEAL of the Italian company INDEX and LAKHTA of the RASTRO SPB company. They are a dry mixture, which is diluted with water and applied to the moistened surface of freshly set or old concrete, from which the loose destroyed layer has previously been removed. The active elements of the sealant penetrate into the pores and capillaries of the material to be protected and, entering into a chemical reaction with it, form inert crystals, which become an insurmountable obstacle for water.

Drainage

When flooding is caused by water or groundwater, the water level can rise above the basement floor. To combat this phenomenon, drainage systems are being built on the site.

Like verbs in Russian, horizontal tubular drainage used in cottage construction can be of perfect or imperfect form - that is, cutting through the aquifer completely and cutting through it only partially. In shape, drainage can be cut-off (intercepts the flow of groundwater from the upper side of the building and from the sides) or ring (borders the structure on all sides). The latter option is more reliable and therefore preferable.

Drainage can be made of different materials - plastic (HDPE, LDPE, PVC), from ready-made corrugated and perforated drains with a geotextile filter (the depth of its filling should not exceed 2-2.5 m), from thick-walled plastic pipes subjected to perforation and wrapped in a filter (depth of laying - 4 m and more), made of porous concrete, from asbestos-cement pipes. There is also pottery drainage. When installing drainage, it is necessary to think about where the water entering the system will be discharged. Ideally, it flows by gravity into a ravine, river valley or stream. If the terrain does not allow this, then the water is pumped out by pumps from special drainage wells.

Electricity that water fears

All of the above methods of protecting basements from moisture are based on the laws of mechanics. And for the second century we have been living in the era of electricity, which has penetrated into all spheres of our life. Not without it and in basement waterproofing.

The installation companies claim that it can solve the problem of excess moisture for at least 10 years. This device was developed in Austria by our former compatriot V.V. Kubalik. The action of "Aquastop" is based on an electrophysical principle: the device generates electrical impulses that charge the surrounding soil, this leads to a change in the charge of water ions. Due to the change in polarity, the direction of movement of moisture changes - it goes into deeper layers of the soil.

The installation of such a device does not imply any construction work - it just needs to be connected to an electrical network with a standard voltage of 220 volts.

Scientific approach is important

When the market is saturated with waterproofing technologies and materials, only one problem can arise - the problem of choice. And here once again I would like to emphasize that only a scientific approach provides a person with power over nature. Therefore, before deciding which technology to use, it is necessary to investigate the site - to study its relief, geology and hydrogeology. It is better if a specialist does it - then you can insure yourself as much as possible against mistakes, which will subsequently cost a lot.

findings

Protecting the foundation from negative wet effects is a responsible and rather complicated matter. And if you decide to equip the waterproofing yourself, you should remember that the key to success in this situation are:

- the right choice of material;

- competent determination of the method of waterproofing;

- as well as adherence to the sequence and timing of the necessary work.

If everything is done correctly, follow the instructions and listen to the opinion of experts, one can hope that the rebuilt foundation and the house above it will last a long time without requiring major repairs.

(67 voice., middle: 4,90 out of 5)

How to properly waterproof your roof

Extension to the country house

Similar posts

Protection of the foundation against heaving

First you need to understand the concept of "soil heaving". This phrase is used to describe those soils that have a lot of moisture in their composition, which means that when severe frosts come, they can increase in volume and rise, according to the simplest physical laws. When erecting houses on such heaving soils, a cushion of gravel, special washed sand or gravel-crushed stone bedding is arranged under the base of the foundation. The base, created from these non-heaving materials, prevents the pushing forces of frost heaving from acting on the lower part of the foundation. It is important to remember here that with a significant increase in the water level in the soil, this can be in the autumn period or during snow melting, water saturated with particles of unnecessary dusty-clay soil accumulates around the bedding. Moving with the water, soil particles penetrate directly into the bedding and thus clog it, slowly turning normal soil into heaving. For several years of operation of the foundation, it again finds itself on the ground, which deforms when freezing. To prevent the silting up of the bedding, you can use special filtering materials such as fiberglass or Taipar. They pass water well, but prevent the penetration of the smallest dusty-clay particles into the bedding. One of the ways to reduce the activity of heaving-type soils is to organize drainage. It allows you to lower soil moisture due to a decrease in the water level in the soil. The traditional drainage system design consists of several drain pipes that are placed in a layer of wash gravel, which retains large soil particles. The pipes are laid with a slight slope, which, in turn, provides a drain of water into a well or just a sewer pit.

Around the drainage pipes, a filter material is laid that does not allow even the smallest particles to pass through and therefore ensures the efficient operation of the entire drainage system without time-consuming cleaning. Protection of the foundation from freezing is carried out in the same way as when preventing the impact of heaving soil.