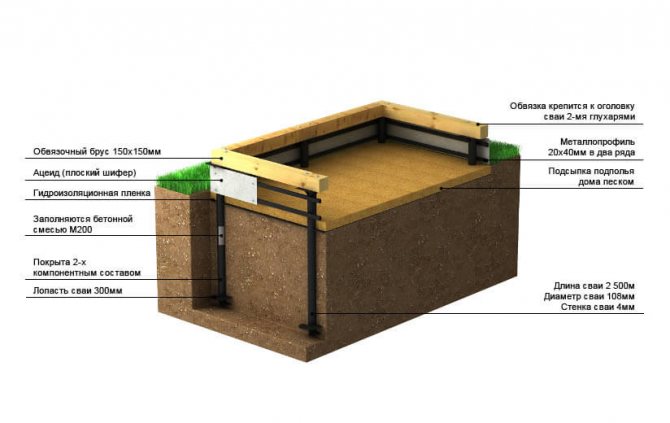

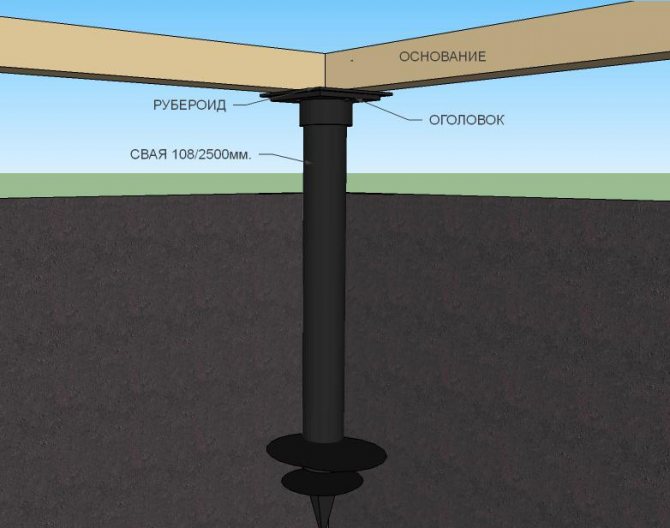

In modern construction, there are many types of foundations. Each of them has its own characteristics and basic functions. But the pile-screw type is considered the most universal foundation, suitable for almost any climatic conditions. This foundation is a metal, pile-and-beam structure. It protects the structure from groundwater, soil deformation and transfers the load to dense soil layers.

Why insulate a pile foundation

In areas with problem soil, where there are areas with floating soil layers, the best solution for building a house would be a pile-screw foundation. It will provide reliability in places with a high level of groundwater, in contrast to strip monolithic or prefabricated foundations.

The pile-and-beam structure and dynamic loads are not terrible. It is very durable and resistant to the process of soil heaving. Also, he is not afraid of the destructive effect of groundwater, since the screw piles are made of anti-corrosion steel.

Another advantage of this type of foundation is the relatively low cost, as well as the speed and ease of construction. The installation of one pile foundation will take only one working day for a team of experienced specialists.

But, despite a number of positive qualities, the pile-screw foundation has a number of negative features. A house built on piles does not have a basement and also has poor thermal insulation parameters.

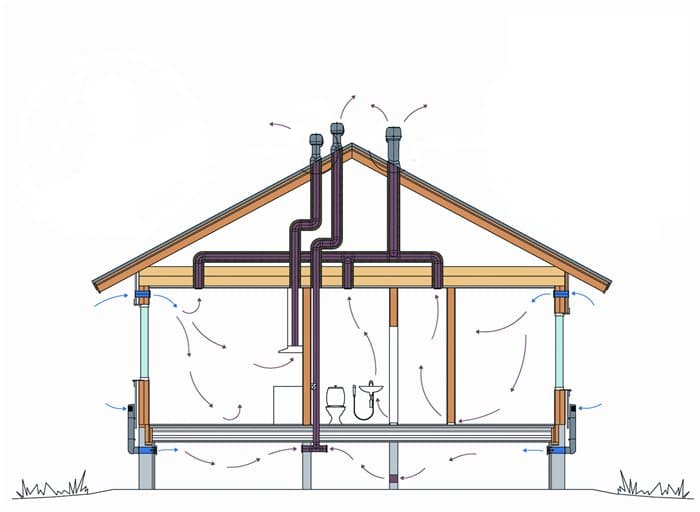

There is a space between the floor and the ground that is easily blown through. It is because of what the precious warmth leaves the house very quickly. This is especially noticeable with the onset of cold weather. Radiators don't do their job as warm air always goes up and the floors stay cold.

To solve this problem, you need to think about it even at the stage of designing a house - thermal insulation. Insulation of the pile-screw foundation occurs at the stage of working with the grillage in order to completely isolate it from external air flows. Finished houses can also be insulated, but this will not be as effective as thermal insulation during the construction phase.

Also, for high-quality and effective insulation of the pile-screw foundation, it is necessary to install a false base. It must exclude wind and precipitation from entering the free space between the soil and the house.

Our services

Our company is based exclusively on services: pile driving, leader drilling, sheet piling, as well as static and dynamic testing of piles. We have our own fleet of drilling and piling equipment at our disposal and we are ready to supply piles to the object with their further immersion at the construction site. Pile driving prices are presented on the page: pile driving prices. To order work on driving reinforced concrete piles, leave a request:

Calculation of the pile foundation - how to calculate?

On this page, we want to compare different types of foundations and show how the calculation of the pile foundation is done, and you yourself can decide which foundation you need ...

More details

Turnkey pile foundation in Moscow

is engaged in the construction of turnkey pile foundations. We carry out a full range of works, providing customers with ready-to-go ...

More details

Installation of reinforced concrete piles in Sergiev Posad

…

More details

Useful materials

Country houses on screw piles

Screw flocks are a pretty good option for building a foundation for a cozy country house.

DIY installation of screw piles

Description of the process of driving screw piles: video, photo, detailed instructions. Pros and cons of doing the work yourself.

Materials for insulation of the foundation

When insulating the pile-screw foundation, it is necessary to pay attention to the false base and the grillage. These elements come into contact with the surface of the house and, when frozen, can transfer a low temperature to it. The screw piles themselves, immersed in the ground, do not need to be insulated.

When insulating a false base, it is necessary to choose a material that is not afraid of water and retains its thermal insulation properties even in a wet state. After all, a large amount of moisture emanates from the ground, which means that the insulation will be in a very humid environment. It must also be resistant to various salts and minerals in the soil. It is better to use high-density sheet materials or a liquid heat-insulating mixture when insulating a pile-screw foundation.

The most popular materials for insulating a pile-screw foundation are:

- Styrofoam;

- liquid penoizol;

- foamed glass blocks;

- extruded polystyrene foam or foam.

Penoplex and polystyrene have the same thermal conductivity, and also do not allow vapors to pass through. Penoizol also has a similar thermal conductivity, but allows moisture to pass through. It is better not to use mineral wool and basalt insulation, as they are not very convenient for installation.

Thermal insulation from the street side

To insulate the pile foundation from the outside, plate expanded polystyrene or expanded polystyrene is most often used (this is the name of an extruded type of expanded polystyrene). The latter is thinner (30 mm versus 50 mm) and contains special fire-fighting additives.

External insulation of the basement with penoplex Source stroyfora.ru

Description of the procedure:

- When it comes to brick wall

, then the elimination of cracks with cement mortar is preliminarily carried out. After the embedded areas have dried, the entire outer surface is hidden with a primer. For fixing individual plates, special glue is used, filling all joint areas with polyurethane foam without toluene. From above, the insulation is plastered over a pre-stretched polymer mesh. As a finish, you can apply paint, tiles or other material suitable for the street.

Frame false plinth

insulated a little differently. In this case, the installation of the penoplex on the pile screw foundation takes place on top of the DSP sheets. Further, without any plaster, they are decorated with a topcoat. For these purposes, you can use siding, cladding panels, etc.

Do-it-yourself pile-screw foundation insulation

You should start warming the foundation only after the grillage of the house has been waterproofed. Waterproofing membranes are perfect for this. The most budgetary option may be roofing material or similar materials on a bitumen basis.

Attention! It is necessary to cover with waterproofing not only the upper surface of the grillage, on which the walls of the house will be erected, but also all its other parts, together with the pile heads.

For the self-made construction and insulation of the false base, the following tools are required:

- welding machine;

- trowel, spatula, hammer, tape measure, knife;

- low speed drill or screwdriver;

- concrete mixer.

The false base of the pile-screw foundation does not bear any load, since its main task is to isolate the free space under the house from external factors. The first option is to build a brick wall under the grillage. Its thickness should be half a brick.The second option is to close the free space with decorative panels that are attached to the grillage.

Creating a brick plinth

This option is more labor-intensive, but the efforts made will not be in vain. Since the brick base is as reliable as possible and has greater durability, while the decorative alternative is easily damaged.

Before erecting and insulating the basement, it is necessary to dig a trench around the house under the grillage. The depth of the trench should be 20-30 centimeters, and the width should be slightly larger than the brick.

The trench should be filled with concrete and allowed to harden. This will be a kind of foundation on which the brick base will be laid. Due to the shallow depth of the concrete, reinforcement with a reinforcement diameter of 10-12 mm should be used.

After the concrete has completely set and hardened, you can start building the walls of the brick basement. It should be laid in small sections with a length of 1-2 meters. This is necessary in order to simplify the insulation on the surface of the base.

To fix the material selected for insulation, you will need specialized adhesives, which should not contain organic solvents.

Advice! Ceresit CT83 glue will be a good option for fixing the material to the base / plinth surface.

After insulating the basement, you need to close the brick wall with a decorative plug. The choice of materials is huge, suitable for everyone's preferences. You can also use plaster.

Creating a plinth with decorative panels

A much simpler way to build and insulate a false base, in contrast to the construction of a brick partition, is the installation of decorative panels. If you approach this issue seriously and competently, then this method will provide durable and reliable insulation of the pile-screw foundation.

To begin with, you should start choosing the supporting structure, on which the decorative panel of the false base and the material selected for insulation will actually be installed.

Advice! A good option when erecting a false base will be a frame made of a metal profile welded to the screw piles of the foundation.

The distance between the guide profiles depends on the height of the free space between the floor of the house and the ground. Usually two or three longitudinal profile frames are enough.

A wooden beam will also cope well with the task of the frame, only it must be pre-treated with an antiseptic or mastic. The main thing is to protect the tree from rotting and insects.

Further, the cavity of the frame is filled with insulation. Styrofoam, penoplex or any other insulation. Do not forget about the thickness of the plates if penoplex is used for insulation. If it goes beyond the grillage, it will greatly complicate the installation of decorative panels.

After installing the thermal insulation material, a decorative fill should be installed on the grillage of the building using an adhesive mixture. The size of the decorative panels is also an important aspect. To ensure reliable fixation, it is necessary that the lower part goes into the ground to a depth of about 5 centimeters, and the upper part fits snugly against the grillage. In the place where the lower part of the panel is in contact with the ground, you need to dig a small ditch 10-15 centimeters deep and fill it with expanded clay.

Expanded clay filler has low thermal conductivity, which excludes the possibility of freezing of the structure at negative temperatures. Therefore, it will also help to reduce the heat loss of the building floor.

The choice of this version of a false base for a pile-screw foundation with vapor barrier materials (penoplex) implies the presence of natural ventilation. It is needed so that moisture does not accumulate in the internal space.Because of it, condensation will settle on the inside of the floor of the house, which can negatively affect the wooden structure. In order to allow air to circulate freely, special ventilation holes must be made. With the onset of cold weather, the holes should be closed with a plug or any heat-insulating material.

Waterproofing

Waterproofing works must be carried out to protect the joints of the piles and grillage from moisture penetration.

Without this, structural elements made of metal are susceptible to corrosive processes, and from wood they begin to rot. In any case, the wear of the base of the house is much faster, it gradually collapses. The waterproofing material is placed at the junction of the grillage and the ends of the piles, as well as on the grillage from above where it touches the wall.

Further, the metal structure is completely covered with specialized mastic. Wooden components are impregnated with a special antiseptic compound. After complete drying of the impregnations, they proceed to the insulation of the foundation itself.

As a rule, it takes about a week for the formulations to dry.

The use of expanded polystyrene for insulation

The excellent sound-absorbing and heat-insulating properties of extruded polystyrene foam distinguish it favorably from other possible materials. Skilled builders use this type of building material when working with various types of foundations, especially pile foundations. Due to the relatively small thickness of the material that is required for this, the basement floor practically does not lose usable area.

Stages of warming the foundation on piles using expanded polystyrene:

- First of all, it is necessary to seal the cracks formed on the concrete or brick wall of the basement. Next, the surface is covered with a primer to prepare it for the subsequent installation of the insulation.

- Expanded polystyrene sheets are attached from the inside of the basement wall to an adhesive or glue-foam. If the second installation option is used, temporary fixation with special umbrellas is used to prevent deformation while the foam swells.

- A study of the joints of the sheets is carried out with a composition of foam to prevent the appearance of cold bridges.

- For better insulation of the foundation, it is required to lay the sheets in two layers. A special type of metal mesh helps to close the access of rodents to expanded polystyrene.

- As a final step, the inside of the plinth is covered with a small layer of soil or expanded clay to prevent blowing from below.