Purpose and properties

The plasticizer is included in almost all building mixtures. A high-quality screed of warm floors without such an additive is practically not carried out. This is due to the fact that plasticizers improve the characteristics of cement slurries:

- increase the adhesion speed;

- increase strength;

- give plasticity;

- simplify the styling process;

- provide a flat screed surface;

- reduce the amount of water in the mixture;

- increase the index of frost resistance;

- contribute to good water resistance.

A screed with a plasticizer for a warm floor turns out to be even and does not crack during operation. At the same time, the thermal insulation characteristics of the solution increase, increasing the efficiency of the heating equipment.

The use of plasticizers makes it possible to increase the strength of the cement-sand screed by up to 50 percent. Such additives do not contain harmful substances, which allows them to be used for any type of premises.

Thanks to the plasticizer, the solution dries faster. This property of the mixture when laying underfloor heating makes it possible to speed up the process of putting the heating system into operation.

Advantages and disadvantages

Like any other consumable, the plasticizer for underfloor heating screed, the price of which will largely depend on the quality of the product and the manufacturing company, has its advantages and disadvantages.

Benefits:

- The floor surface becomes denser, becomes waterproof, and this is important when installing and using a warm floor in the future.

- Due to this additive, it is possible to achieve high indicators of the mechanical strength of the concrete pour. Even after several decades, the concrete base will still be the same monolithic and high-strength.

- Saving consumables. Thanks to the use of a suspension, it turns out to reduce the laying of the cement base by 15%, while this does not affect the characteristics, especially the strength.

- The composite is flexible and flexible, which, when filling the screed, will help to ensure solidity without any air pockets and voids.

- Certain types of plasticizers (which are more expensive than conventional ones) help protect the metal mesh from corrosion. Thus, both fittings and metal elements of the floor heating system will not be damaged.

- The main advantage is the high rate of exploitation of the harvested mixture - you have the opportunity to prepare a sufficient amount of the mixture in advance and not be afraid of hardening before you finish the filling work.

- The plasticizer helps to neutralize the effect of a 5% -1 mixture of potassium nitrate, due to which salt will not appear on the concrete.

I would like to add that plasticizers do not have a pungent odor and retain their properties for a long time. They also do not emit any toxic substances, i.e. the product is completely ecological.

Disadvantages:

The only drawback of this composition is that it hardens for a very long time. But you can still fix this by adding special hardening accelerators. Given this disadvantage, we do not recommend resorting to using such a component in cases where you do not have the opportunity to wait until everything hardens naturally, so that the surface is ready for the rest of the work, namely laying the finishing layer.

The problem of long hardening is solved simply - use a hardening catalyst.Such additives as a modification, although they will increase the final cost of the screed, will allow it to quickly harden, while with this approach, the hardening time will be even less than that of a cement-concrete mixture.

Types of plasticizers

To improve the quality and improve the characteristics of mortars, various types of additives are made. According to the structure and method of use, plasticizers are of two types:

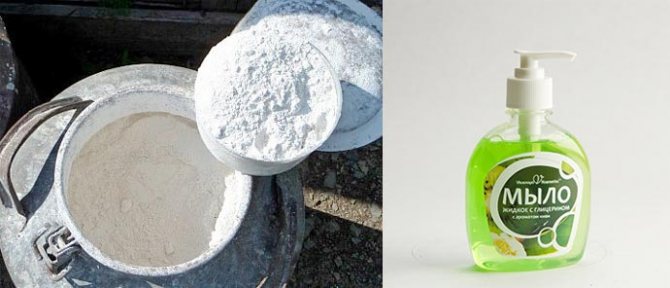

- Dry. Such additives for building mixtures are produced in powder form. They are added directly during mixing of the solution or diluted with water before mixing all components.

- Liquid. Plasticizers of this type are concentrated. They are poured into the cement mixture in small quantities. When using liquid additives, much less water is required to mix the mortar. This speeds up the bonding process of the screed and shortens the drying time.

Liquid plasticizer for underfloor heating

Plasticizers can differ in their chemical composition. There are additives for solutions based on:

- polycarboxylates;

- technical lignosulfonates;

- polymer compounds.

Depending on the composition and purpose, plasticizers are divided into several main categories:

- contributing to the rapid set of strength of the solution;

- super plasticizers that increase the fluidity of mixtures;

- antifreeze;

- modifiers to improve frost resistance and strength;

- self-compacting additives;

- means for entraining air to increase frost resistance.

For screed floor heating, special plasticizers are used. Thanks to them, the solution completely fills all voids, contributes to the accumulation of heat and its transfer to the floor covering, and also provides full protection to the heating system from various types of loads.

The main types of plasticizers

Modifiers for dry screed solutions are selected depending on the technology used. According to their composition, the following types of plasticizers are distinguished:

- liquid mixture of underfloor heating modifiers. Such substances are ready for use without preliminary preparation, they must be thoroughly mixed before use. The additive is added to the solution together with water. The required proportions are indicated in the instructions for the material;

- dry plasticizers have a long guaranteed shelf life. Before use, prepare the liquid form of the modifier by adding water in a 1: 2 ratio;

- polyamide modifier, when added to the screed exhibits reinforcing properties. After drying, the mixture increases strength characteristics, does not crack during the entire service life;

- antifreeze appearance contributes to the preservation of all properties of the material at low temperatures.

As a rule, the choice of plasticizer depends on the specific operating conditions of the warm floor. If it is necessary to increase the level of homogeneity of the solution, a dry modifier solution is used, which is quickly introduced into the composition of the building mixture.

The preparation of the mixture for the screed does not require complex devices; all operations are performed with simple tools in the form of a conventional construction mixer mounted on a drill.

Criterias of choice

Not all types of plasticizers are used for installing a warm floor on a screed. The main points of choosing an additive are marks on the packaging, which indicates that the product is intended for laying heating systems.

Also, when selecting a plasticizer for a floor screed in which heating equipment is installed, the following factors are taken into account:

- quality and manufacturer of the composition for improving the properties of the cement slurry;

- additive consumption;

- operational characteristics;

- type of plasticizer - dry, liquid;

- absence of harmful components;

- cost.

When choosing a plasticizer for a warm floor, consider the consumption of the additive

When choosing a plasticizer for a floor heating system, the type of heating equipment itself is taken into account. If the installation of an eclectic device is envisaged, then a dry additive is used for the screed. When mixing a solution intended for a water-heated floor, it is recommended to use liquid plasticizers.

Recommended modifiers

The list of plasticizing admixtures for underfloor heating is quite large. But the following brands are most in demand in terms of their effectiveness:

- polyplast SP-1, also known as plasticizer S-3, is an analogue of the foreign product "Mayti100", it is considered a superplasticizer used in working with concrete. It is a generic type of impurity. It is used in an amount of not more than 0.7% of the total mass of cement. The additive helps to increase the fluidity of screed mixtures by almost 9 times. The amount of water is reduced, practically by 15%, providing an increase in the strength of the screed up to 30%, the corrosion resistance is increased by more than 3 times;

- plasticizer "Warm floor" brand HLV-75 is used to prepare a rough base of a house under a warm floor with water or electric heating elements. For 100 kg of cement, it is necessary to use from 0.5 to 2 liters of the product. The screed strength index for underfloor heating increases by 25%, the rate of hardening increases by 3 times or more;

- plasticizing additive Batichem - a powdery mass, has a wide range of uses, including for preparing a screed for installing a warm floor. The additive is used in the procedure for pumping concrete using pumps. The effectiveness of this action increases by more than 30%, the absorption rate increases by 20%. The setting time of concrete increases significantly, while the final indicators of concrete strength increase many times;

- manufacturers of the Rehau additive will help to avoid unpleasant consequences in the form of cracks, waves and other defects on the coating surface. This is facilitated by a plasticizer for a warm floor. The peculiarity of the product is that it, introduced into the composition of the sand-cement or cement mass for the underfloor heating screed, restrains the change in its crystal lattice during the heating or cooling of the structure.

We recommend: How to make a warm water floor in a private house with your own hands?

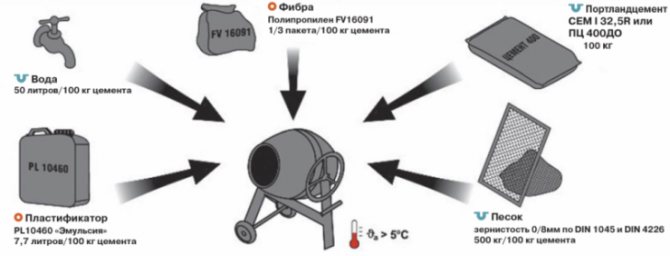

In the process of preparing solutions for underfloor heating by mechanical (using a concrete mixer) or manual (mixing the mixture with a simple product) methods, you should adhere to this order: first, water with a plasticizer is poured into the prepared container.

Then the cement and the remaining components are poured. It is recommended to add the plasticizer together with water, thus achieving good mixing.

Manufacturers supply modifiers for underfloor heating to the construction market in special containers, which ensure reliable storage of substances at home for a long time in specially designated places.

They are securely closed, each container has an instruction, a label with the name of the substance, and an indication of the manufacturer.

- Similar posts

- How to make underfloor heating from central heating?

- How to assemble a Valtec underfloor manifold?

- What is National Comfort underfloor heating?

- What is the layout of the underfloor heating mixing unit?

- Features of the system "combined heating: warm floor and radiators"

- What is a film underfloor heating?

Consumption of plasticizer for underfloor heating

The quality of the screed for underfloor heating depends not only on the correctly selected plasticizer and on how much of the additive is added to the solution. Therefore, when mixing the components, it is important to accurately calculate the dosage that will improve the performance of the cementitious flooring.

You can find out the necessary proportions in the instructions indicated on the packaging of each type of plasticizer.In this case, the amount of the additive used should not exceed ten percent of the total volume of cement going into the solution.

For 100 kilograms of dry cement, from 1 to 1.5 liters of liquid-type plasticizer is consumed. Dry additives are initially diluted with water in a 1: 2 ratio, and then applied in the same way as concentrated solutions.

Preparation of the plasticizer

The purchased plasticizer is added to the original sand-cement mixture in compliance with all manufacturer's recommendations. Particular attention should be paid to the proportions of the plasticizer taken and the prepared screed solution. The operational properties of the finished warm floor depend on this.

The dry mixture of the plasticizer should be no more than 0.7% of the volume of the solution prepared for pouring the screed. The volume of liquid can be about 0.3% of the resulting mass.

Most often, on the Russian construction market, the buyer is offered a liquid, viscous consistency plasticizer C-3. The composition is diluted with water and the screed is mixed with a plasticizer in a deep container. For every 100 kg of cement, add about 0.5 to 0.8 g of the prepared plasticizer composition.

We recommend: How does the floor heating automation work?

There are recipes for self-preparation of a modifier for a cement-sand mixture using the following components:

- liquid soap solution, it is necessary to dilute with water at the rate of 250 cm3 per 50 kg of cement mixture;

- 150 g of washing powder dissolved in water is added to 50 kg of screed solution;

- construction grade PVA glue is used to prepare a modifying additive. For 50 kg of sand-cement mixture, 299 g of glue is used.

Instructions for use

To obtain a solution with good technical parameters, it is necessary to correctly combine all its components, including the plasticizer:

- the additive is added to the building mixture simultaneously with all its constituent components;

- to obtain the required consistency, the solution is mixed in a concrete mixer;

- the process of complete connection of all parts of the cement-sand mixture consists of several stages;

- the components are mixed for twenty minutes, and then the solution is left to stand for half an hour;

- after that, the procedure is repeated.

Depending on the type of plasticizer, the screed hardens within 14 - 20 days. The final maturation of the solution occurs only after a month.

Actions of additives on concrete

Plasticizers significantly improve the quality of the concrete mix

It must be remembered that the chemical composition of the impurity is not simple, therefore it must be added to solutions, strictly following the instructions, in small quantities.

The effects of the supplement are as follows:

- concrete with the presence of a plasticizer sets faster;

- the solution is highly durable, hydraulic, has a dense structure;

- the admixture allows you to create a low pressure if subsequent mixes of the solution occur;

- concreting in winter excludes accelerated hardening and the release of heat energy during hydration;

- during long-term transportation, liquid concrete containing a plasticizer is activated by slightly adding potassium nitrate to the concrete mixer.

Related article: DIY New Year's home decor outside (65 photos)

The best brands of plasticizers

On the modern market, you can find various types of plasticizers for underfloor heating with distinctive characteristics. The strength and durability of the screed depends on the quality of such an additive. Therefore, it is recommended to purchase such mortar mixes from trusted reputable manufacturers.

Among the plasticizers for floor heating systems, the best are:

- "Rehau". Such a screed additive is produced in liquid form. Its use provides good elasticity of the mortar and increases the heat-conducting properties of the cement-sand coating.

- "Neolas". Plasticizer from a Russian manufacturer, produced in the form of a gel. With the help of it, the porosity of the screed composition is reduced and the process of its hardening is accelerated.

- "C3". The substance belongs to superplasticizers that significantly improve the properties of the mortar, providing the screed with high strength, frost resistance and water resistance. The cement mixture with such an additive becomes mobile and plastic.

- Batichem. The additive helps to increase the final strength of the screed. When using it, the drying time of the solution is accelerated. This plasticizer is produced in the form of a powder and is widely used for laying electric underfloor heating.

- "PL10460". This emulsion improves the adhesion of mortars. The screed turns out to be reliable and durable. The frozen cement-sand mixture cracks during operation.

Plasticizer for warm floor PL10460

It is necessary to purchase such plasticizers in specialized stores. Before buying, you should pay attention to the specified method of application of the additive and its purpose. An important factor is also the shelf life of the product.

Varieties

Let's take a closer look at the types of plasticizers for water floor screed:

- Liquid.

- Dry.

- Antifreeze additive.

- Reinforcing polyamide fiber.

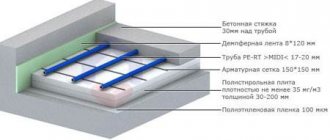

Each of these types of substances helps speed up the hardening process and makes the solution more plastic. Antifreeze additive makes it possible to work with concrete even at negative temperatures. The choice of plasticizer should be based on the floor heating system, as well as the installation method. This is important for a water floor, since the screed must necessarily tightly fit the pipes. These are possibilities only with an elastic solution. The plasticizer will help to ensure that the screed is homogeneous without air gaps - this will help to make it durable. Such a screed can withstand heavy loads, and this is important for floor heating pipes, because if the floor is damaged, there is a danger of damage to the pipes. For this reason, the screed must be at least 2.5 cm.

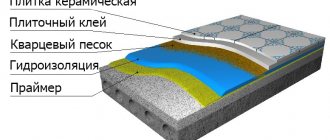

When creating an electric floor heating system, it is a dry mixture that is used under the tiles, and adhesives are added for better elasticity and strength. The price for the plasticizer will be the same or even slightly less than that of high quality cement. Also, the cost will be affected by consumption and characteristics. As a rule, 600 to 1000 ml of plasticizer are used per 1 m2 of mixture. If you buy a cheap composition, the consumption will be higher, so you will hardly be able to save. It is better to purchase high-quality materials, as this is a guarantee of reliability, and the period of use will be much longer.

On the construction market there are a huge number of brands of plasticizers for sand-cement and other similar mortars. They can be bought on the market, in special stores, and on the Internet.