In our work, we are constantly faced with such questions from clients:

- Is the house made of laminated veneer lumber cold?

- Is such a house blown out?

- What is the thermal conductivity of wood compared to other materials?

- Do I need to insulate a house from laminated veneer lumber?

- What wall thickness is needed for year-round living?

- How much will it cost to heat a house?

The client's questions and concerns about them are understandable. Winters in Russia are cold and a large home heating bill can be a major problem.

Realizing this, our clients prefer to thoroughly study the issue of heat loss and make the necessary calculations before building a house from laminated veneer lumber, because in the end, the cost of house maintenance is usually a priority.

In this article, we will try, based on our own experience, to reveal the topic of keeping warm in a wooden house made of glued beams.

Is the house made of laminated veneer lumber cold?

This is the most popular question from our clients.

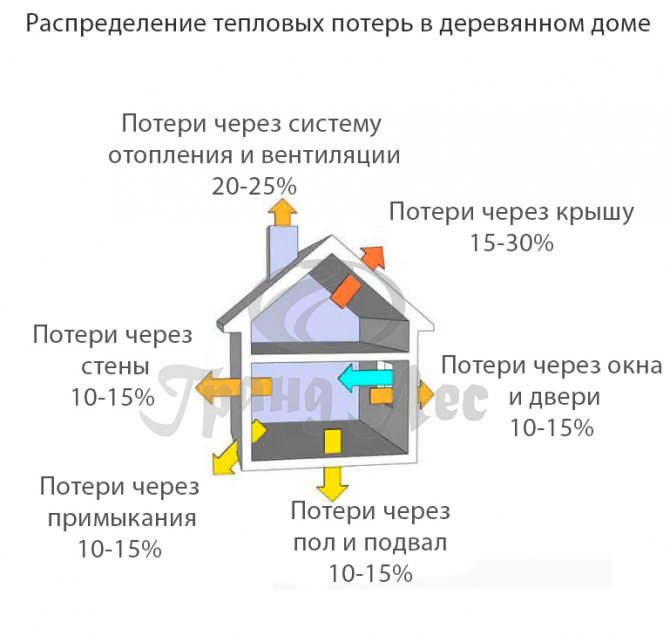

A house made of laminated veneer lumber will be warm if heated. The only question is how much heat is needed to maintain a comfortable temperature. Without heating in winter, a wooden house, even with the thickest walls and modern multi-layer insulation, will inevitably cool down to the ambient temperature. Thus, how warm the house will be is determined by two factors: heating intensity and heat losses.

Below we will present a comparative diagram of materials, in which the thermal conductivity properties of popular building materials will be clearly indicated.

Looking ahead, let's say that among the wall material, wood has the lowest thermal conductivity and, as a result, it will be much easier and cheaper to keep heat in a wooden house under equal conditions.

Is the house blown out of laminated veneer lumber?

The second most popular question is about the heat-saving properties of a country house made of laminated veneer lumber. There are many articles and videos on the Internet that feature problem houses. In these materials, thermal imaging measurements were made, which revealed cold blown areas in the load-bearing walls of the house. More often - in corner joints, less often - directly in the solid wall.

After reviewing a number of such materials, we assume that a number of typical mistakes were made in problem houses, typical of inexperienced construction companies, low-quality and cheap building materials, and unskilled builders.

With a high probability, these problems appeared for a trivial reason: they decided to save money. Save money on materials, on builders, on a project.

There are many reasons why a house may be purged, but they all boil down to three fundamental mistakes:

- The technology for the production of glued beams has been violated;

- The beam has an uneven profile and as a result - increased gaps and loose joints; - The bar is unstuck; - The beam jars and leads - its geometry is violated; - The timber has internal stress and deforms over time; - The timber is poorly dried and has a moisture content above 15% and, as a result, the timber shrinkage goes beyond the norm of 2-3%;

- House assembly technology is violated;

- Low-quality mezhventsovy insulation was used; - Screw ties are loose or not installed at all; - Nagel is missing, or installed with violations of technology; - The shedding on windows and doors was installed with violations of technology; - The rafter system and the roof were installed in violation of technology;

- The builder saved on materials and work;

- The foundation is not insulated; In winter, the foundation freezes through, becoming a kind of "refrigerator" on which the house stands. Through the spot of contact between the foundation and walls, the load-bearing walls quickly freeze through. To reduce freezing of the foundation, it is additionally insulated along the perimeter to the entire depth of occurrence. Thus, the foundation slab will be less susceptible to freezing and has a temperature several degrees higher than the frozen soil. - The floor is not insulated; Even with an insulated foundation, it is necessary to additionally install floor insulation. In conjunction with a correctly installed basement insulation, the insulation on the floor allows you to maximally isolate the house from heat leaks through the floor. - The roof is not insulated; A very vulnerable place in the house from the point of view of heat loss is the roof and the place of its installation to the load-bearing walls of a wooden house. If the roof of the house is not insulated, heat loss can be 15-30%, which is unacceptable. - Used cheap double-glazed windows and doors;

All these problems can be avoided by not making the mistake of choosing a construction company.

What are the best materials to use?

The market for building materials for facade insulation is diverse. It is necessary to choose the right material for facade insulation, evaluate its quality, thermal conductivity, cost. So what is the best way to insulate a wooden house from a bar?

The most popular and correct material for insulating external walls of wooden houses is mineral wool slabs.

There are many types of insulation on the market: penoplex, polystyrene, polyurethane foam.

But unlike them, mineral wool is less flammable, has good thermal conductivity, has an important property of steam conductivity.

Foam insulation is the cheapest. The material is lightweight and is not afraid of water. Polyfoam has good thermal insulation properties. But the main disadvantages of this material are that it does not allow the wall to breathe and, in addition, is flammable. When burning, it emits toxic substances that are dangerous to human health.

Penoplex is the most expensive insulation. It is well suited for floor insulation (even under a concrete screed), but it is better not to use it for the facade of a house made of timber. Like foam, foam insulation will keep your wooden house from breathing.

Mineral wool comes in the form of stone (basalt) wool, ecowool, glass wool and slag wool. The most popular is the first.

Mineral wool is sold in rolls or slabs. Rolls for facade insulation are not recommended, they are inconvenient to use on vertical bases.

The disadvantage of mineral wool insulation is that it is attractive to rodents. The lower bar is used to protect against unwanted "tenants". For reliability, it can be installed in the form of a metal profile. It should also be remembered that when mineral wool gets wet it loses its quality, so it is important to install it in dry weather.

Here's what to look for when choosing a builder:

- The company exists on the market and has actually been building for more than 5 years;

- The company has its own production of laminated veneer lumber;

- Quality assurances are clearly spelled out in the contract;

- The company provides a wide range of services. All works - on one person, within the framework of one contract;

- The client has the opportunity to visit the construction site of the object under construction;

- The company has its own designer or design department;

- The company has its own projects;

Remember!

A house made of laminated veneer lumber is not blown out and is completely sealed only in the case of the strictest adherence to construction technology, and only if high-quality glued laminated lumber made in profiled production was used in the construction.Such production is located at the Grand Les company - and we are legally responsible for our material, giving a documented guarantee of 5 years.

Why the outer surface of the walls of the house is not insulated

One of the advantages of laminated veneer lumber is that the material itself does not need to be insulated. Its thermal conductivity is significantly higher than that of brickwork, concrete and solid wood.

Deep cracks do not form in laminated veneer lumber, therefore the material resists heat transfer equally well at every point. The high thermal performance of laminated veneer lumber has been repeatedly proven by special thermographic examinations of such houses.

It is undesirable from an aesthetic point of view to cover the timber walls with heat-insulating plates. The smooth, high-quality planed surface of natural wood looks very attractive, this is one of the reasons for the popularity of this building material.

What other methods of insulating a house from laminated veneer lumber exist?

There are many design features to reduce heat loss in a log house.

House projects made by professional architectural bureaus already provide a maximum of techniques to make your house as warm as possible:

- High-quality double-glazed windows;

- Tambour for cutting off the cold;

- Roof thermal insulation;

- Thermal insulation of the foundation;

- Thermal insulation of the floor;

- Quality glued laminated timber from a reliable and experienced manufacturer;

- Professional and experienced construction company;

Content

- Features of laminated veneer lumber as a building material

- Which is better: finishing the facade or installing thermal insulation inside

- Materials for home insulation from the inside Mineral wool

- Ecowool

- Polyurethane foam

- Styrofoam

- Preparation of premises

- Preparation of walls and installation of lathing

Types of heating boilers for country houses

In the absence of a central heating system, a private boiler room is used to heat the country house. The boiler room is a separate technical room with a boiler installed in it. There are several types of heating boilers for certain types of fuel:

- Solid fuel boilers

- Diesel boilers

- Gas boilers

- Electric boilers

We will describe each of the types of boilers below:

Solid fuel boilers

Such a boiler works on almost any solid fuel: firewood, peddeyas, fuel briquettes, coal and peat. The most widespread and economical solid fuel is Firewood. The cost of wood firewood is stable and does not depend on geographic location, like coal, for example.

Advantages of solid fuel boilers:

+ ease of maintenance and use + almost any solid fuel is suitable + environmental friendliness and low waste + low boiler cost + low fuel cost + does not require electricity to operate

Cons of solid fuel boilers:

- It is necessary to load fuel several times a day - It is necessary to maintain a high temperature, otherwise tar is released - It is necessary to regularly clean the ash - Low efficiency - no more than 80% - Low degree of automation

Diesel boilers

This type of boilers runs exclusively on liquid diesel fuel (diesel fuel). Combustion of diesel fuel generates heat, which heats the heat carrier (water or special liquid) that circulates in the heating system. The boiler itself includes a diesel burner, a fuel filter and a pump, an automatic control system. Diesel boilers are also divided into:

- single-circuit (The heat carrier circulating in the heating system is heated)

- double-circuit (There is a second heating circuit for tap water)

Pluses of diesel boilers:

+ High efficiency + Large selection of models for any needs + High safety. + Low power consumption + Fuel availability in any region of the country + Easy to install + No permits required + There is a possibility of long-term autonomous operation

Cons of diesel boilers:

- High cost of operation - High cost of equipment - An additional tank for diesel fuel is required - A high quality chimney is required and its careful installation. - Diesel fuel combustion products are hazardous to the body. - Additional heating of the fuel tank is required (In severe frost, diesel fuel thickens and the pump cannot pump it) - The diesel boiler makes noise during operation - Unpleasant smell in the boiler room - Dependence on the quality of the fuel

Features of the insulation of log houses

Heat insulating materials

First of all, consider the best way to insulate a house from a bar. Currently, there is a large selection of thermal insulation materials, however, not all of them are suitable for these purposes.

The fact is that the heat insulator must meet the following requirements:

- fire resistance;

- vapor permeability;

- the ability to mount on walls;

- sufficient thermal insulation qualities.

Mineral mats meet all these requirements. Therefore, they are the most popular heat insulator for insulating wooden housing.

Of course, there are other types of materials that are also suitable for these purposes. For example, many developers are interested in whether it is possible to insulate a house from a bar with penoplex or polystyrene foam?

Heat insulator penoplex

The use of these materials is quite permissible, the only thing should be borne in mind that they are vapor-tight. Accordingly, it is necessary to ensure effective ventilation of the insulated rooms.

Note! The thickness of the insulating material must be at least 10 cm.

Penoizol is also often used to insulate houses, which is applied to the surface of the walls with the help of special equipment.

Warming the room from the inside

Warming options

There are several ways to insulate a log house with your own hands:

| Warming method | Features of the |

| From within | This method is rarely used, since it has many disadvantages:

As for the advantages of this method, they include the ability to insulate the premises at any time of the year. In addition, it is not always possible to insulate the walls from the outside. |

| Outside | This method is devoid of all the disadvantages inherent in internal insulation. It should be noted that there are two ways to insulate a log house from the outside;

|

Note! It is possible to engage in insulation and wall decoration only after the house has shrunk. This usually takes a year and a half from the moment of its construction.

Ventilated facade device diagram

Insulation technology

As an example, consider how to insulate a log house from the outside using the ventilated facade technology.

So, the instruction looks like this:

- first of all, it is necessary to prepare the facade - to dismantle all the hinged elements, if necessary, seal the gaps between the crowns, and also apply a protective impregnation;

- then vertical posts are attached to the walls. For these purposes, you can use an aluminum profile or wooden bars. You can fix the racks with aluminum adjustable brackets, which are used for mounting drywall.

In the photo - a frame for house insulation

The distance from the walls to the racks must correspond to the thickness of the heat insulator.

The position of the frame must be controlled by the level, as well as by beacons. In addition, it is important to observe a certain step so that the distance between the posts is one or two centimeters less than the width of the insulation mats;

- then a vapor barrier film is attached to the wall;

- then a heat insulator is placed in the space between the racks. You can fix it on the wall using dowels "fungi";

- another layer of vapor barrier and windproof film is attached on top of the heat insulator;

- then finishing facade material is mounted on the frame. It can be siding, lining, block house, etc. Panels are fixed with self-tapping screws;

- at the end of the work, you need to make slopes, install drains and other additional elements.

This completes the process of insulating a log house. I must say that the insulation of the premises from the inside is also carried out in the same way.

The only thing is that the vapor barrier film is not attached to the wall, but to wooden slats 1-2 cm thick. This is necessary to ensure ventilation of the space between the insulation and the wall.

Gas boilers

This type of boilers runs on fired natural gas - Methane or propane-butane. The gas burned in the boiler generates heat, heating the coolant in the pipes.

Advantages of gas boilers:

+ High autonomy; + Efficiency over 90%; + Environmental friendliness, safety of combustion products; + Low cost of fuel, especially if it is main gas; + Relatively low cost of boiler equipment; + Compactness, small size of gas boilers; + Low operating costs;

Cons of gas boilers:

- It is necessary to obtain permission to install the boiler; - It is necessary to install a gas meter; - Explosion hazard of gas; - Difficulty in installation. Obligatory involvement of a specialist;

Electric boilers

This type of boiler is completely powered by electricity. Unlike previous types of boiler equipment, an electric boiler does not work due to the combustion of fuel, but due to heating from the electrical network.

Pluses of an electric boiler:

+ High reliability and fire safety; + Low installation cost; + Relatively low cost of boiler equipment; + Large selection of models for any task; + Compactness of the heating system; + Silence; + Environmental friendliness ;; + Easy to operate; + No need for approval and obtaining permits (up to 9 kW); + High efficiency (up to 99%); + It is possible to connect a second heating circuit for hot water ;;

Cons of an electric boiler:

- High cost of electricity. This is the most expensive way to heat a country house; - Limitation in the choice of radiators (cast iron and steel batteries will not be economical); - Complete dependence on the power grid; - Strong electromagnetic radiation (in induction type boilers); - It is necessary to have a reserve of power supply;